Weighing type bulking system

A filling system and weighing technology, used in packaging, bottle filling, liquid bottling, etc., can solve the problems of filling capacity deviation, inability to detect filling in real time, etc., to reduce pressure fluctuations, improve flexibility and equipment utilization , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

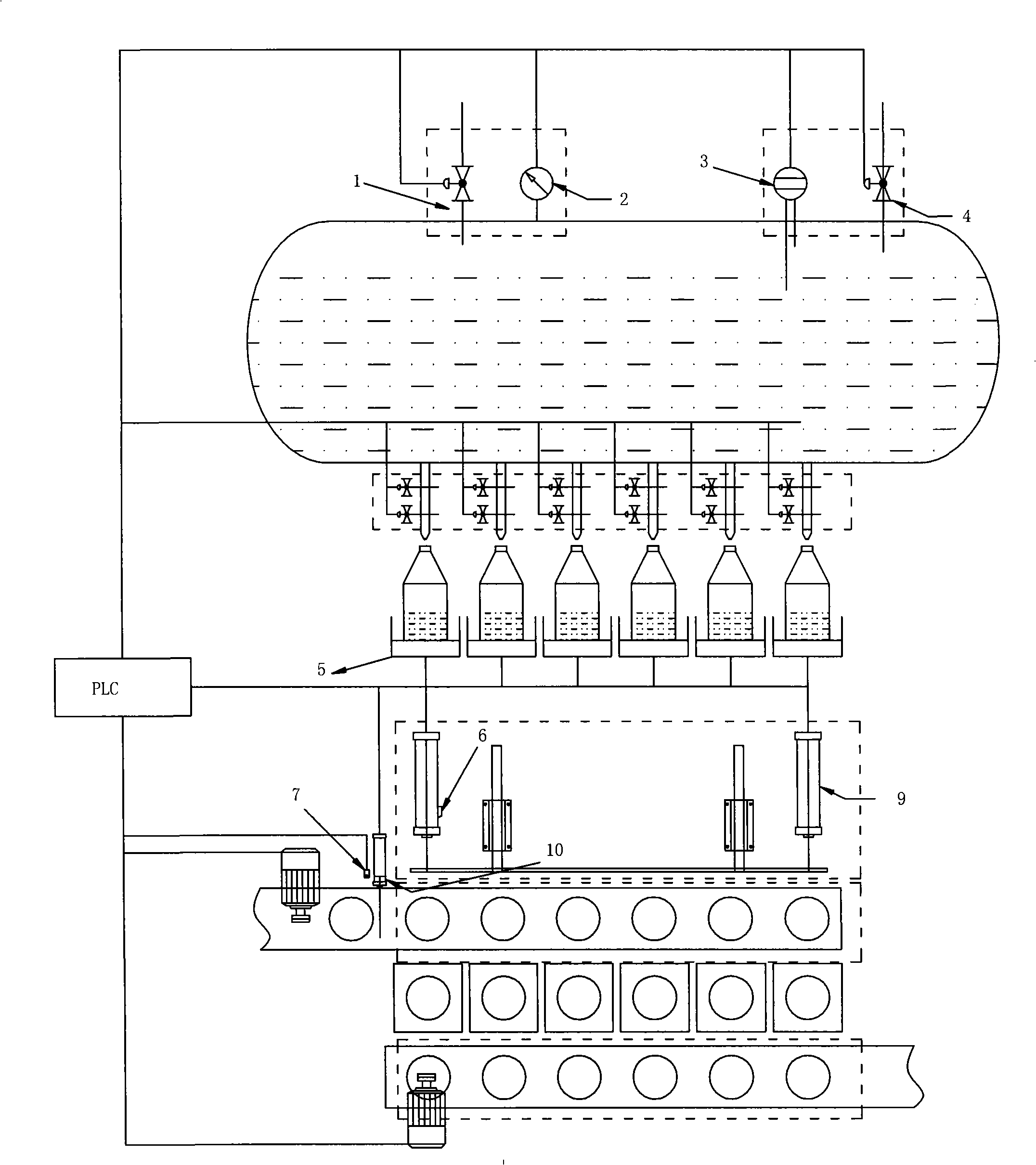

[0026] In order to clearly illustrate the solutions in the present invention, preferred embodiments are given below and detailed descriptions are given in conjunction with the accompanying drawings.

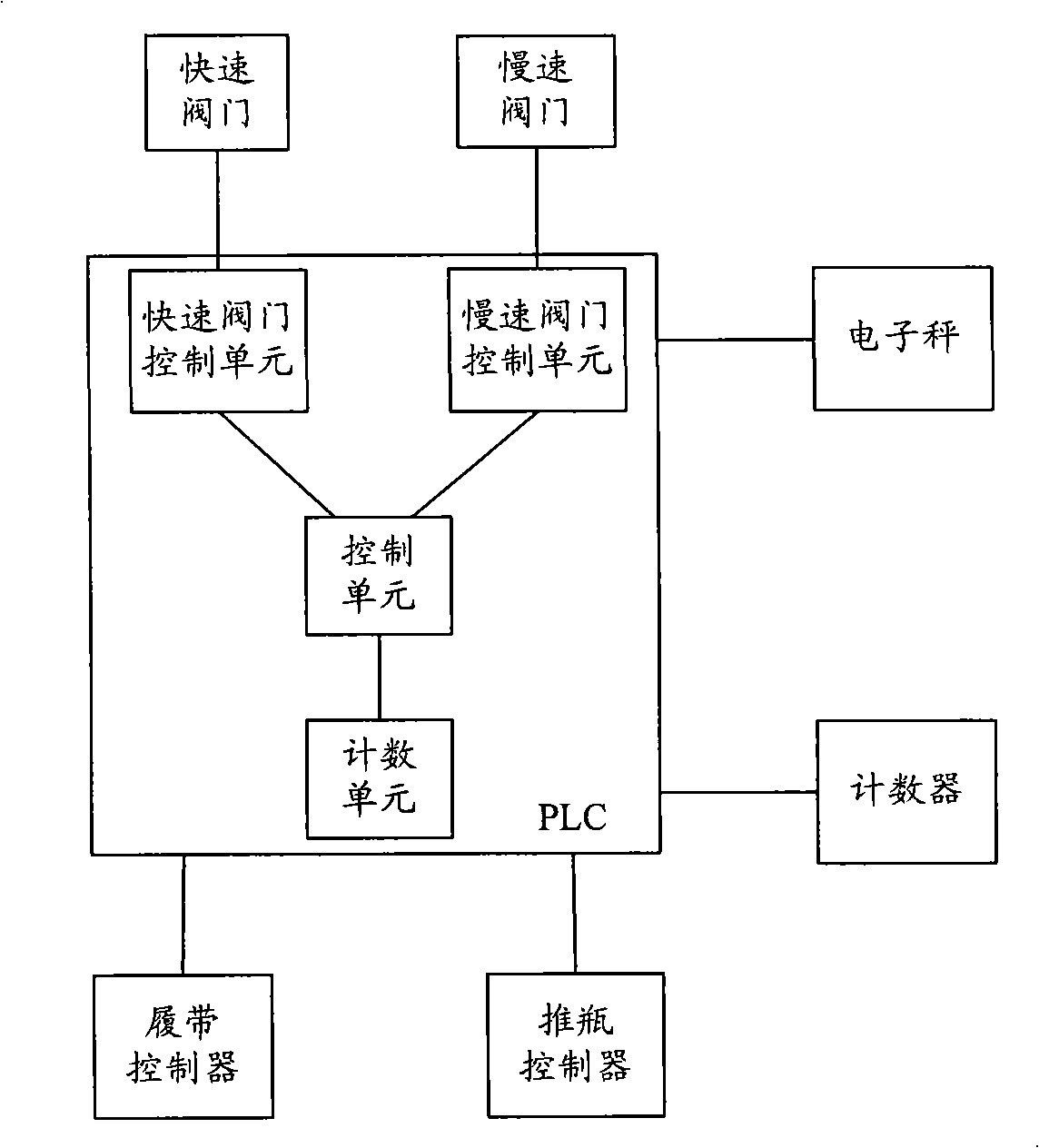

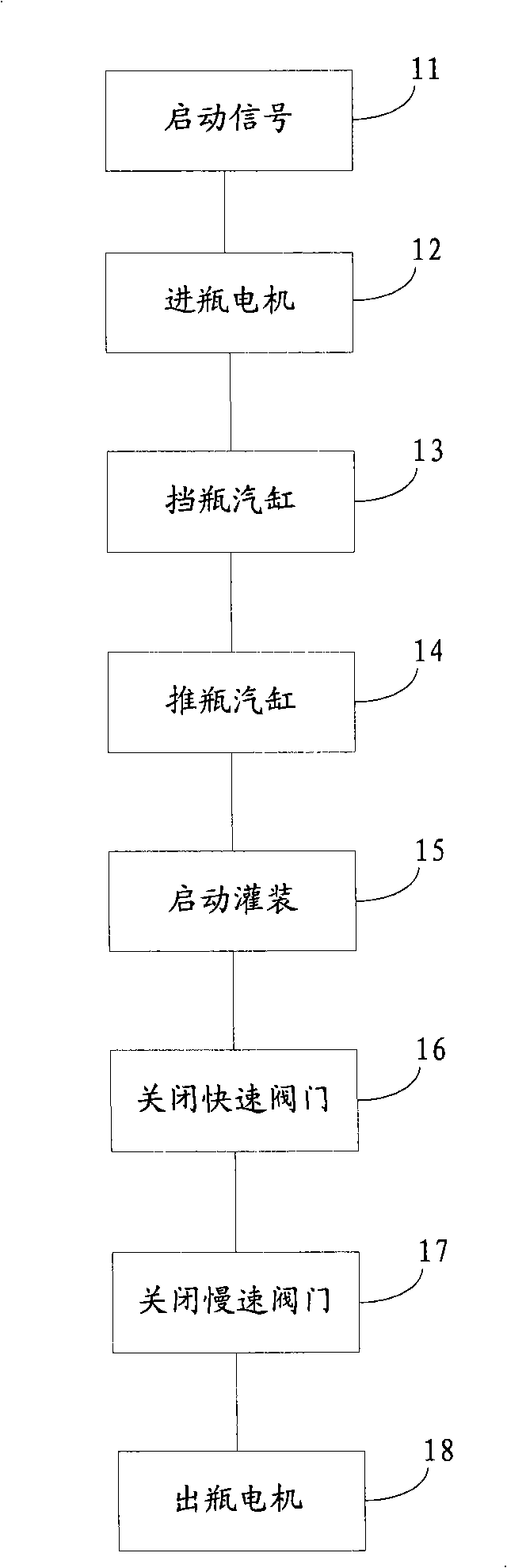

[0027] see figure 1 , the system includes: a PLC controller that controls the filling process, the PLC controller drives the crawler controller that transmits the filled bottles, the counter records the number of filled bottles, and transmits the recorded information about the number of filled bottles to the PLC controller , when the set value is met, the PLC controller drives the push bottle controller to send the empty bottle to the filling valve on the electronic scale, and the PLC controller controls the filling.

[0028] The PLC controller includes: a counting unit connected to the main control unit, a fast valve control unit and a slow valve control unit,

[0029] The main control unit drives the crawler controller to send the filling bottle;

[0030] The counting unit wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com