Liquid fine-expansion pumping agent

A micro-expansion and pumping agent technology, applied in the field of concrete additives and liquid micro-expansion pumping agents, can solve the problems of plastic phase shrinkage and uncontrollable cracks, and achieve the effect of reducing plastic cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

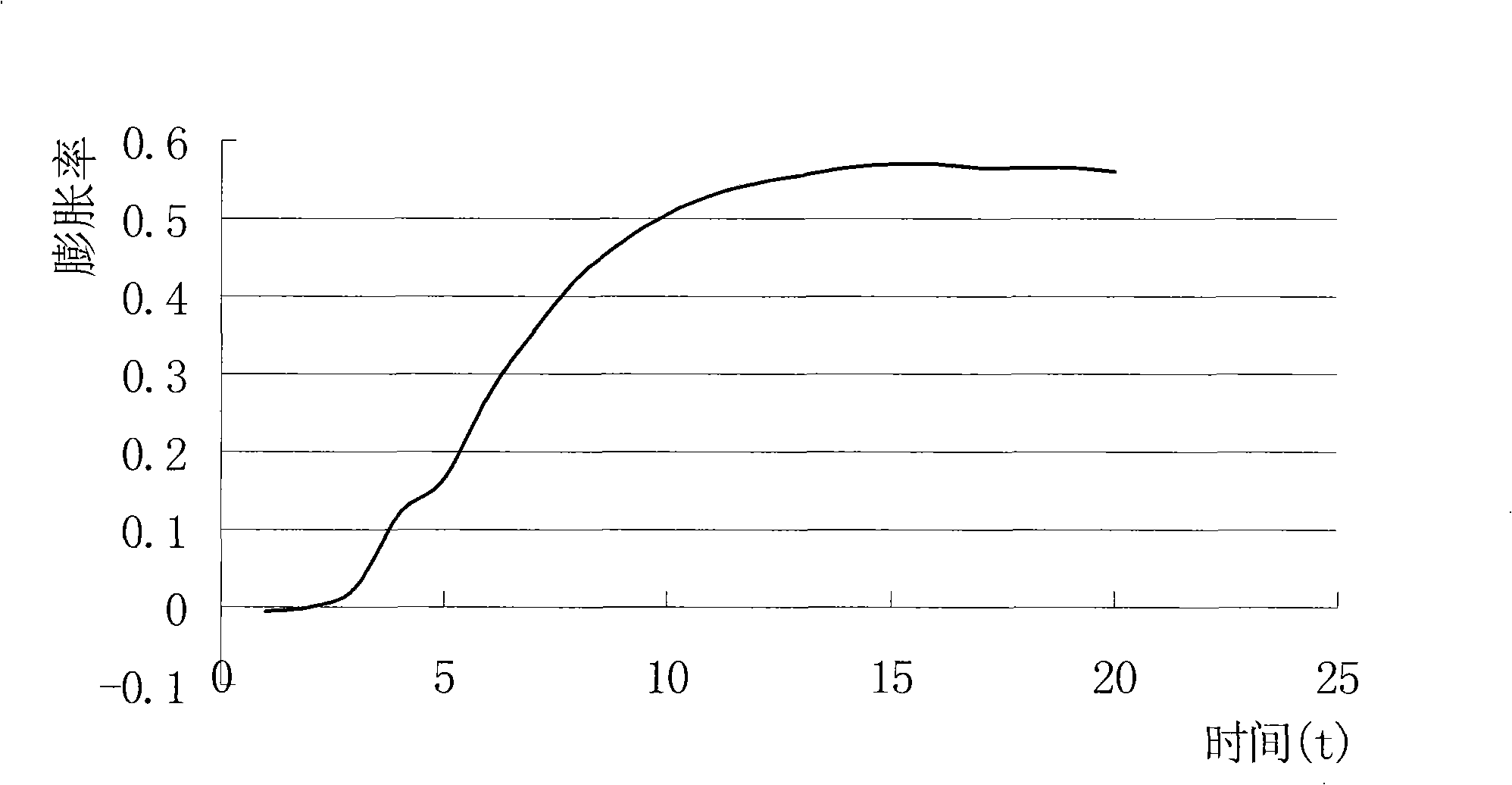

Embodiment 1

[0046] Sodium polymethylene naphthalene sulfonate: 50%; dispersant: 10%; retarder: 15%; initiator: 6%; water: 19%. After the above composition is mixed and stirred, a liquid micro-expansion pumping agent is obtained.

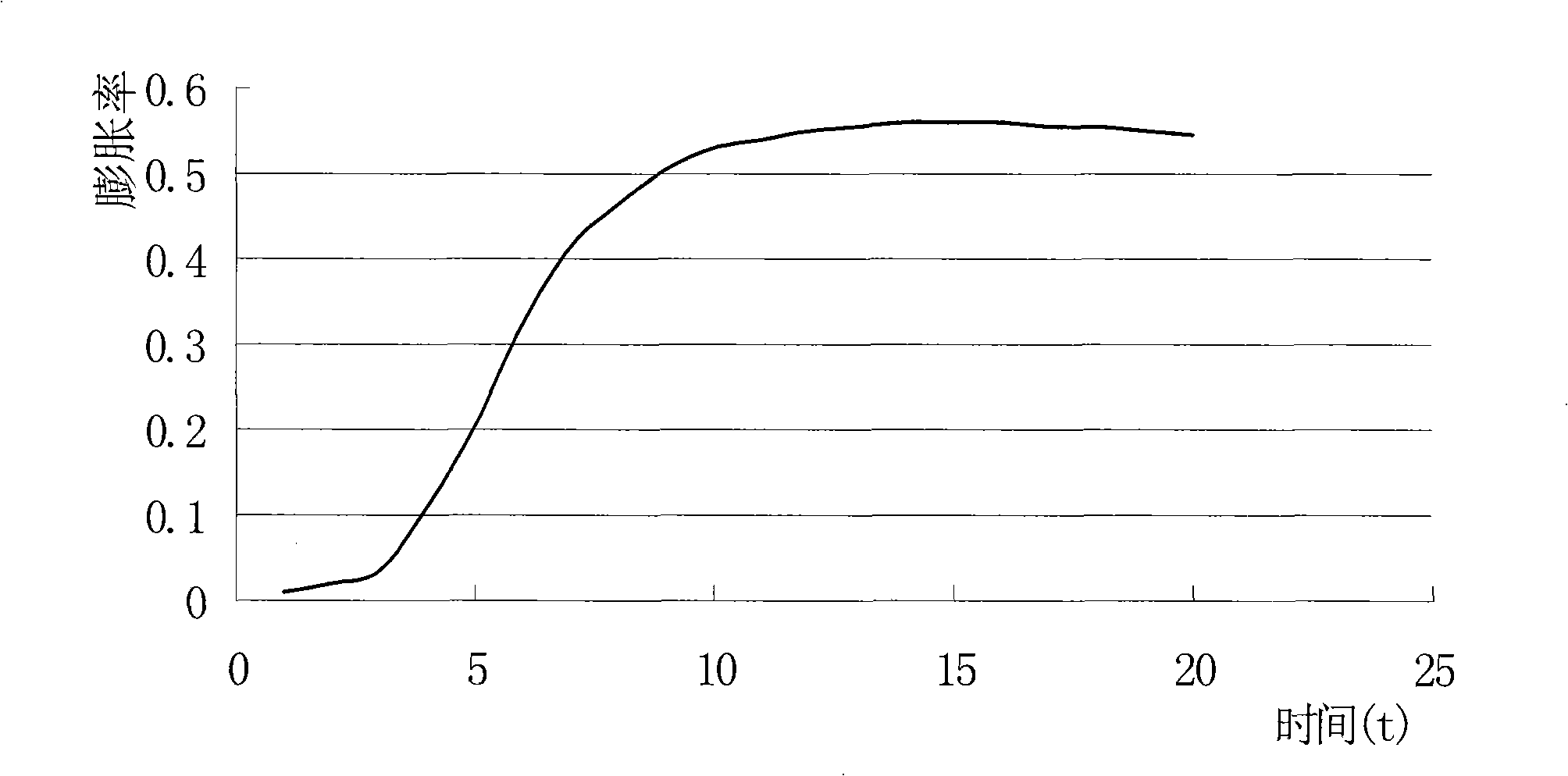

Embodiment 2

[0048] Sodium polymethylene naphthalene sulfonate: 60%; dispersant: 5%; retarder: 16%; initiator: 4%; water: 15%. After the above composition is mixed and stirred, a liquid micro-expansion pumping agent is obtained.

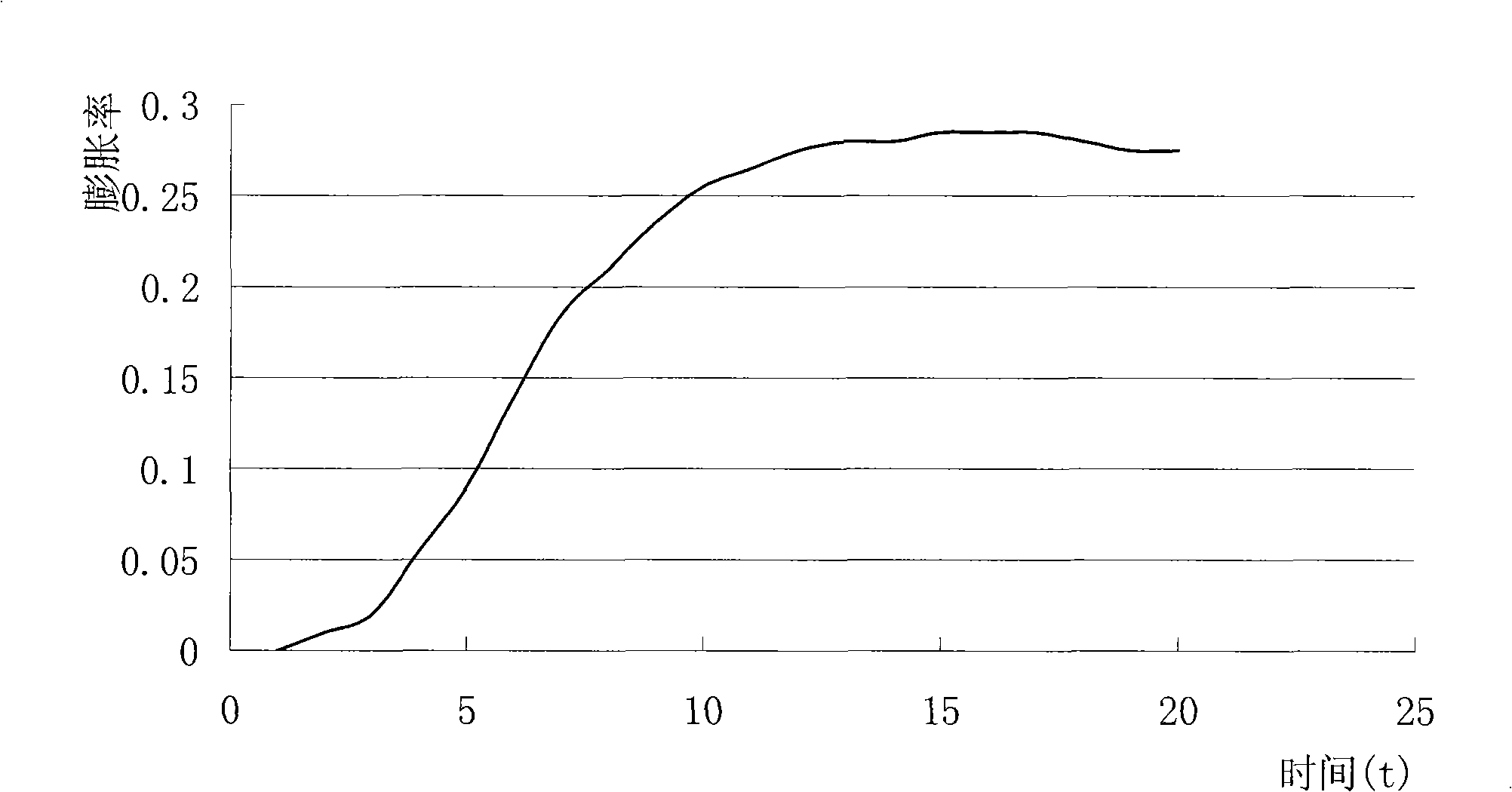

Embodiment 3

[0050] Sodium polymethylene naphthalene sulfonate: 50%; dispersant: 8%; retarder: 20%; initiator: 5%; water: 17%. After the above composition is mixed and stirred, a liquid micro-expansion pumping agent is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com