Additive used in ice slurry preparation with secondary refrigerant HCFC-123

A technology of additives and brine, which is applied in the field of additives for making ice slurry, and the field of additives used for making ice slurry by using brine agent HCFC-123, which can solve the problems of inconspicuousness and achieve good fluidity and high ice content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The additive used when making ice slurry by using the refrigerant HCFC-123 is a compound mixed solution composed of sodium lauryl sulfate and glycerol, wherein sodium lauryl sulfate accounts for the total amount of the compound mixed solution 2%, and glycerol accounts for 98% of the compound mixed solution total amount.

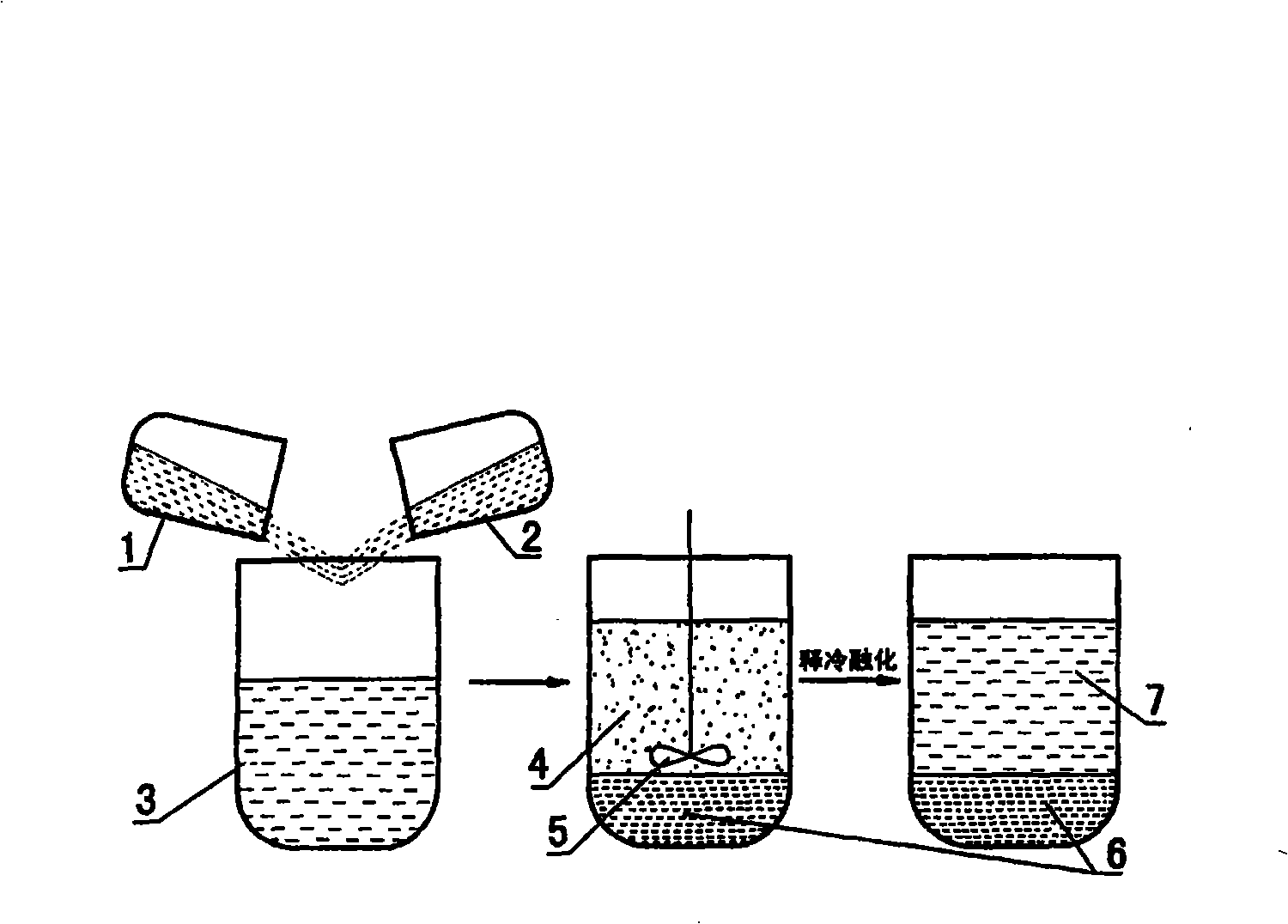

[0016] A small sample test was carried out in the laboratory to prepare ice slurry. Such as figure 1 As shown, there is 1000 milliliters of water in container 3, 20 milliliters of brine HCFC-123 solution at -10°C in container 2, and 10 milliliters of brine in container 1. Additives used.

[0017] The additives used in the preparation of ice slurry by using the brine HCFC-123 in the container 1 and the brine HCFC-123 solution in the container 2 are added to the water in the container 3 to obtain a mixed solution.

[0018] After the mixed solution is fully stirred by the agitator 5, a soft and fluffy ice slurry 4 with excellent fluidity is generated, ...

Embodiment 2

[0020] The additive used when making ice slurry by utilizing the refrigerant carrier HCFC123 is a compound mixed solution composed of sodium lauryl sulfate and glycerin, wherein sodium lauryl sulfate accounts for the total amount of the compound mixed solution 3wt%, and glycerol accounts for 97wt% of the compound mixed solution total amount. All the other are with embodiment 1. The ice slurry produced by using this additive in a small sample test in the laboratory has an ice content rate of 73%.

Embodiment 3

[0022] The additive used when making ice slurry by utilizing the refrigerant carrier HCFC123 is a compound mixed solution composed of sodium lauryl sulfate and glycerin, wherein sodium lauryl sulfate accounts for the total amount of the compound mixed solution 5wt% of glycerol accounts for 96wt% of the compound mixed solution total amount. All the other are with embodiment 1. The ice slurry produced by using this additive in a small sample test in the laboratory has an ice content rate of 70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com