Plunger type double-ejector rod gas-liquid vat and gas-liquid combination-controlled position and speed servo control device

A technology of double rods and gas-hydraulic cylinders, which is applied in the direction of servo motors, servo motor components, fluid pressure actuators, etc., to achieve the effects of positioning accuracy and rapidity, high precision, and no overshoot accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

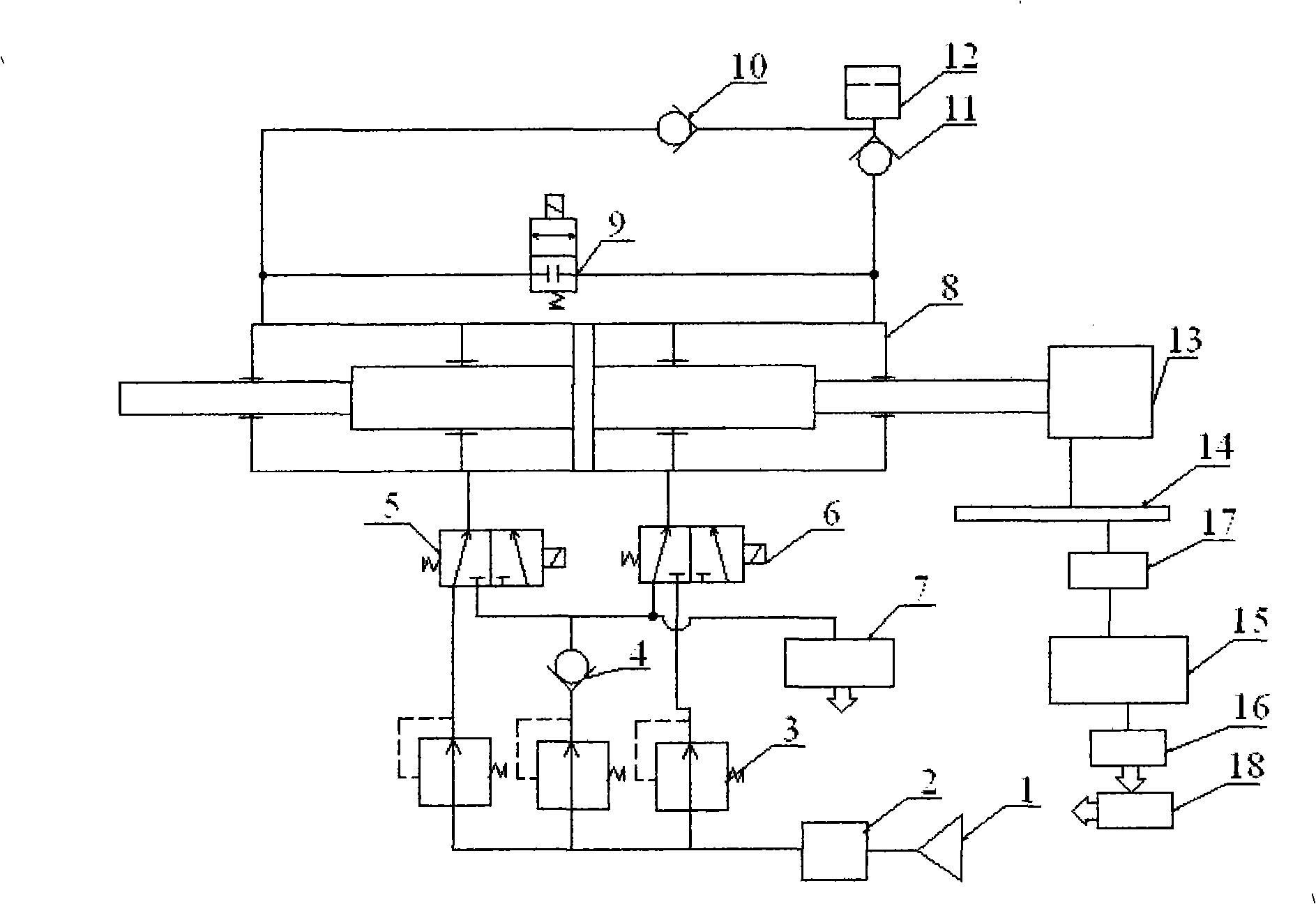

[0018] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

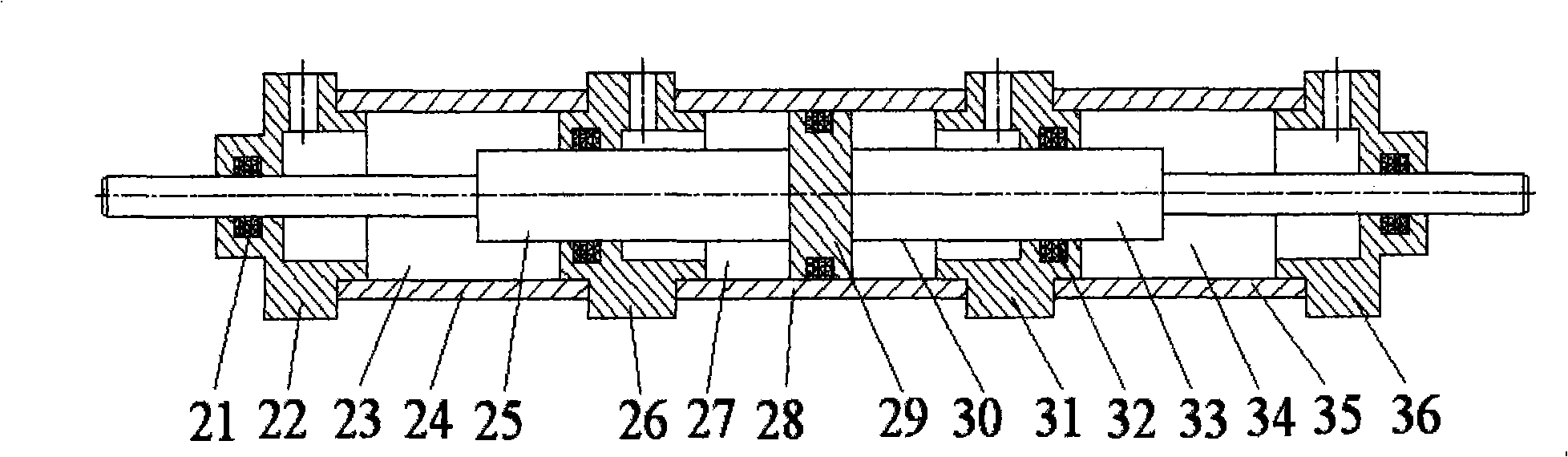

[0019] Such as figure 2 As shown, the plunger-type double-rod air-hydraulic cylinder 8 includes two oil chambers and two air chambers, namely the left oil chamber 23 , the right oil chamber 34 , the left air chamber 27 and the right air chamber 30 . The left oil chamber 23, the right oil chamber 34, the left air chamber 27 and the right air chamber 30 are respectively connected with the outside world through pipelines. The left air chamber 27 and the right air chamber 30 are arranged in the air chamber cylinder 28 and separated by the piston 29. The two ends of the air chamber cylinder 28 are provided with a left air-oil chamber transparent cover 26 and a right air-oil chamber transparent cover 31. Left air-oil chamber see-through cover 26 and right air-oil chamber see-through cover 31 are connected with left oil c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com