Helical-conveyer centrifugal

A screw discharge and centrifuge technology, applied in the field of centrifuges, can solve the problems of poor wear resistance, increase manufacturing costs, and troublesome processing, achieve separation effect guarantee, improve solid-liquid separation effect, and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

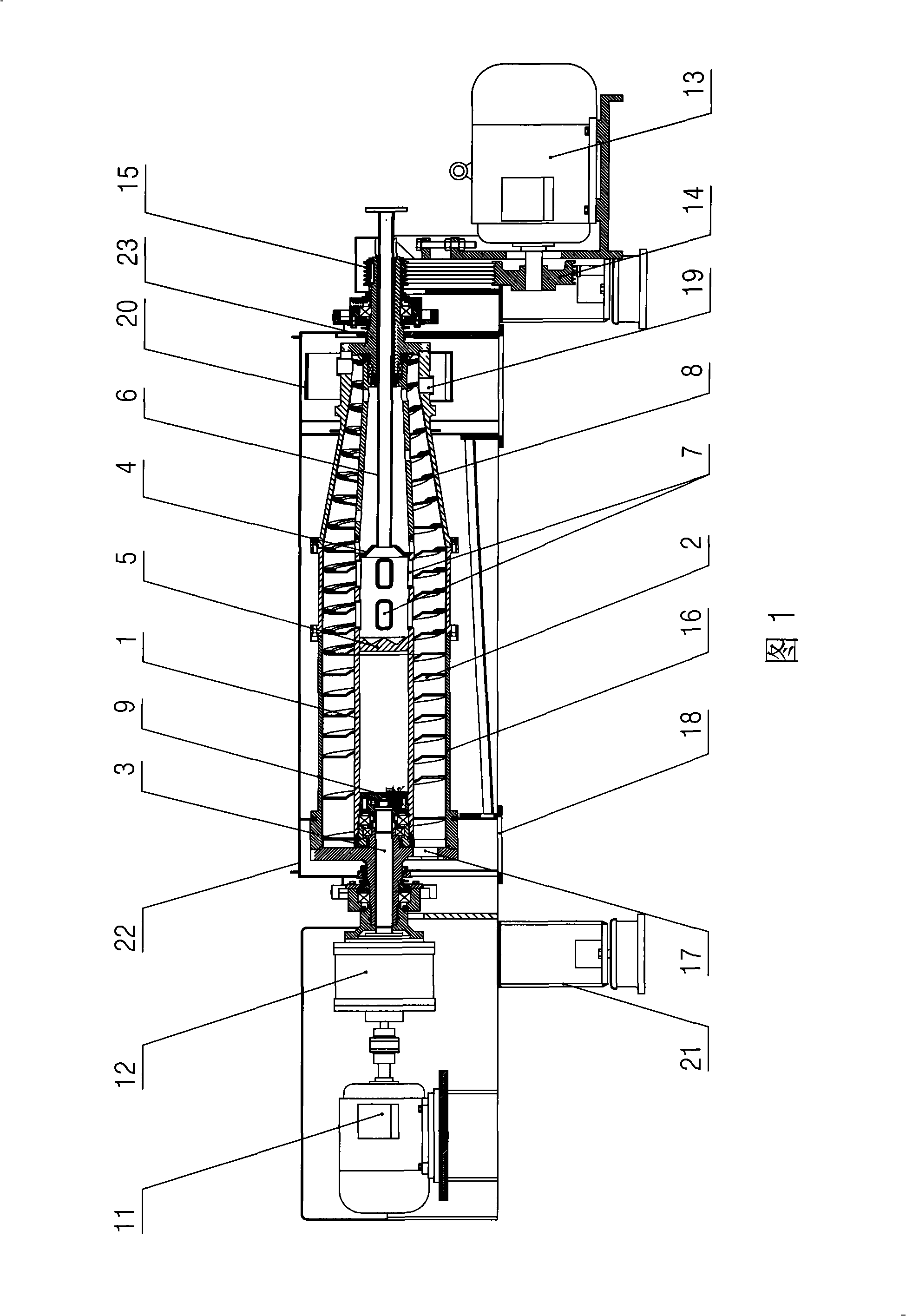

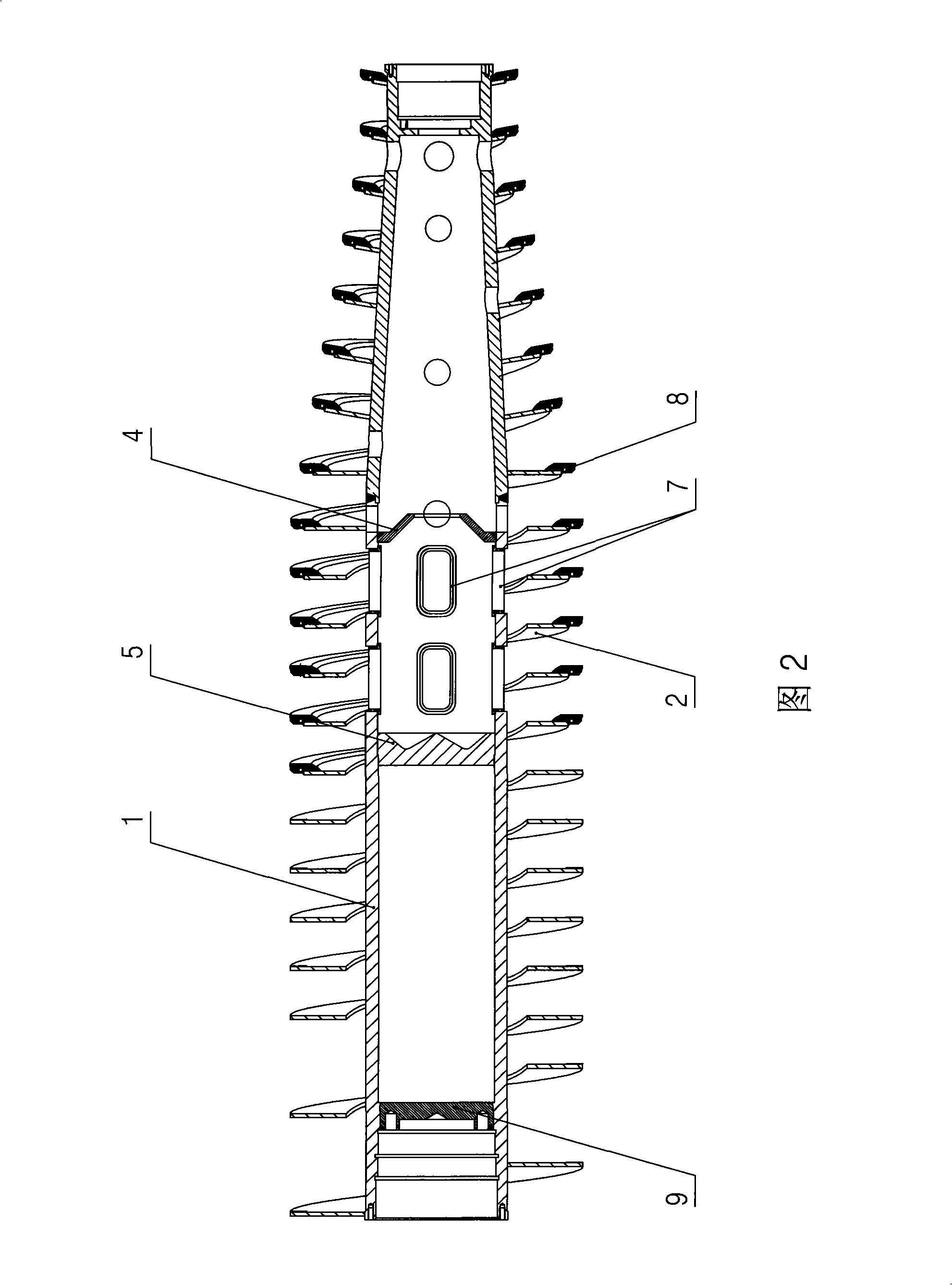

[0012] As shown in Figure 1, the screw discharge centrifuge of the present invention comprises: feed pipe 6 and support 21, on support 21, be provided with rotating drum 16 through bearing activity, be provided with in rotating drum 16 through bearing activity Pushing device, machine base 21 is also provided with organic casing 22, differential drive device and main shaft drive device, drum 16 is covered in casing 22, and drum 16 is connected with main shaft drive device through drum shaft 23, described The pushing device includes: a hollow spiral mandrel 1, the bottom of the spiral mandrel 1 is provided with a transmission shaft 3 - the transmission shaft 3 extends into the installation cavity at the bottom of the spiral mandrel 1, and is fixed with the bottom plate 9, the transmission The shaft 3 is connected to the differential drive device, and the front and rear parts of the outer wall of the spiral mandrel 1 are respectively provided with a spiral pusher blade 2, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com