Crystallization system

A crystallization system and crystallization technology, applied in the direction of solution crystallization, crystallization separation, general layout of crystallization equipment, etc., can solve the problems of evaporation crystallization system evaporation reduction, scaling, corrosion intensification, etc., to reduce the risk of pipeline blockage, The effect of extending the operation and discharge cycle and improving the effect of solid-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the accompanying drawings.

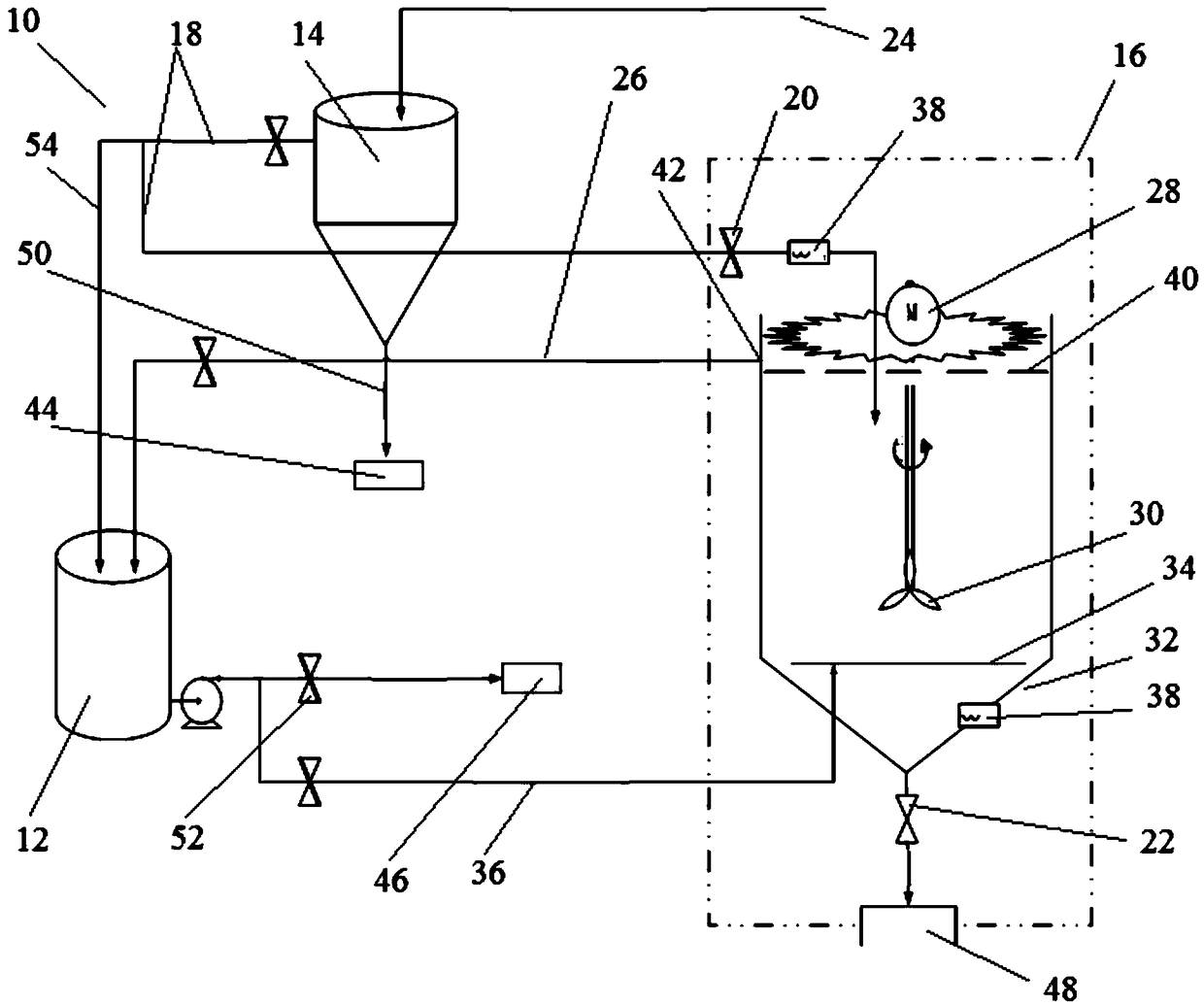

[0019] figure 1 A crystallization system 10 including a mother liquor tank 12 and a thickener 14 is shown in accordance with one embodiment of the present invention. The mother liquor tank 12 and the thickener 14 are connected through the branch pipe 54 of the first overflow pipe, wherein the branch pipe 54 of the first overflow pipe is connected to the feed port of the mother liquor tank 12 and the overflow pipe port of the thickener 14 . The feeding port of the mother liquor tank 12 is located at the top of the mother liquor tank 12 , and the overflow nozzle of the thickener 14 is located on the side wall of the top of the thickener 14 . In other words, the thickener 14 conveys the supernatant liquid to the mother liquor tank through the branch pipe 54 of the first overflow pipe.

[0020] According to an embodiment of the present invention, the crystallization syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com