Forced solid-liquid separator for feces of livestock and poultry

A technology of solid-liquid separator and poultry manure, which is applied in the direction of filtration separation, separation method, animal husbandry wastewater treatment, etc. It can solve the problems of poor separation effect, high moisture content of solids, and inability to process livestock and poultry manure, etc., to achieve The effect of improving fermentation efficiency, low moisture content, and improving solid-liquid separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

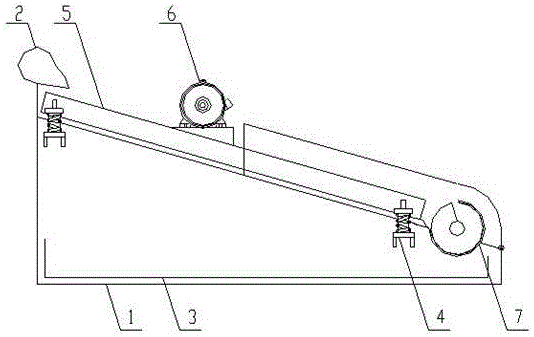

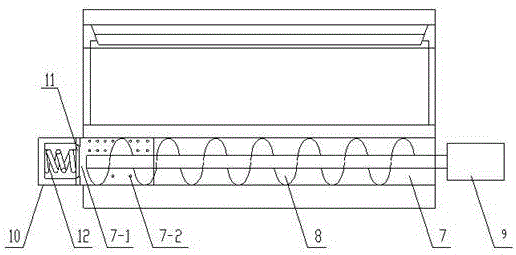

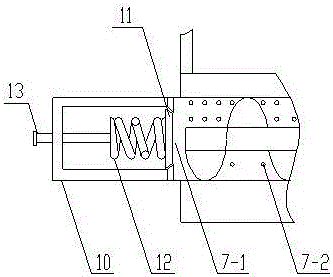

[0012] Such as Figure 1-3 As shown, the present invention comprises: frame 1, feed hopper 2, filtrate collection tank 3, screen mesh separation mechanism and extrusion separation mechanism, described feed hopper 2 is positioned at frame 1 top, and filtrate collection tank 3 is positioned at frame 1 Bottom, the screen separating mechanism includes four sets of springs 4, a screen 5 and a vibrating motor 6, the screen 5 is obliquely installed on the frame 1 through four sets of springs 4, and the four sets of springs 4 are respectively located at the four corners of the bottom of the screen 5, The top of the screen 5 is connected to the outlet of the feeding hopper 2, the vibration motor 6 is installed on the screen 5 through the support, and the extrusion separation mechanism includes a sleeve 7, an extrusion dragon 8, a reduction motor 9, a bracket 10, and a valve 11 and return spring 12, the sleeve 7 is installed at the bottom of the frame 1, the upper part of one side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com