Method for detecting purity of reconstituted tobacco coating solution

A technology of reconstituted tobacco leaves and detection methods, which is applied in the field of tobacco manufacturing, can solve the problems that the measured data cannot faithfully reflect the true level, the liquid concentration and viscosity are large, and the detection results have a great influence, so as to improve the effect of solid-liquid stratification , Small amount of sampling, easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

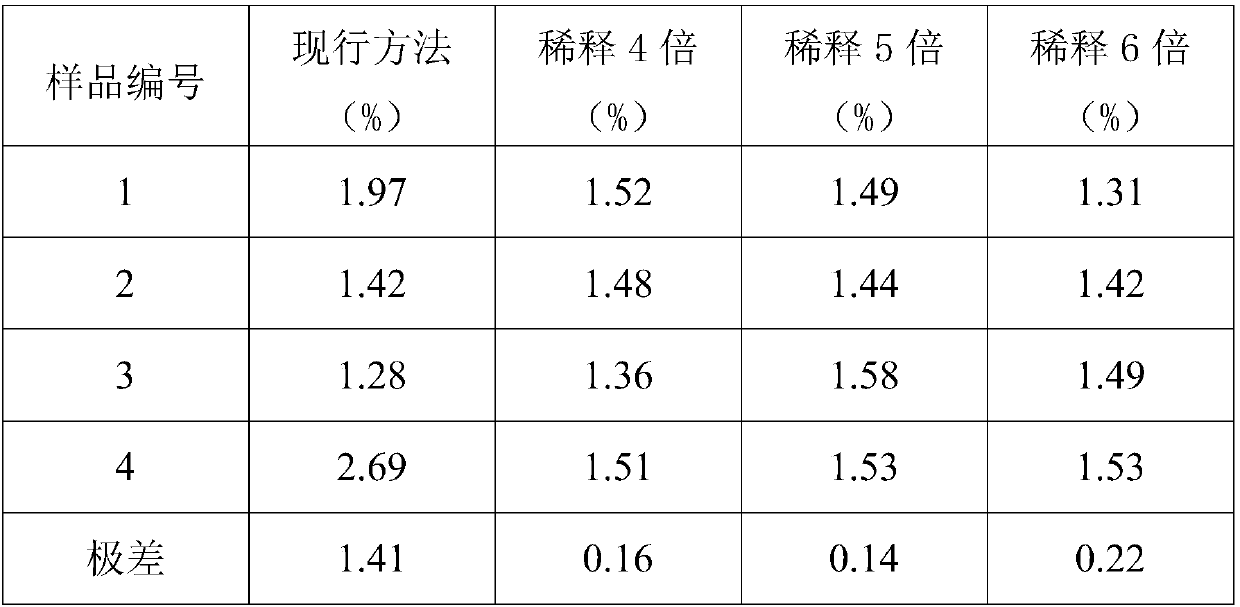

Embodiment 1

[0021] A method for detecting the purity of reconstituted tobacco leaf coating solution, comprising the following steps:

[0022] (1) Dilute the reconstituted tobacco leaf coating solution 4 times (by weight), weigh two samples of the diluted coating solution with a mass of a gram and b gram respectively, and put the two samples into two oven-dried constant In the heavy No. 1 and No. 2 drying cylinders, the mass of the No. 1 drying cylinder is c grams, and the mass of the No. 2 drying cylinder is d grams;

[0023] (2) Put No. 1 and No. 2 spin-drying cylinders equipped with diluted coating liquid samples in the sleeve of the centrifuge respectively in the above step (1);

[0024] (3) Set the operating parameters of the centrifuge, the centrifugation time is 5 minutes, the rotating speed is 3000 rpm, and the safety protection cover is covered, and the centrifuge is started;

[0025] (4) After the centrifugation is completed, take out the two drying cylinders, pour out the liqui...

Embodiment 2

[0035] A method for detecting the purity of reconstituted tobacco leaf coating solution, comprising the following steps:

[0036] (1) Dilute the reconstituted tobacco leaf coating solution 5 times (by weight), weigh two samples of the diluted coating solution with a mass of a gram and b gram respectively, and put the two samples into two oven-dried constant In the heavy No. 1 and No. 2 drying cylinders, the mass of the No. 1 drying cylinder is c grams, and the mass of the No. 2 drying cylinder is d grams;

[0037] (2) Put No. 1 and No. 2 spin-drying cylinders equipped with diluted coating liquid samples in the sleeve of the centrifuge respectively in the above step (1);

[0038] (3) Set the operating parameters of the centrifuge, the centrifugation time is 5 minutes, the rotating speed is 3000 rpm, and the safety protection cover is covered, and the centrifuge is started;

[0039] (4) After the centrifugation is completed, take out the two drying cylinders, pour out the liqui...

Embodiment 3

[0049] A method for detecting the purity of reconstituted tobacco leaf coating solution, comprising the following steps:

[0050] (1) Dilute the reconstituted tobacco leaf coating solution 6 times (by weight), weigh two samples of the diluted coating solution with a mass of a gram and b gram respectively, put the two samples into two oven-dried constant In the heavy No. 1 and No. 2 drying cylinders, the mass of the No. 1 drying cylinder is c grams, and the mass of the No. 2 drying cylinder is d grams;

[0051] (2) Put No. 1 and No. 2 spin-drying cylinders equipped with diluted coating liquid samples in the sleeve of the centrifuge respectively in the above step (1);

[0052] (3) Set the operating parameters of the centrifuge, the centrifugation time is 5 minutes, the rotating speed is 4000 rpm, and the safety protection cover is covered, and the centrifuge is started;

[0053] (4) After the centrifugation is completed, take out the two drying cylinders, pour out the liquid in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com