Patents

Literature

43results about How to "Prevent gravity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

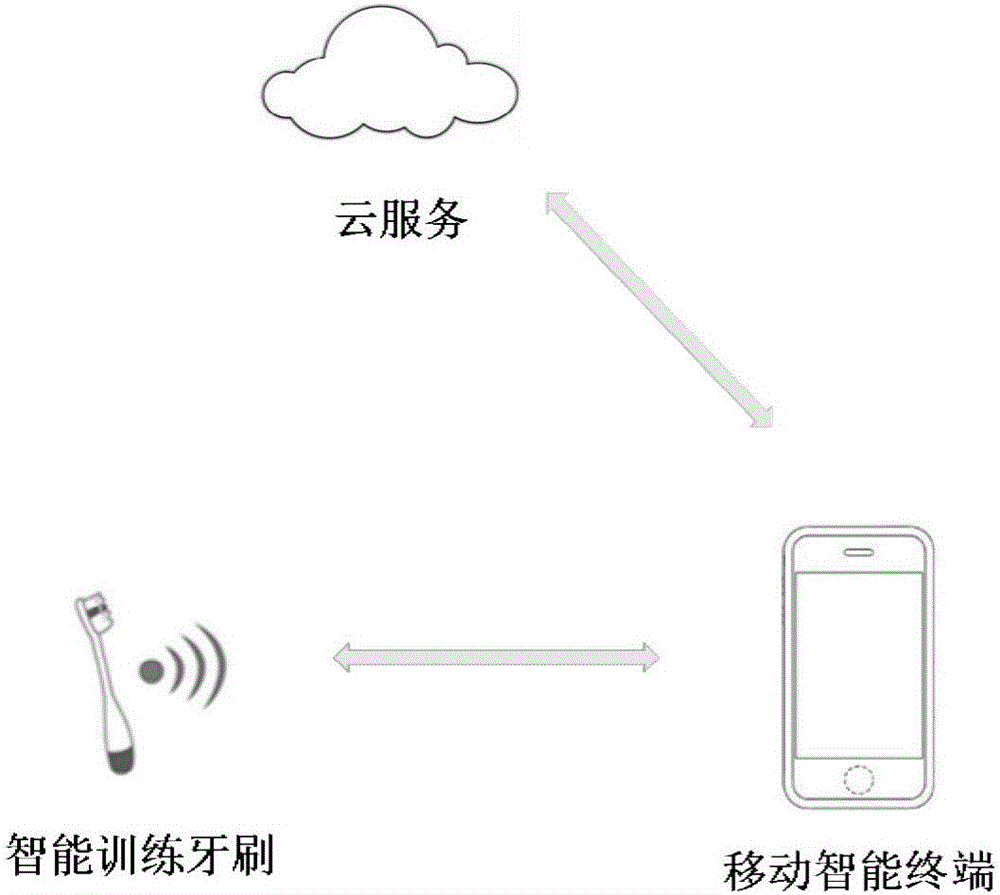

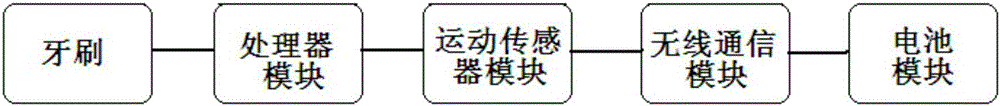

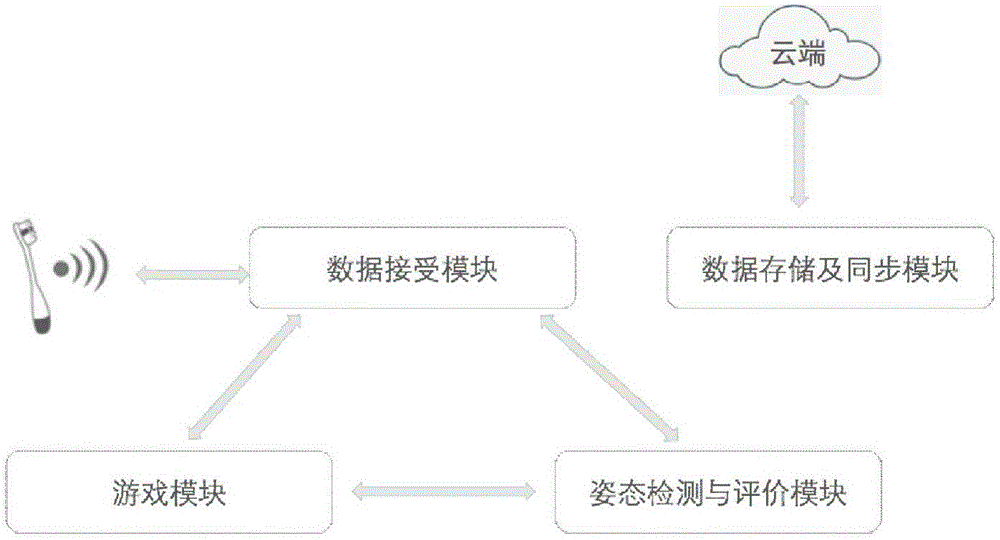

Smart children tooth-brushing guiding system

The invention discloses a smart children tooth-brushing guiding system. The system comprises smart training toothbrush hardware, an application software system installed on a mobile smart terminal, and cloud service, wherein the smart training toothbrush hardware comprises a toothbrush body, a motion sensor module, a processor module, a wireless communication module and a power supply module which are arranged on the toothbrush body; the application software system is installed on the mobile smart terminal, has functions of receipt receiving and transmitting, tooth-brushing posture detection and evaluation, tooth-brushing action guiding, smart reinforcing, data uploading to cloud and the like; the cloud service is deployed on Internet public cloud, and is used for providing history record storage, data analysis, ranking sharing and the like. According to the smart children tooth-brushing guiding system, children are guided to form a correct tooth-brushing posture and an excellent tooth-brushing habit by a game interacting mode, tooth-brushing entertainment and motivation of children are improved, and a smart living mode for future home is provided.

Owner:成迪寒

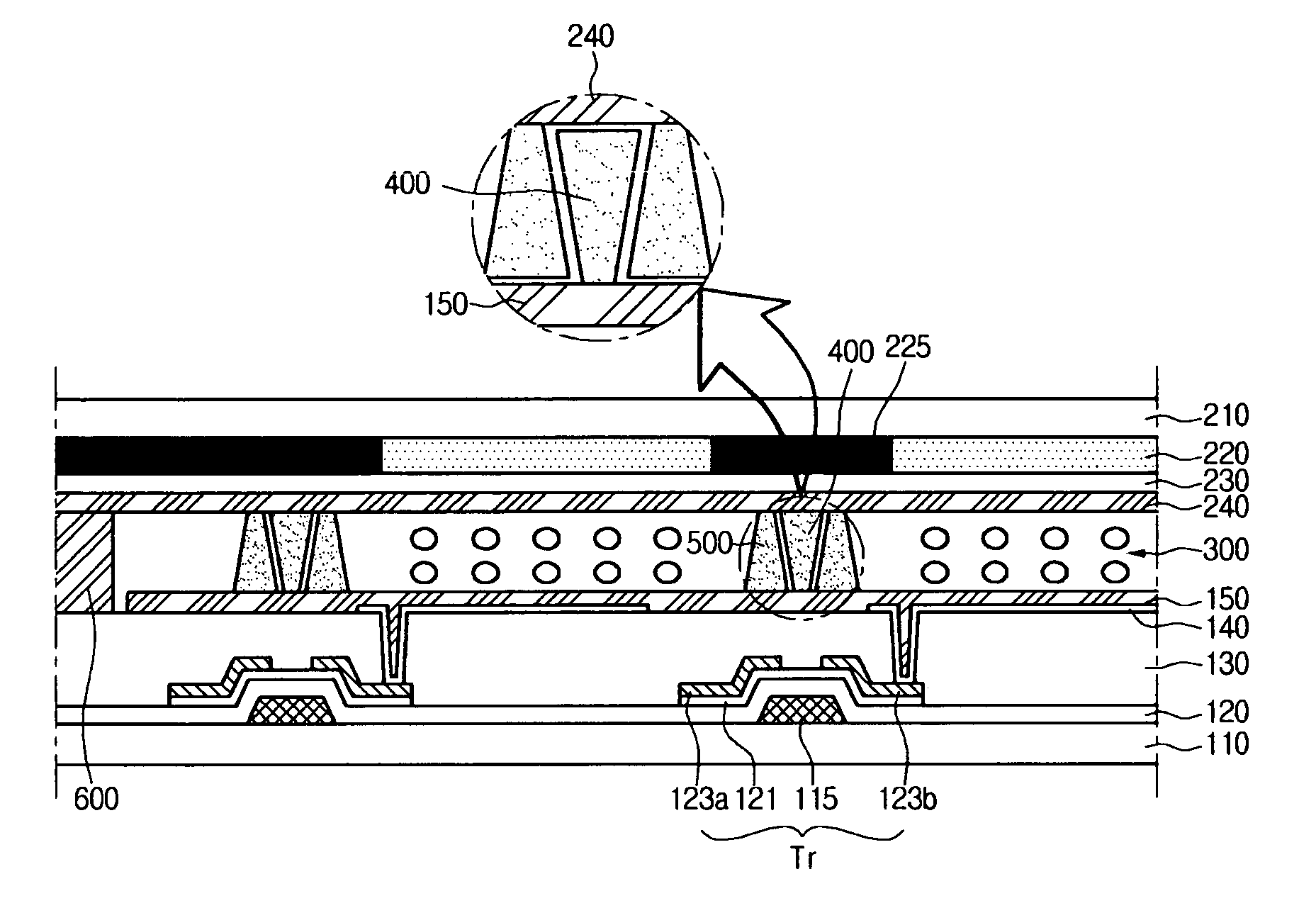

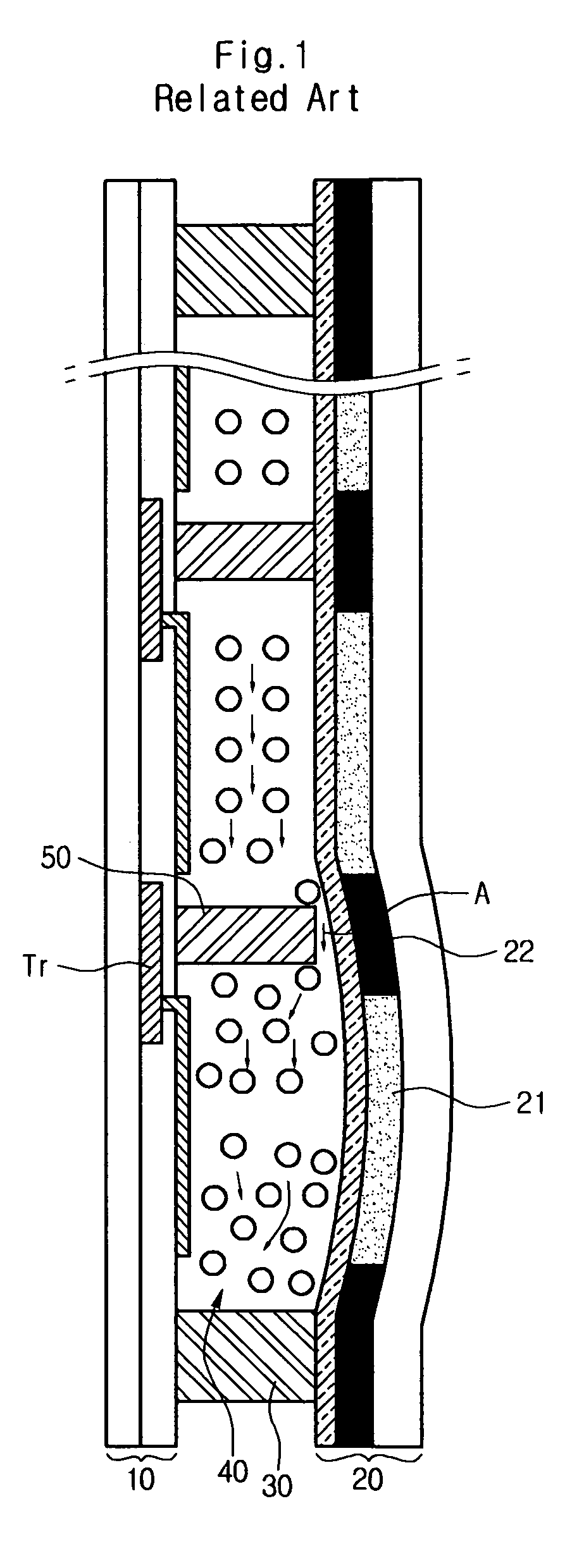

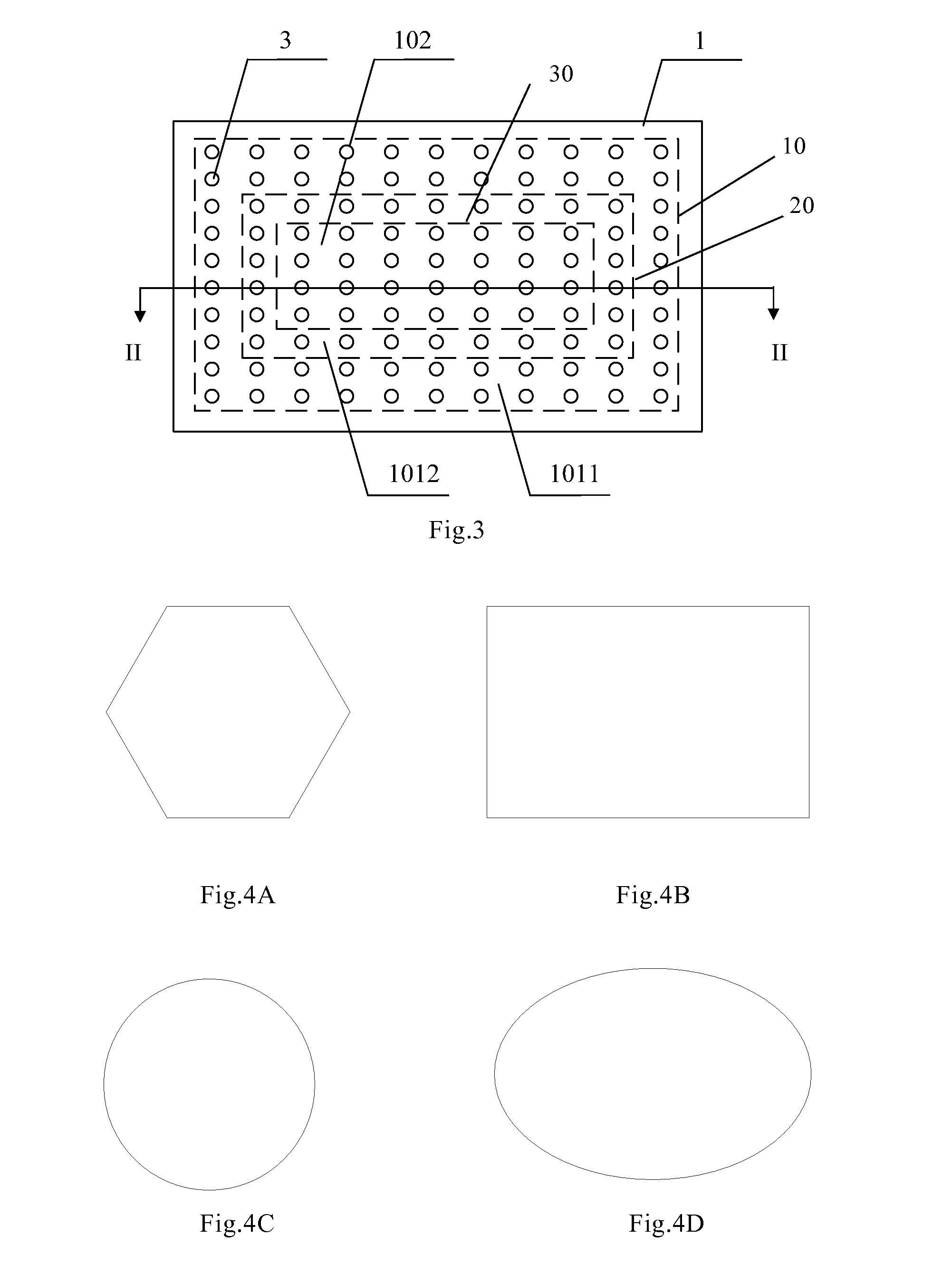

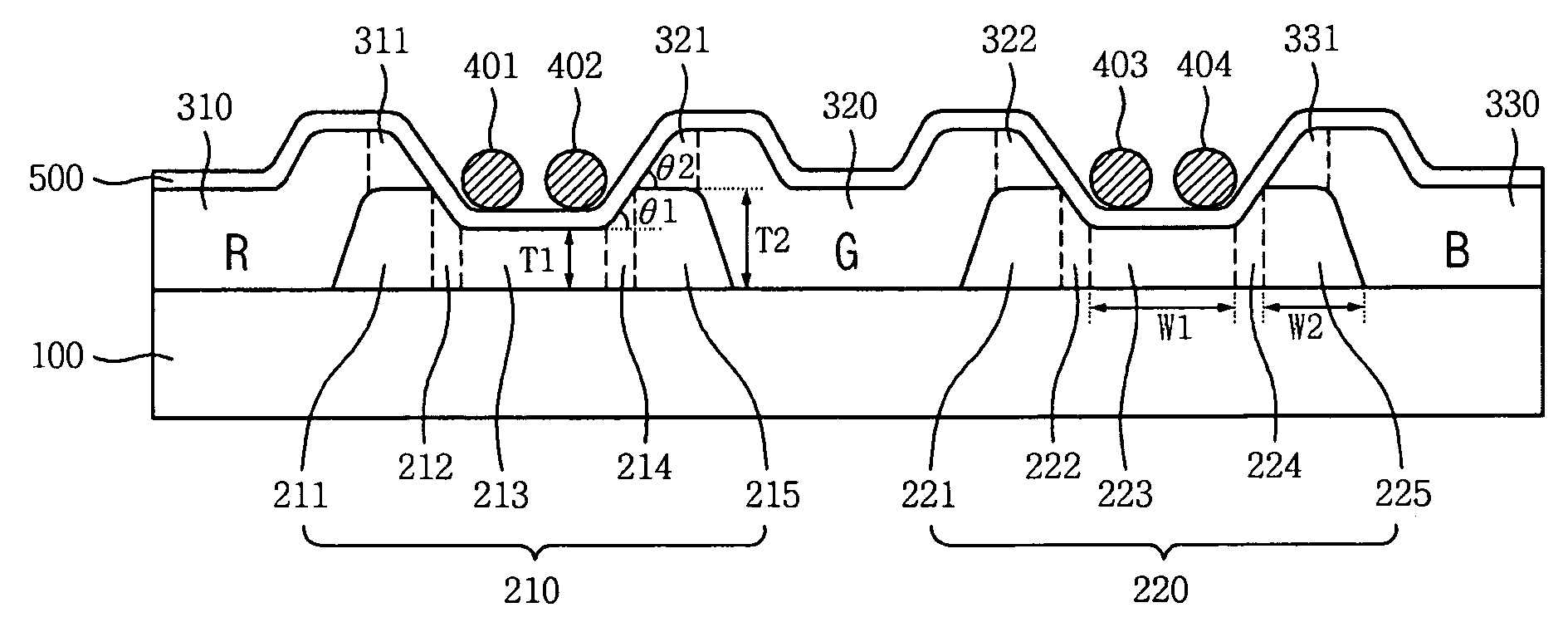

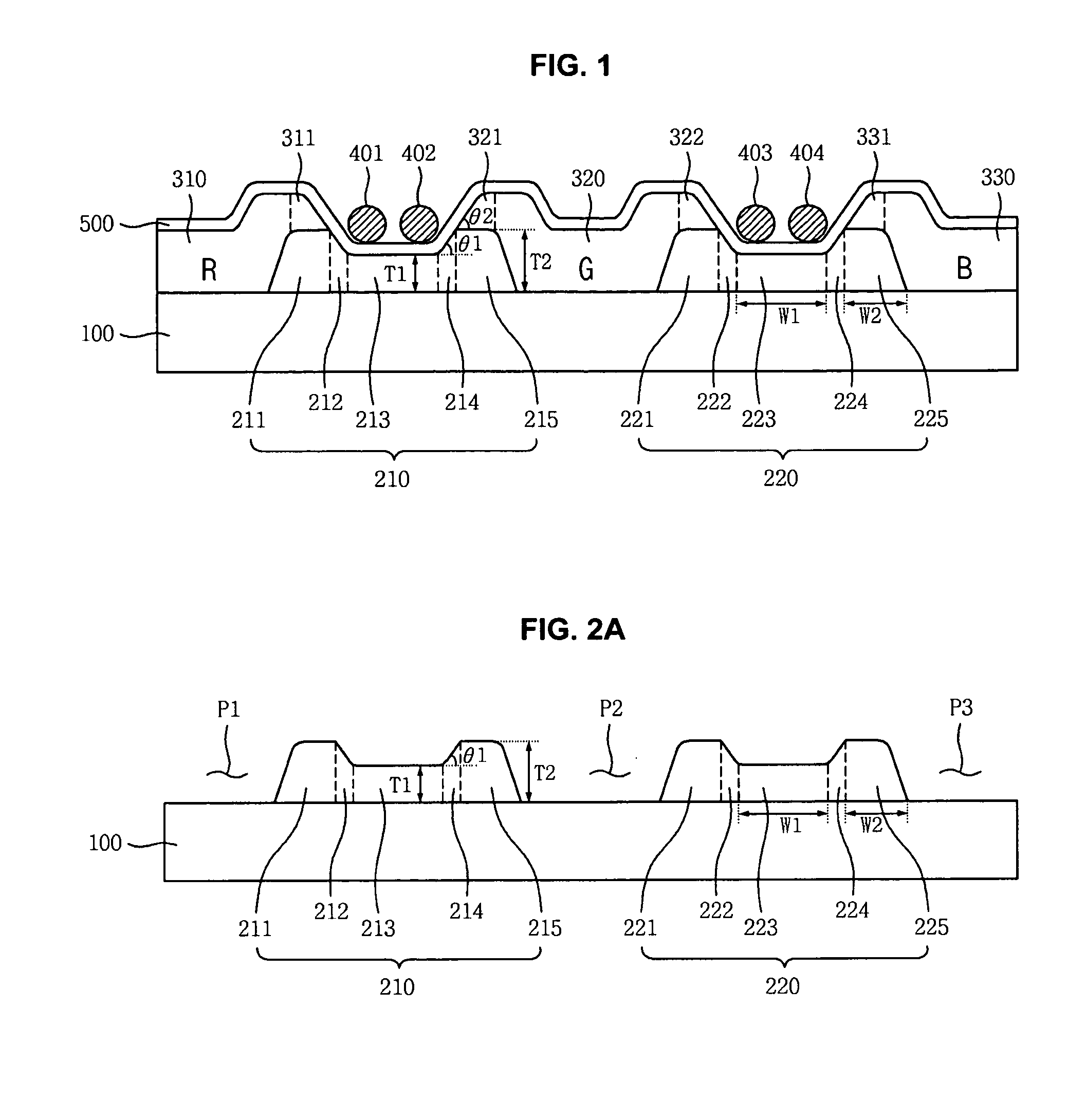

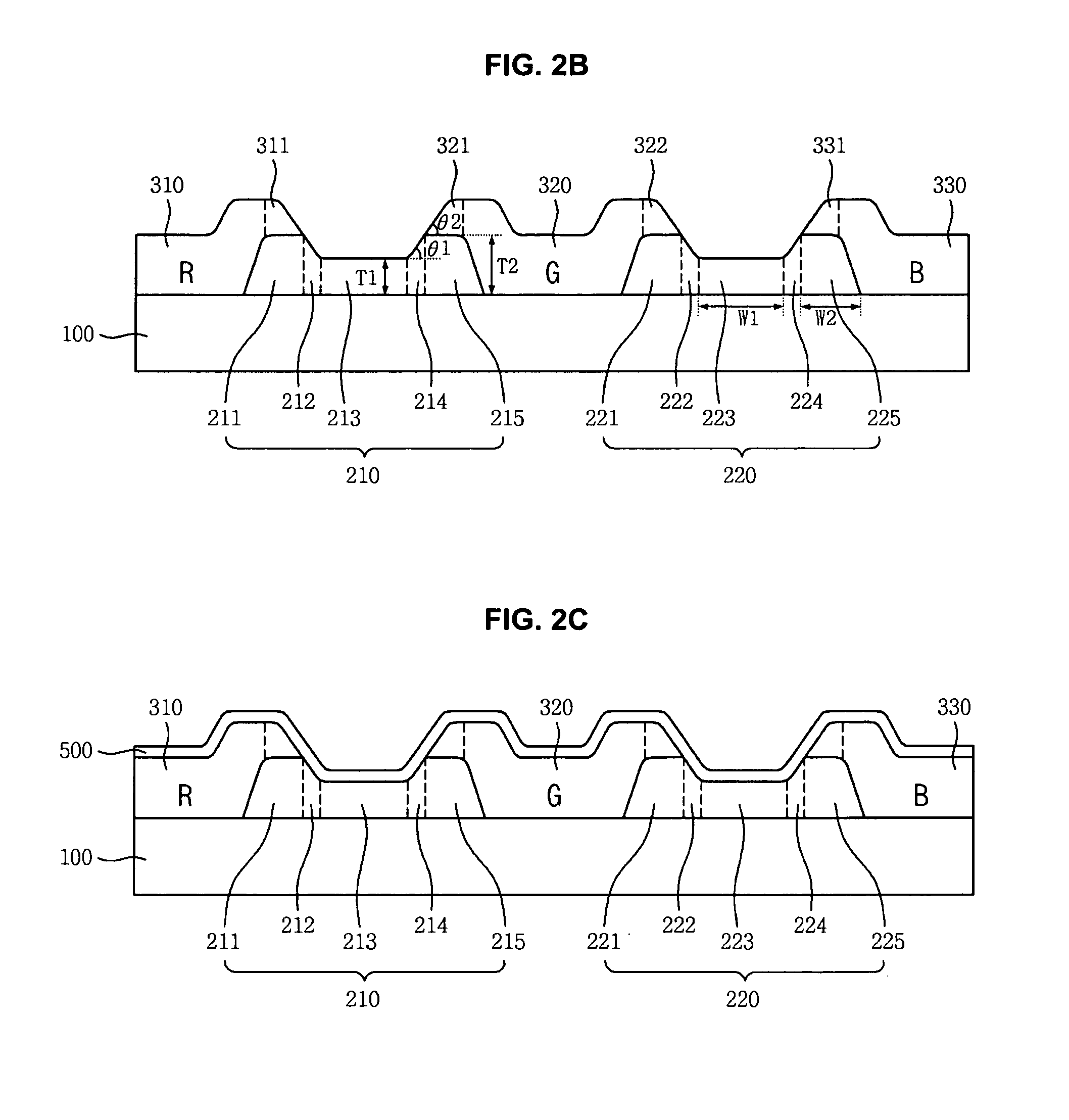

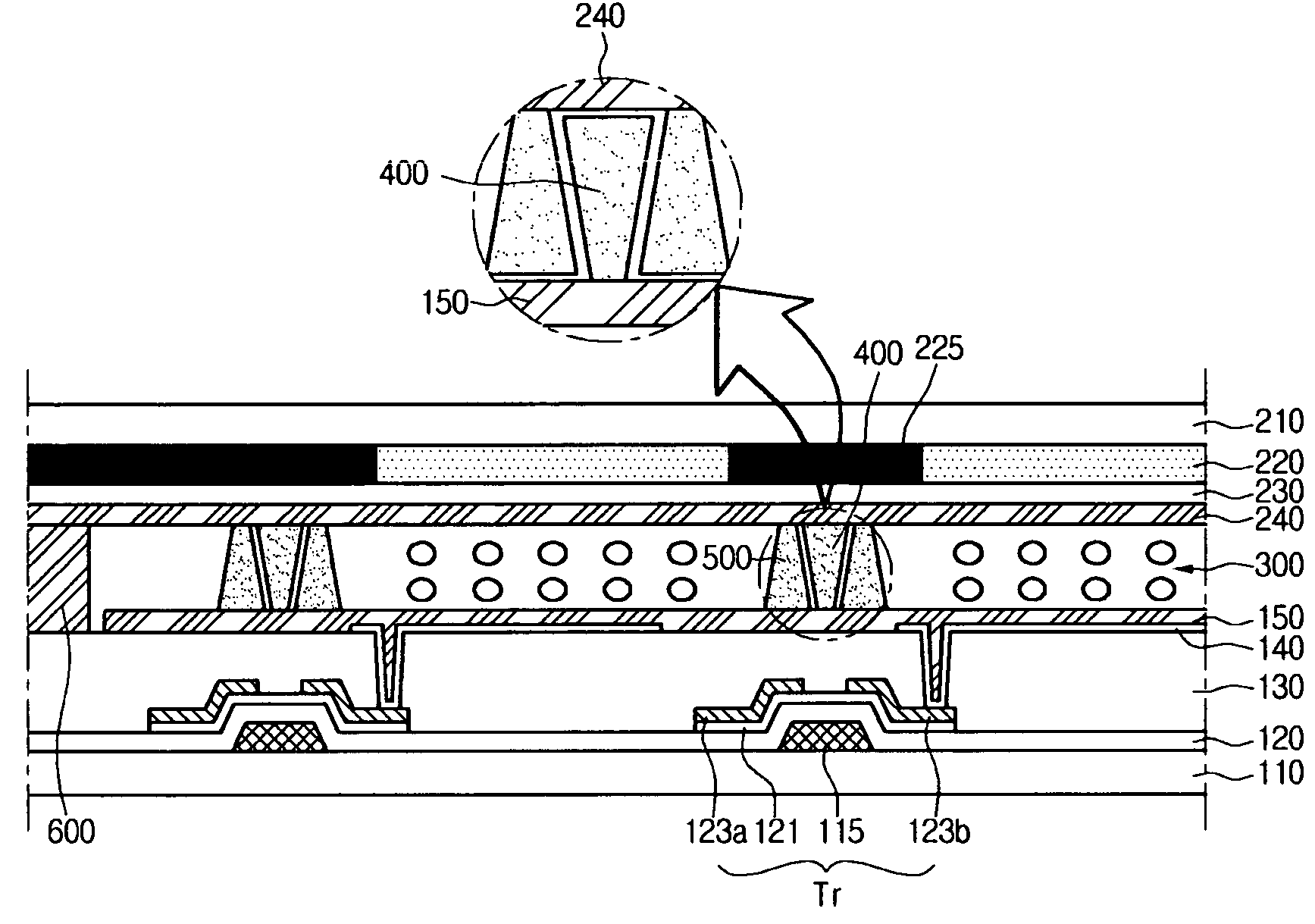

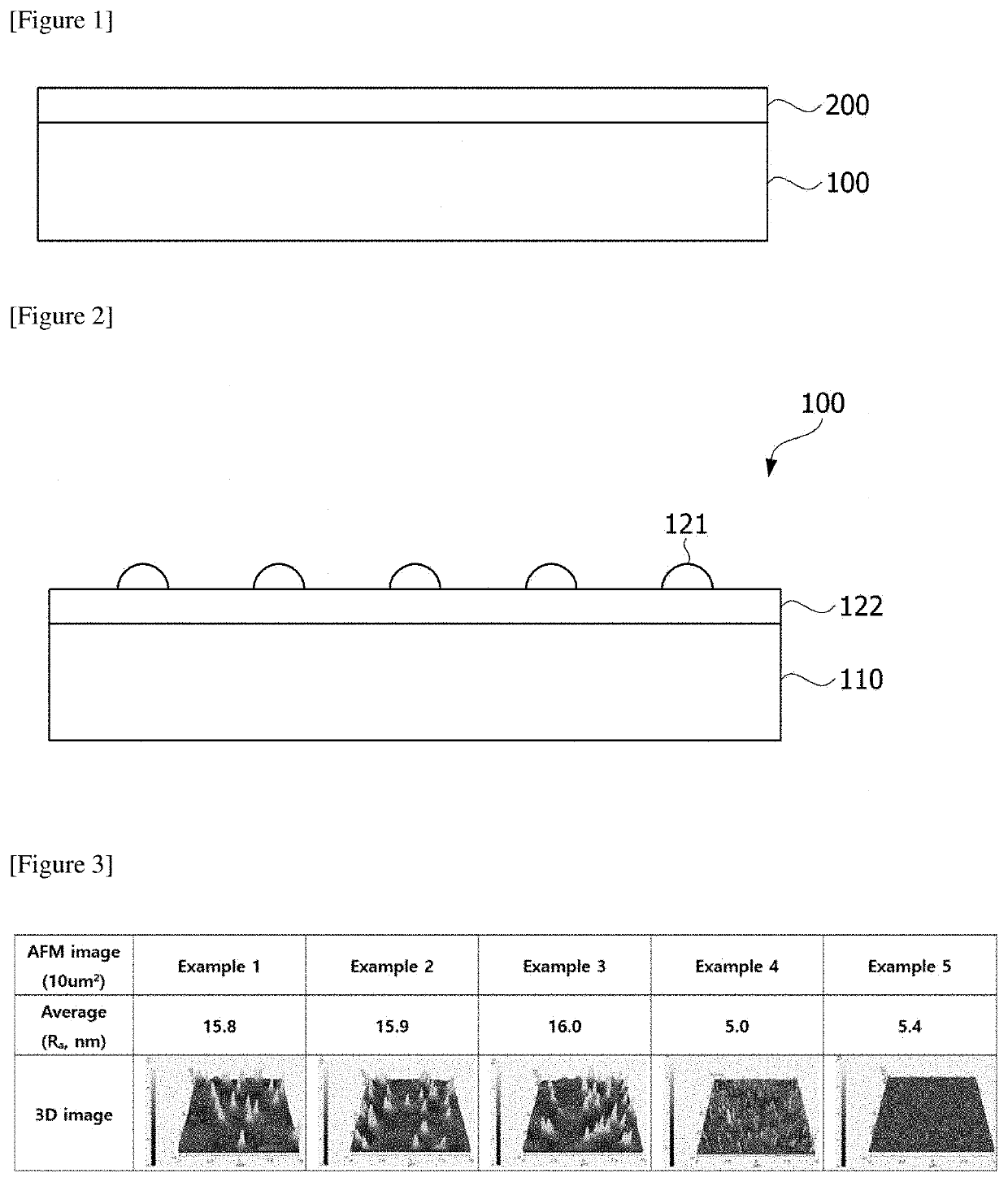

Liquid crystal display device and method of fabricating the same

InactiveUS20070070284A1Preventing touch brightness failurePrevent gravityNon-linear opticsLiquid-crystal displayEngineering

A liquid crystal display device includes: a first substrate having a plurality of gate lines and a plurality of data lines crossing each other; a second substrate facing the first substrate; a first pattern spacer having an inverse tapered shape on an inner surface of the first substrate; a second pattern spacer having an inverse tapered shape on an inner surface of the second substrate; a seal pattern on a peripheral edge of the first and second substrates; and a liquid crystal layer between the first and second substrates.

Owner:LG DISPLAY CO LTD

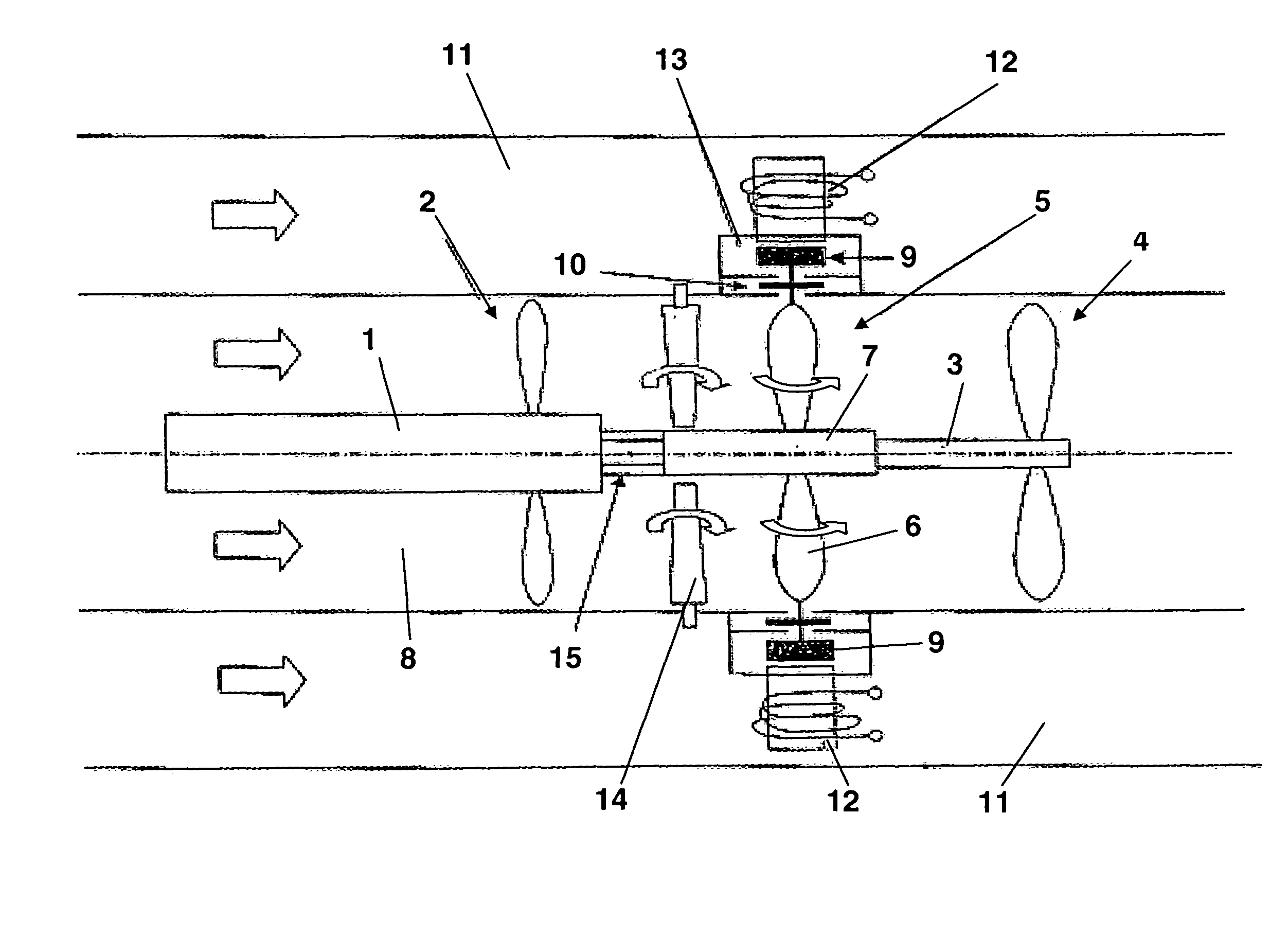

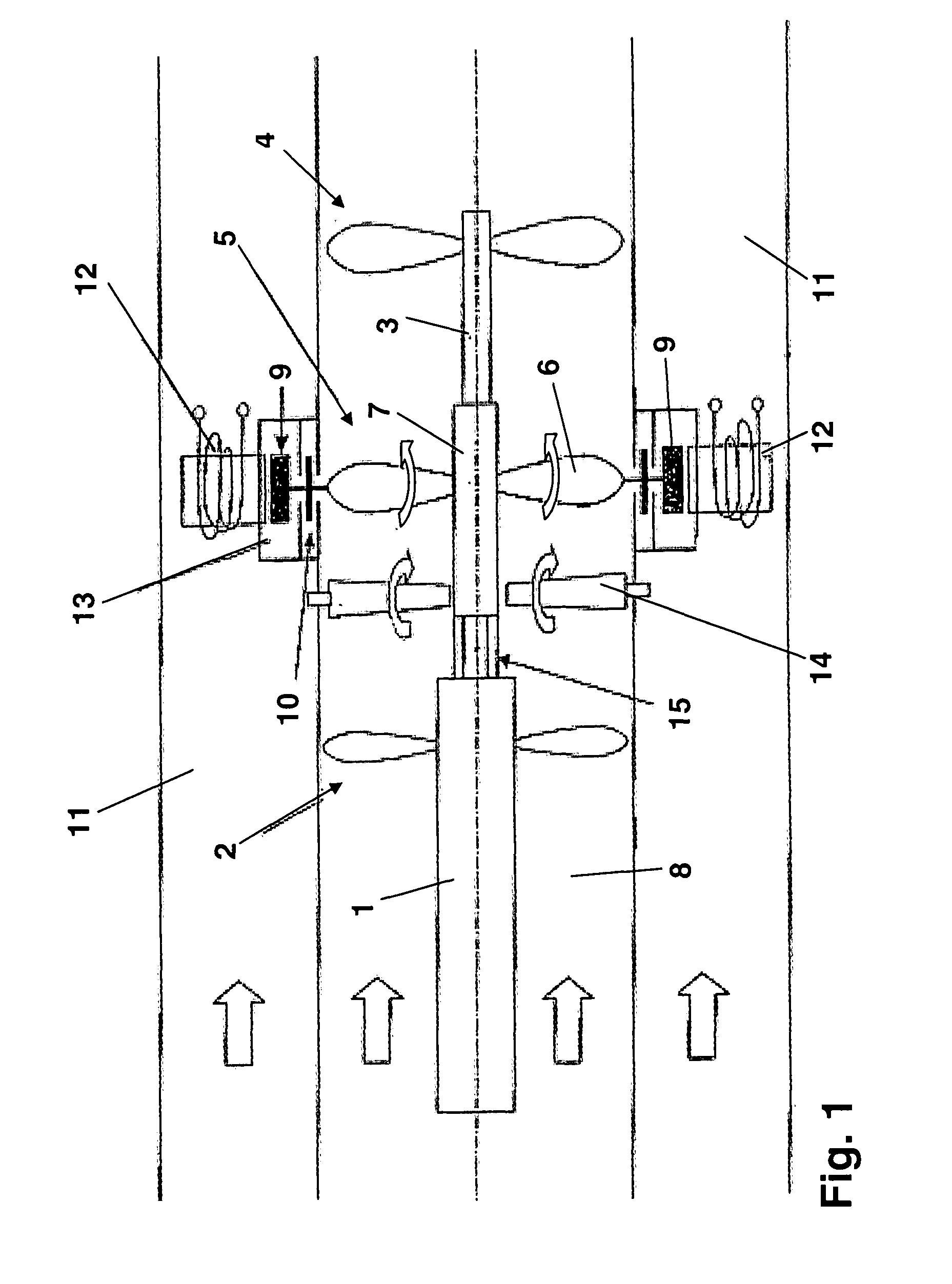

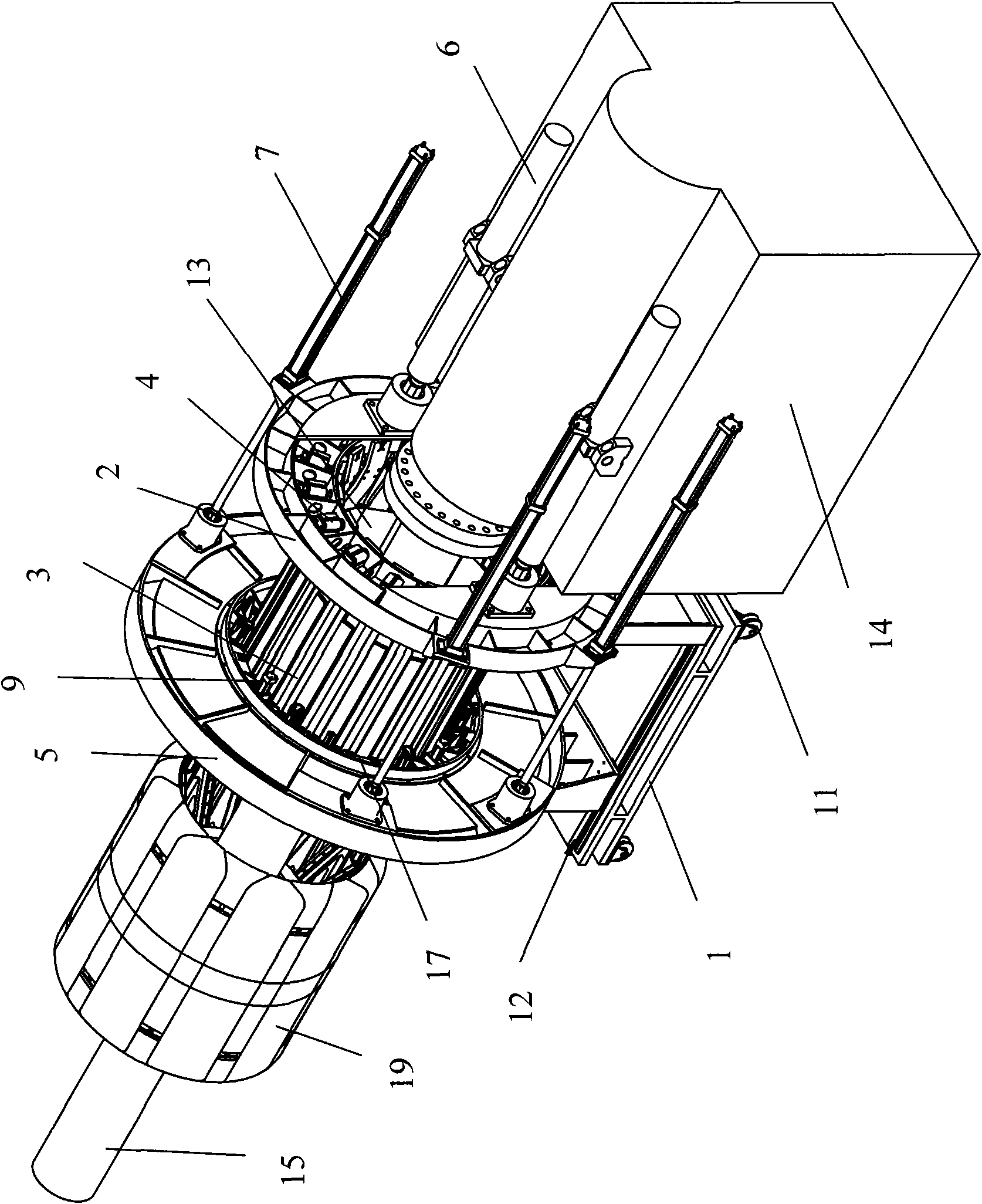

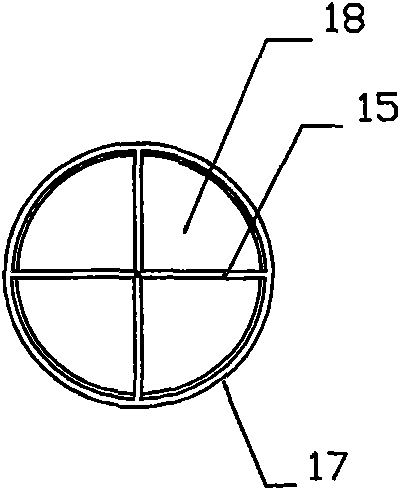

Generator-starter system for a multi-shaft engine

InactiveUS7745950B2Easily maintainableEasily repairableEngine fuctionsTurbine/propulsion engine ignitionHigh pressureTurbine

In order to provide a high electric power for an aircraft via a generator driven by the engine, an additional free turbine is included in the hot-gas flow of the engine, which—equipped with generator-starter magnets (9) and surrounded by annularly arranged generator-starter coils (12)—forms a generator-starter turbine (5) and is connected to the high-pressure shaft (1) via an overrunning clutch (15), and hence, is also used for starting the engine.

Owner:ROLLS ROYCE DEUT LTD & CO KG

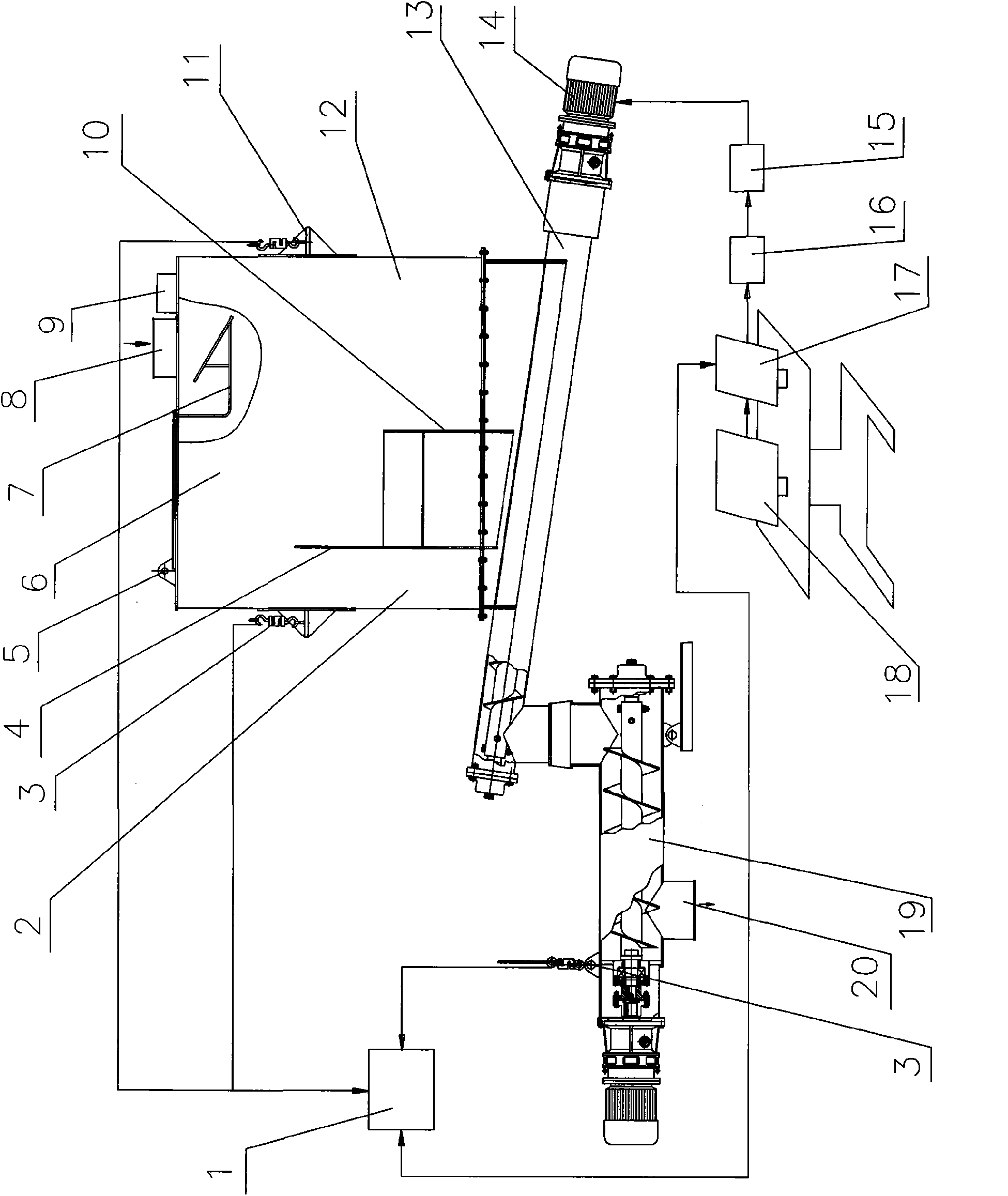

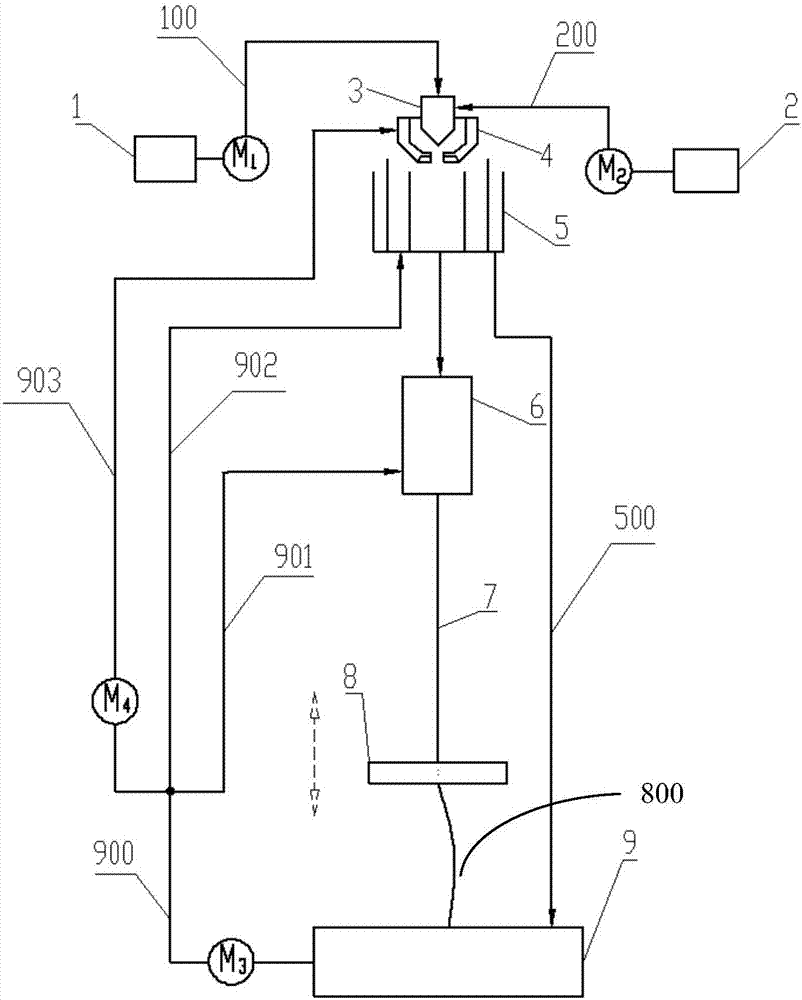

Cement supply online calibration system of stable soil plant mix equipment

ActiveCN101554753AImprove and increase metering accuracyRealize online calibrationControl apparatusSold ingredients supply apparatusReal time analysisFrequency conversion

The invention discloses a cement supply online calibration system of stable soil plant mix equipment, comprising an inclined frequency-conversion spiral feeder, a calibration bin, a detection unit 1, a detection unit 2 and a control system, wherein the detection unit 1 and the detection unit 2 are both connected with the control system. The calibration bin is fixed at the upper part of the inclined frequency-conversion spiral feeder and used for temporarily storing and buffering supplied cement to prevent the cement from directly impacting the inclined frequency-conversion spiral feeder; the detection unit 1 is used for detecting the change value Q1 of cement weight in the calibration bin before and after the calibration; the detection unit 2 is used for detecting the instant cement flow value of a discharging hole of the inclined frequency-conversion spiral feeder; and the control system is used for correspondingly controlling the rotate speed of the inclined frequency-conversion spiral feeder according to calibration coefficient obtained from real-time analysis and processing. The invention has reasonable design, simple and convenient operation and high calibration precision, and can overcome the defect that the cement calibration of prior stable soil plant mix equipment is achieved only by manpower, is difficult to operation and has low calibration precision.

Owner:广东能达公路养护股份有限公司

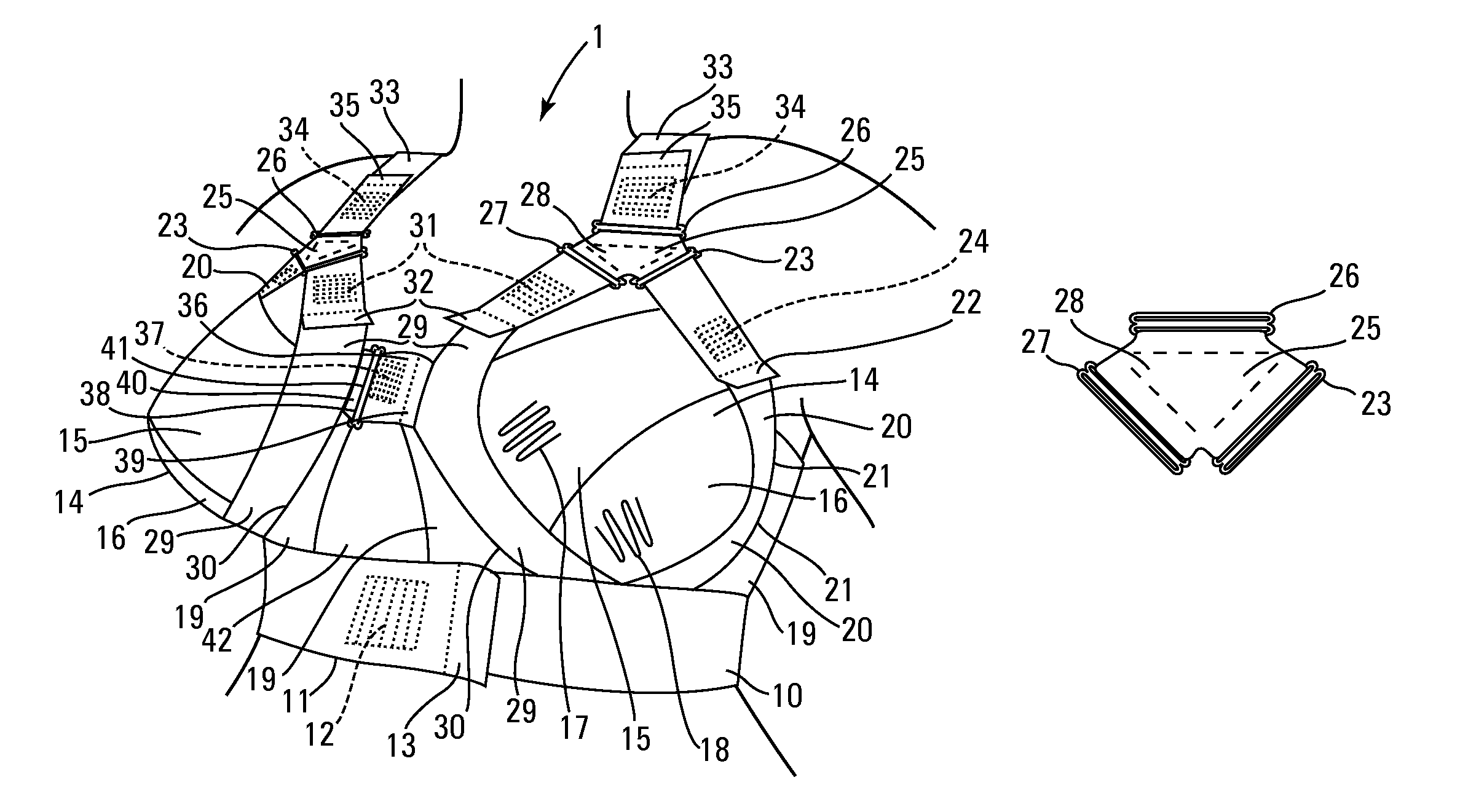

Post-operative brassiere

A breast-supportive and breast-positioning brassiere designed to be used postoperatively by patients including obese patients and fuller-sized women who have undergone cardiothoracic surgery that requires a mid-sternal incision (sternotomy). The brassiere is also for other interventions in the thoracic region, when a comfortable and efficient individual positioning and support of the breast(s) would be desirable; an example being to prevent symmastia after breast augmentation surgery. The brassiere prevents gravitation of the breast tissue to the lateral sides, keeps the breast tissue away from the mid center, and supports the weight of the breasts. The brassiere is designed to promote less pain, less wound complications, esthetically improved wound healing, less heat generation, improved wound inspection and access for wound care, while maintaining support and dignity.

Owner:QUALITEAM SRL

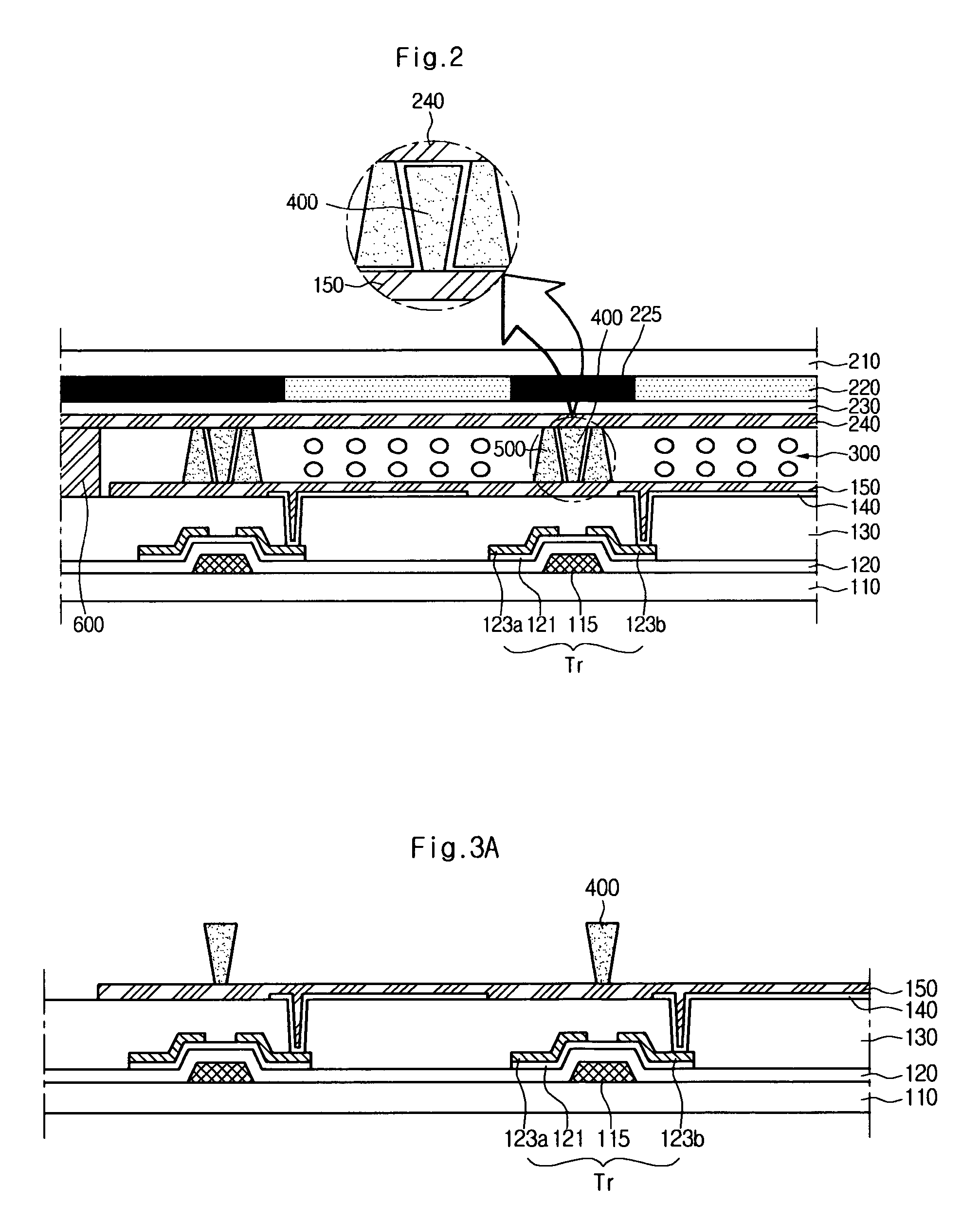

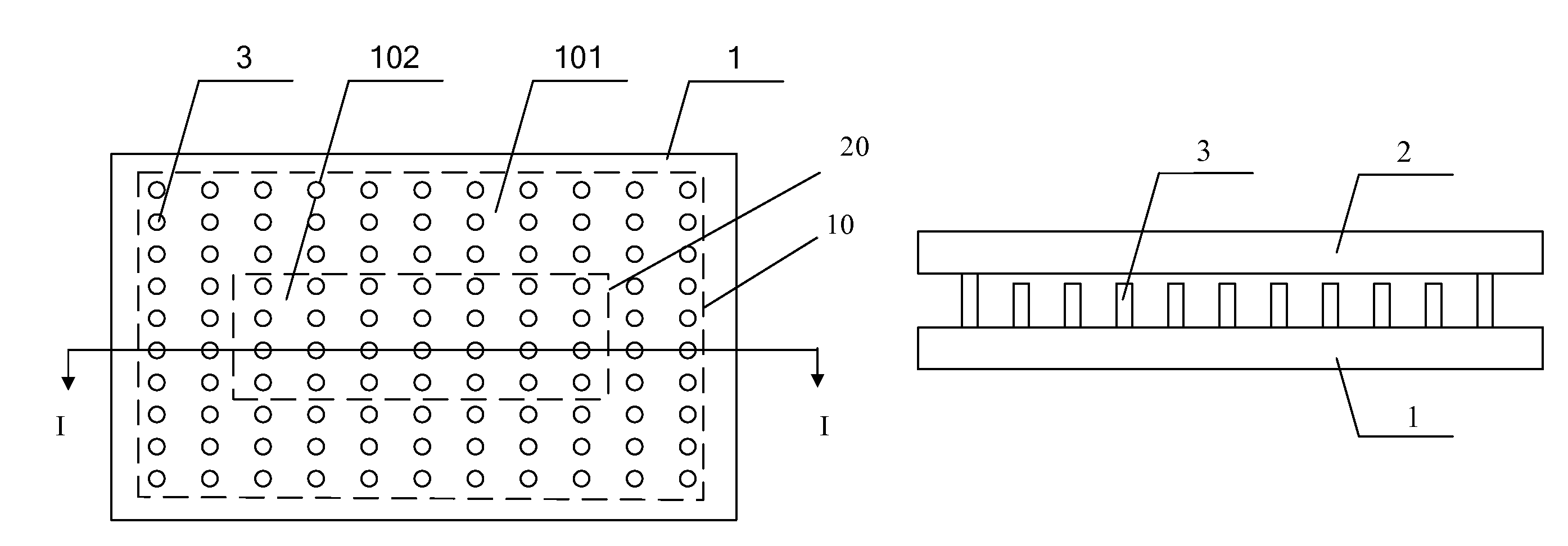

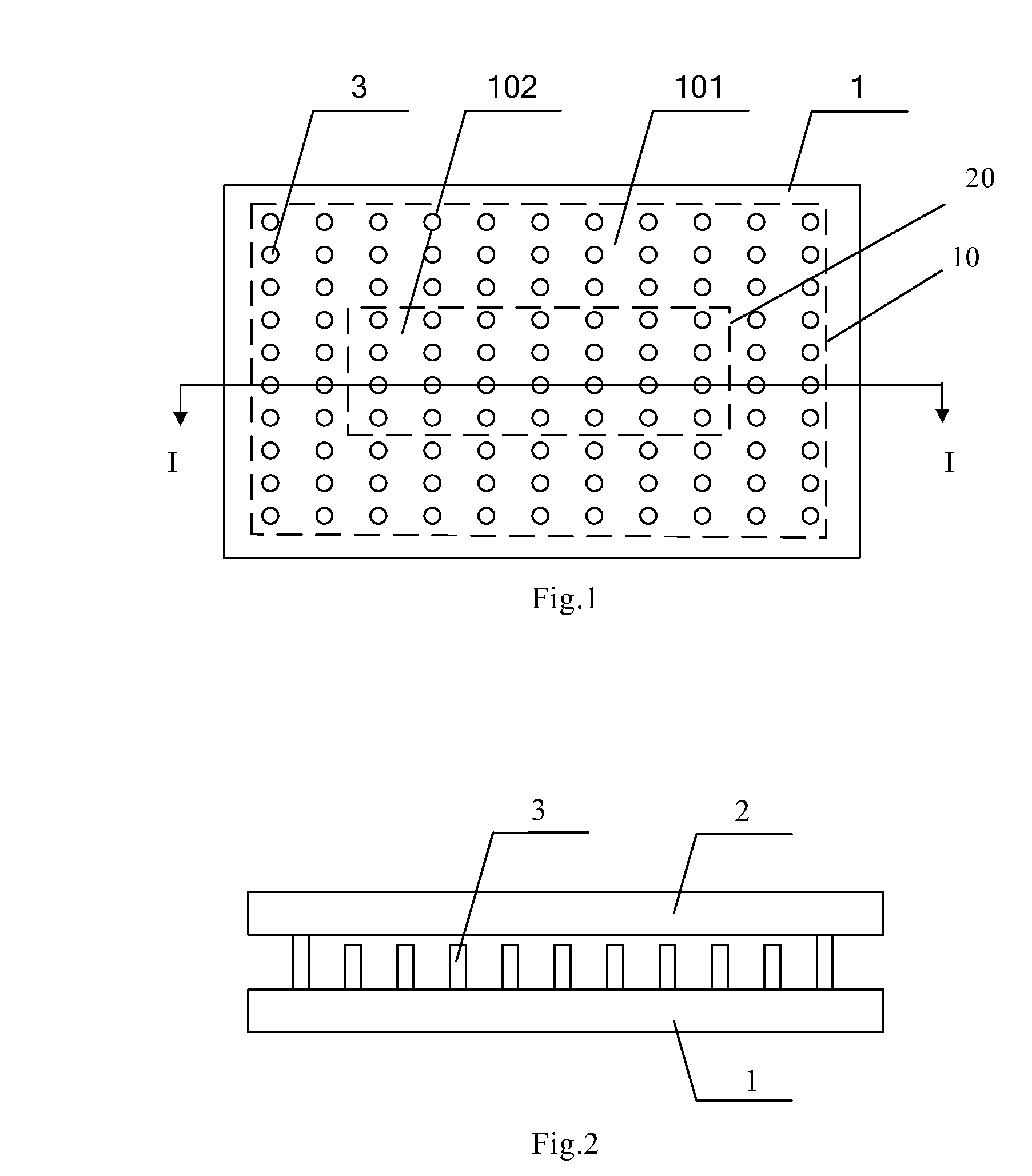

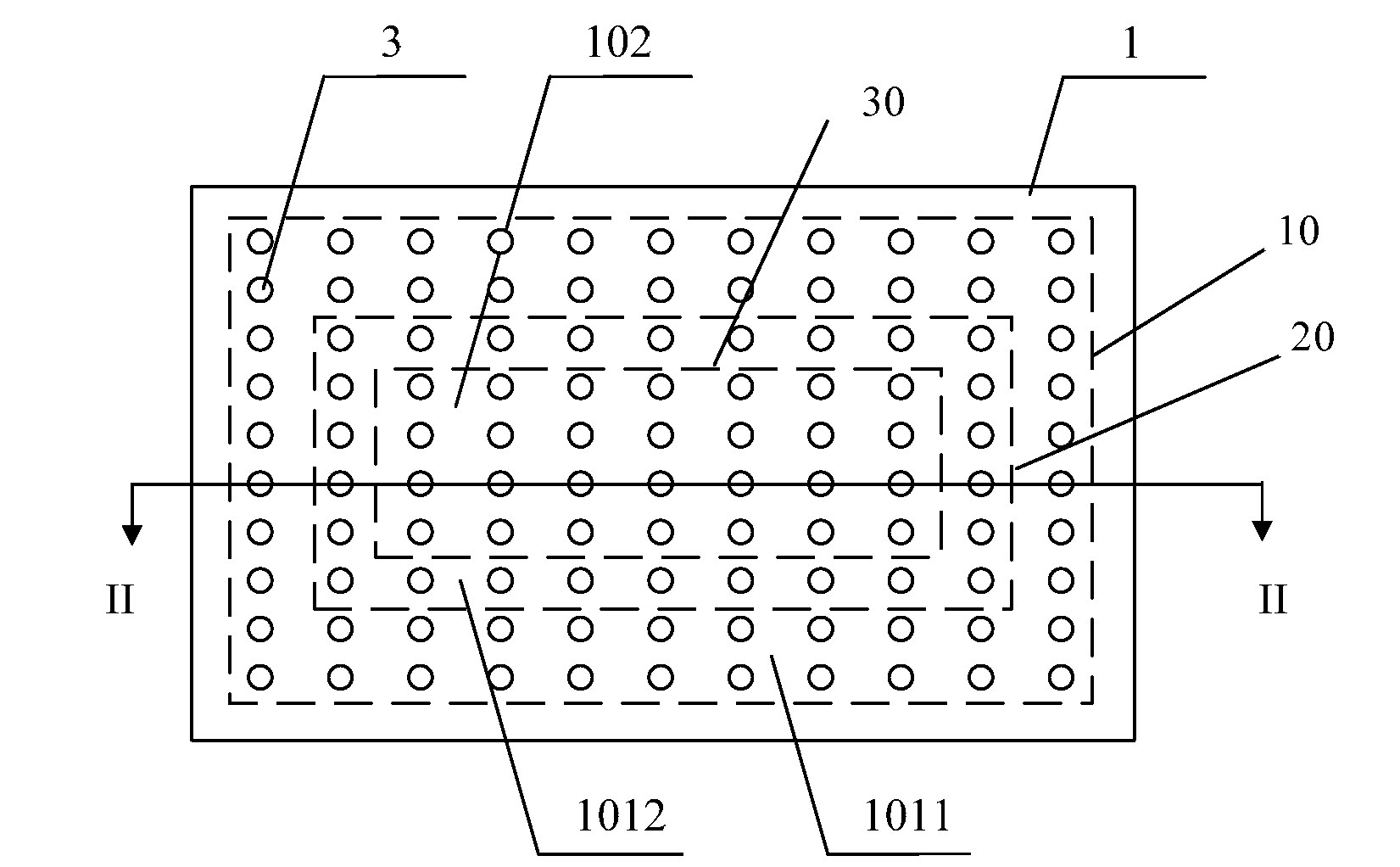

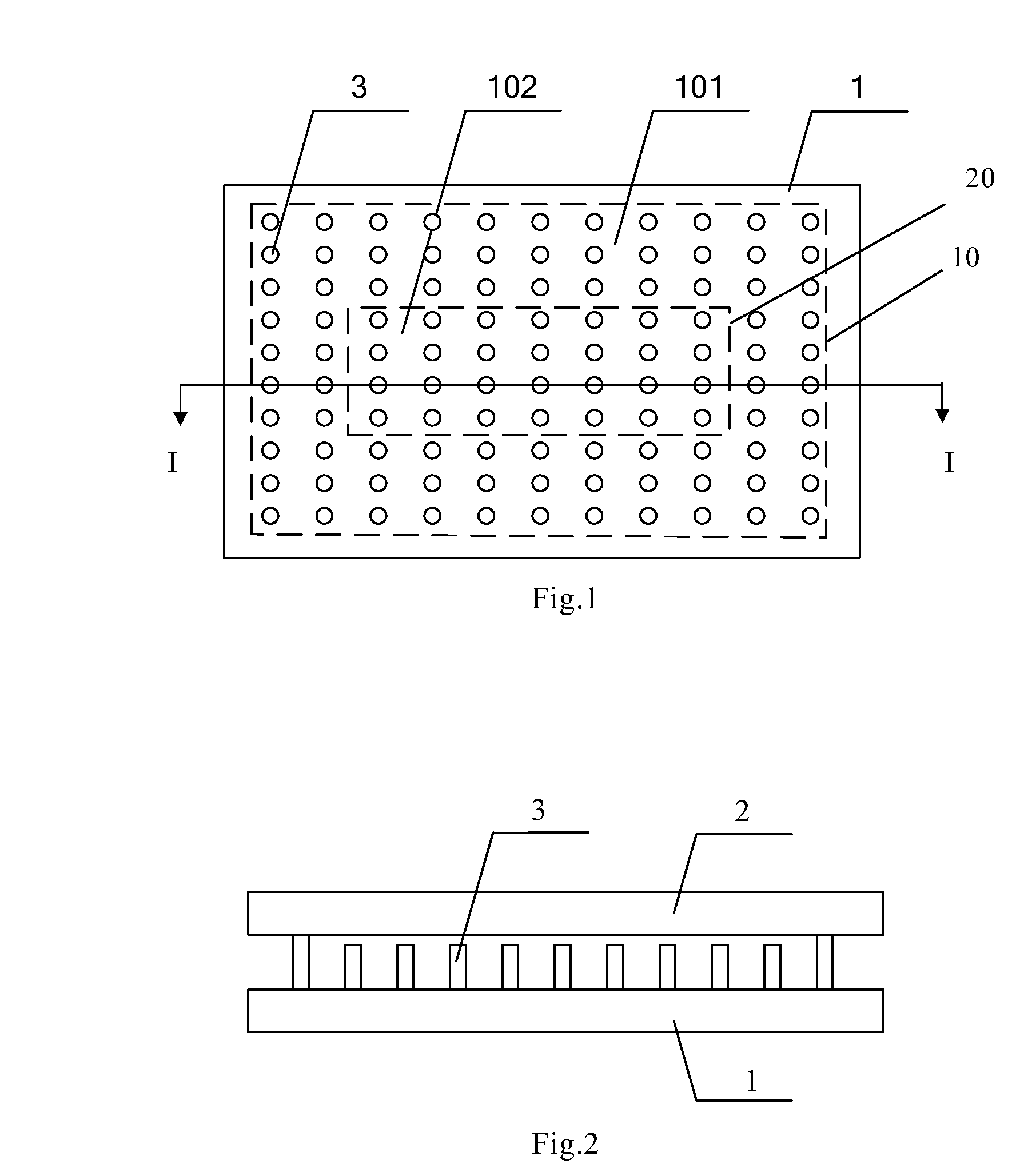

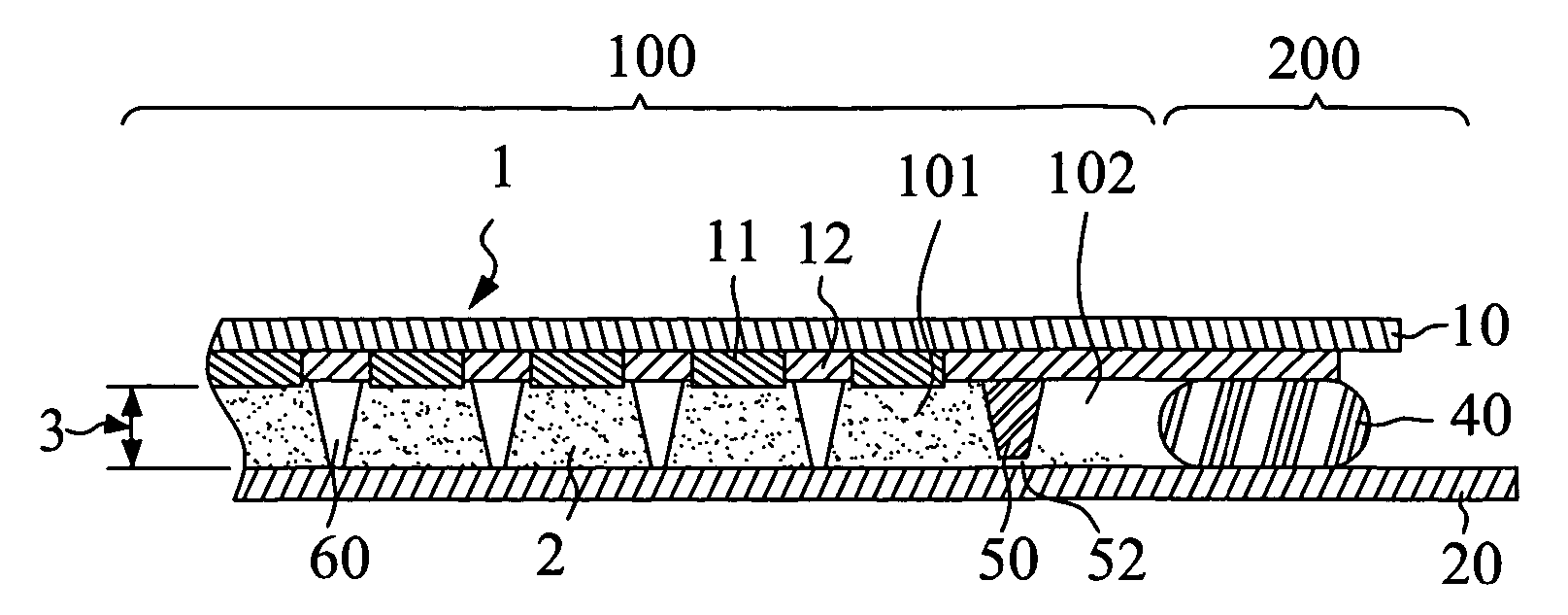

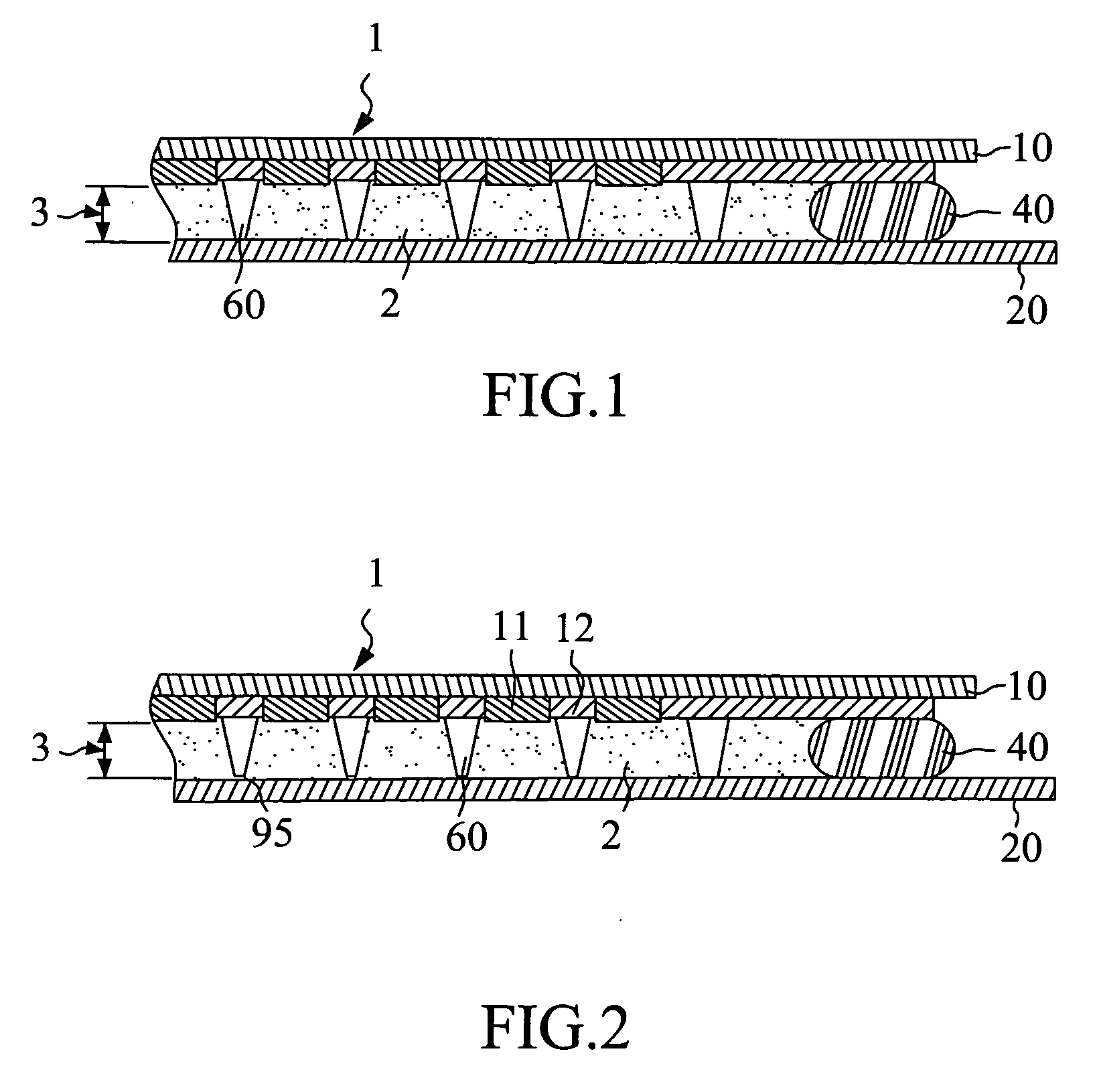

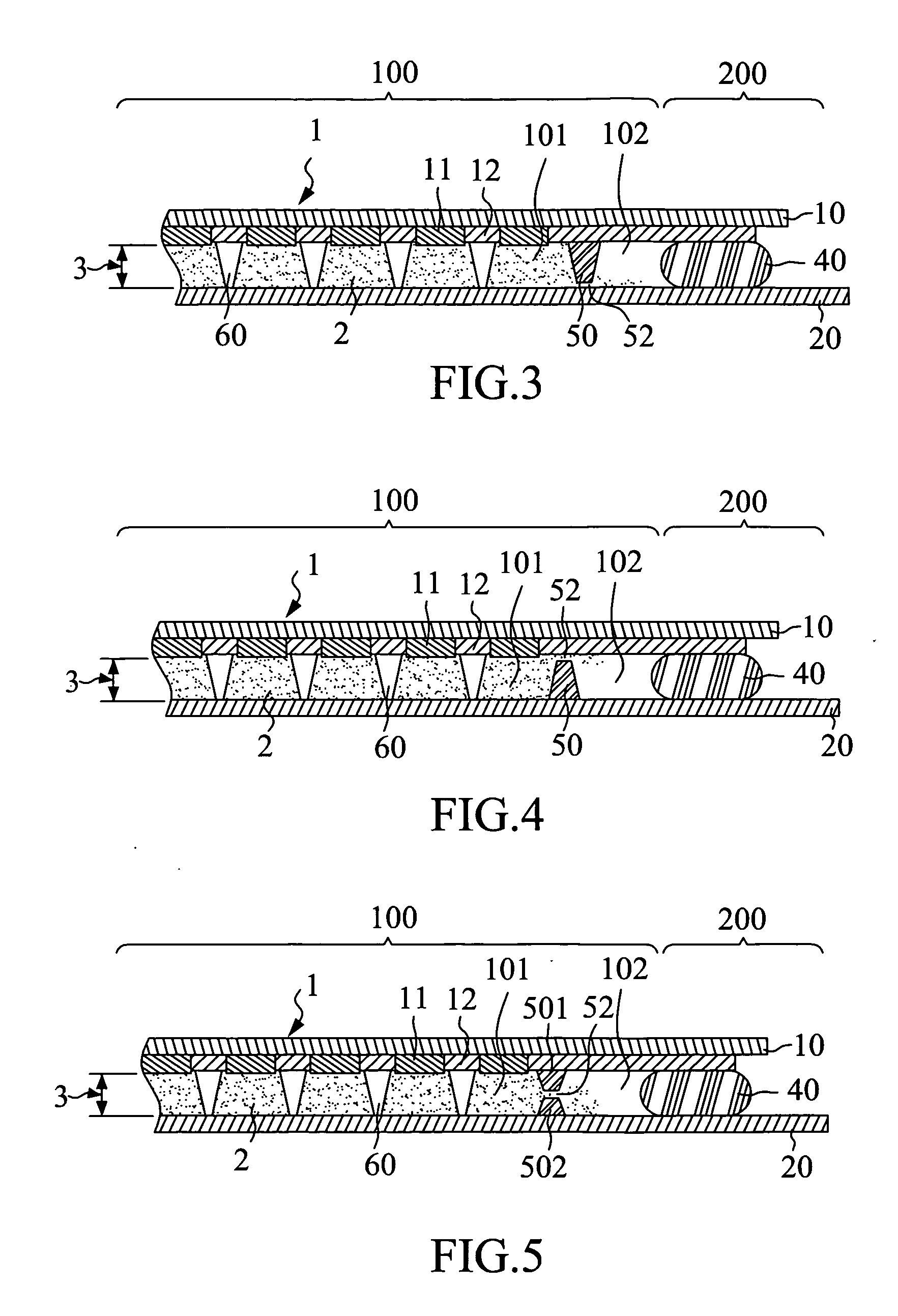

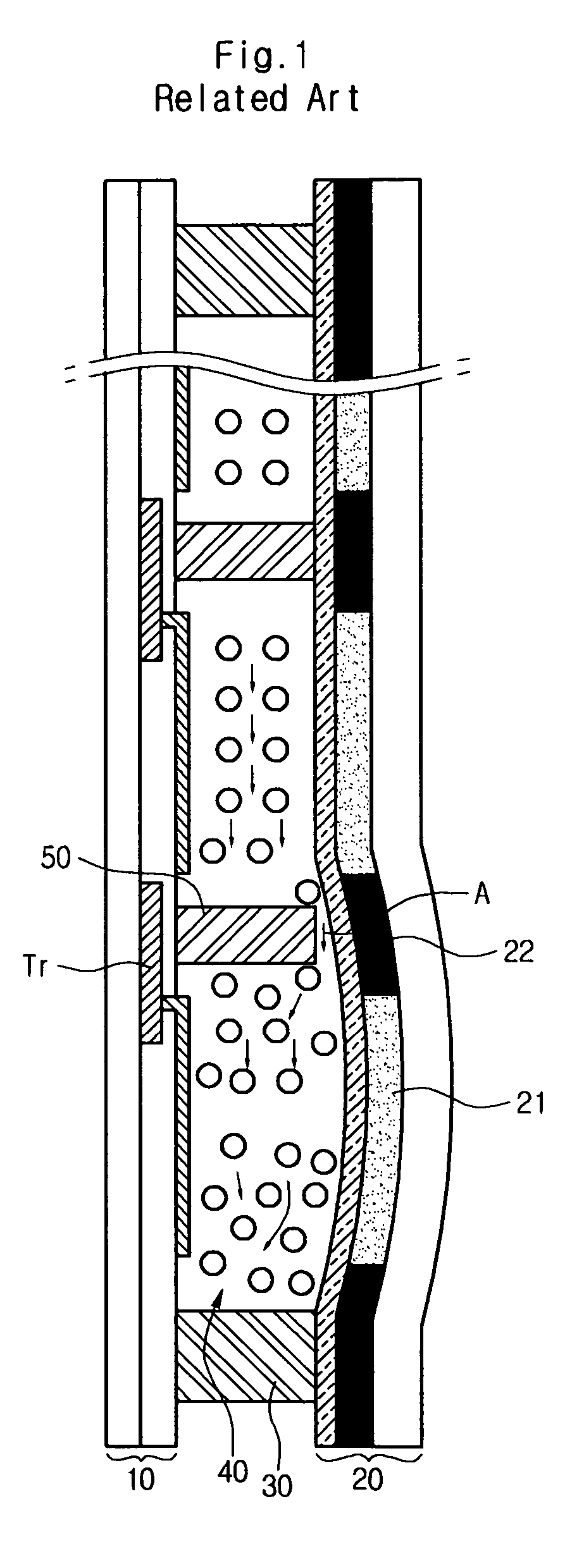

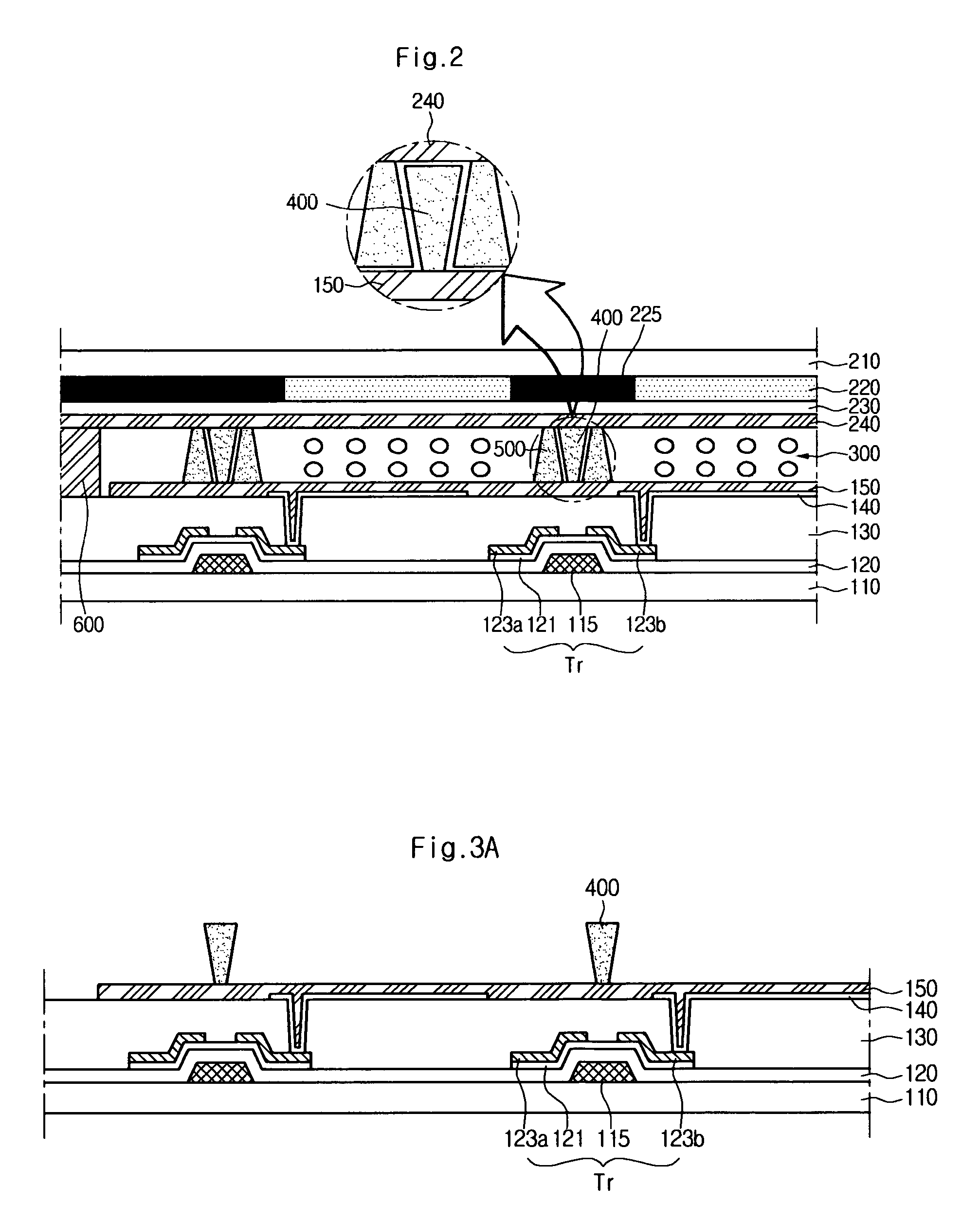

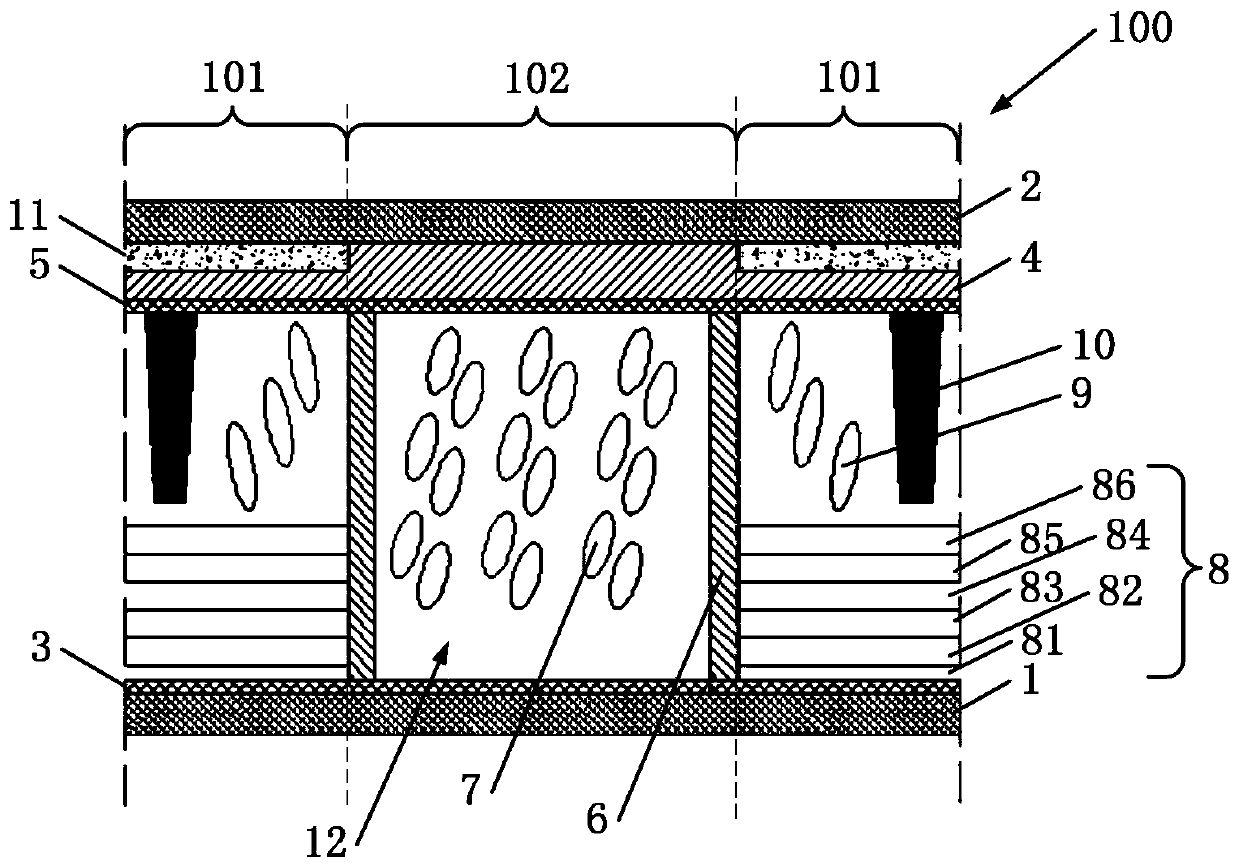

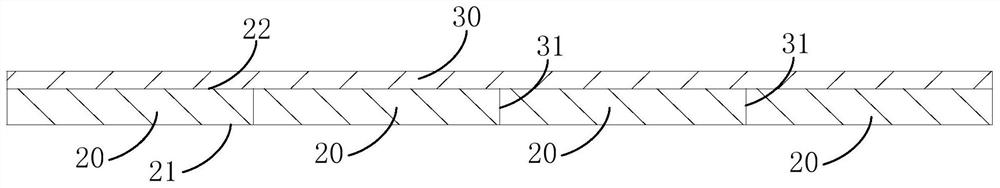

Liquid crystal cell and method of manufacturing the same

ActiveUS7932985B2Prevent gravityPrevented from excessively buildingNon-linear opticsEngineeringPeripheral

Provided are a liquid crystal cell of a liquid crystal display and a method of manufacturing the same, comprising spacers disposed between a color filter substrate and an array substrate, wherein the color filter substrate comprises a central area and a peripheral area, and the spacers provided in the peripheral area are higher than those provided in the central area. The embodiments of the present invention can effectively prevent the occurrence of the gravity mura, the peripheral mura, and the gap mura to improve the display quality.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD +1

Color filter substrate for liquid crystal display device and method for fabricating the same

ActiveUS20070291385A1Increase contrastSuppressing light leakage defectLiquid surface applicatorsCoatingsLiquid-crystal displayEngineering

A color filter substrate for a liquid crystal display device and a method of fabricating the same includes black matrixes on a transparent insulating substrate, the black matrixes defining pixel areas and having a first region and a second region, color filters in the pixel areas and having areas overlapping the first region of the black matrixes, and ball spacers above the second region of the black matrixes, wherein a thickness of the first region is greater than a thickness of the second region.

Owner:ULVAC INC +1

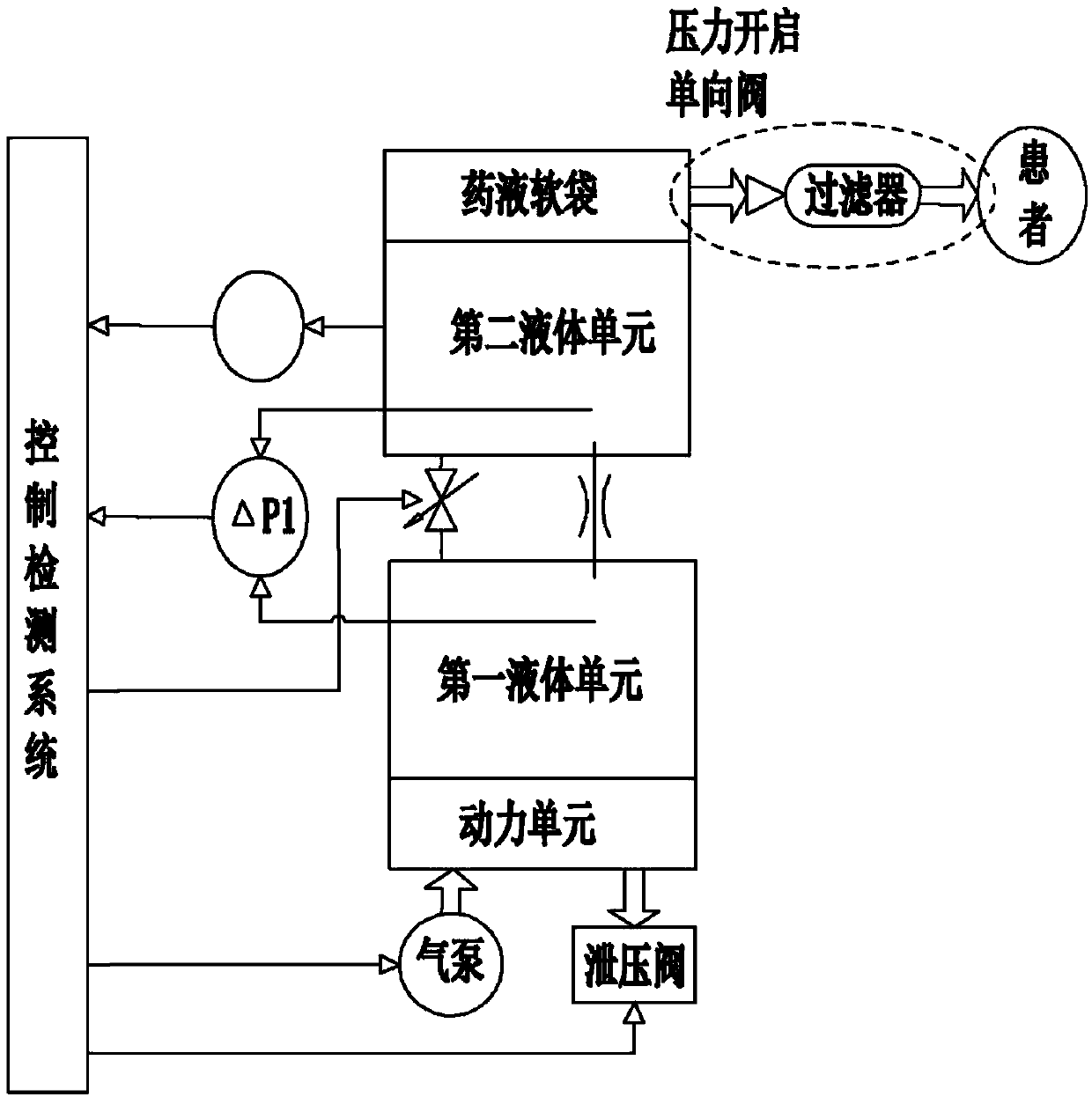

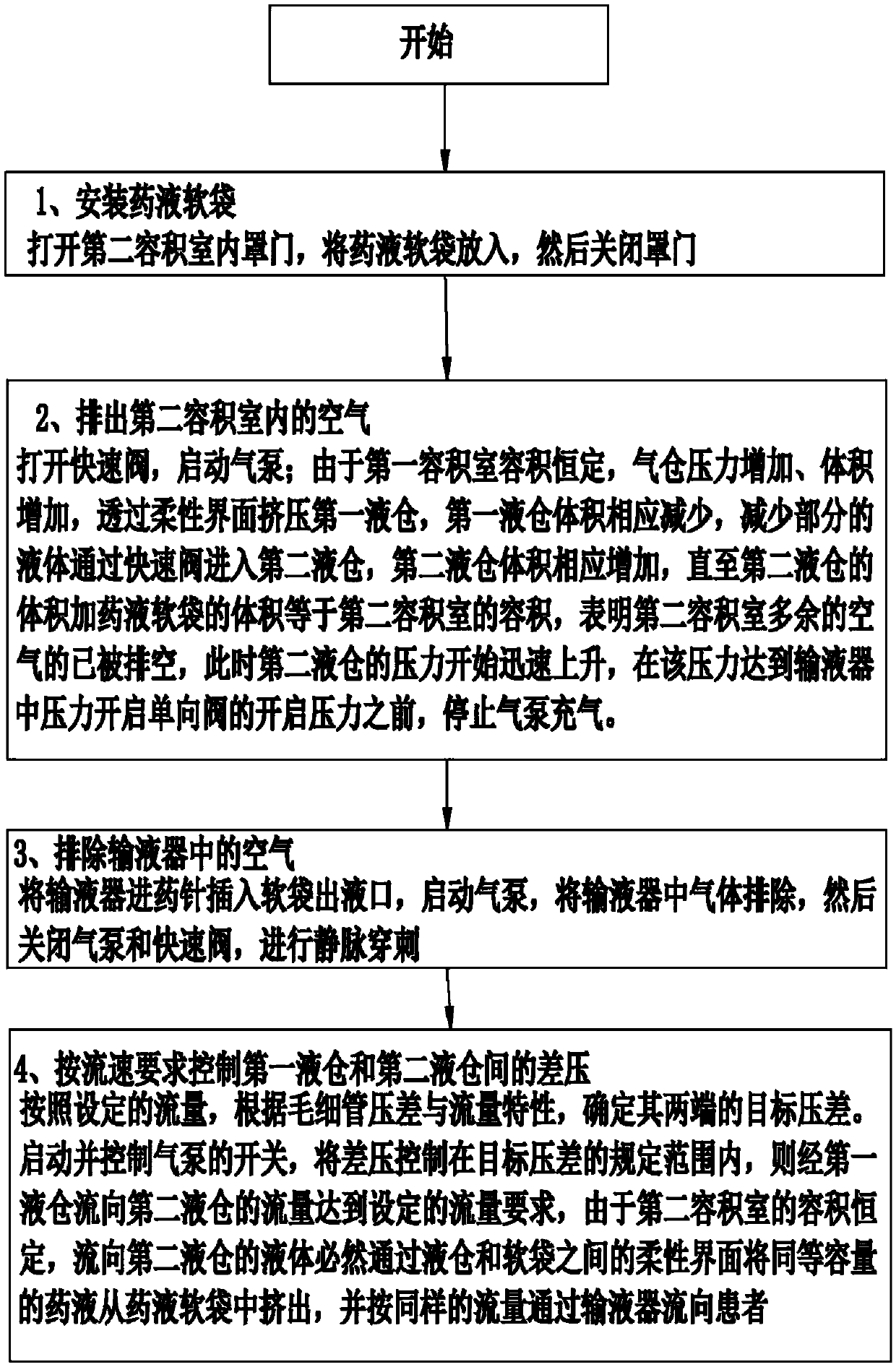

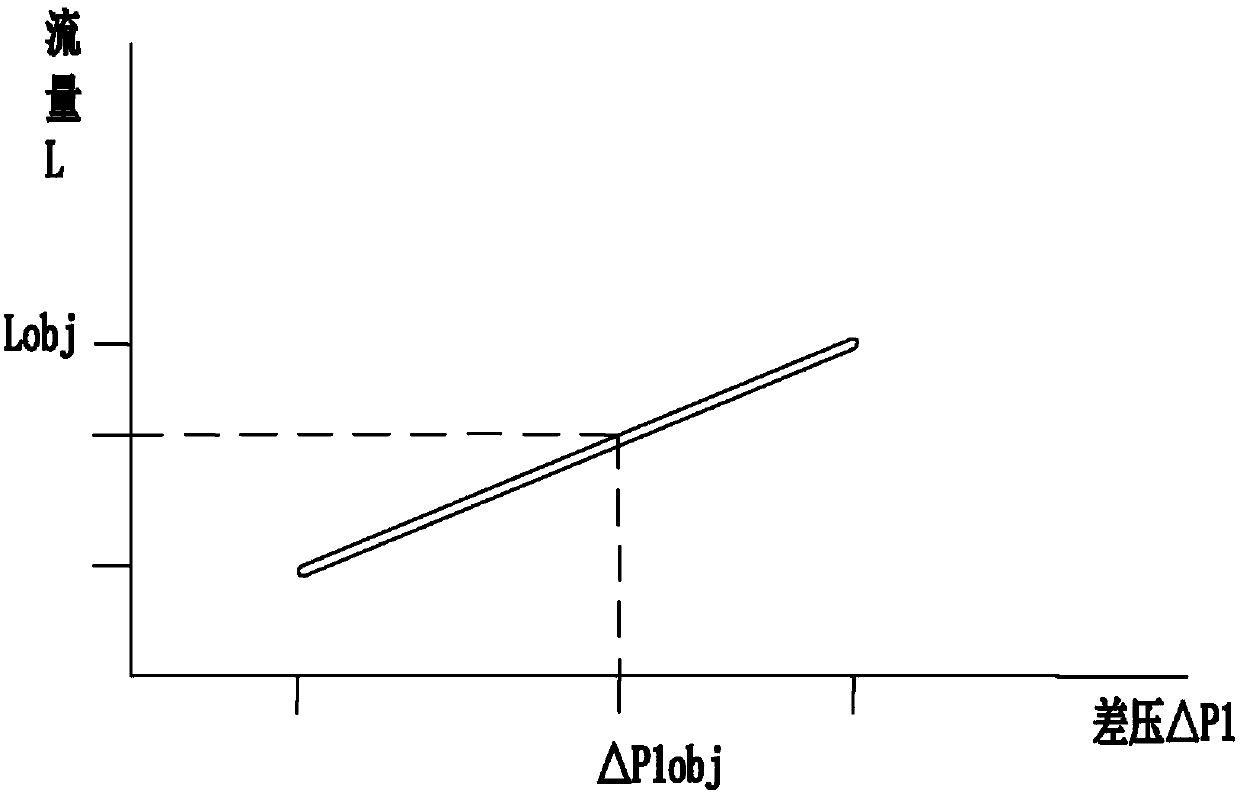

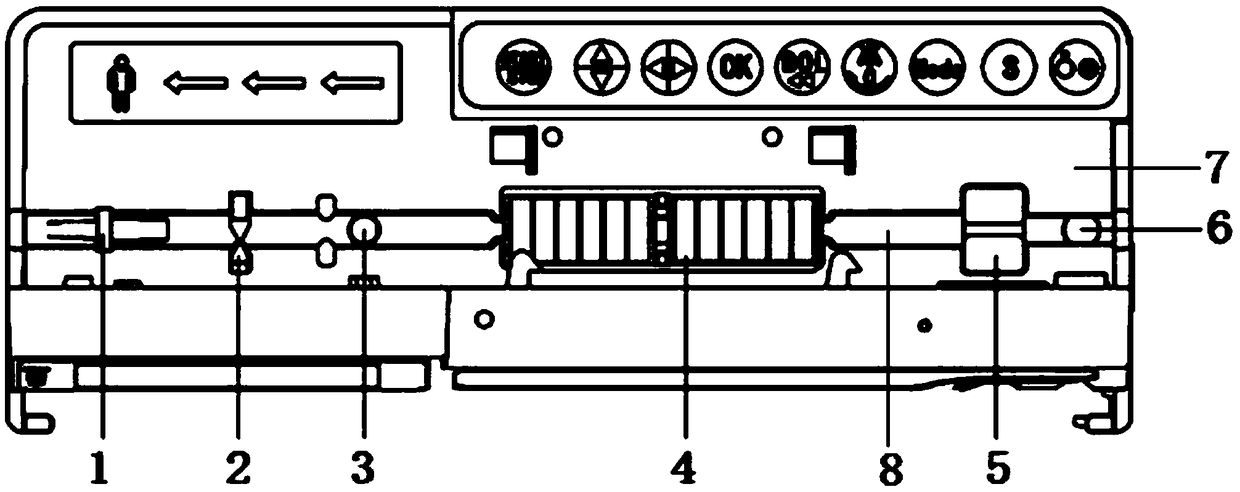

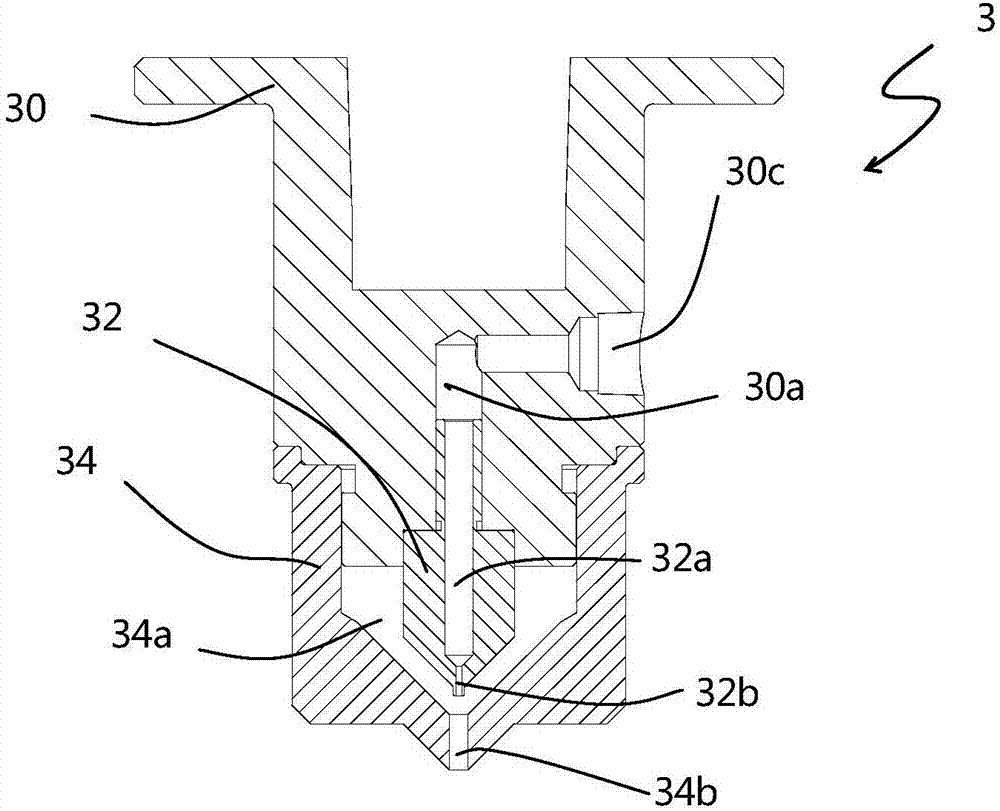

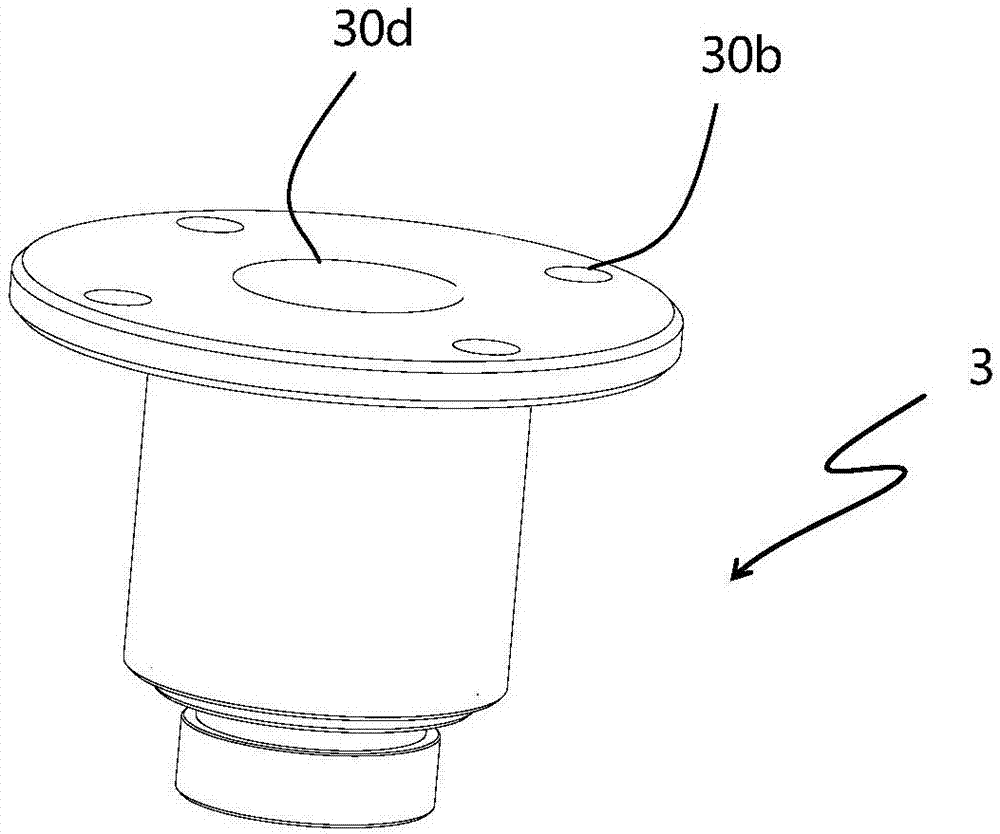

Transfusion control method and system with power acting on soft medicinal-liquid bag

InactiveCN107802918AStable flowMonitor temperature in real timeMedical devicesPressure infusionControl systemEngineering

The invention discloses a transfusion control method and system with power acting on a soft medicinal-liquid bag. The transfusion control method includes the following steps that when a first liquid unit is subjected to pressing force and deforms, the first liquid unit makes liquid injected into a second liquid unit through a capillary tube at a constant flow rate, and meanwhile, the pressed and deformed second liquid unit presses the soft medicinal-liquid bag to output medicinal liquid with the same volume for transfusion at the same flow rate. Compared with the prior art, 1, the soft medicinal-liquid bag is placed in equipment, power directly acts on the soft medicinal-liquid bag, and the defects that in an existing transfusion process, infusion bottles or soft bags need to be hung for transfusion and movement is inconvenient are avoided; 2, the speed of liquid flowing out of the soft bag is accurately, continually and stably controlled, the situation that the accuracy of an existingtransfusion pump depends on the geometric dimension, extrusion resistance and fatigue resistance of a transfusion tube is avoided; 3, through the cooperation of the matched transfusion tube, the system has the automatic liquid stop function and avoids gravitational flow caused by the gravity; 4, through the cooperation of the matched tube, the system has the automatic exhaust function and prevents air from entering the patient's body.

Owner:LIFEPUM MEDITECH CO LTD

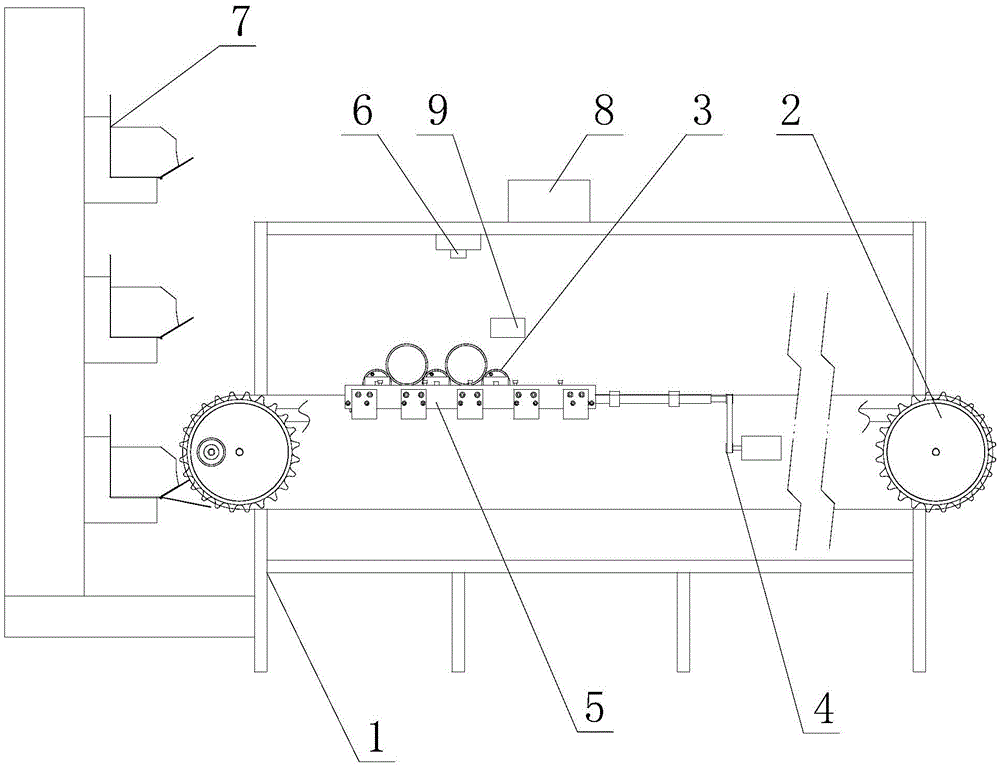

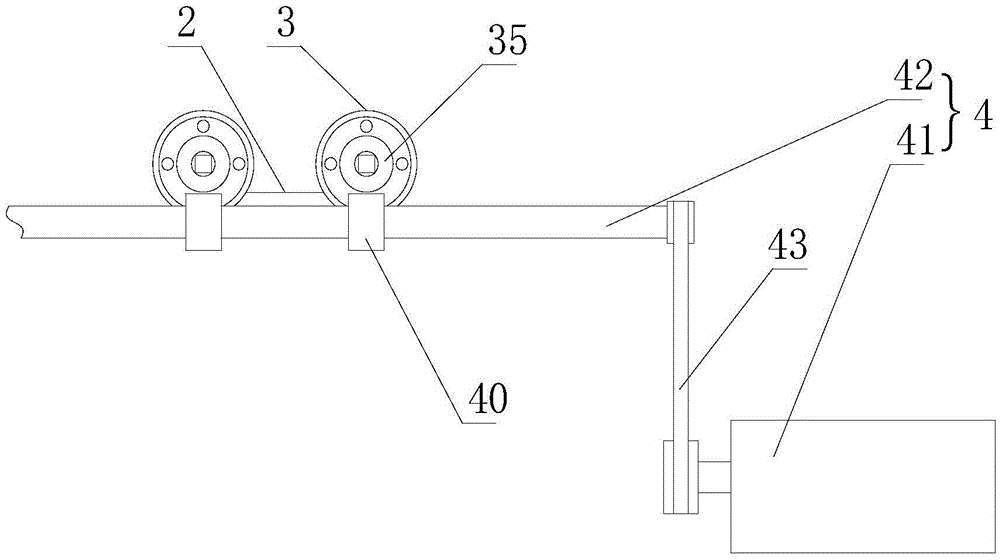

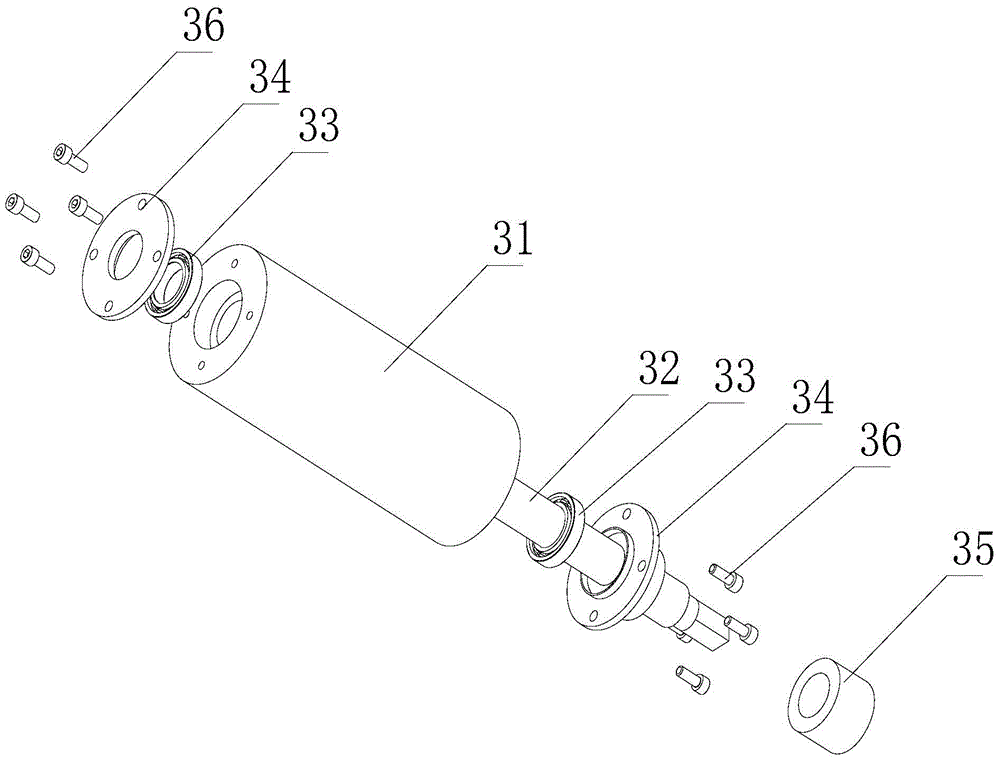

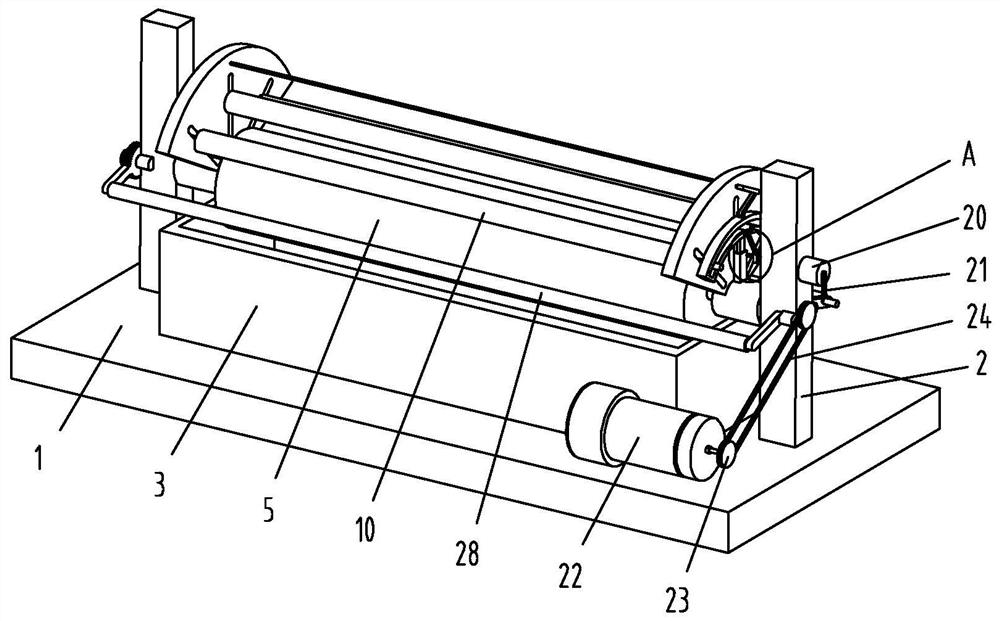

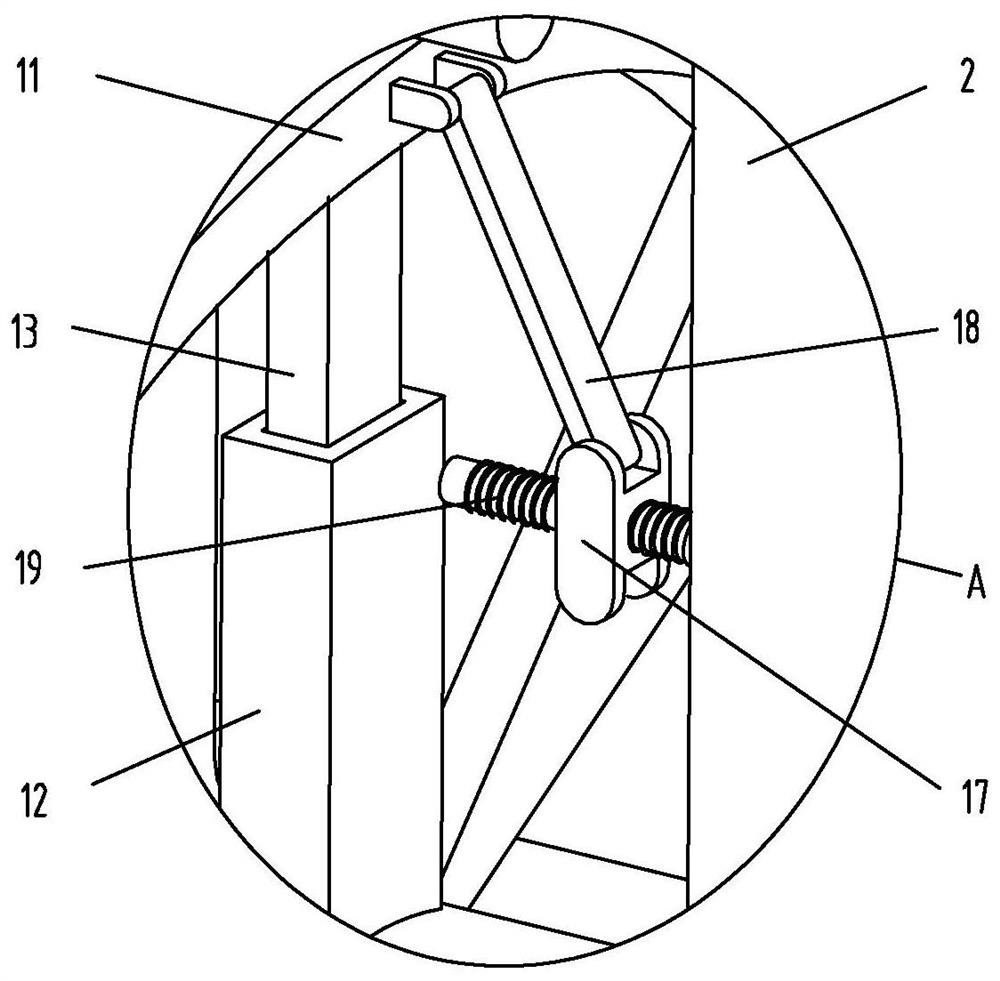

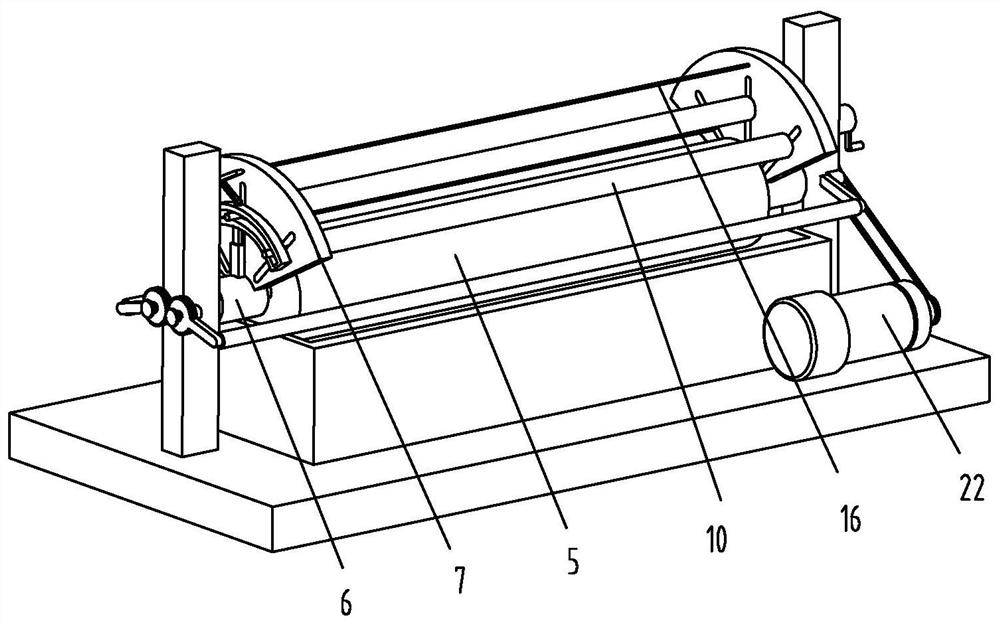

Paper tube detection device

ActiveCN105572141AAchieve level adjustmentPrevent saggingOptically investigating flaws/contaminationConveyor partsDrive shaftPulp and paper industry

The invention relates to a paper tube detection device which comprises a rack and a transmission device, wherein a transmission shaft is arranged on the transmission device, a drive assembly is connected onto the transmission shaft, a support assembly is arranged on the rack, a first camera and a second camera are arranged on the rack, and a PC computer is connected onto the rack. The paper tube detection device has the advantages that the rotation of the transmission shaft is realized through the drive assembly, the rotation of the transmission shaft is realized under the effect of revolution of the transmission device through the drive assembly, so paper tubes are subjected to feed detection in a rotation mode of the transmission shaft, the cost for rotating the paper tubes through the existing equipment is greatly reduced, the detection efficiency is improved, the phenomenon of dropping of the transmission device in the transmission process due to gravity is effectively prevented through the support assembly, the transmission effect of the transmission device is ensured and damage of the transmission device is avoided. The first camera and the second camera shoot the paper tubes and judge the quality of the paper tubes through the PC computer, so the detection is convenient and the qualification rate of paper tube detection can be ensured.

Owner:浙江三信智能机械股份有限公司

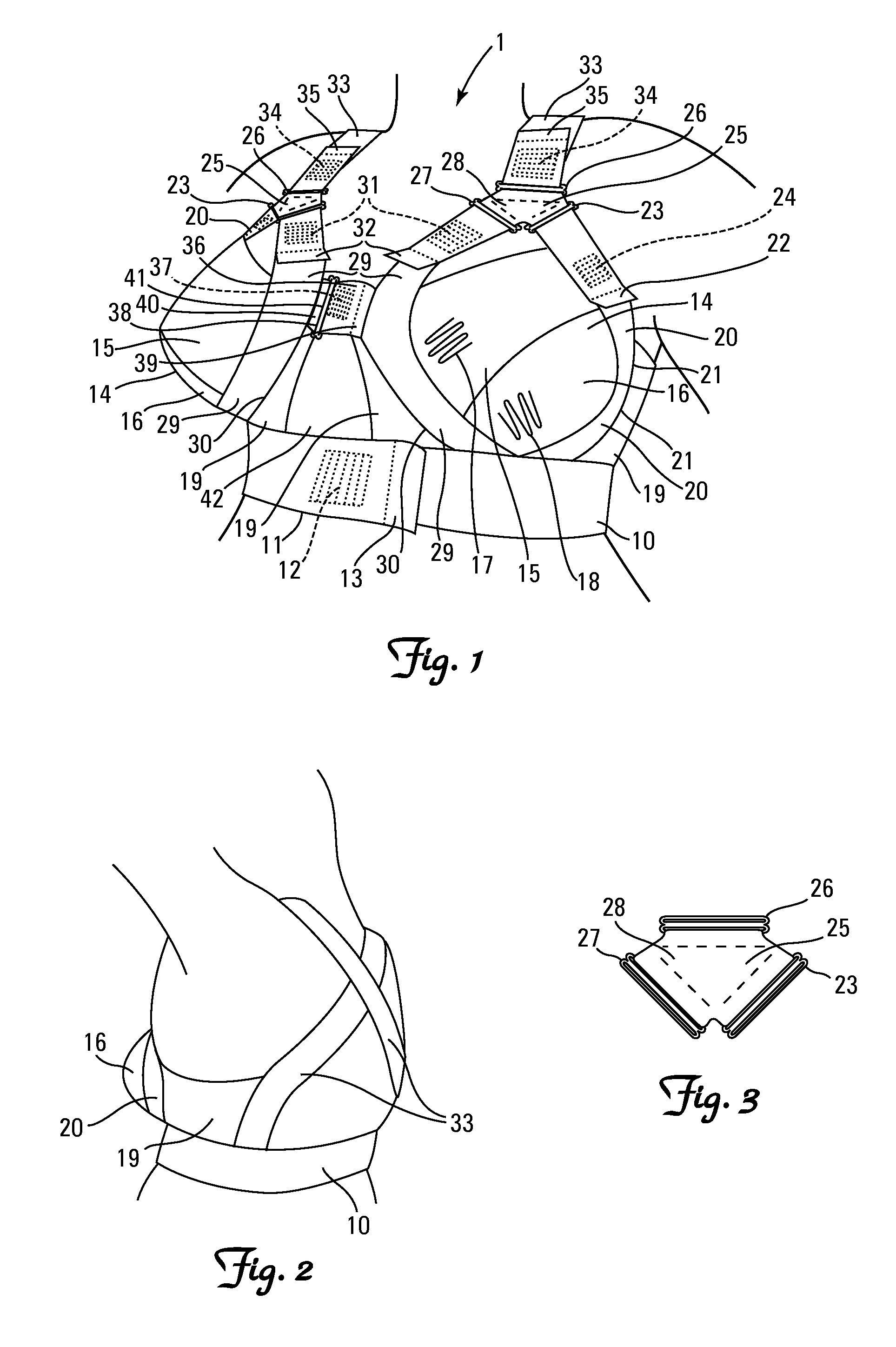

Liquid crystal cell and method of manufacturing the same

ActiveUS20080297715A1Prevent gravityPrevented from excessively buildingNon-linear opticsEngineeringPeripheral

Provided are a liquid crystal cell of a liquid crystal display and a method of manufacturing the same, comprising spacers disposed between a color filter substrate and an array substrate, wherein the color filter substrate comprises a central area and a peripheral area, and the spacers provided in the peripheral area are higher than those provided in the central area. The embodiments of the present invention can effectively prevent the occurrence of the gravity mura, the peripheral mura, and the gap mura to improve the display quality.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD +1

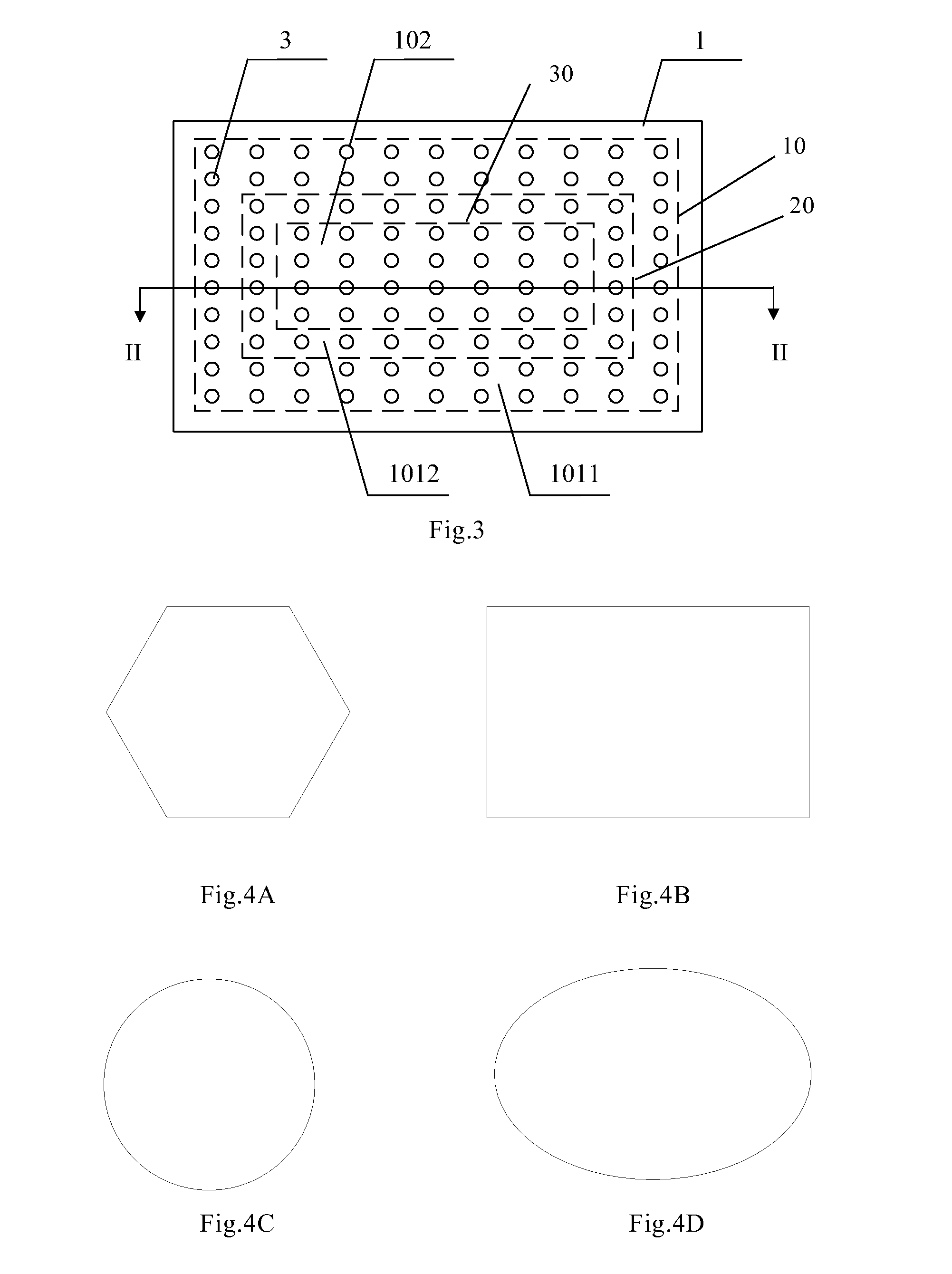

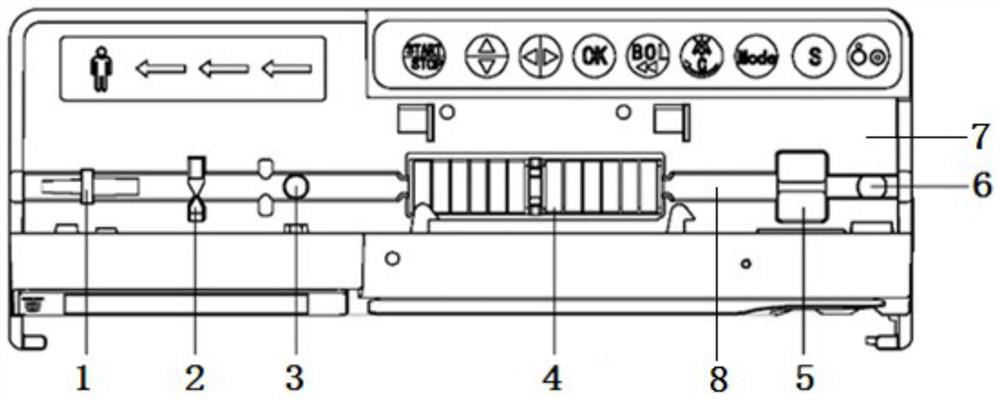

Intelligent infusion pump

ActiveCN108939209AImprove work efficiencyImprove experienceMedical devicesFlow monitorsPeristaltic pumpControl system

The invention discloses an intelligent infusion pump. The intelligent infusion pump comprises a control system and a housing, an infusion pipeline is arranged on the outer surface of the housing, anda bubble probe sensor, a peristaltic pump, a lower blocking sensor and an electric infusion stopping clip which are separately connected to the control system are arranged along the infusion pipelinein sequence; the electric infusion stopping clip comprises a micro motor which is fixedly connected with the housing and used for driving an infusion stopping clip sliding block to move up and down, the end, protruding out of the housing, of the infusion stopping clip sliding block is wrapped with infusion stopping clip sliding block plastic, and the infusion stopping clip sliding block and the housing are used for clamping an infusion tube. The intelligent infusion pump is high in automation degree, convenient to use and capable of improving the work efficiency of a user, and defects in the prior art are overcome.

Owner:ZHEJIANG MDKINGDOM TECH CO LTD

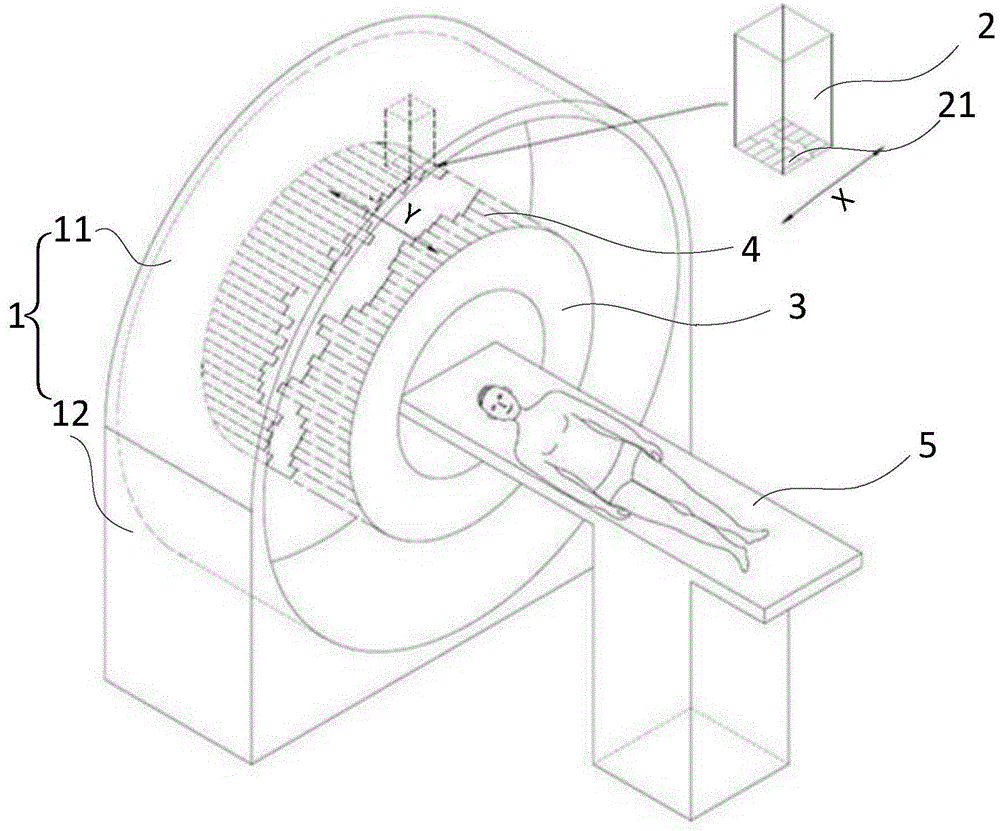

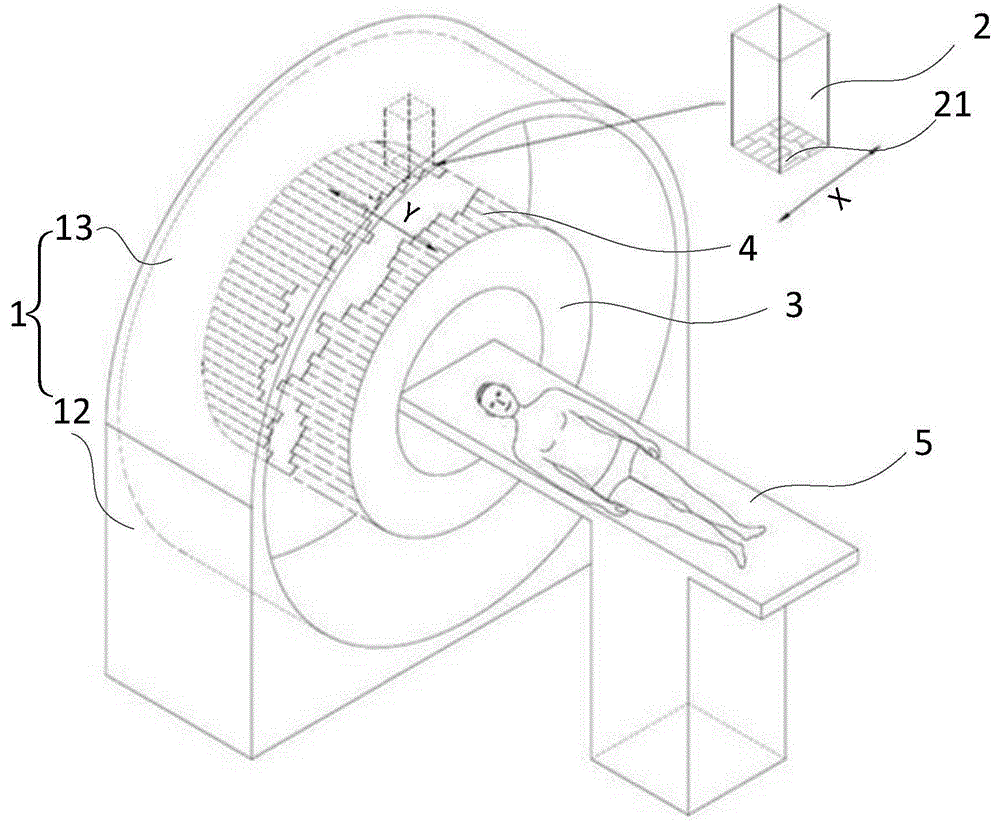

Linear accelerator

InactiveCN106334274AEasy to controlExtend your lifeX-ray/gamma-ray/particle-irradiation therapyEngineeringCentrifugal force

The invention provides a linear accelerator. The linear accelerator comprises a frame, a machine head and an annular carrier. The annular carrier is fixed to the frame and limits a vertical axis. The machine head is connected to the frame and can rotate about the vertical axis on an radial outer side of the annular carrier. The machine head comprises a radiation source and a first collimating device. The first collimating device comprises multiple pairs of blades, wherein each two blades are adjacent to each other. A second collimating device is fixed to the annular carrier. The second collimating device comprises the multiple pairs of blades so that the second collimating device can be limited into an annular closed field around the vertical axis, wherein each two blades are adjacent to each other. During operation, the multiple pairs of blades of the first collimating device are oriented to a first direction, and the multiple pairs of blades of the second collimating device are oriented to a second direction which forms an angle with the first direction. The invention provides the linear accelerator, a rotation structure is light so that adjusting precision of an angle is increased; a dosage deviation caused by gravity and centrifugal force influences is avoided; and requirements to a motion frequency and a speed of the blades are reduced and a servicel life of a collimator is prolonged.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

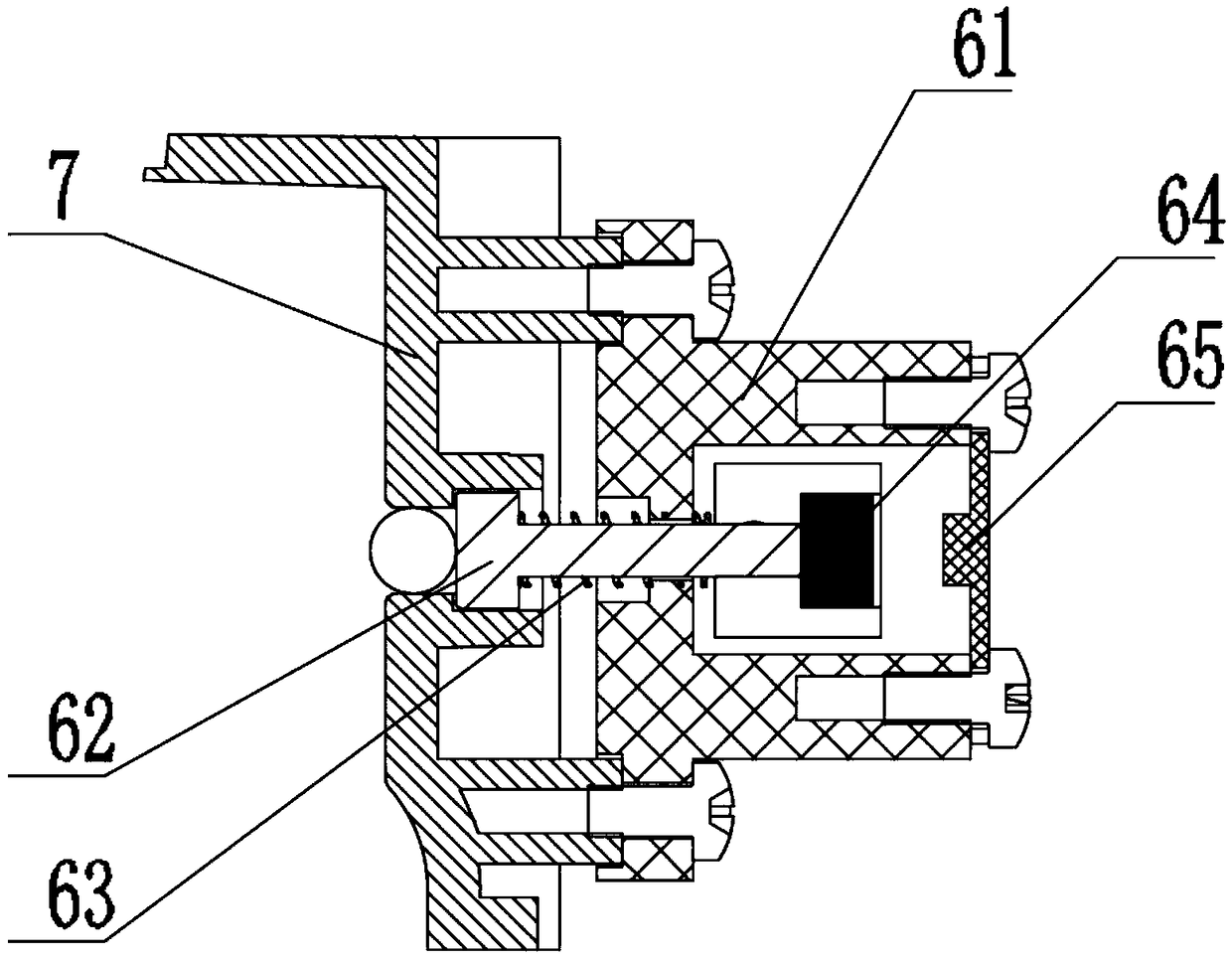

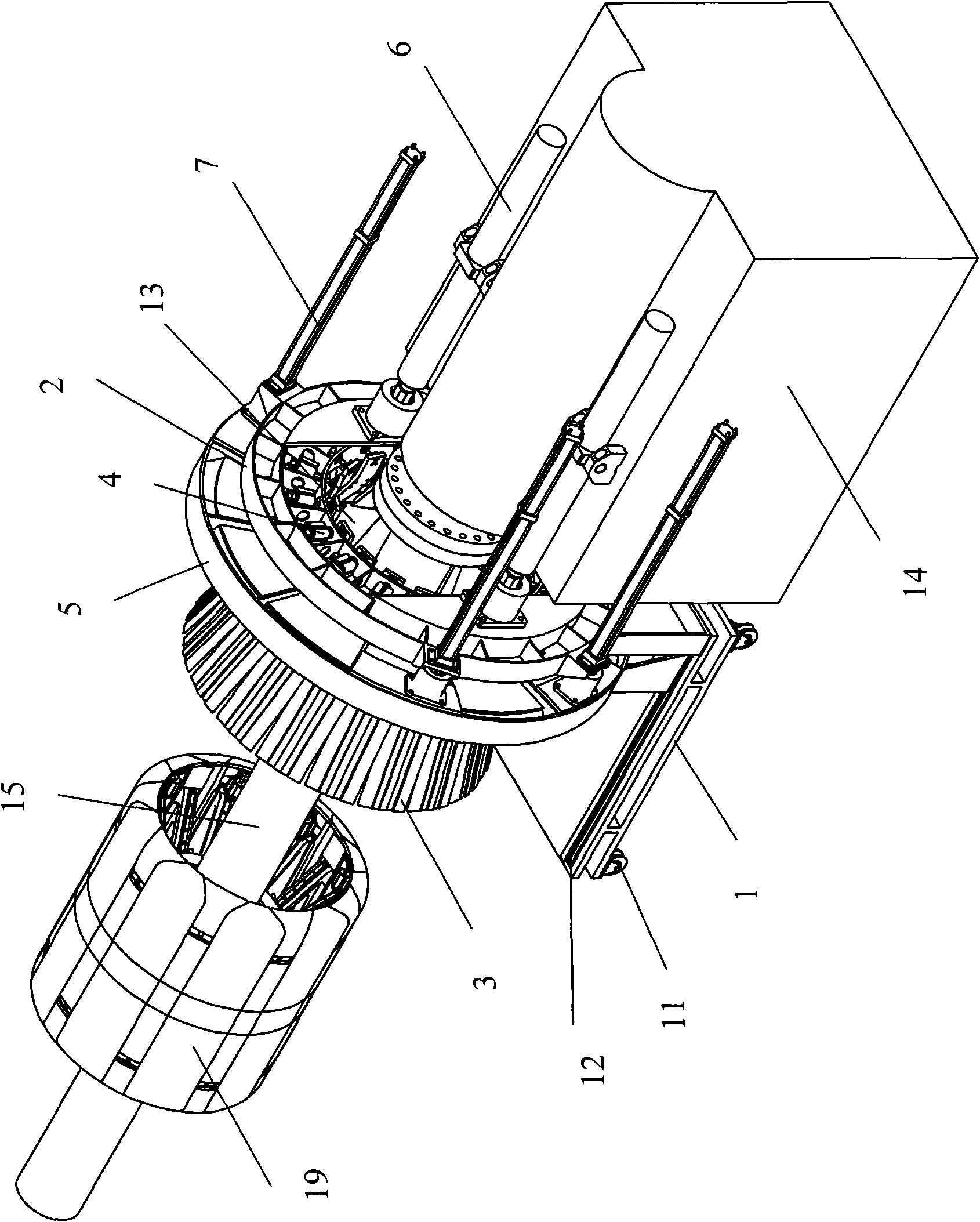

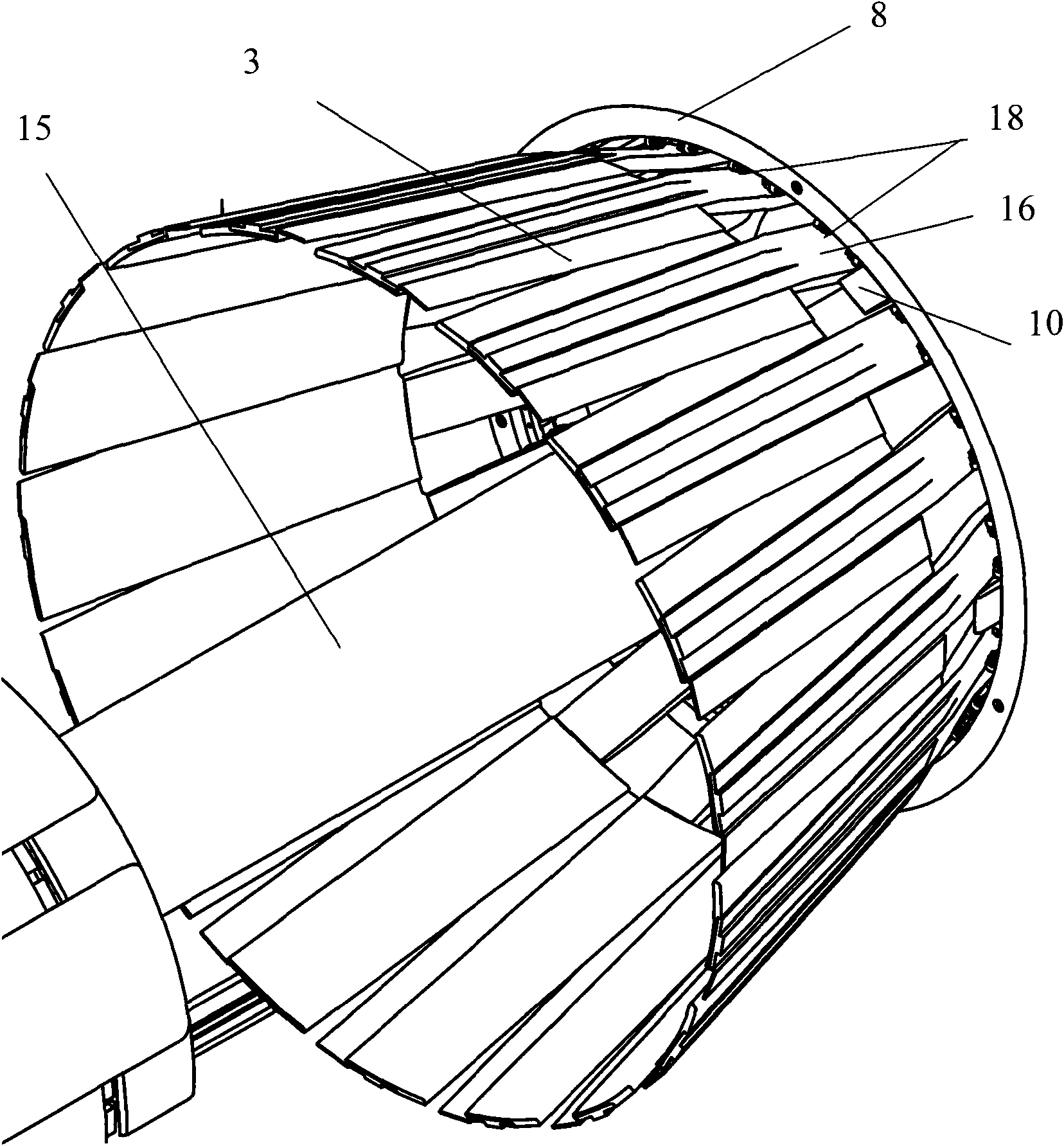

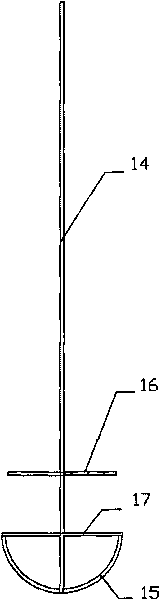

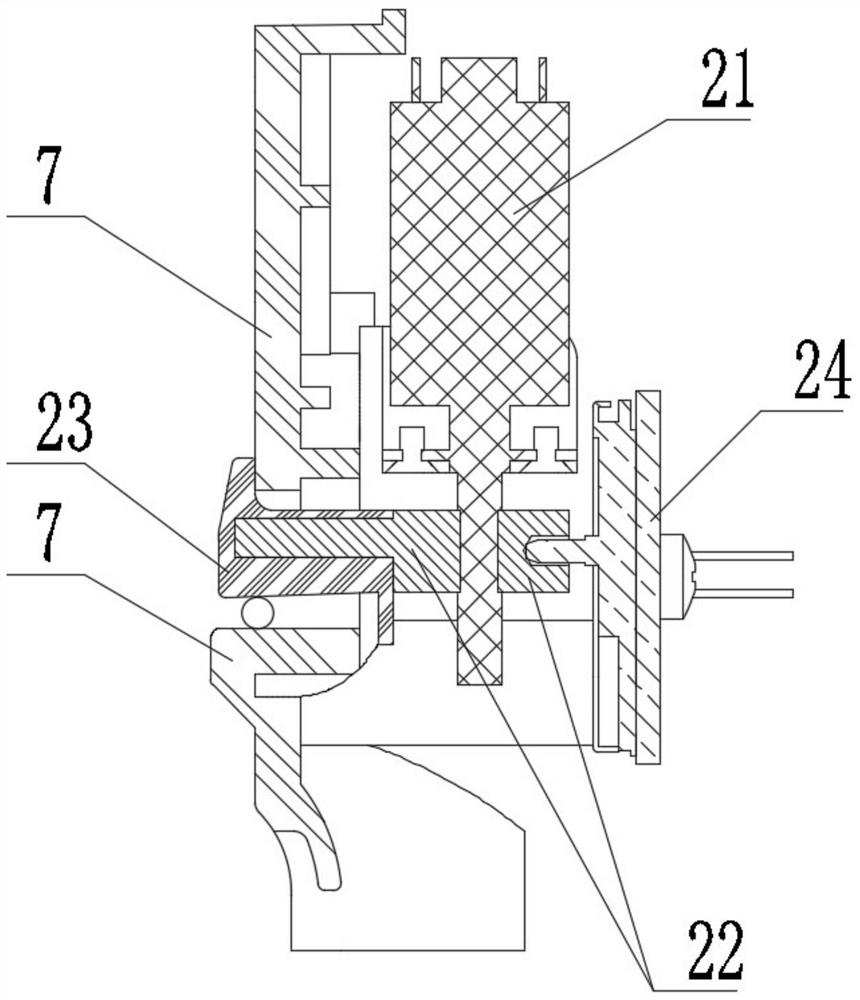

Finger-shaped turning down device for tyre molding machine

The invention relates to a finger-shaped turning down device for a tyre molding machine. The finger-shaped turning down device comprises a base, a support of finger-shaped pieces, a plurality of finger-shaped pieces, an opening driving pneumatic cylinder of a plurality of finger-shaped pieces, a push tray, two overall stroke oil cylinders, a plurality of turning down oil cylinders, a buckle ring disc, a plurality of buckle ring oil cylinders and a plurality of bead supports. The finger-shaped turning down device for the tyre molding machine integrates the functions of finger-shaped turning down, a buckle ring, bladder turning up and boosting into a whole, the finger-shaped turning down device is arranged on a guide track by utilizing the base and not contacted with a main shaft, so that the finger-shaped turning down device can prevent the whole device from rotating along with the whole device and the problems of holding shaft caused by gravity reason and the like, and simultaneously reduce loads of the main shaft. In addition, the opening of the finger-shaped pieces is completed by the pneumatic cylinder with constant output thrust, the actions of the finger-shaped pieces are stable, and the replacement is more convenient; furthermore, the closing of the finger-shaped pieces is completed by driving a pressing wheel to push the finger-shaped pieces by the push tray, as the contact between the pressing wheel and the finger-shaped pieces is rolling friction, the service life of the device can be greatly prolonged.

Owner:TIANJIN SAIXIANG TECH

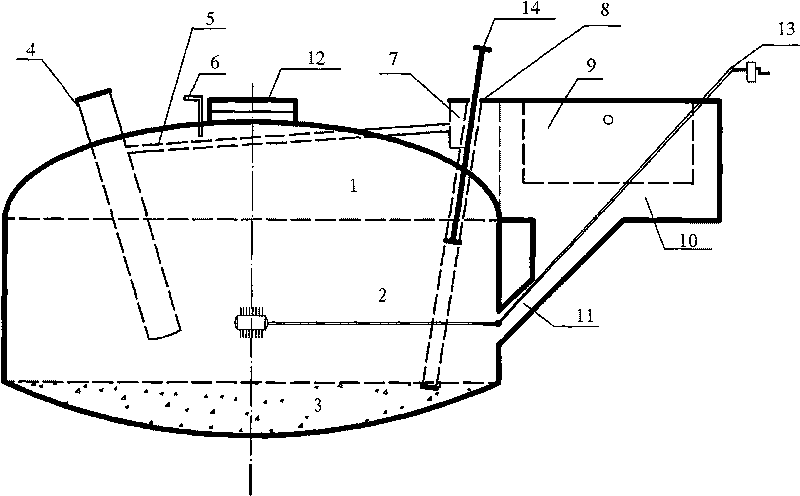

Marsh gas pool

InactiveCN101691534ASecurity pressureReduce water consumptionGas production bioreactorsWaste based fuelGuide tubeFermentation

The invention relates to a marsh gas pool, which consists of a fermentation room, a gas storage room, a pool bottom, a water pressure room, a feed pipe, a gas-guide tube and a pipeline, wherein the pool bottom and the water pressure room are positioned at the lower bottom of the fermentation room; the feed pipe and the gas-guide tube are arranged on the gas storage room; the pipeline communicates the fermentation room, the gas storage room and the water pressure room; the water pressure room is communicated with the fermentation room through a communicating pipe which is arranged in an inclination way and is 80 to 100 cm higher than the bottom of the fermentation room; a manure pumping pool is arranged besides a manure storage pool; the pool bottom of the manure pumping pool is higher than the manure storage pool; a discharge tube is arranged in the manure pumping pool; the lower end of the discharge tube extends to the bottom of the marsh gas pool; a sidewall close to the bottom of the manure pumping pool is provided with a return pipe communicated with the feed pipe; and one end of the feed pipe is positioned out of the marsh gas pool, while the other end is arranged in the fermentation room.

Owner:LANZHOU UNIVERSITY

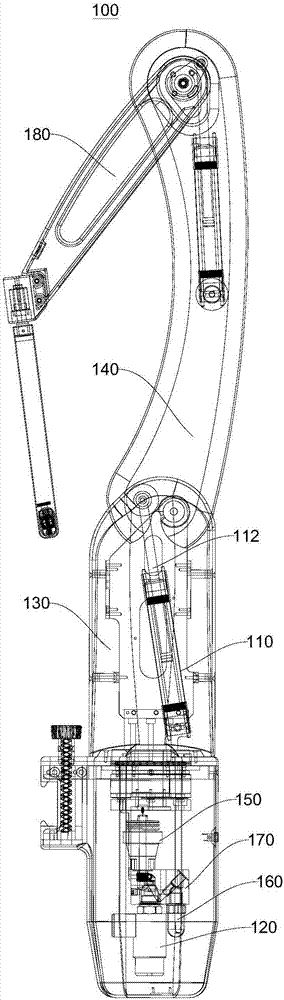

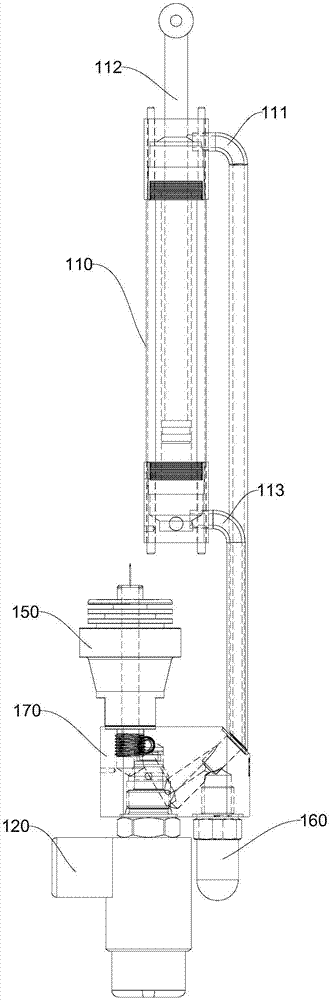

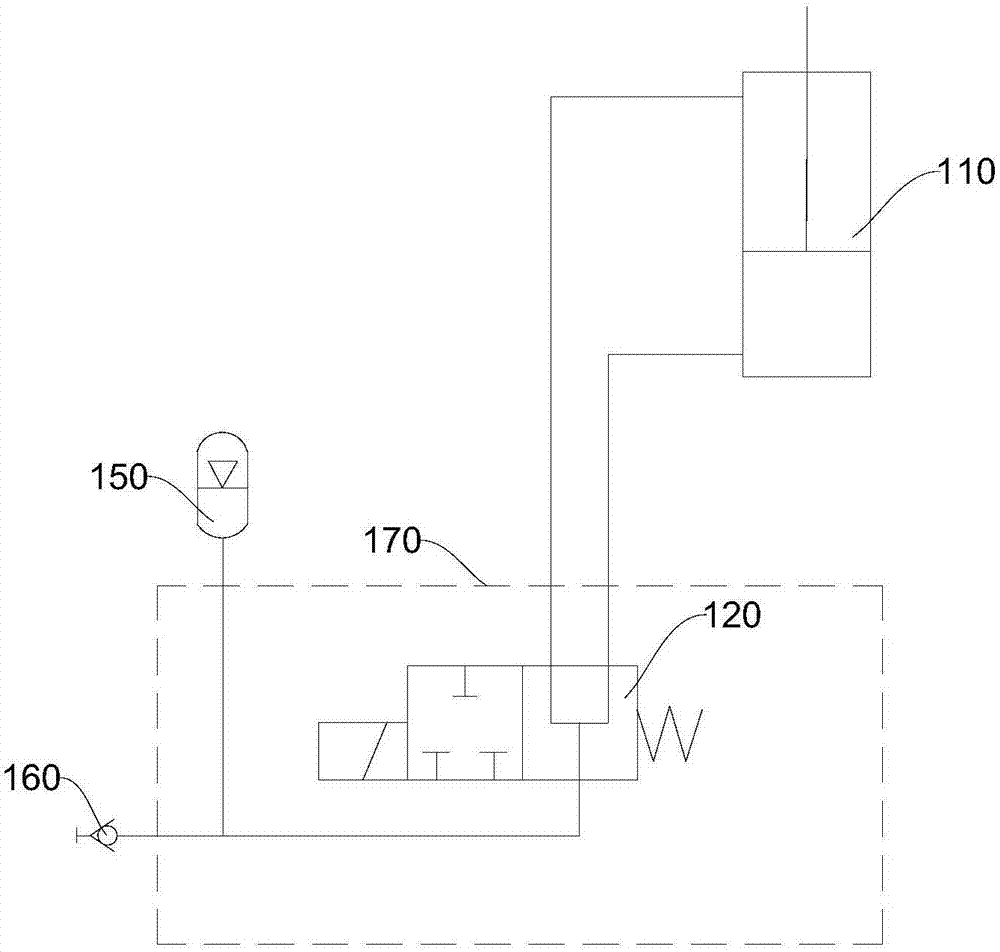

Mechanical arm and medical instrument

PendingCN107053164AFlexible rotationFlexible lockingProgramme-controlled manipulatorSurgical robotsOil pressureEngineering

The invention relates to the field of instruments, in particular to the field of medical instruments, and is a mechanical arm and a medical instrument. A mechanical arm includes a control valve, a hydraulic cylinder, a first arm, a second arm, and an accumulator. The control valve is respectively connected with the hydraulic cylinder and the accumulator. Two ends of the hydraulic cylinder are respectively connected in rotation with the first arm and the second arm, and the hydraulic cylinder can drive the second arm to rotate relative to the first arm. The oil pressure difference caused by the expansion and contraction of the piston rod of the hydraulic cylinder can be replenished and stored through the accumulator. A medical device includes the above-mentioned mechanical arm. The closing or opening of the hydraulic circuit formed by the hydraulic cylinder is controlled by the control valve, thereby controlling the rotation and locking of the second arm relative to the first arm. The entire hydraulic circuit also includes pressure measuring joints and oil circuit valve blocks. Thus, the flexible rotation and locking of the mechanical arm can be realized, and the operability is good and the maintenance is convenient.

Owner:重庆金创谷医疗科技有限公司

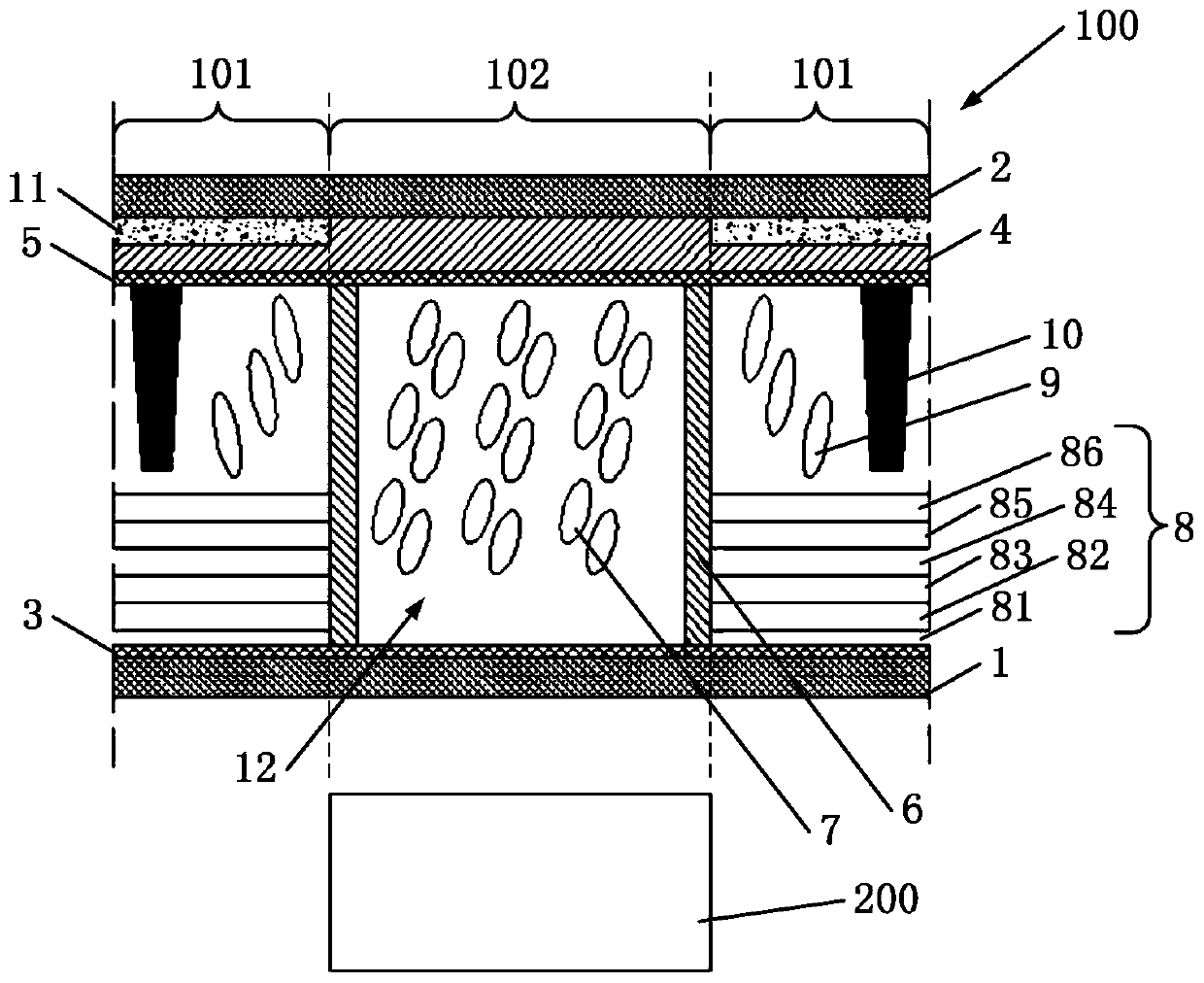

Liquid crystal display device

InactiveUS20070091245A1Prevent gravityReduce liquid viscosityNon-linear opticsLiquid-crystal displayEngineering

A liquid crystal display device is disclosed, which comprises a upper substrate; a lower substrate; a liquid crystal layer; a sealing member sandwiched between the upper substrate and the lower substrate; and at least one rampart. The sealing member divides the space between the upper substrate and the lower substrate into a center region inside the sealing member and a peripheral region outside the sealing member. The rampart positioned in the center region divides the center region into a display region and a buffer region. The height of the rampart is smaller than the cell gap between the upper substrate and the lower substrate. Therefore, the level of the liquid crystal inside the display region can be properly controlled and the undesirable “gravity mura” phenomenon can be prevented.

Owner:AU OPTRONICS CORP

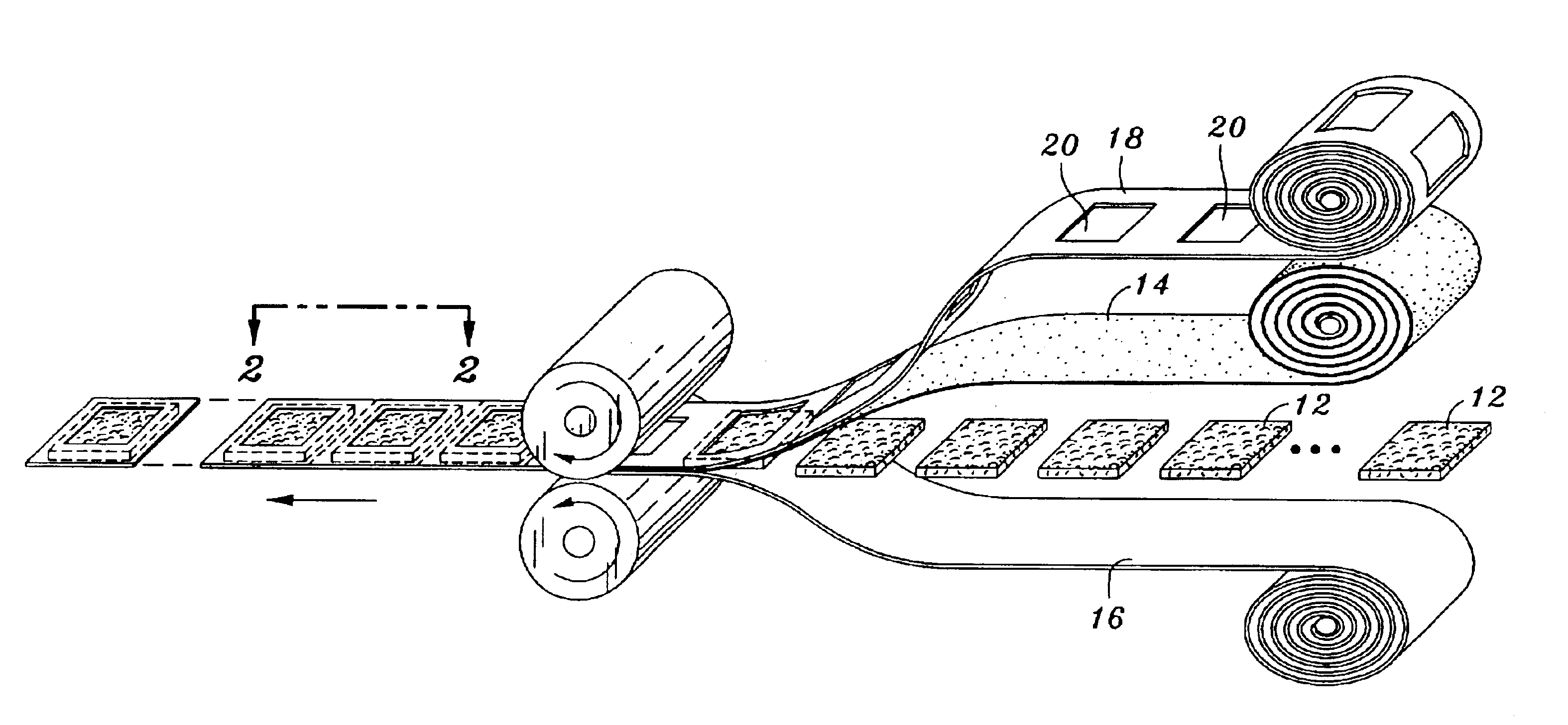

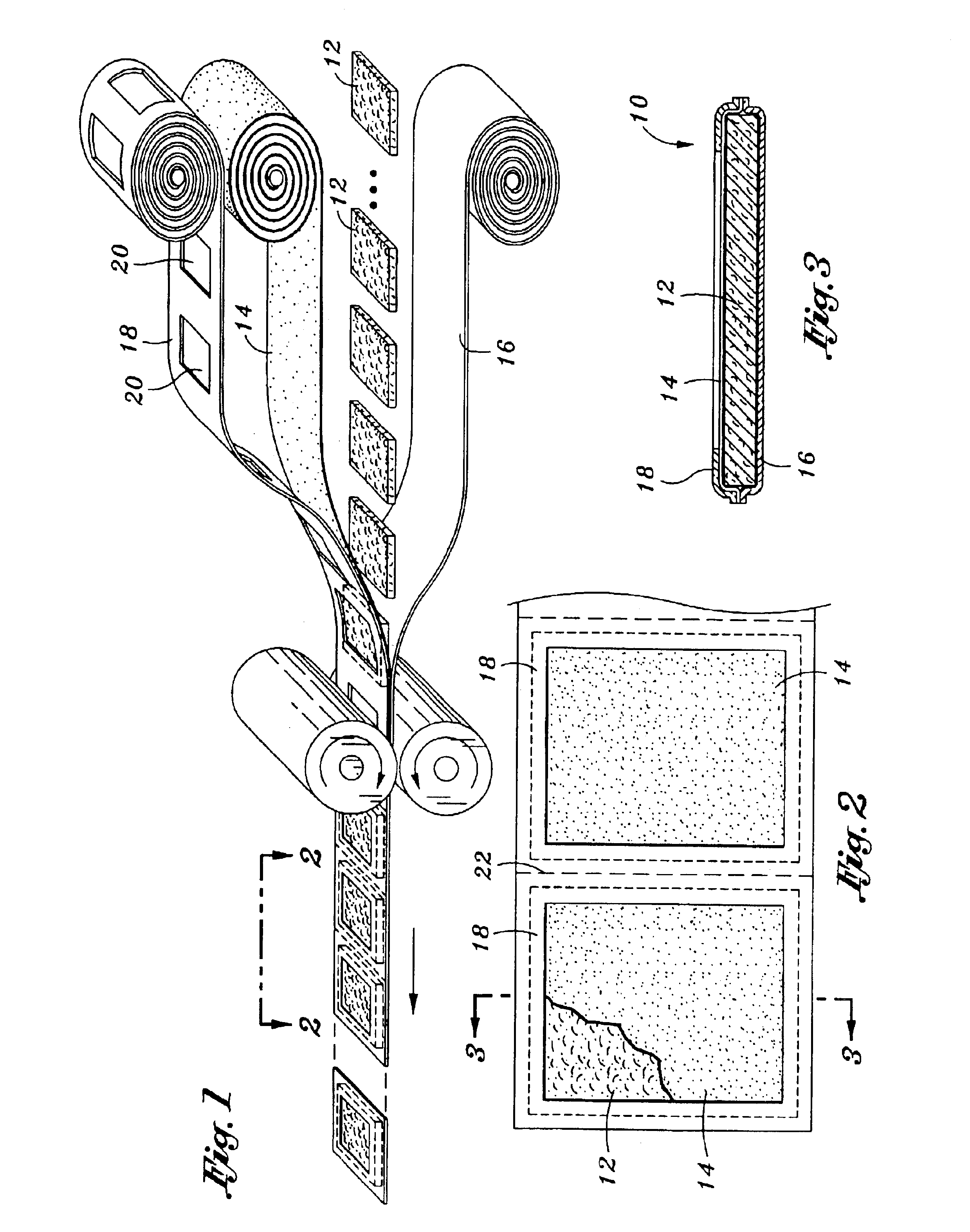

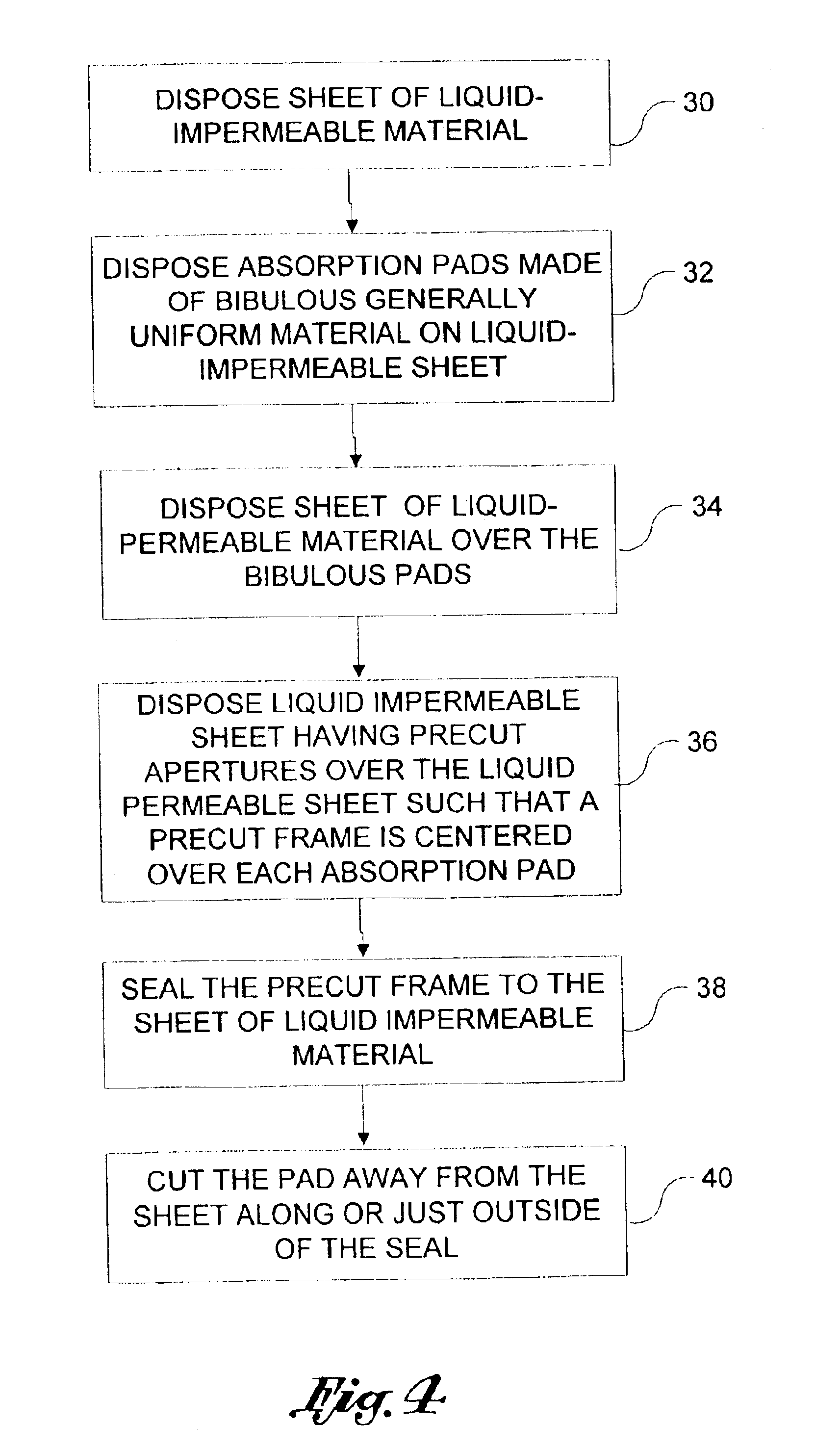

Method of forming absorbent pad using precut overlay

InactiveUS6849775B2Prevent gravityNon-adhesive dressingsNon-surgical orthopedic devicesEngineeringAbsorbent Pads

A method of forming a generally leak-proof peripherally sealed absorbent pad and a pad formed by such method are disclosed herein. Non-sealed layered pads are formed by assembling the following layers: (1) a sheet of liquid-impermeable material; (2) bibulous pads disposed on the sheet of liquid-impermeable material, the bibulous pads disposed relative to each other based on a predetermined spacing; (3) a liquid-permeable sheet disposed on top of the bibulous pads; and (4) a sheet of liquid-impermeable material having precut apertures disposed on the liquid-permeable sheet, the apertures sized and shaped to be framed by the pads and spaced relative to each other based on the predetermined spacing. The non-sealed layered pads are then sealed along a periphery of the precut apertures to the sheet of liquid-impermeable material to form a sheet of absorbent pads. The sheet of absorbent pads are then cut proximate sealed edges of the precut apertures to form a plurality of generally leak-proof peripherally sealed absorbent pads.

Owner:KLEIN JEFFREY A

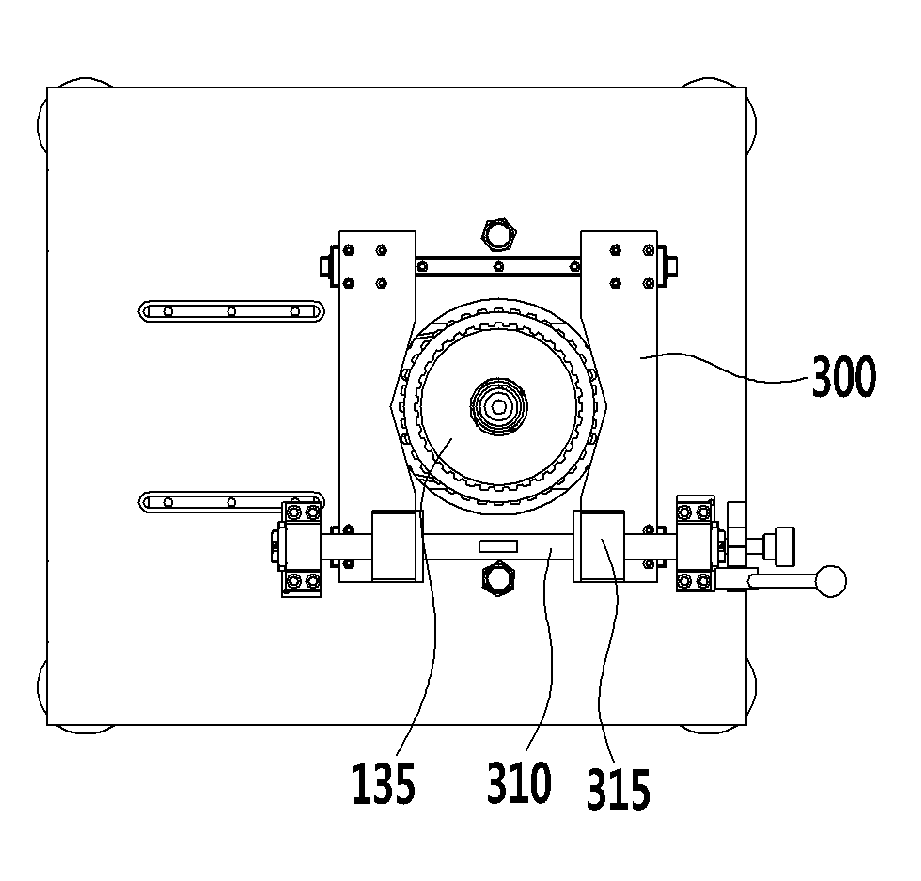

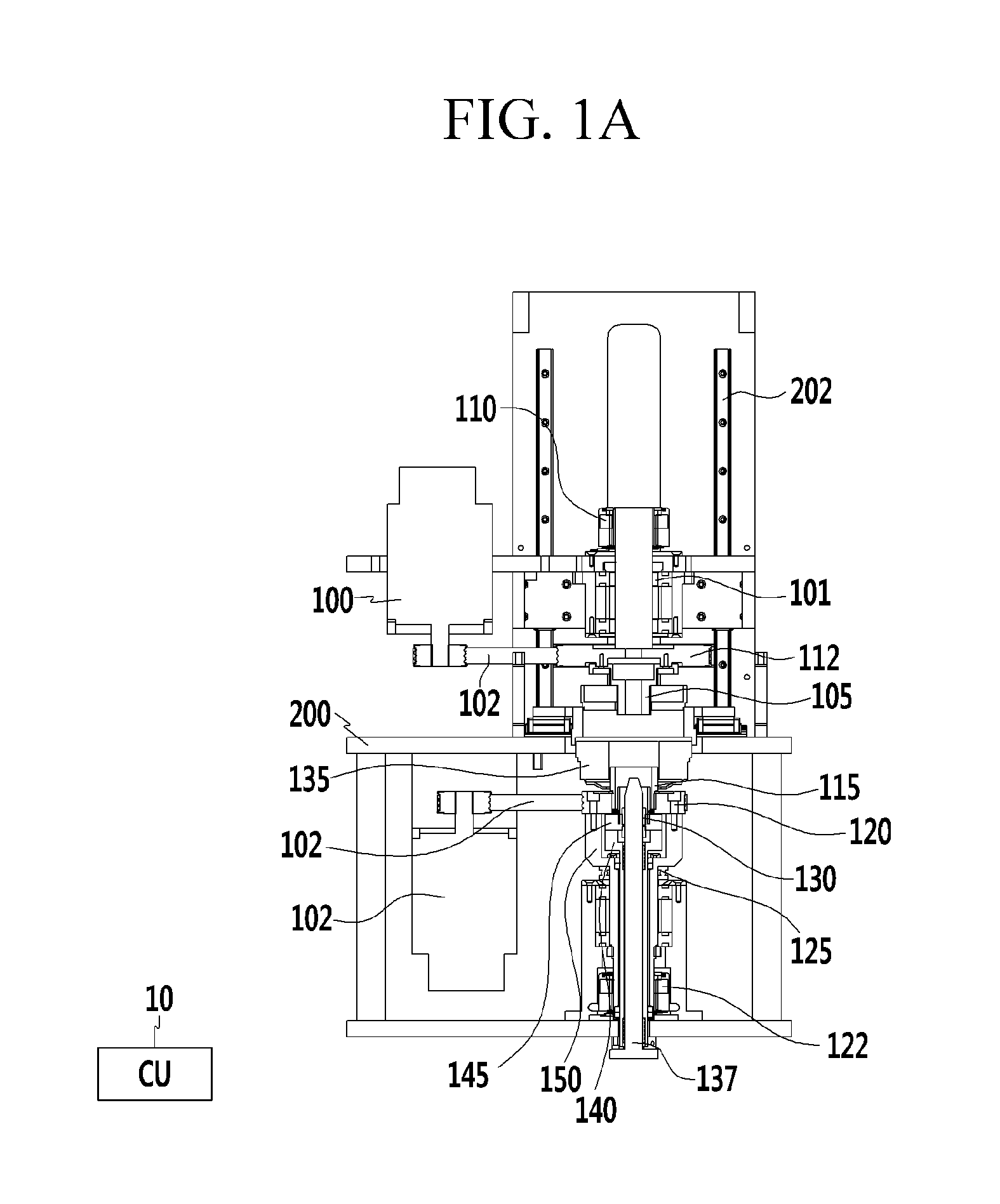

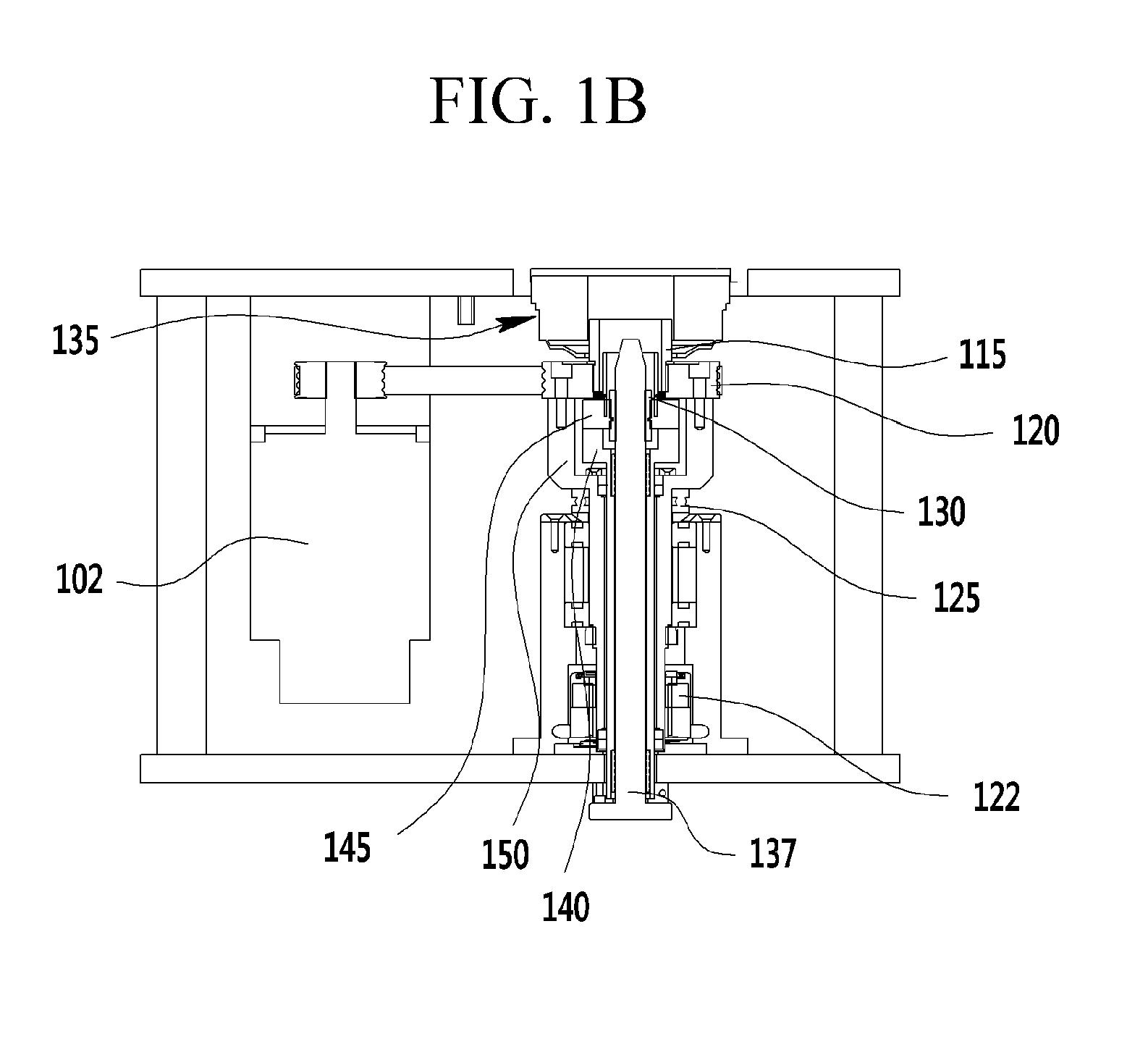

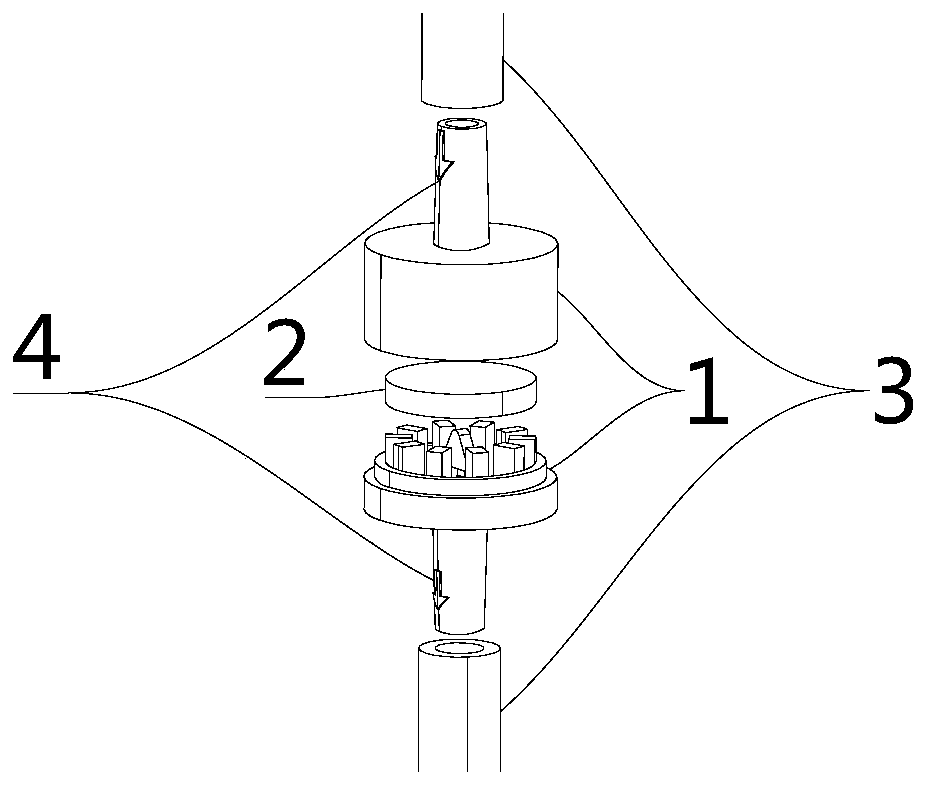

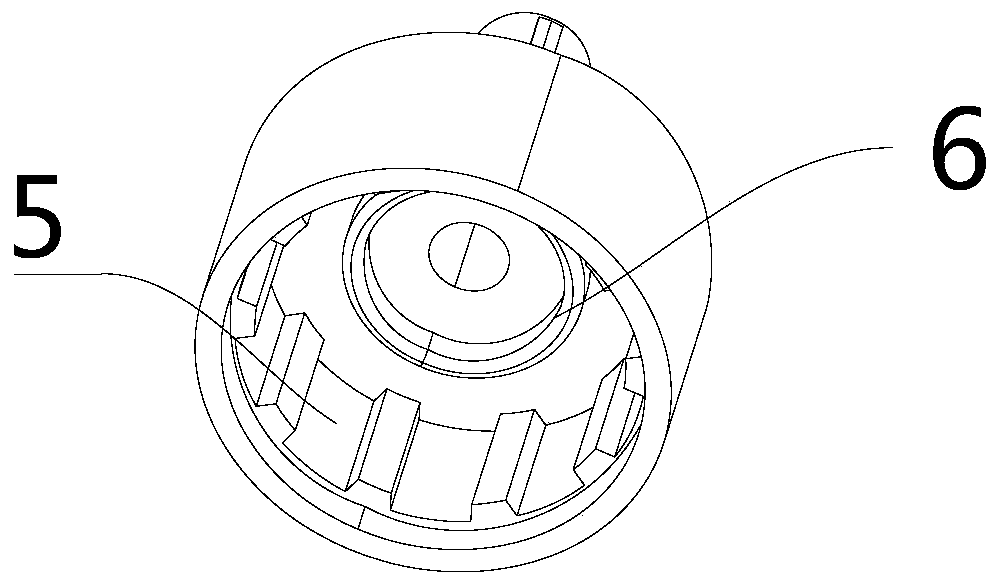

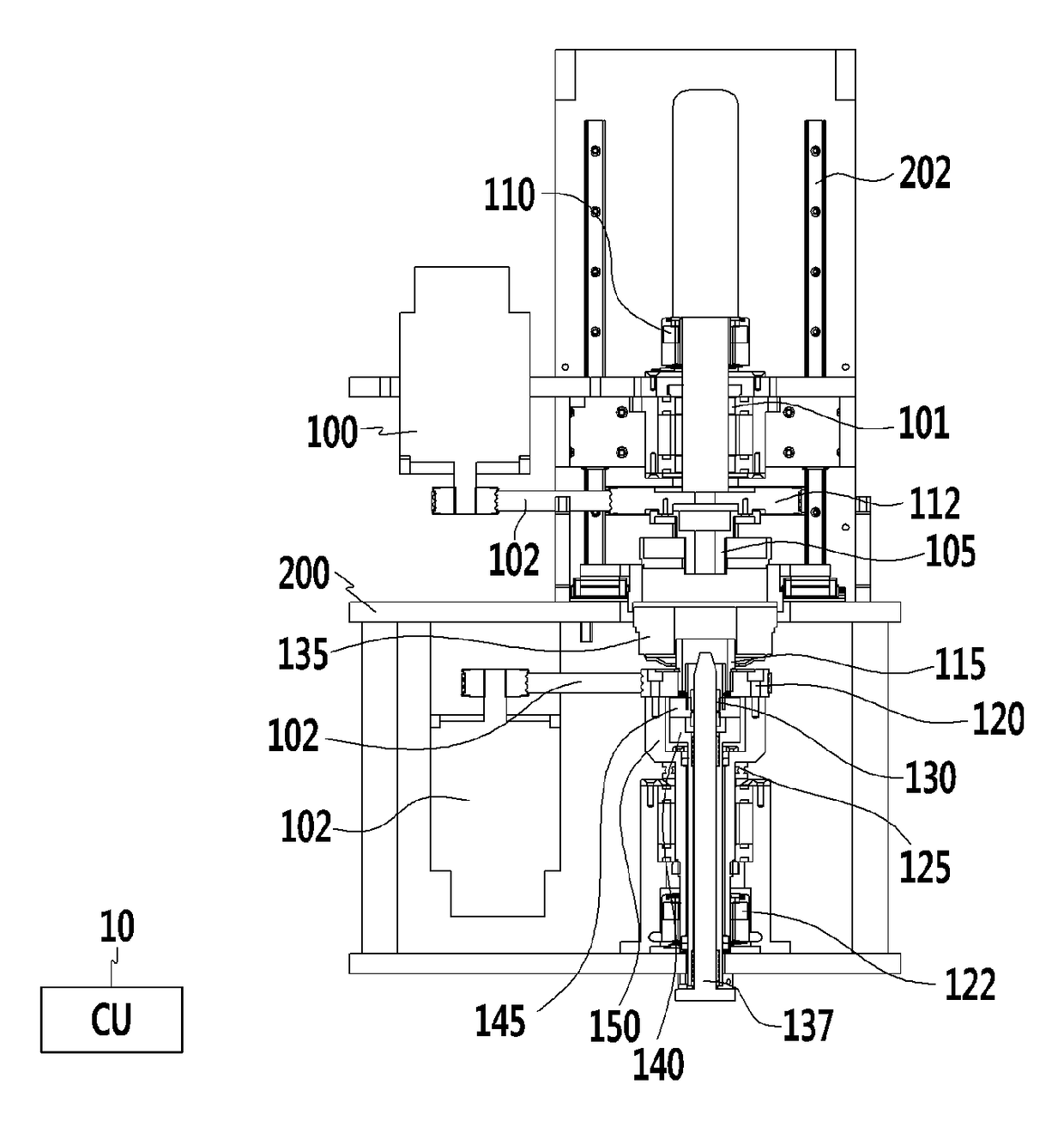

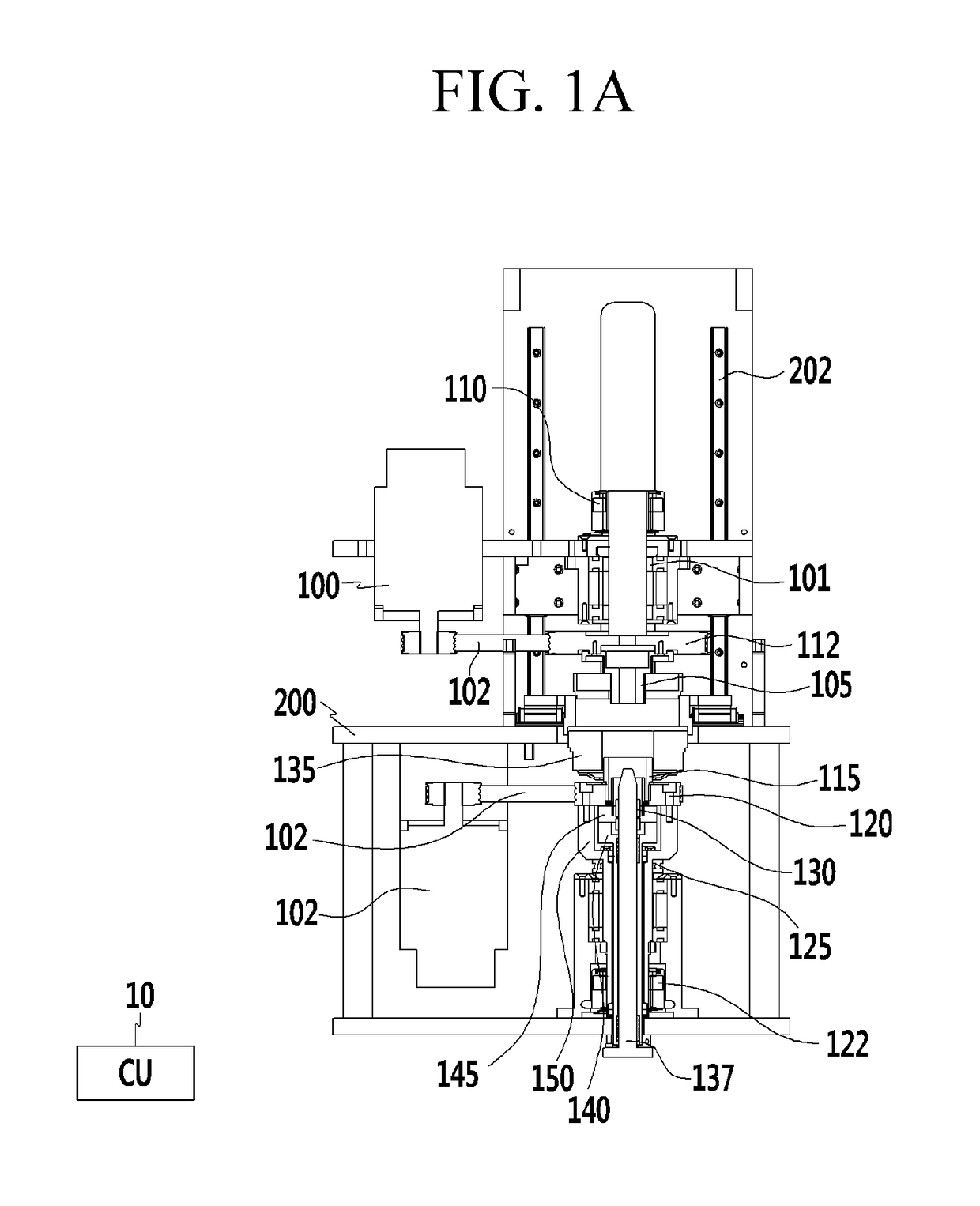

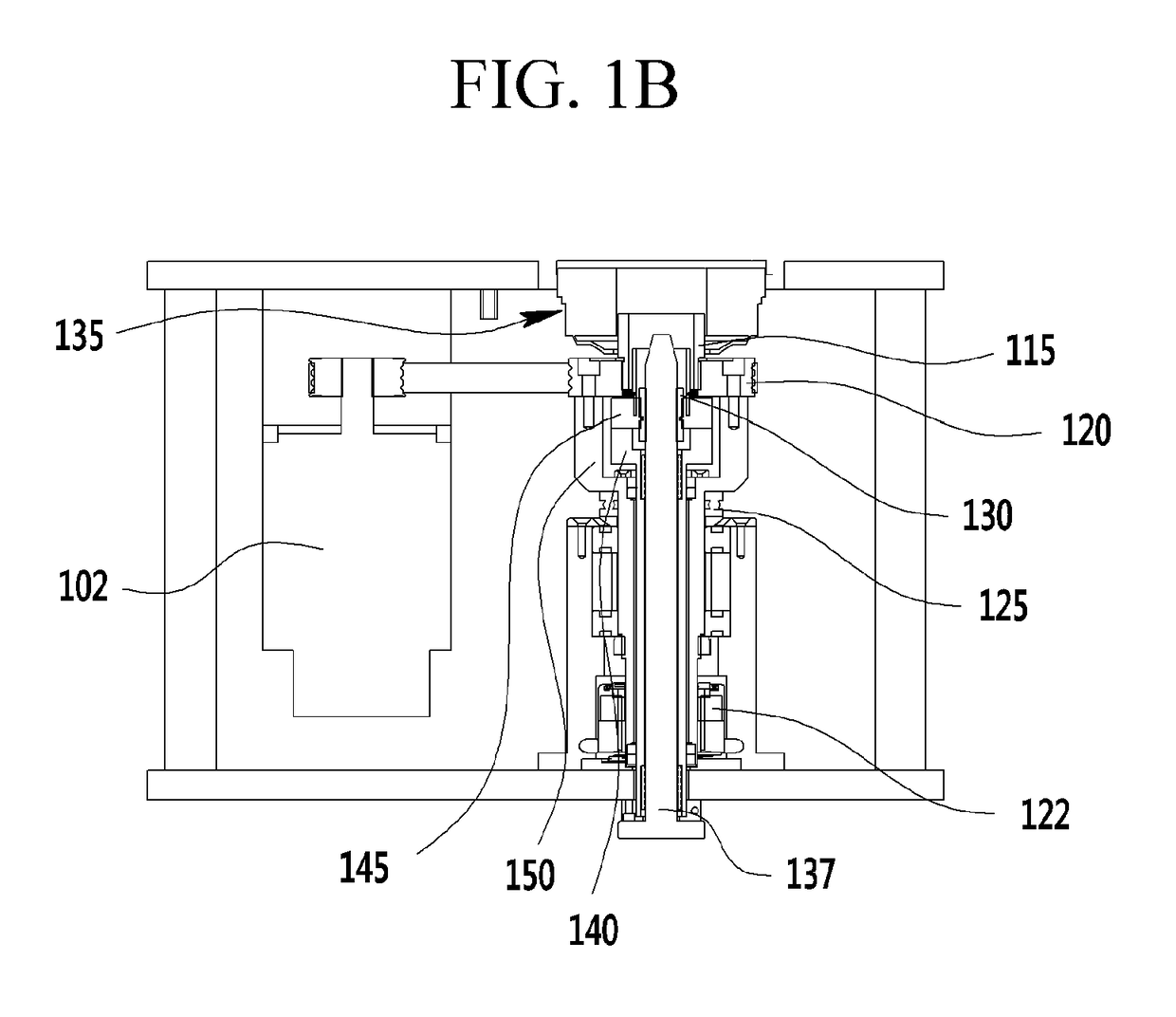

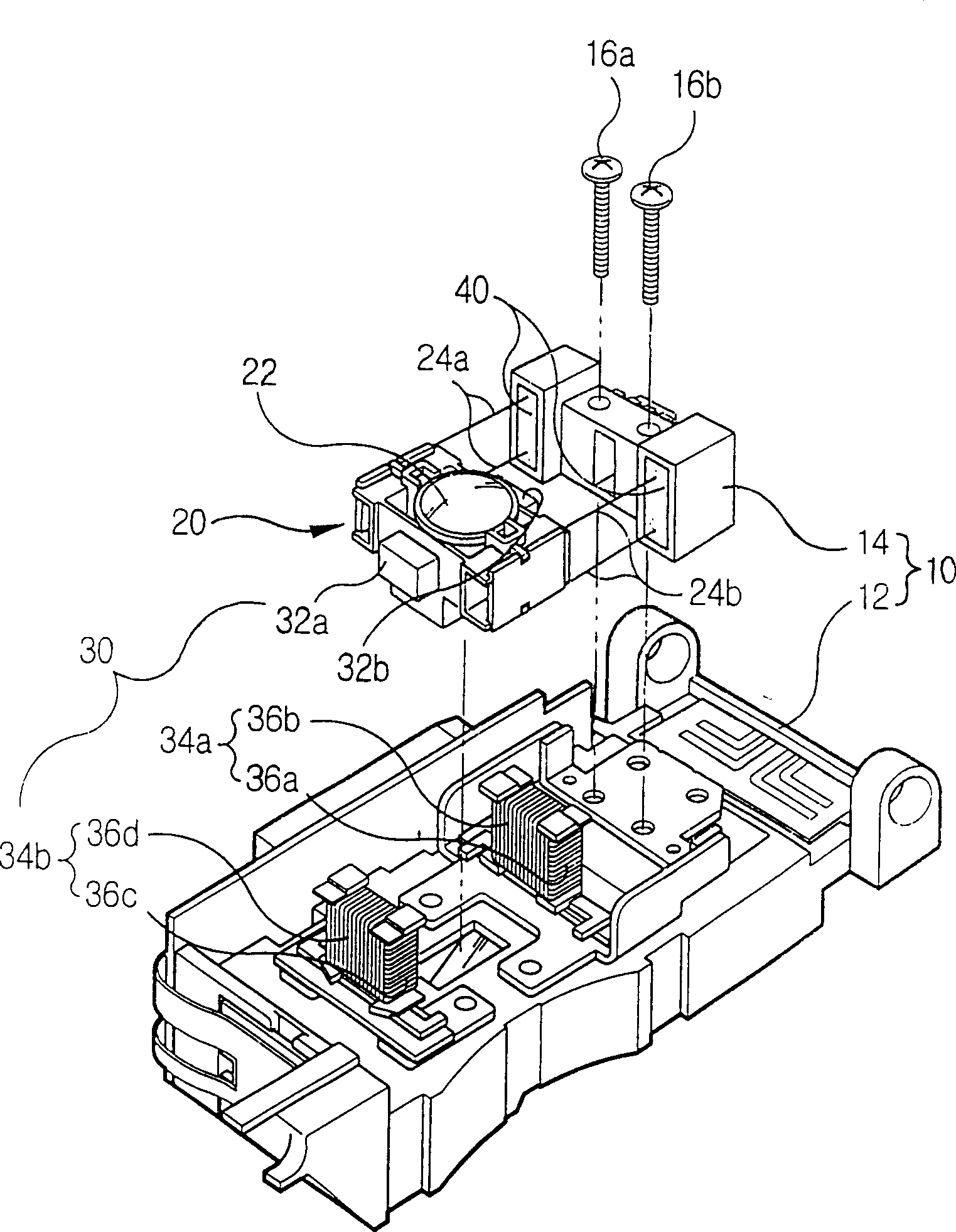

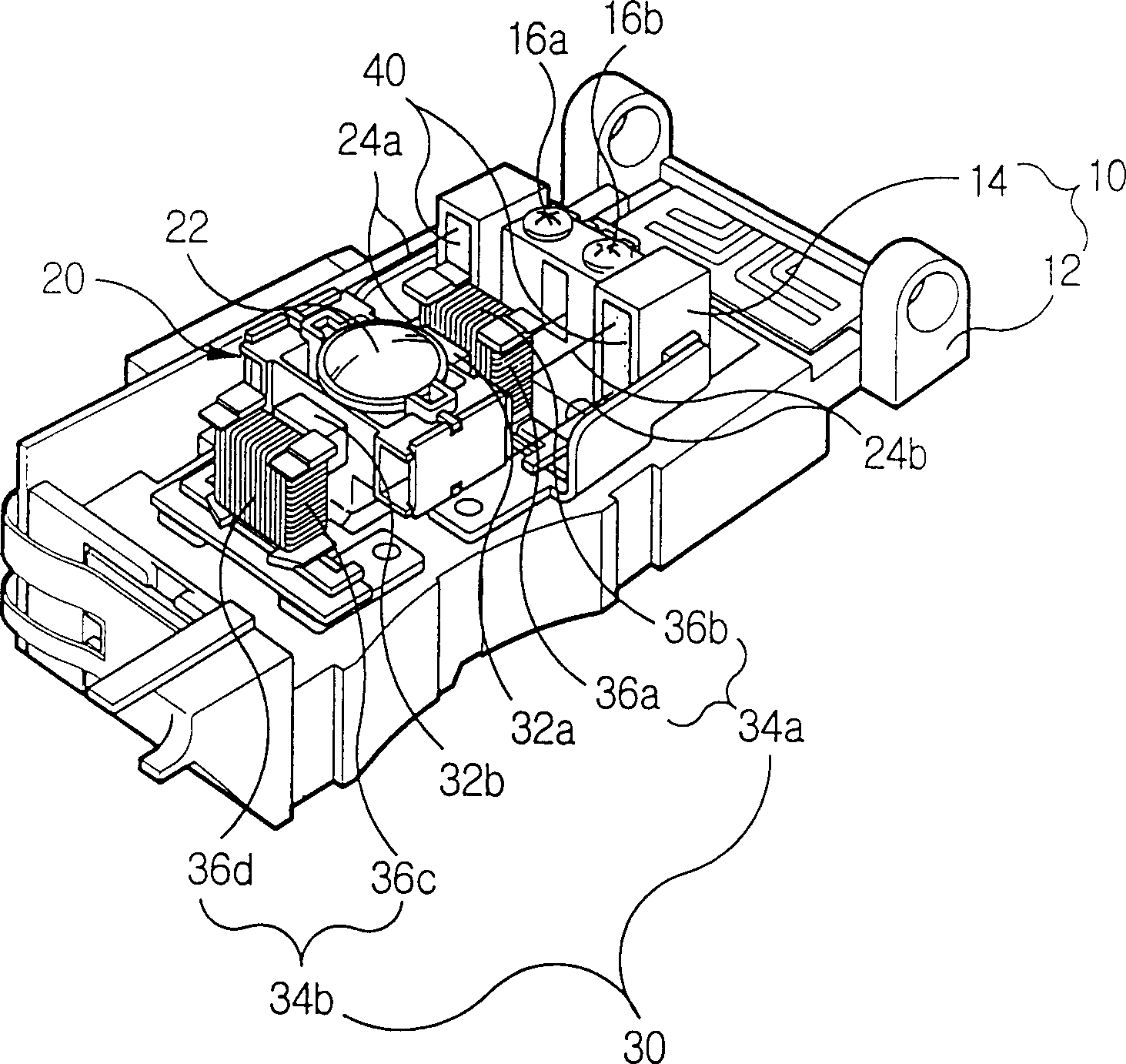

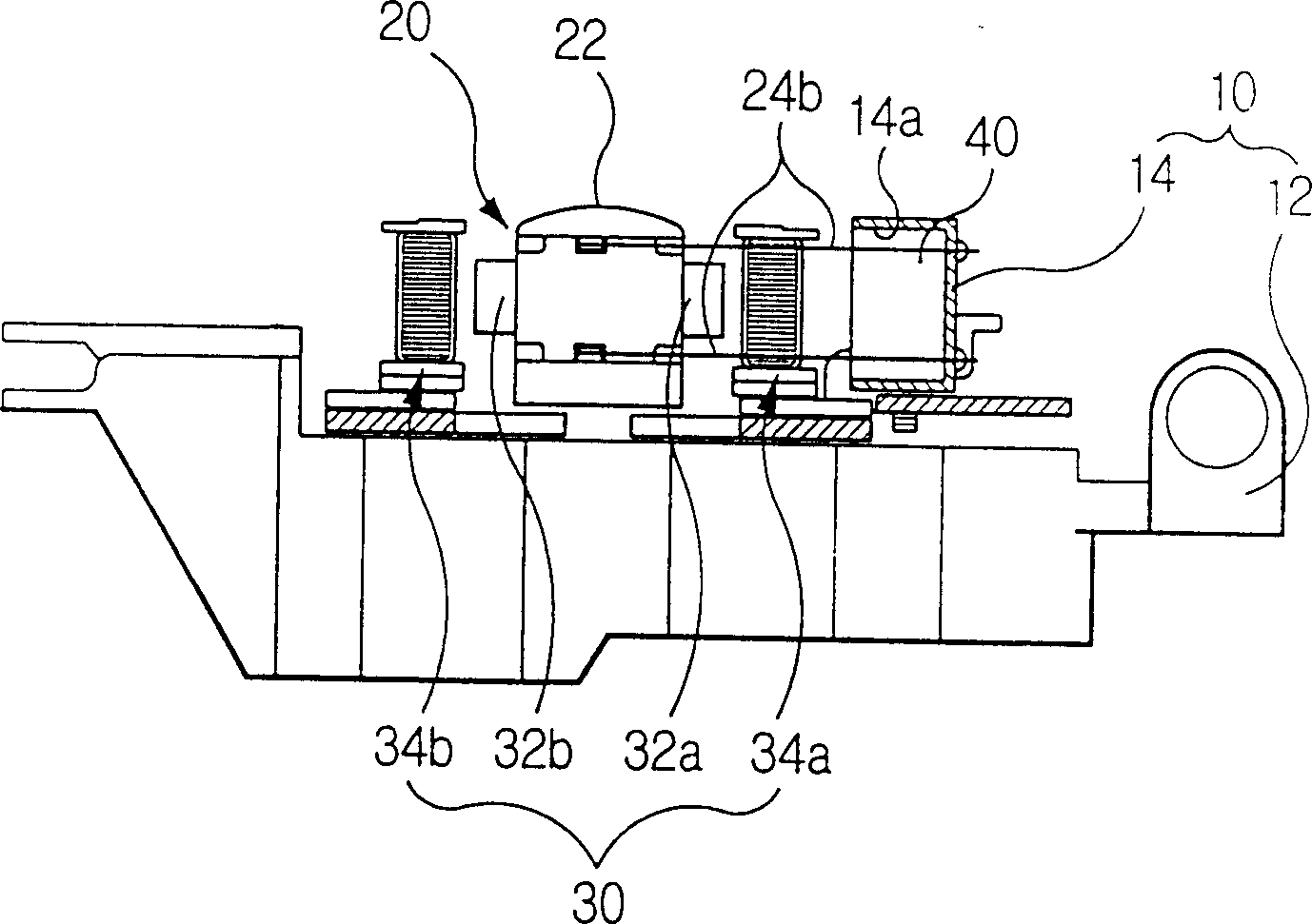

Planetary gear carrier pack transmission error inspection device

ActiveUS20150192496A1Accurate measurementEasy to measureMachine gearing/transmission testingGear trainSpur gear

A planetary gear carrier pack transmission error inspection device is provided. The device includes a planetary gear carrier pack that outputs a rotation speed input to an input side through a planetary gear, a sun gear and a ring gear at a predetermined gear ratio to an output side. An input unit is arranged on an upper side of the planetary gear carrier pack to input a predetermined input rotation speed to the input side of the planetary gear carrier pack. A load unit is arranged on a lower side of the planetary gear carrier pack connected to the output side of the planetary gear carrier pack to apply a predetermined output load to the output side. In addition, an adjusting block is arranged to adjust the planetary gear carrier pack to secure the planetary gear carrier pack.

Owner:HYUNDAI MOTOR CO LTD +1

Liquid crystal display device and method of fabricating the same

InactiveUS7576827B2Preventing touch brightness failurePrevent gravityNon-linear opticsLiquid-crystal displayEngineering

Owner:LG DISPLAY CO LTD

Display panel, display device and mobile terminal

The invention relates to a display panel, a display device and a mobile terminal. The display panel is defined to have a display area and a camera area. A closed accommodating space is formed by a first substrate layer, a second substrate layer and frame glue, and the accommodating space is filled with a liquid crystal material to form a first liquid crystal layer, so that the phenomenon of gravity or non-uniform box thickness caused by liquid crystal box thickness height difference between the first liquid crystal layer and a second liquid crystal layer is avoided. On the other hand, a cameraelement is arranged to correspond to the camera area and arranged on one side, away from the second substrate, of the first substrate, the display panel in the camera area is a transparent visual area relative to the camera element, so that the display panel is prevented from being perforated, the integrity of the display panel is protected, and the phenomena of poor chemical resistance of the display panel, imperfect full-screen visual effect and the like are avoided.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Glue ball production system and method

The invention provides a glue ball production system and method. Glue saluting and a content are converged at the exit of a water dropper device to form a concentric flow, the concentric flow is cut by cooling liquid from a cutting device at a cutting mouth to form sugar-gourd-shaped fluid. The sugar-gourd-shaped fluid drops in a current stabilizer and is cooled by the cooling liquid entering the current stabilizer to form glue balls. A glue ball and cooling liquid mixture moves down to a flow accelerator through a cooling column and then is collected into a ball receiving device through the cooling column and a lifting device. The glue ball production system and method have the advantages that the production speed of glue balls can be accelerated, and meanwhile the production stability is enhanced.

Owner:MASTERWORK GROUP CO LTD

Impressing device of photogravure press

PendingCN113510998AAvoid capacity differencesAvoid differencesRotary intaglio printing pressPhotogravureEngineering

The invention discloses an impressing device of a photogravure press, and relates to the field of photogravure printing. The impressing device comprises a bottom plate, two supporting beams are mounted on the top side of the bottom plate, a motor is mounted on the top side of the bottom plate, and a transmission shaft is mounted at the output end of the motor through a transmission mechanism. One end of the transmission shaft penetrates through one supporting beam and is rotationally connected with one side of the other supporting beam. According to the impressing device of the photogravure press, a plurality of impression cylinders are driven by an adjusting mechanism to synchronously and centripetally move, a printing stock is pressed and attached to the surface of a plate cylinder, during impression, the multiple impression cylinders replace a single cylinder for impression, and the impression cylinders press and attach the printing stock to the plate cylinder for a long time and a large area; and the difference between the amount of ink on the printing stock and the capacity of an ink cell due to the fact that ink in the ink cell cannot be completely transferred during high-speed imprinting can be avoided, the color difference of the printed image-text and even the poor saturation degree of image-text printing due to blank printing can be avoided, and the image-text printing effect is good.

Owner:温州鸿涛包装有限公司

Infusion system using automatic flow resisting valve as main body

PendingCN110327509APrevent gravityEliminate operator errorsPressure infusionFlow monitorsSurgeryInfusion pump

The invention discloses an infusion system using an automatic flow resisting valve as a main body, and relates to the technical field of medical apparatuses. The infusion system comprises an infusionpump, infusion pipes, and the automatic flow resisting valve arranged at any position of the infusion pipes, wherein the automatic flow resisting valve is used for providing initial pressure, so thatthe automatic flow resisting valve is under a normal off condition of blocking the infusion of the infusion pipes; only when the infusion pump normally works, pressure provided by the infusion pump overcomes the initial pressure, so that the automatic flow resisting valve is under an opening condition where the infusion pipes can perform infusion; the automatic flow resisting valve comprises a valve body and a valve core; the valve body comprises a valve body inner cavity; the valve body inner cavity is formed between the infusion pipes, and communicates with the infusion pipes; the valve coreis arranged in the valve body inner cavity; and the valve body is used for providing the initial pressure to the valve core, so that the infusion pipes are under the normal off condition. The infusion system disclosed by the invention can automatically stop infusion; in the using process, a manual operation factor is removed, the possibility of operation faults is eliminated, and the problem of automatic flowing of the infusion pump can be effectively solved; and the infusion system is in one-way conduction, so that reverse flow of blood is effectively avoided.

Owner:巨翊科瑞医疗技术(上海)有限公司

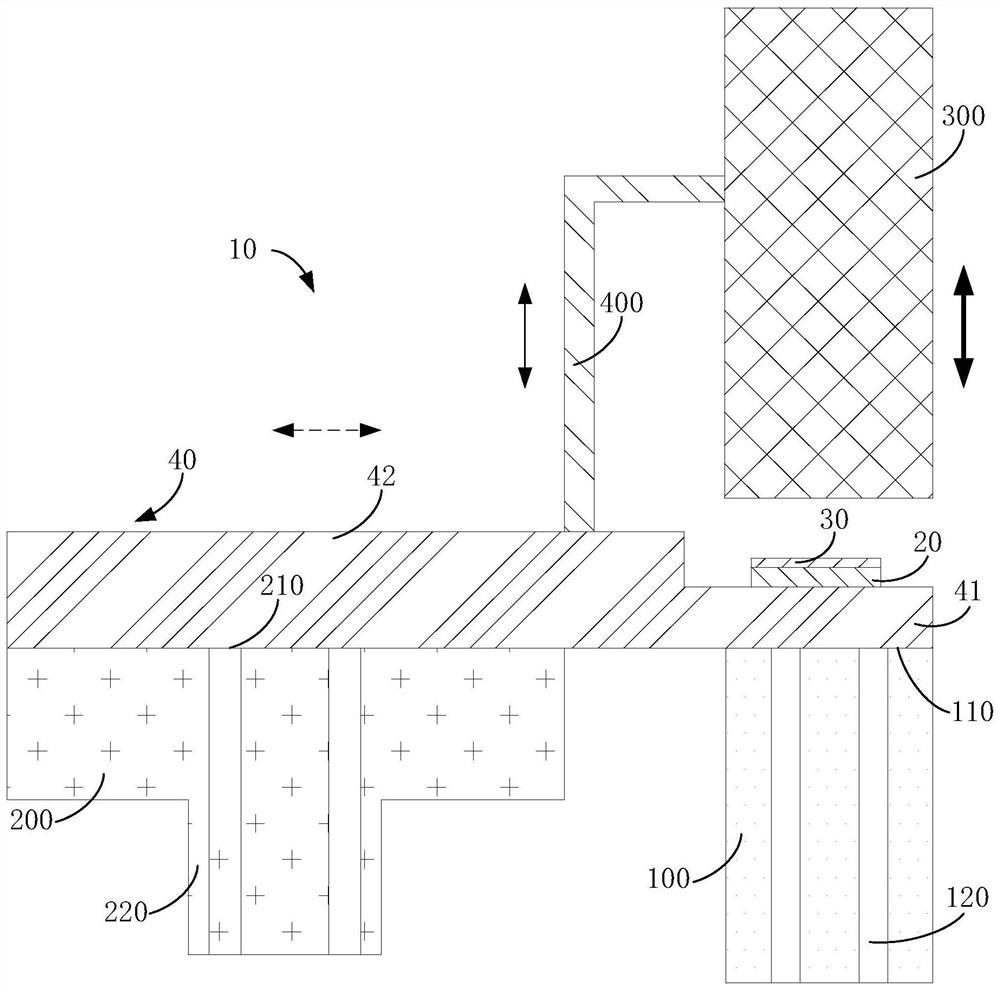

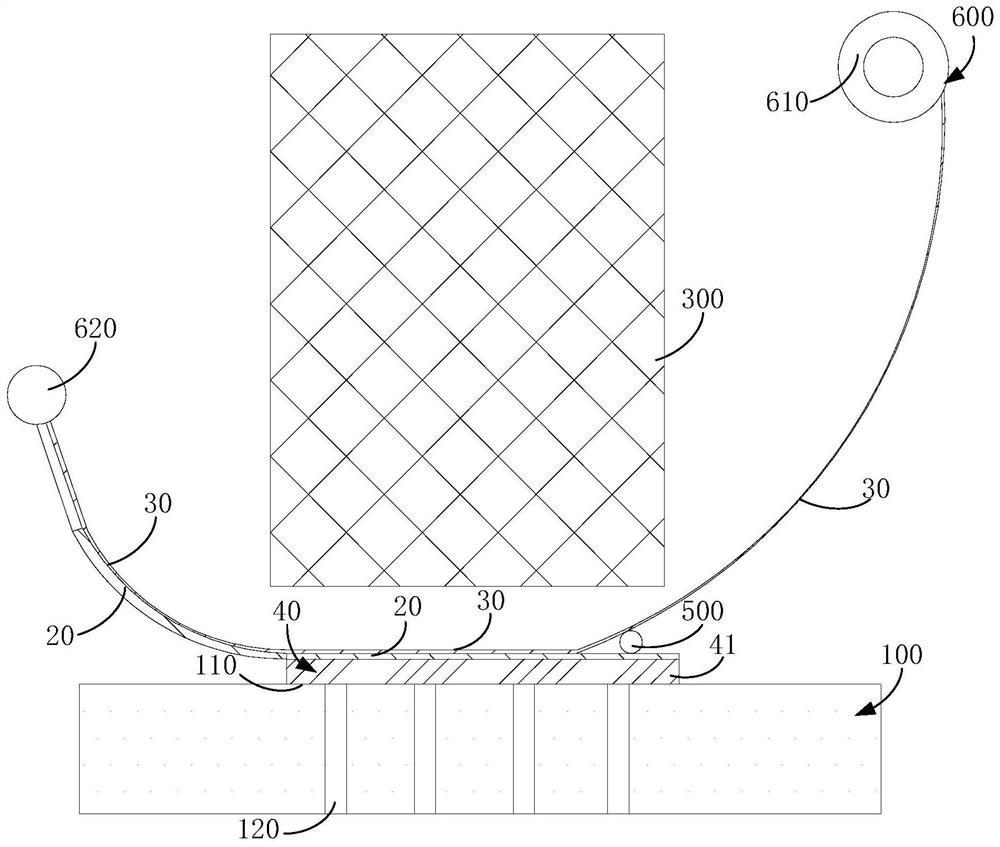

Automatic film sticking device and film sticking method

InactiveCN112550876AAvoid warpingEliminate wrinklesLabelling flat rigid surfacesLabelling machinesEngineeringMechanical engineering

The invention relates to an automatic film sticking device and a film sticking method. The automatic film sticking device is used for sticking an adhesive film adhered with release paper to an attaching part of a workpiece and comprises a supporting platform, a carrying piece and pressing piece, and the supporting platform is used for bearing and fixing the attaching part of the workpiece; the carrying piece is used for fixing the non-attaching part of the workpiece, and the carrying piece can move in the first direction relative to the supporting platform so that the attaching part of the workpiece can be borne on the supporting platform; and the pressing piece can move relative to the supporting platform in the second direction forming an included angle with the first direction, and thepressing piece is used for pressing the release paper so as to attach the adhesive film to the workpiece. Therefore, the stability and reliability of attachment between the adhesive film and the workpiece can be guaranteed, and finally the attachment yield of the adhesive film and the workpiece is improved.

Owner:SHENZHEN LIANDE AUTOMATION EQUIP

Planetary gear carrier pack transmission error inspection device

ActiveUS9664592B2Accurate measurementEasy to measureMachine gearing/transmission testingEngineeringGear train

A planetary gear carrier pack transmission error inspection device is provided. The device includes a planetary gear carrier pack that outputs a rotation speed input to an input side through a planetary gear, a sun gear and a ring gear at a predetermined gear ratio to an output side. An input unit is arranged on an upper side of the planetary gear carrier pack to input a predetermined input rotation speed to the input side of the planetary gear carrier pack. A load unit is arranged on a lower side of the planetary gear carrier pack connected to the output side of the planetary gear carrier pack to apply a predetermined output load to the output side. In addition, an adjusting block is arranged to adjust the planetary gear carrier pack to secure the planetary gear carrier pack.

Owner:HYUNDAI MOTOR CO LTD +1

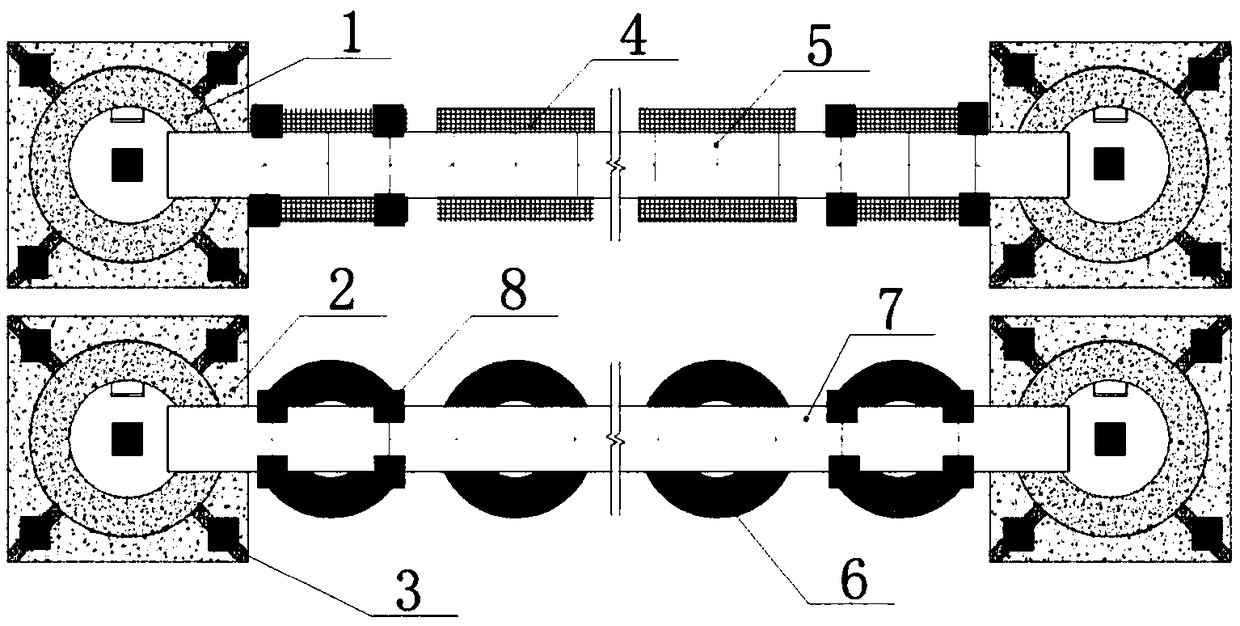

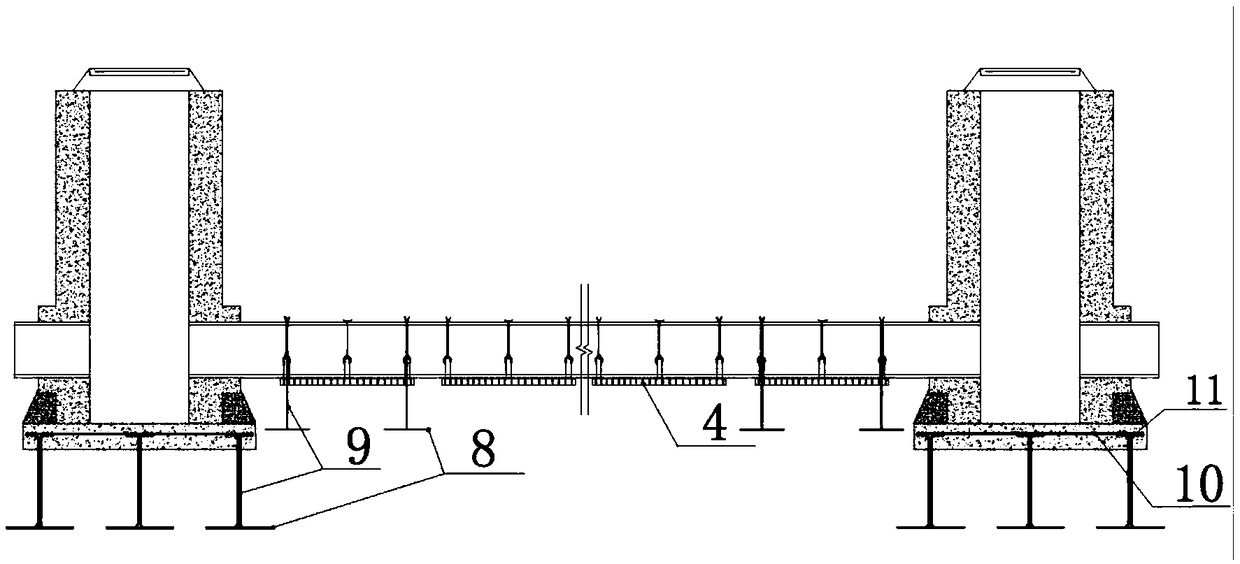

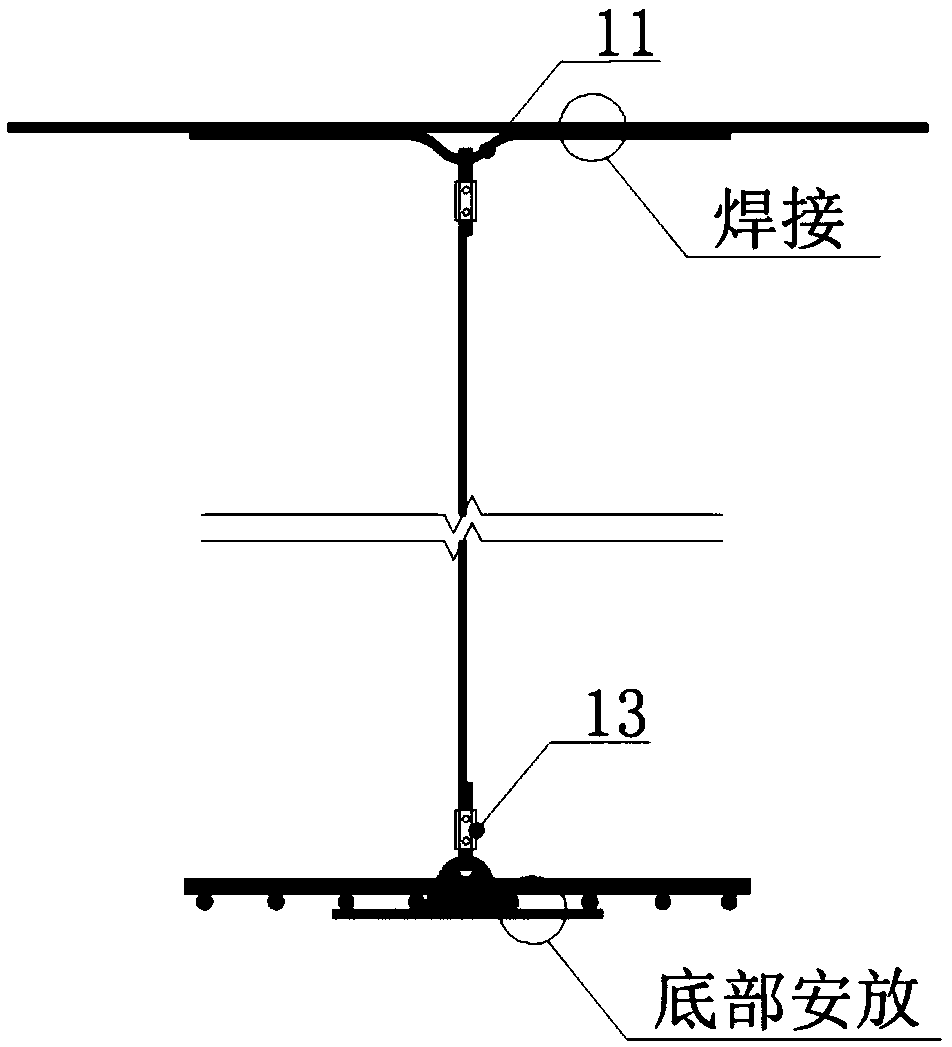

Anti-floating system and construction method of sandbar sewage pipe, well

ActiveCN108894206AEliminate buoyancyAvoid deformationProtective foundationSoil preservationArchitectural engineeringSewage

The invention discloses a sandbar sewage pipe, well anti-floating system, include anti-float plates, Bundle wire, clip rib, steel mesh, U-groove ribs, steel plate fasteners, Staples, bracing ropes, Anti-float plate are arranged at that bottom of the pipeline and bind to the pipeline through bundle wires, A loc wire rib is inserted into that inn side of the bundle wire, and a binding surface with the pipe is added. The steel bar mesh sheet is arranged below the pipe and below the sewage well. The steel bar mesh sheet is welded with U-groove reinforcement or steel plate buckle, and the U-groovereinforcement is not only welded with the mesh surface of the steel bar mesh sheet, but also bound or welded with the reinforcement of the bottom plate foundation; The steel plate buckle is welded onthe reinforcing bar mesh sheet or pierced from the bottom of the reinforcing bar mesh sheet; The clasp binds the wire drawing rope to the pipe, the U-groove rib and the steel plate fastener. The claspbinds the wire drawing rope to the pipe, the U-groove rib and the steel plate fastener. The invention also discloses a construction method of the sandbar sewage pipe and the well anti-floating system. The invention changes the traditional method of deep burying, increasing dead weight and increasing fixed foundation, and provides a stable and safe anti-floating system and construction method forsandbar high-water-level pipe and well construction.

Owner:CHINA FIRST METALLURGICAL GROUP

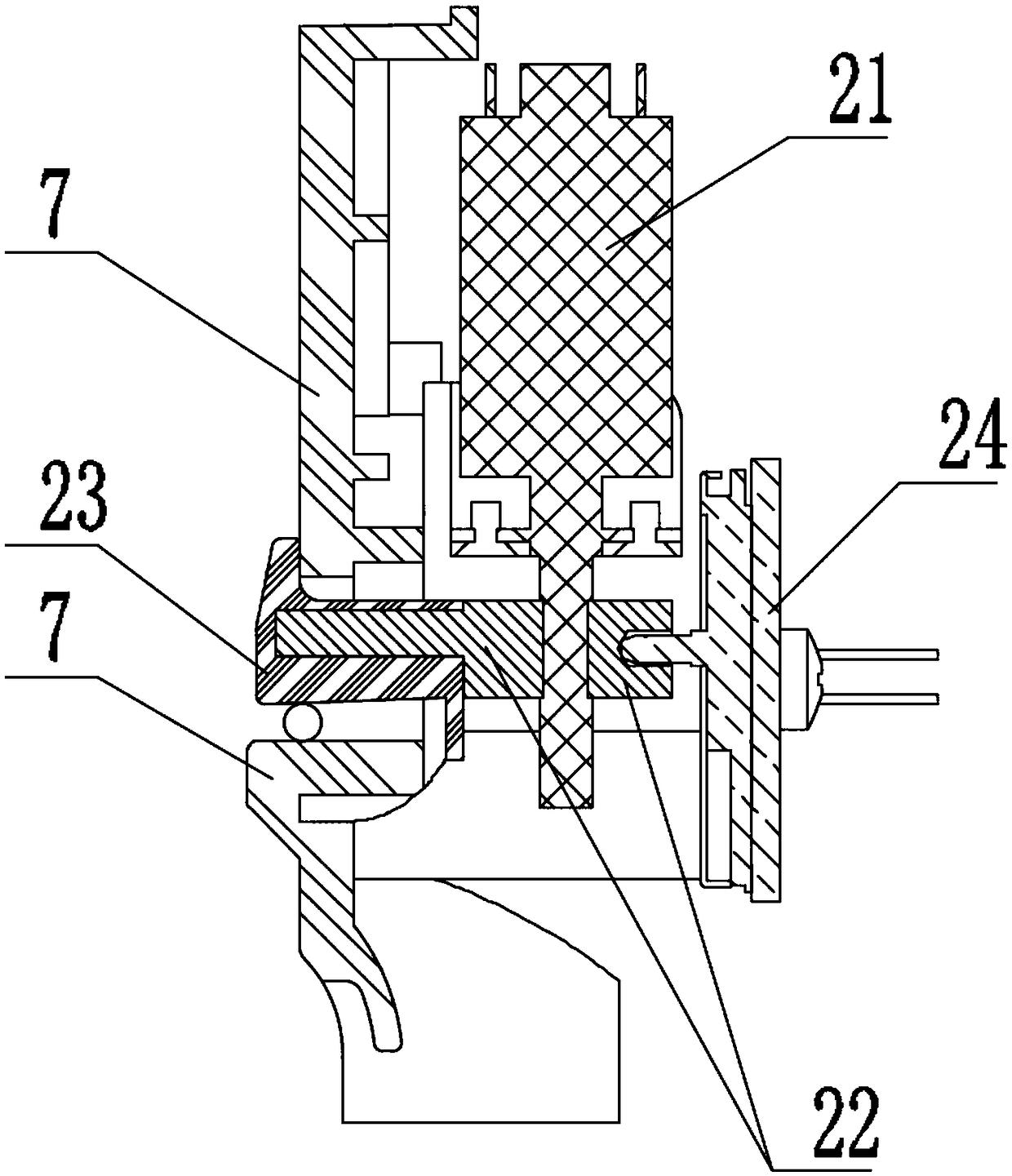

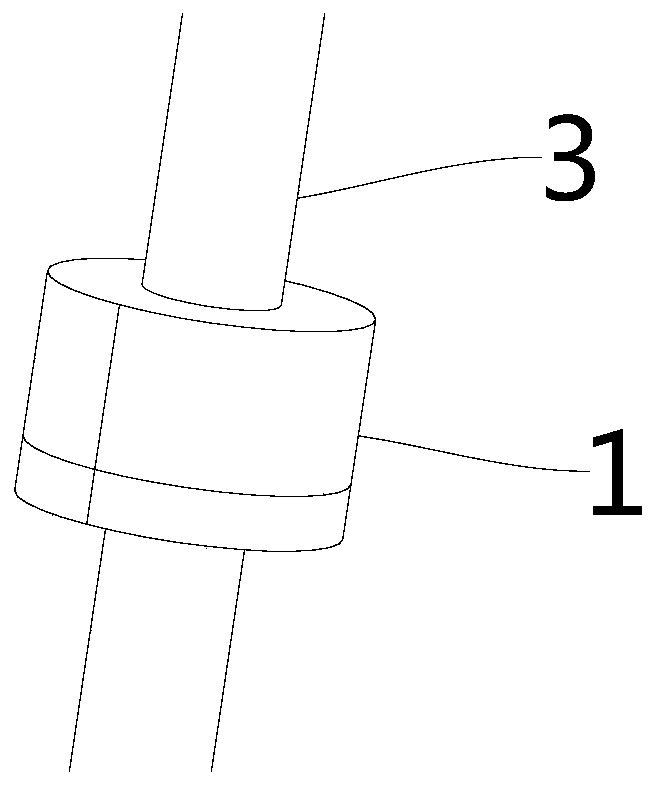

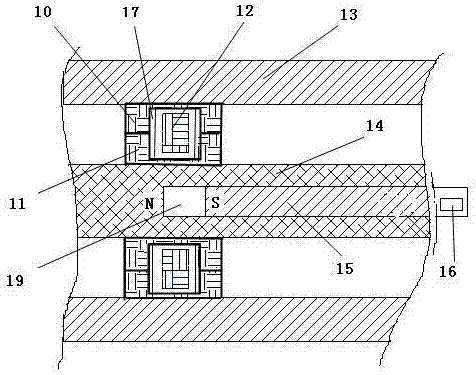

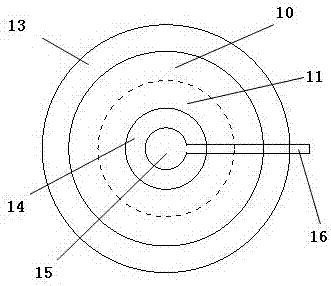

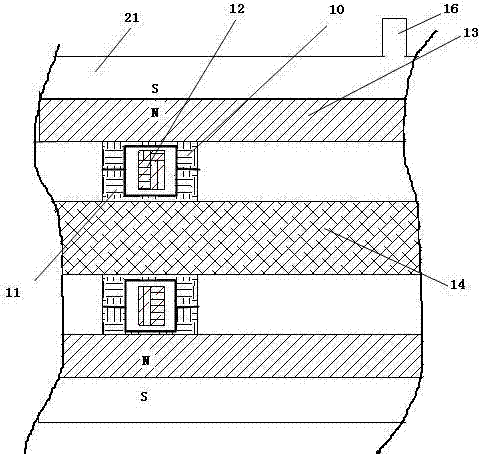

A non-contact magnetically controlled one-way clutch

ActiveCN105937564BExtended service lifeReduce frictionMagnetically actuated clutchesMagnetic polesContact type

The invention discloses a non-contact type magnetic control one-way clutch, and belongs to the field of vehicle components. An outer shaft is connected to an outer seat ring of the one-way clutch, an inner shaft is connected into an inner seat ring, a movable magnetic component is arranged on the side of the outer seat ring or the side of the inner seat ring of the one-way clutch, the outer seat ring or the inner seat ring is provided with a magnetic pole with magnetism opposite to magnetism of the movable magnetic component, and when the magnetic pole of the movable magnetic component and the magnetic component of the side of the outer seat ring or the side of the inner seat ring are close to the one-way clutch, a wedge block and the outer seat ring or the inner seat ring are in the non-contact state, and the one-way clutch is in the controllable failure state; and when the magnetic component is away from the one-way clutch, the one-way clutch comes into effect, and the one-way clutch can be used for removing the limitation of the rotating speed difference existing in the one-way clutch, the use range of the one-way clutch can be widened, friction resistance of the one-way clutch can be reduced, and the service life of the one-way clutch can be prolonged.

Owner:宋宝玲

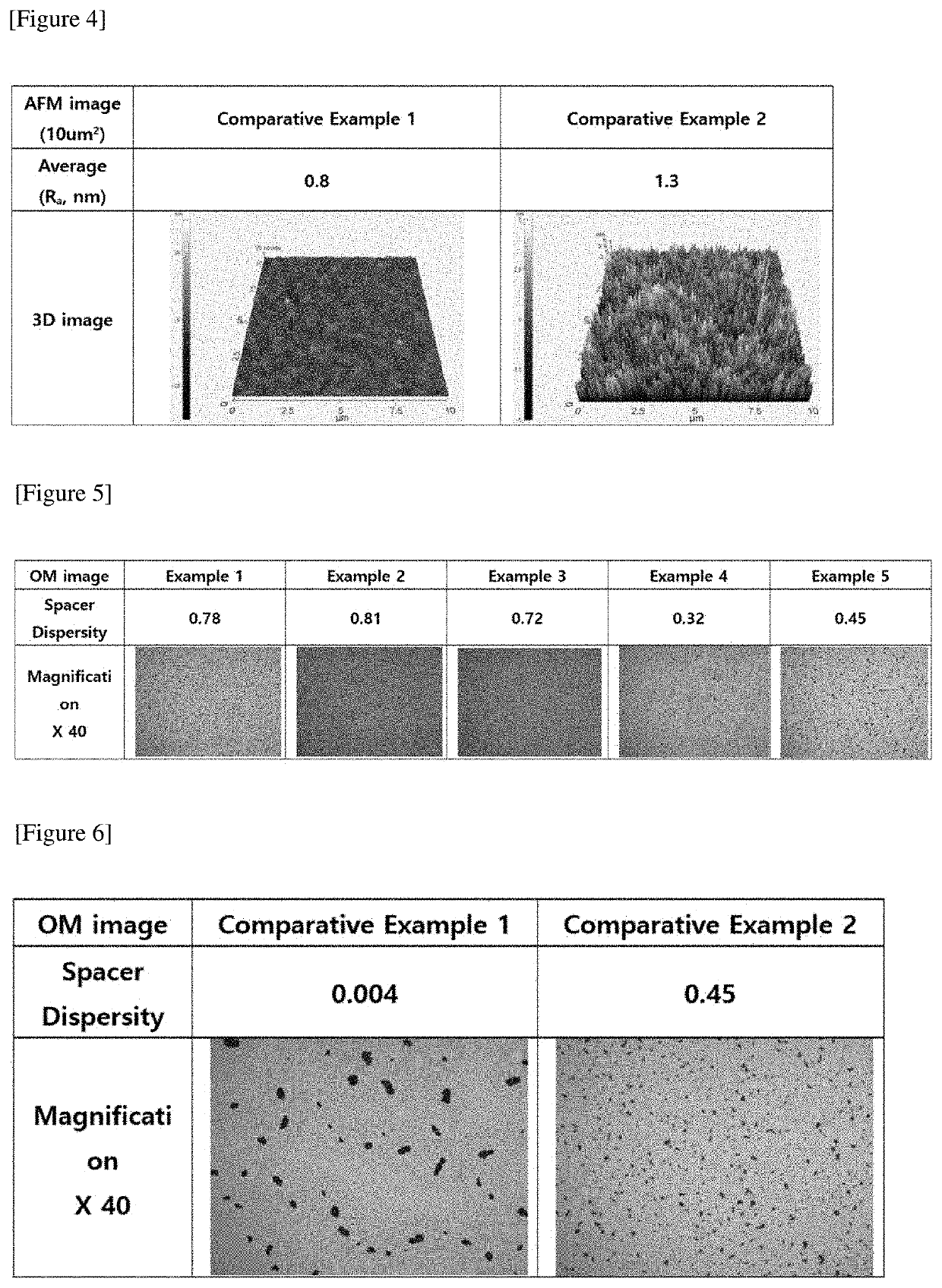

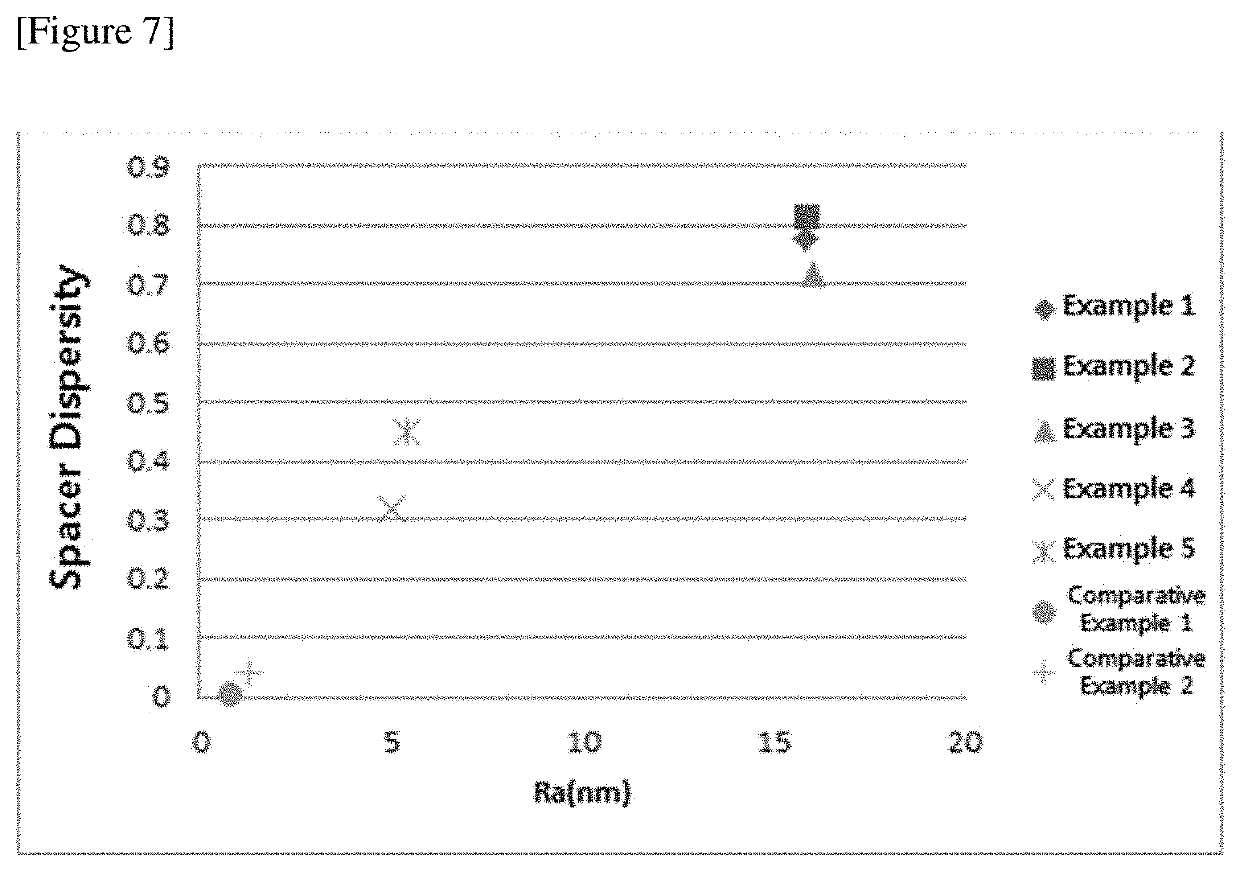

Method of applying particles

ActiveUS11300837B2Good particle dispersionSimple manufacturing processMaterial nanotechnologyNanoopticsChemical physicsMaterials science

The present application relates to a method of applying particles, an optical film and a method of manufacturing an active liquid crystal device. In the method of applying particles of the present application, the particles can be uniformly applied on a base material and fixed while maintaining the shape of particles. The optical film of the present invention produced by the above method can have excellent particle dispersity. A method of manufacturing an active liquid crystal device using the above method can maintain a cell gap uniformly while simplifying the manufacturing process and preventing gravity defects.

Owner:LG CHEM LTD

An intelligent infusion pump

ActiveCN108939209BImprove work efficiencyImprove experienceMedical devicesFlow monitorsPeristaltic pumpControl system

The invention discloses an intelligent transfusion pump, which comprises a control system and a casing. An infusion pipeline is arranged on the outer surface of the casing, along which an air bubble probe sensor, a peristaltic pump, and a lower blockage sensor respectively connected to the control system are sequentially arranged. And the electric stop clamp; the electric stop clamp includes a micro motor, which is fixedly connected with the shell, and the micro motor is used to drive the slide block of the stop clamp to move up and down. The clamp slider is plastic, and the plastic of the liquid stop clamp slider and the housing jointly complete the clamping of the infusion tube. The invention has high degree of automation, is convenient to use, can improve the working efficiency of users, and overcomes the shortcomings in the prior art.

Owner:ZHEJIANG MDKINGDOM TECH CO LTD

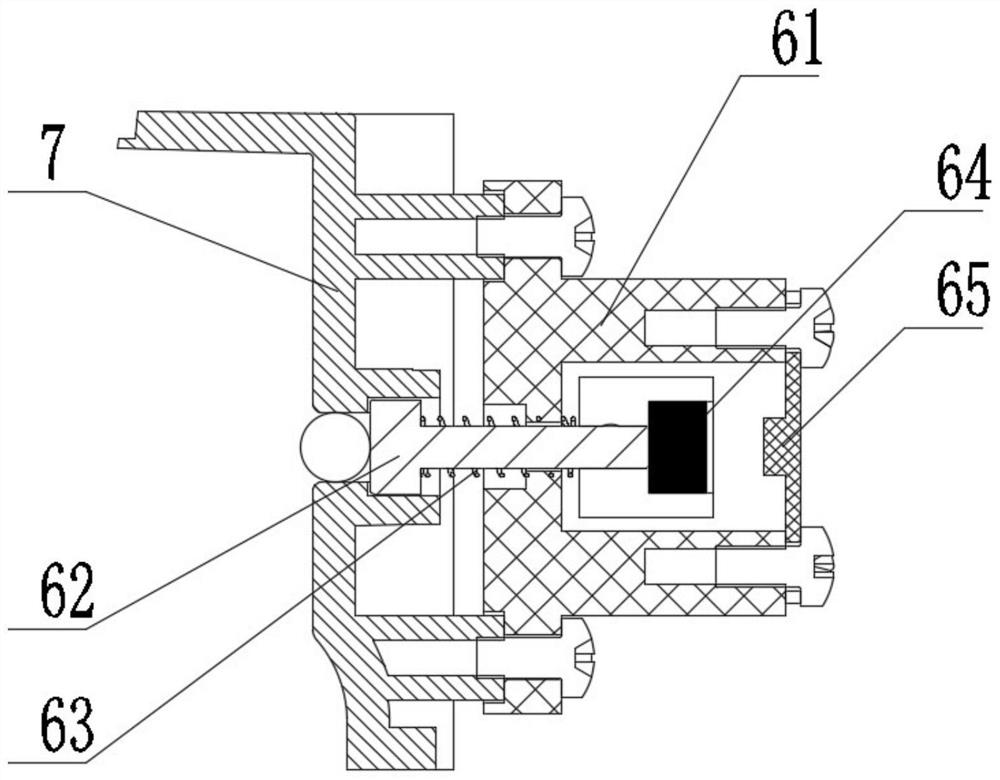

Sensing head drive

InactiveCN1155953CArrive quicklySimple manufacturing processRecord information storageDisposition/mounting of headsParticulatesEngineering

A pickup actuator having a base member as a fixed member, a lens holder as a travelling member, wherein a damping fluid is applied therebetween. The damping fluid damps a vibration occurring at the lens holder when the lens holder is driven. Here, the damping fluid has a viscosity ranging from 1000cP to 2000cP at 27 DEG C, in which magnetic particulates are stably dispersed. It is preferable that the damping fluid is magnetized to 100G SIMILAR 200G in a magnetic field of 3 SIMILAR 4k0e. When there occurs vibration at the lens holder by any reasons, such vibration is directly damped by the damping fluid applied between the base member and the lens holder.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com