Impressing device of photogravure press

A gravure printing machine, printing plate cylinder technology, applied in gravure rotary printing machines, printing machines, rotary printing machines, etc., can solve the difference between the amount of ink and the capacity of the mesh, the ink can not be completely transferred to the top, and the graphic printing is saturated To avoid problems such as color difference, to achieve the effect of avoiding color difference, convenient printing and adjustment machine operation, and large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

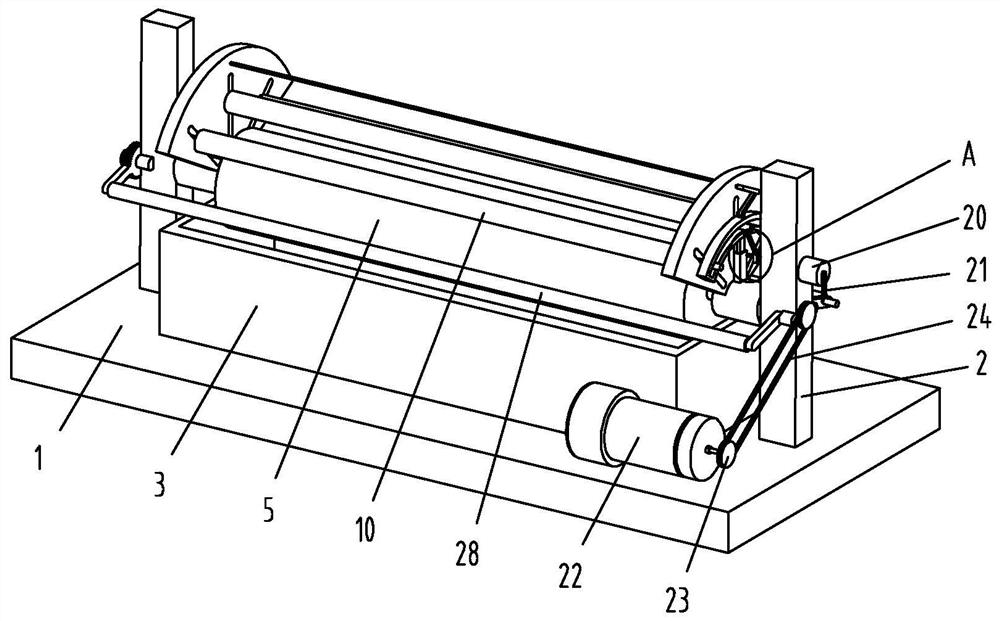

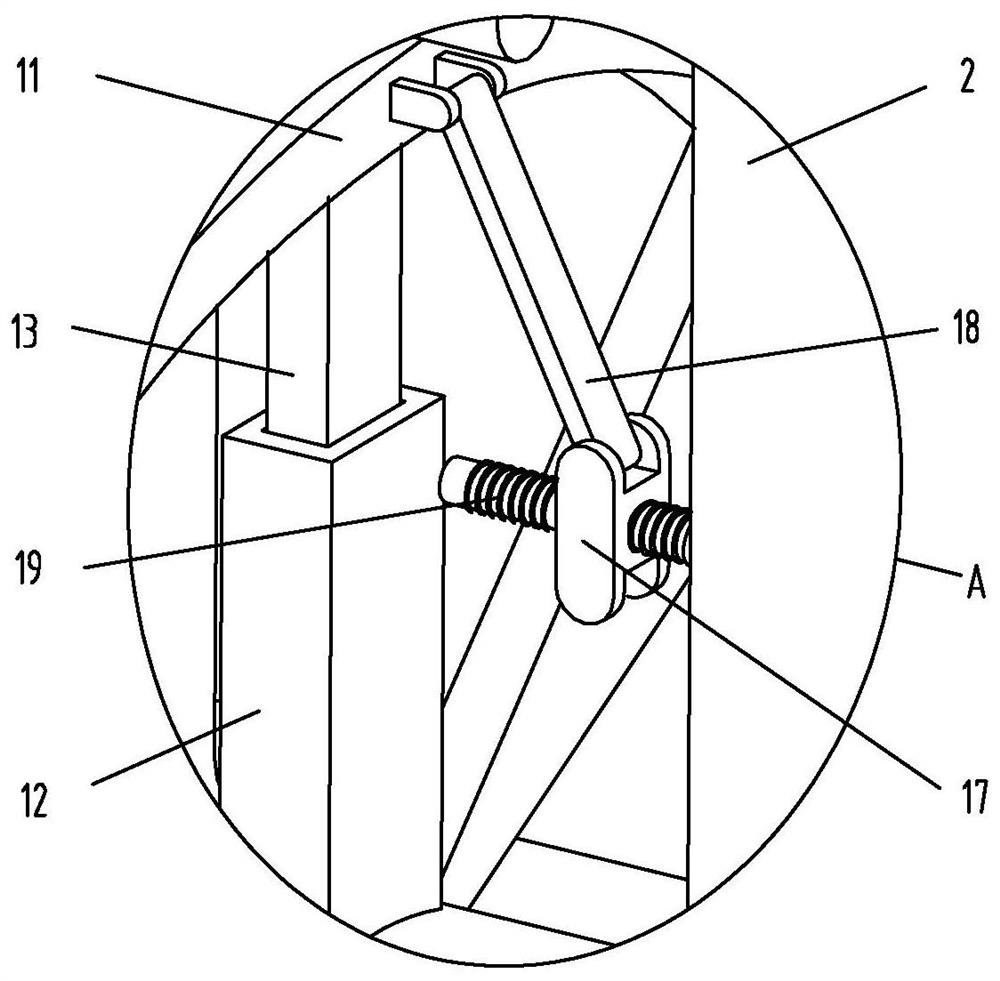

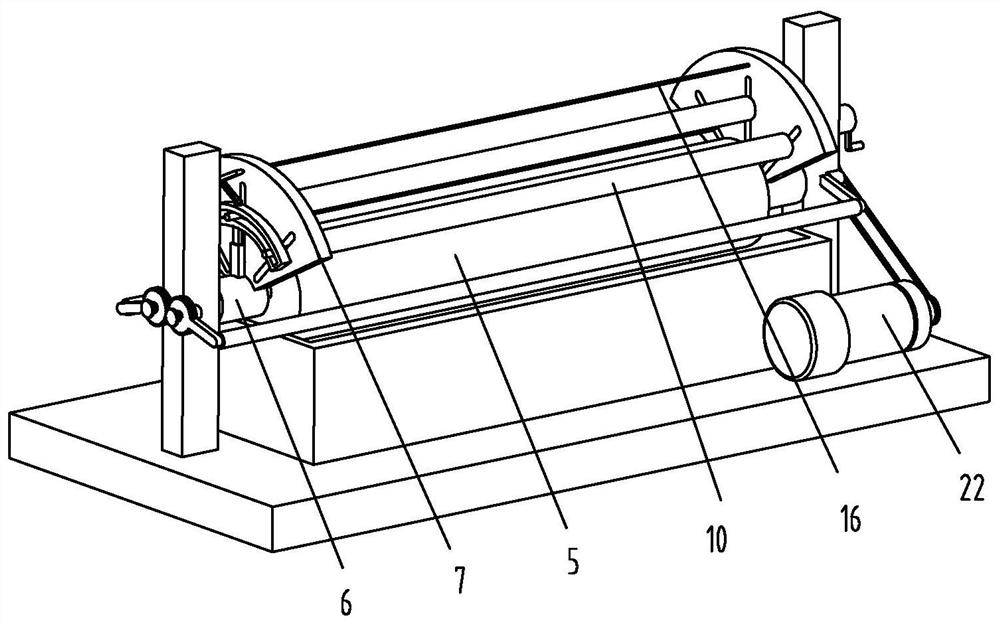

[0042] Example: Reference Figure 1-8 The embossing device of the gravure printing machine shown includes a bottom plate 1 . The base plate 1 may be any base structure in the prior art, such as a metal plate body.

[0043] Two support beams 2 are installed on the top side of base plate 1, and motor 22 is installed on the top side of base plate 1, and motor 22 can be any one in the prior art, and the output end of motor 22 is equipped with transmission shaft 4 by transmission mechanism, One end of the drive shaft 4 passes through one of the support beams 2 and is rotatably connected to one side of the other support beam 2 .

[0044] The support beam 2 is fixedly sleeved with a printing plate cylinder 5, which can be any one in the prior art, and the bottom side of the printing plate cylinder 5 extends into the ink tank 3 installed on the base plate 1, two One side of the support beam 2 is equipped with a fixed cylinder 6 movably socketed on the transmission shaft 4, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com