Marsh gas pool

A biogas digester and material pond technology, applied in the field of biogas digesters, can solve problems such as reduction, and achieve the effects of reducing losses, saving water, reducing depth and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

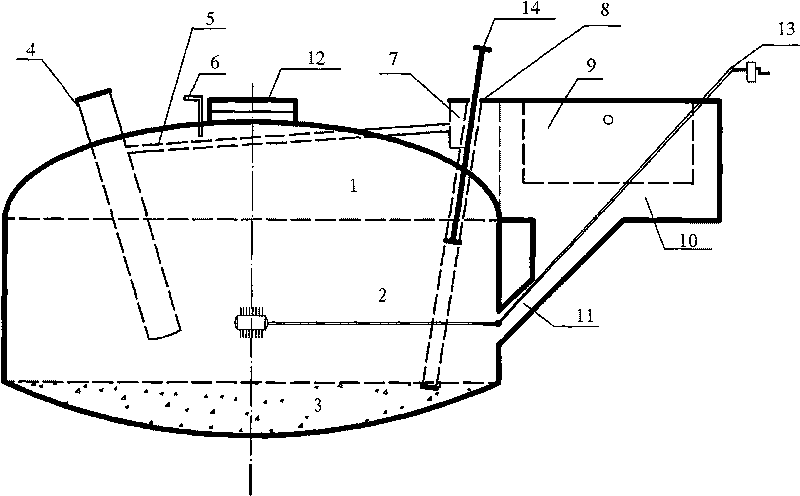

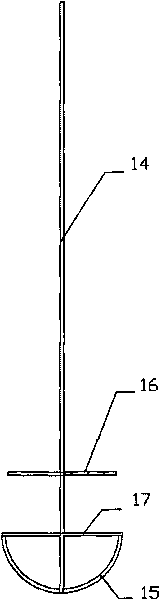

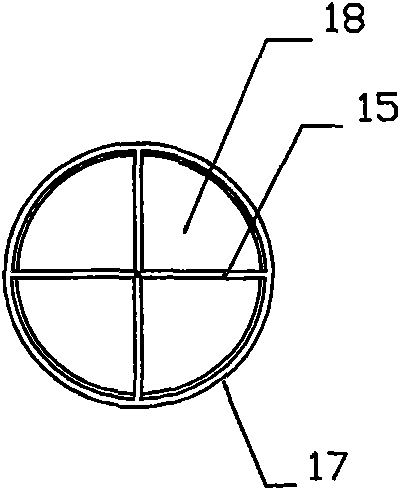

[0020] The present invention is illustrated below in conjunction with the accompanying drawings.

[0021] see figure 1 , above the bottom of the pool 3 of the present invention is a fermentation room 2, above the fermentation room 2 is a gas storage room 1, and the top shell above the gas storage room 1 is provided with a movable cover 12, an air guide pipe 6 and the bottom of the pool 3, The longitudinal axis of the main body of the biogas digester composed of the fermentation room and the gas storage room is a feed pipe 4 arranged obliquely. A water pressure room 10 is arranged outside the biogas digester main body. The lower bottom of the water pressure room 10 is provided with a connecting pipe 11 obliquely inserted into the fermentation room 2, and the connecting part of the connecting pipe 11 between the fermentation room and the tank bottom plane (i.e. figure 1 The part indicated by the dotted line in the middle) the distance is 80-100 cm. Depend on figure 1 It can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com