Finger-shaped turning down device for tyre molding machine

A technology of tire building machine and positive wrapping device, which is applied in the field of rubber machinery, can solve the problems of large main shaft load, low production efficiency, shaft holding, etc., and achieve the effects of reducing labor intensity, improving service life and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The finger-shaped wrapper for a tire building machine provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

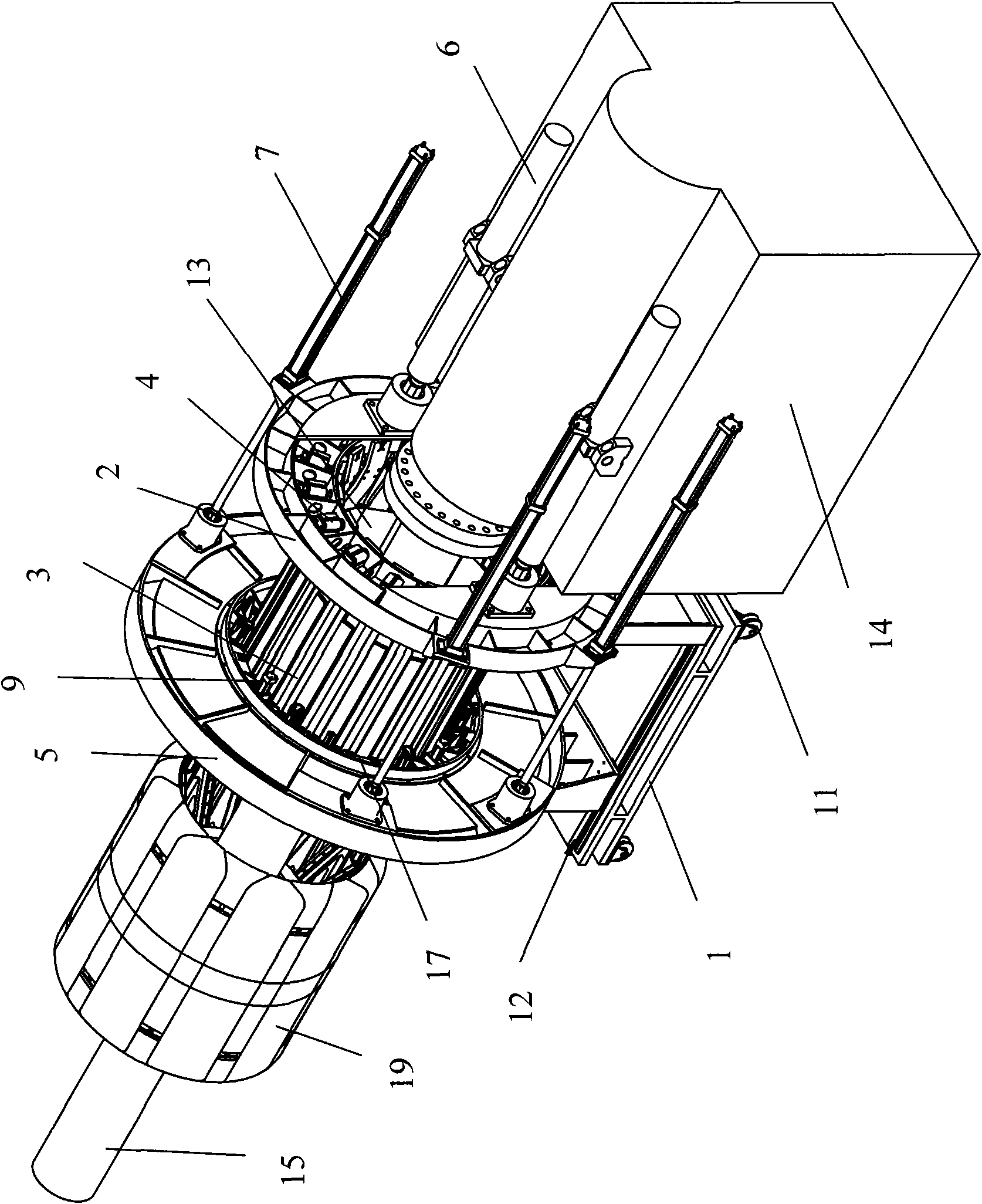

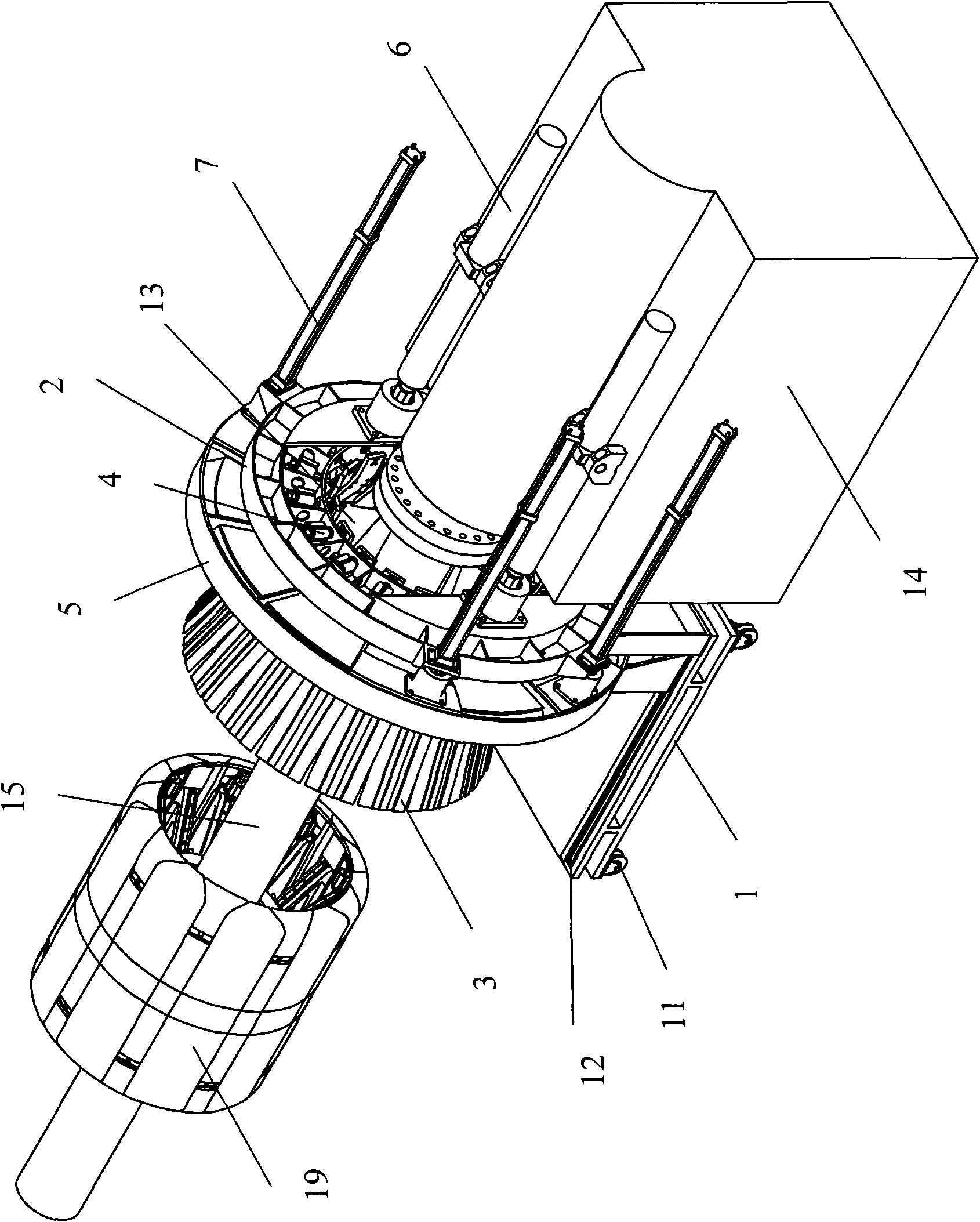

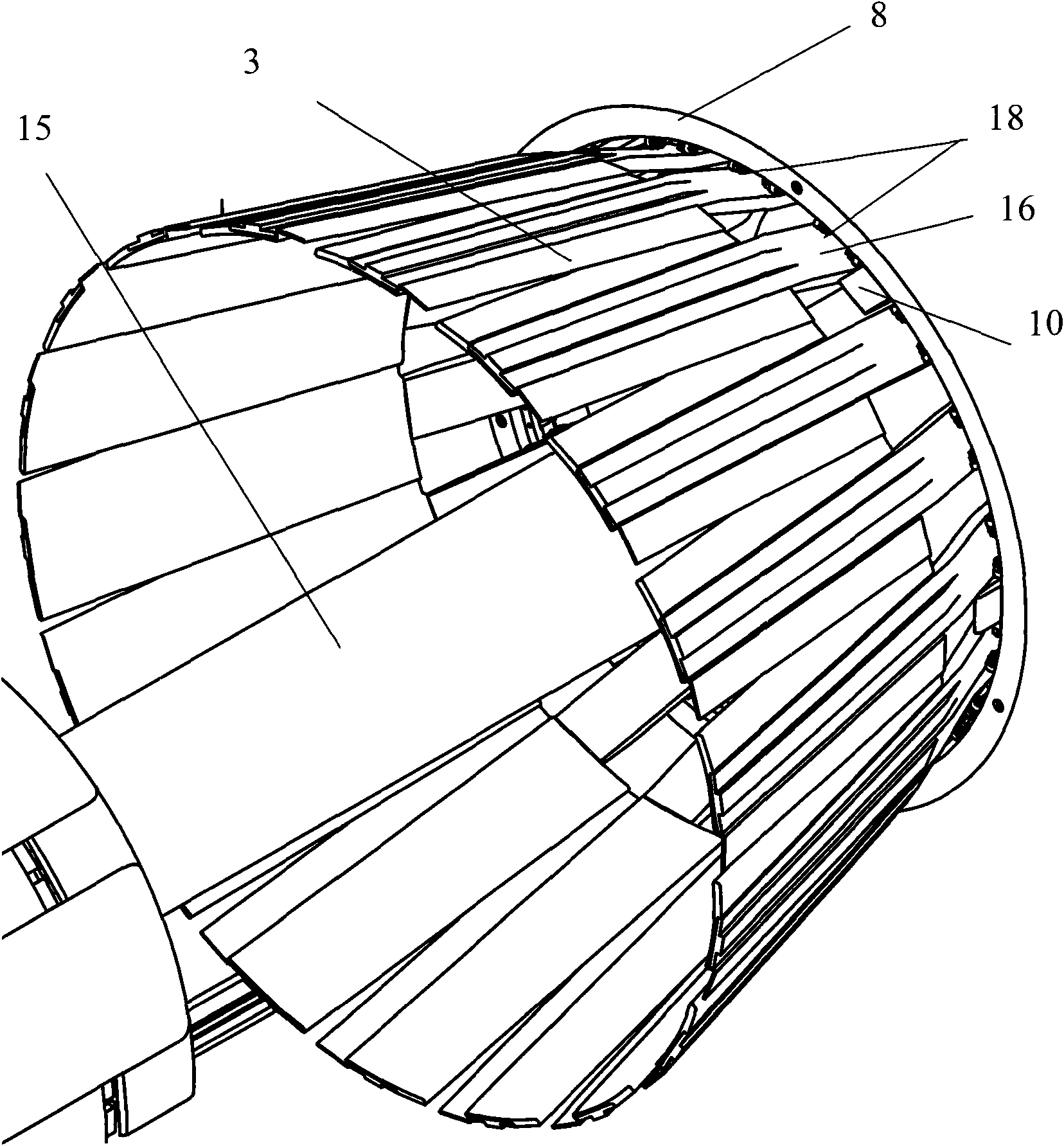

[0015] Such as Figure 1 ~ Figure 3 As shown, the finger wrapper for tire building machine provided by the present invention includes a base 1, a finger support 2, a plurality of fingers 3, a plurality of finger opening drive cylinders 4, a push plate 5, two Integral stroke oil cylinder 6, a plurality of positive package oil cylinders 7, buckle ring discs 8, a plurality of buckle ring oil cylinders 9 and a plurality of bead frames 10; the base 1 is horizontally arranged on the On the guide rail of the ground, while the surface is equipped with two parallel linear guide rails 12; The cylinder 13 of the shaft; the tail end of each finger 3 is inclined obliquely downward to form a bent part 16, and the ends of the bent parts 16 on all the fingers 3 are evenly installed on the fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com