Infusion system using automatic flow resisting valve as main body

A valve body and main body technology, which is applied in the field of infusion systems, can solve the problems of large space occupation and achieve the effects of small space occupation, easy manufacture and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

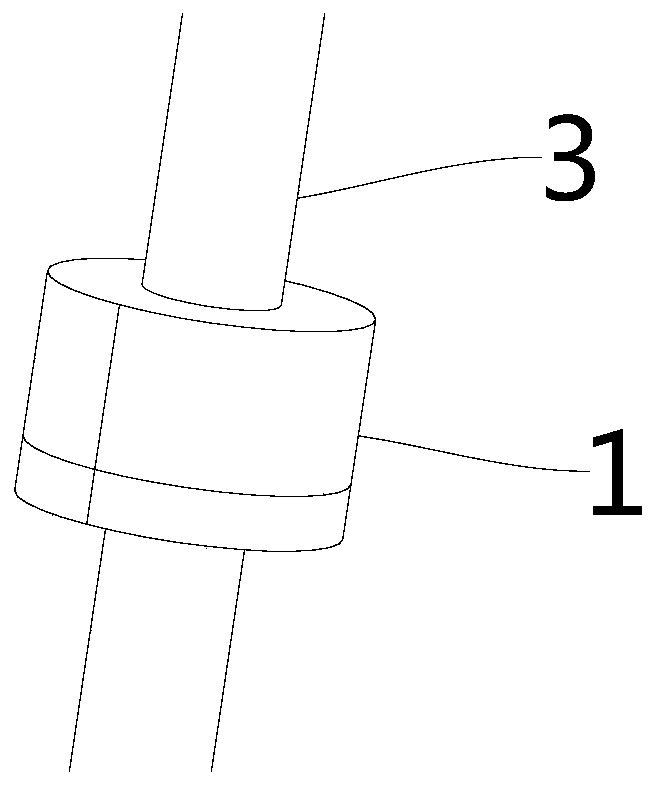

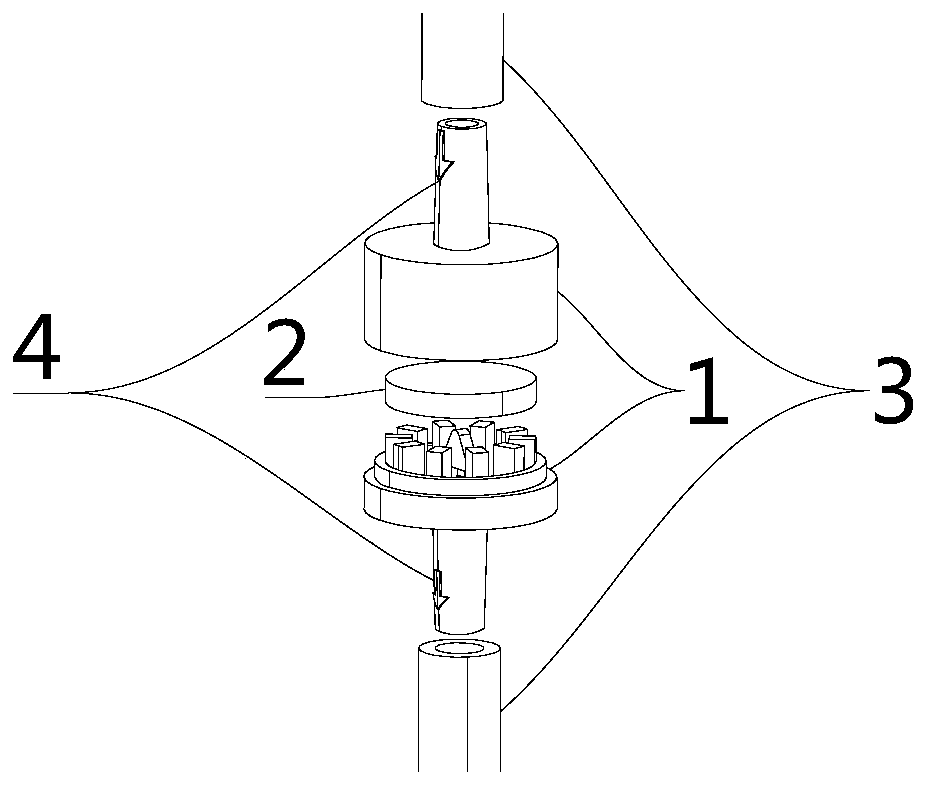

[0031] Such as Figure 1-5 Shown is an infusion system with an anti-flow valve as the main body, including an infusion pump and an infusion tube 3, and an anti-flow valve, which can be set at any position of the infusion tube. The anti-self-flow valve provides an initial pressure, so that the anti-self-flow valve is in a normally closed state that blocks the infusion of the infusion tube. Only when the infusion pump is working normally, the pressure provided by the infusion pump overcomes the initial pressure, so that the anti-self-flow valve is in the infusion tube. The open state of the infusion. Among them, the anti-free flow valve includes a valve body 1 and a valve core 2. The valve body 1 includes a valve body cavity, the valve body 1 is arranged between the infusion tube 3, the upper and lower end surfaces of the valve body 1 are respectively communicated with the infusion tube 3, and the liquid can circulate in the valve body 1. The valve core 2 is arranged in the inne...

Embodiment 2

[0033] Such as Figure 2-5 As shown, the valve body 1 is cylindrical, the inner cavity of the valve body is cylindrical, and the valve core 2 is disc-shaped. The diameter of the valve core 2 is smaller than the diameter of the inner cavity of the valve body. The axis of the valve core 2 coincides with the axis of the valve body 1. A boss 6 extends in the radial direction and then along the axis of the valve core 2 around the liquid inlet at the liquid inlet end of the valve body cavity. Between the boss 6 and the valve core 2 is formed a liquid inlet isolated from the valve body cavity. The chamber 7, the boss 6 and the valve body 1 are integrally formed, and the valve core 2 is made of silicone material with certain elasticity. Further, the cross section of the boss 6 is ring-shaped and forms a cylindrical liquid inlet chamber 7 with the valve core 2. The end surface of the boss 6 close to the valve core 2 is set as a curved surface, so that the contact mode of the boss 6 a...

Embodiment 3

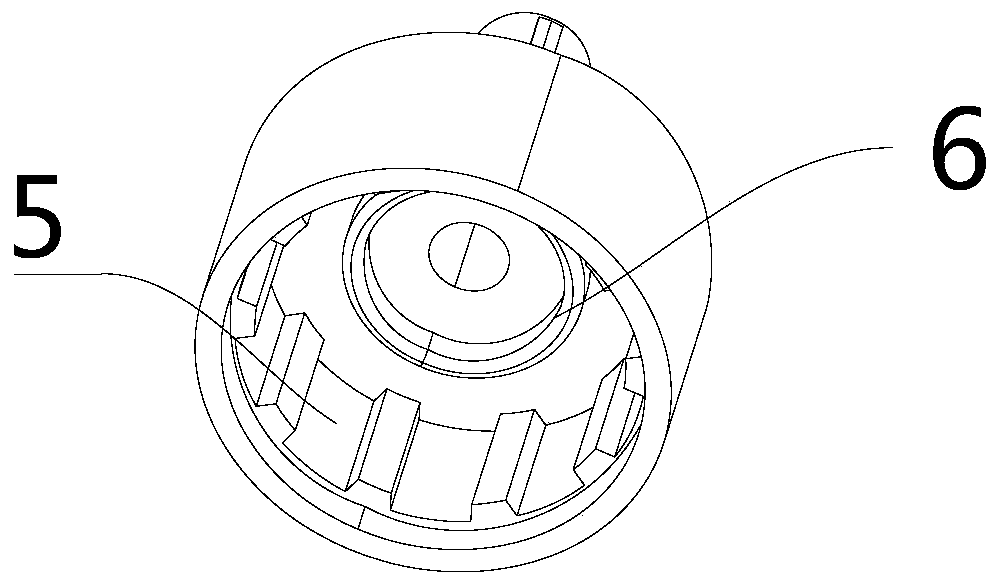

[0035] Such as image 3 As shown, the difference between this embodiment and Embodiment 2 is that the diameter of the valve core 2 in this embodiment is equal to the diameter of the inner cavity of the valve body, so that the liquid medicine is blocked by the valve core 2 and cannot be conducted. Therefore, it is necessary to provide a groove 5 on the side surface of the valve body cavity to allow the liquid medicine to flow to the valve body cavity through the groove 5. Further, the cross section of the groove 5 is a trapezoid, and a plurality of grooves 5 are evenly arranged along the circumferential direction of the side surface of the inner cavity of the valve body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com