Pump

a technology of pump and pump body, applied in the field of pumps, can solve problems such as the difficulty of pumping efficiently using other types of pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

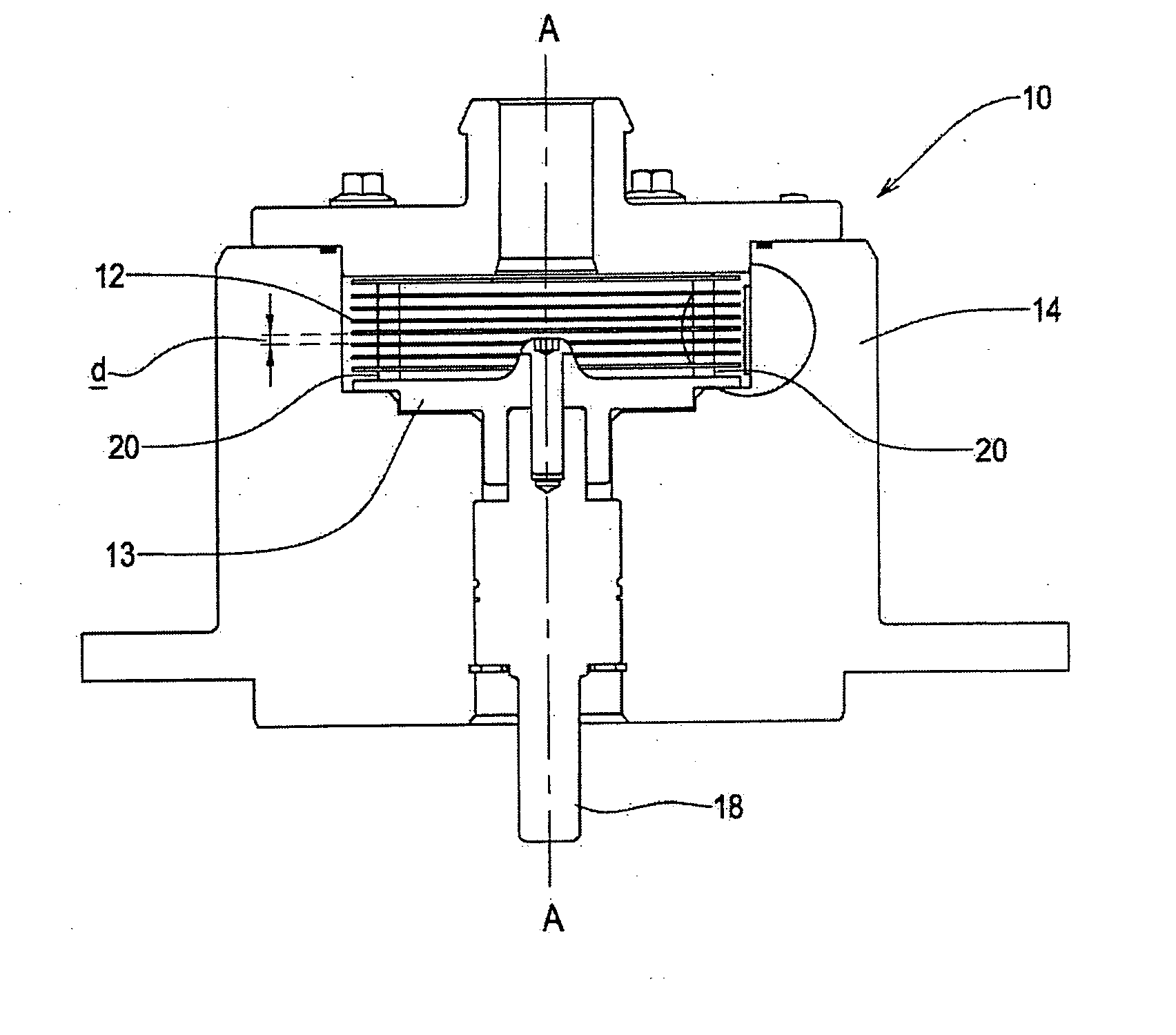

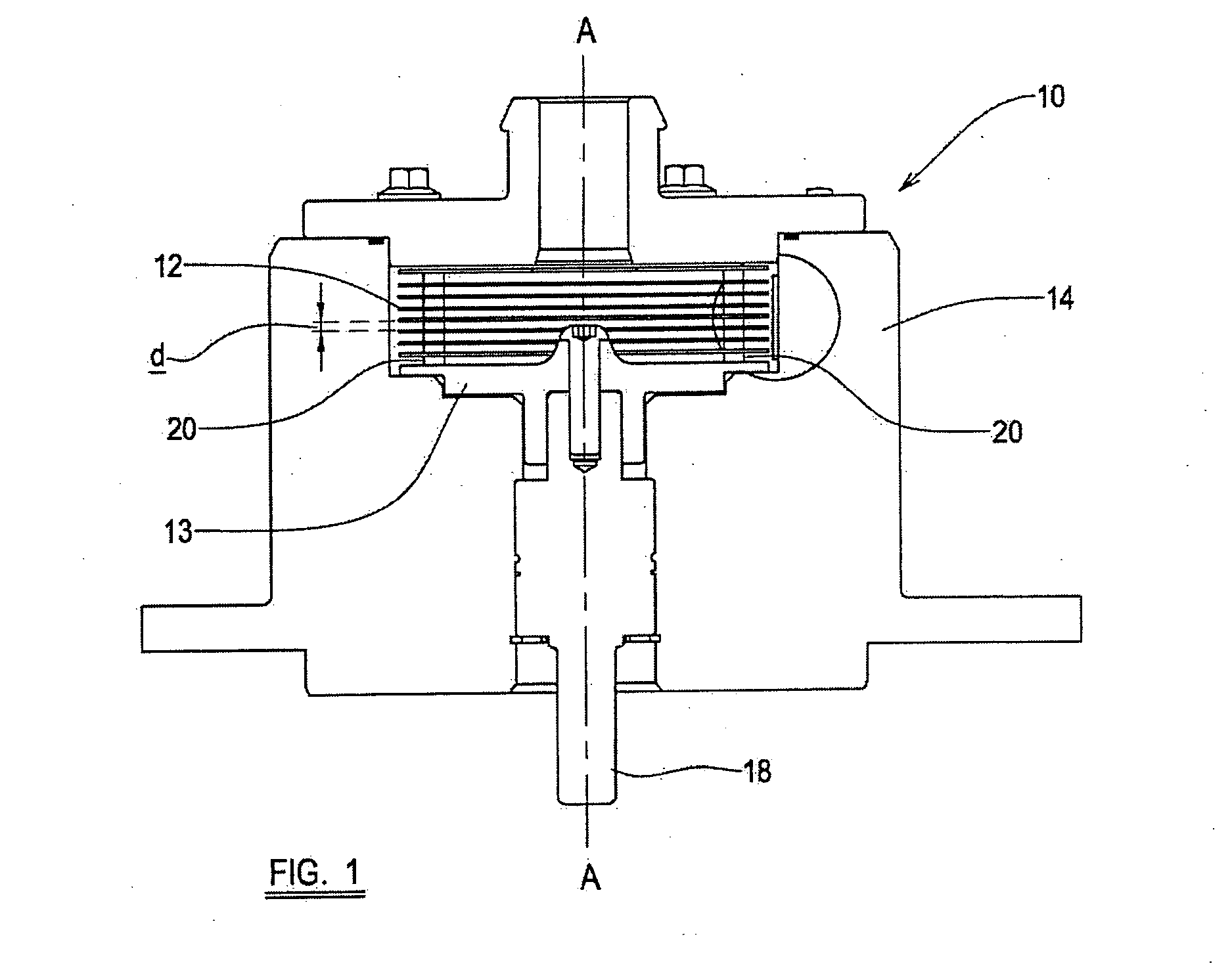

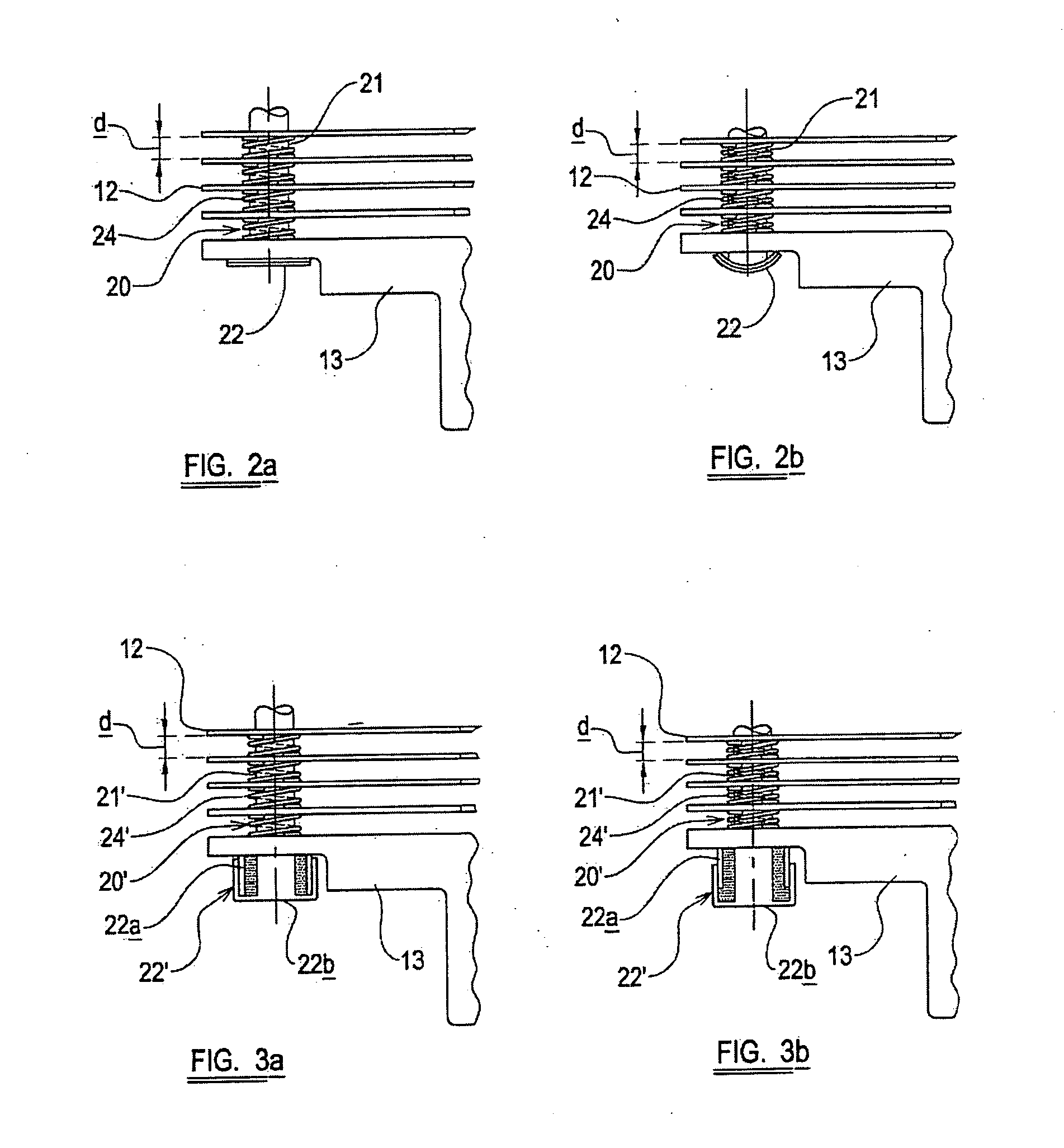

[0028] Referring now to FIG. 1, there is shown a pump 10 including a plurality of spaced apart generally mutually parallel plates 12, which in this example are generally circular discs. The discs 12 are supported on a base plate 13, and mounted for rotation in a housing 14 about an axis A which extends generally normal to the discs 12, to effect pumping of a fluid within the housing 14, from an inlet to an outlet provided in the housing 14. Rotation of the discs 12 is achieved by the operation of a driving means (not shown), in this case an electric motor, which is connected to the base plate 13 by means of a drive shaft 18.

[0029] Pumping of fluid within the housing 14 is achieved as follows. When a fluid enters the housing 14 via the inlet, a layer of fluid adheres to the surfaces of the discs 12, forming a so-called boundary layer that remains stationary relative to the rotating discs 12. As the discs 12 rotate about axis A, the effects of boundary-layer adhesion and viscous drag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com