Production method for improving wearing resistance of plasma arc surfacing

A technology of plasma arc and production method, which is applied in the production field of improving the wear resistance of plasma arc surfacing welding, can solve the problems of rising surfacing welding costs, limiting the application and promotion of inventions, etc., so as to improve physical properties, refine the structure, and improve the overall The effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

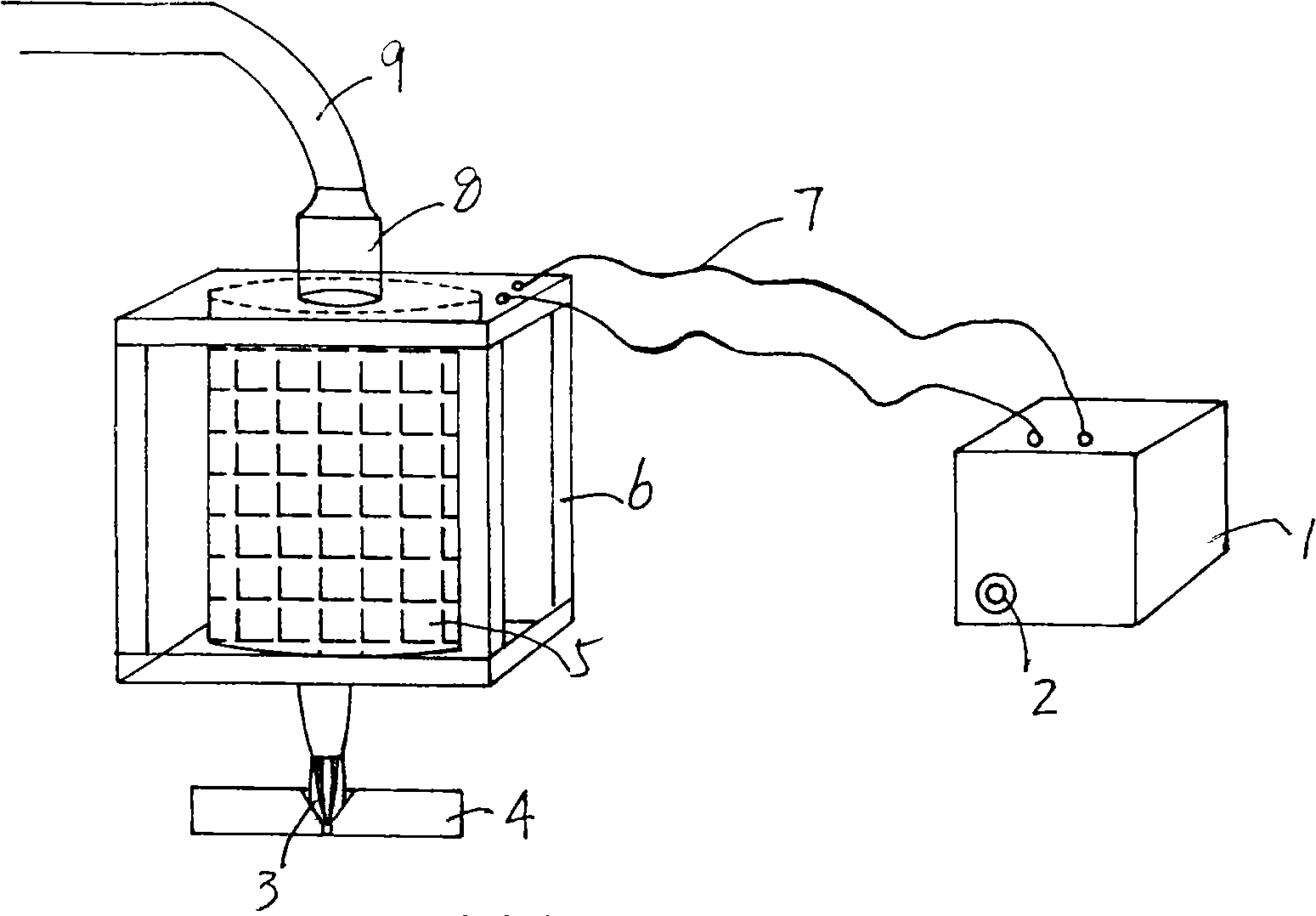

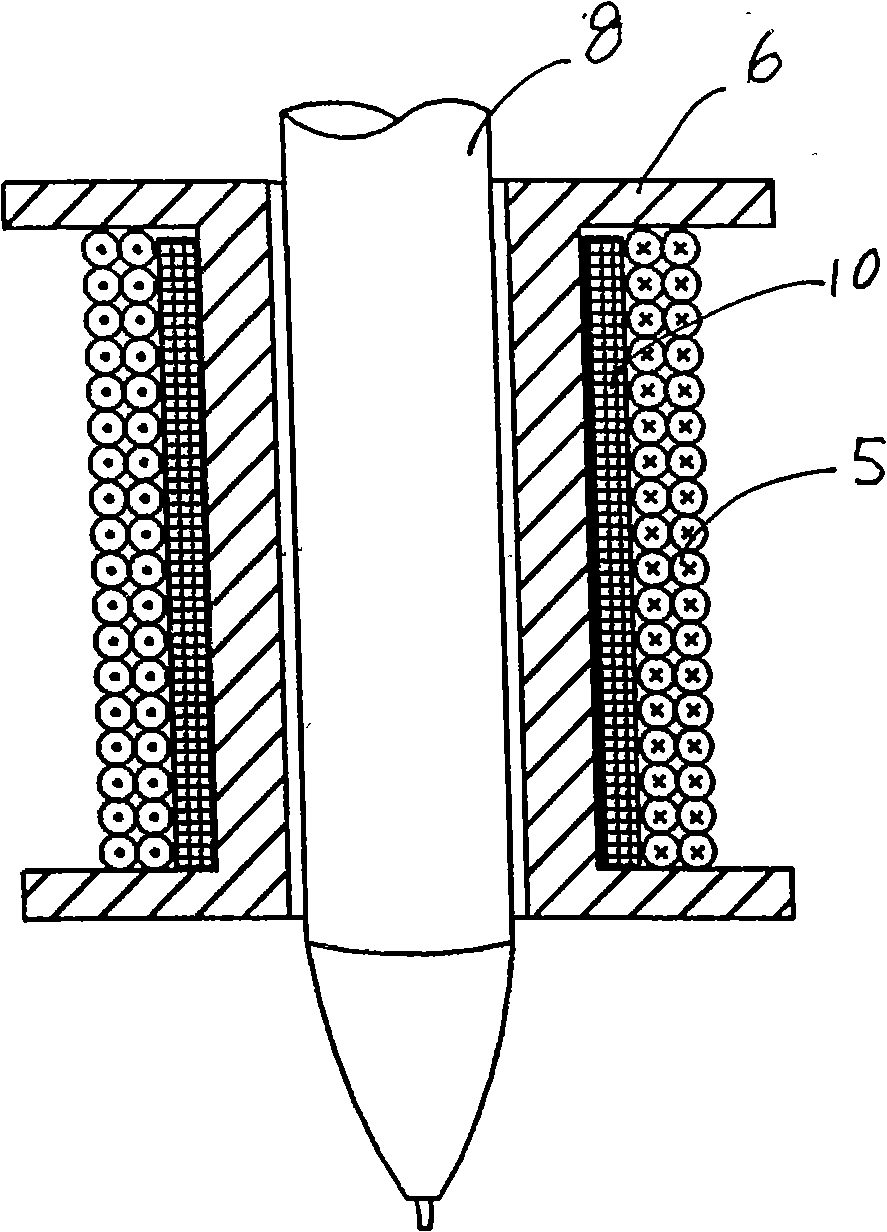

[0010] The present invention includes a power supply device 1, which is connected with a coil 5 in a supporting frame 6 through a wire 7;

[0011] A silicon steel sheet 10 can be arranged in the coil 5; thereby increasing the strength of the magnetic field.

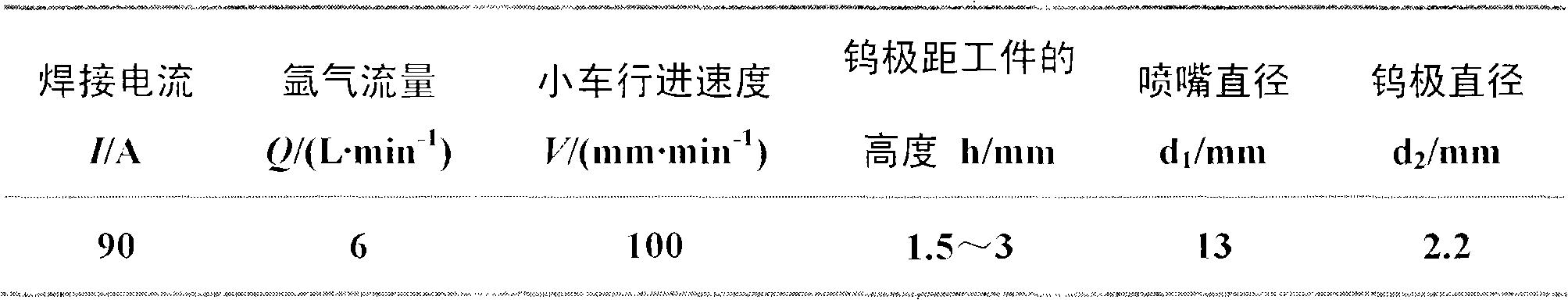

[0012] The coil 5 is placed on the outer surface of the plasma arc welding torch 8 connected to the cable 9 and fixed on the corresponding feeding device with the support frame 6. The whole of the coil 5 of the present invention is placed directly above the workpiece 4, and two adjustments are made as required. the distance between them. When in use, first connect the power supply device 1 of the welding machine equipment, start the welding machine, then turn on the switch 2 of the magnetic field power supply device 1 to energize the coil 5 and generate a corresponding magnetic field, and then let the plasma arc welding torch 8 contact the workpiece 4 to start the arc 3. Then the workpiece 4 is welded by moving the plasm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com