Workstation structure for improved vertical grinder

A vertical grinding machine and worktable technology, used in grinding machines, manufacturing tools, metal processing equipment, etc., can solve the problems of poor structure rigidity, small bearing capacity, easy bearing wear, etc. of the worktable, and achieve the effect of stable rotation and rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

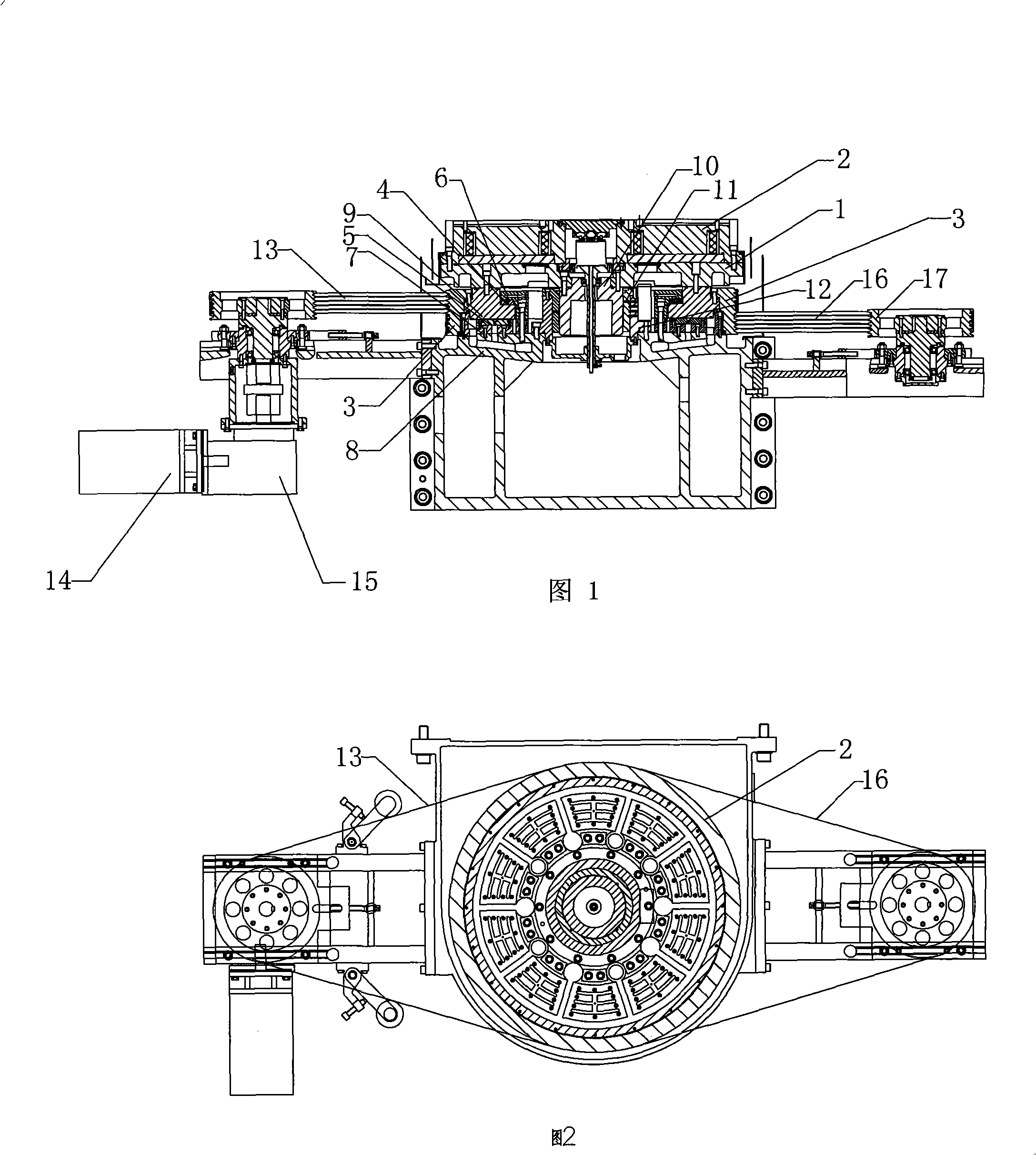

[0009] See Fig. 1, Fig. 2, the present invention comprises connecting plate 1, electromagnetic sucker 2, pulley 3, connecting plate 1 is installed with electromagnetic sucking cup 2, connecting plate 1 is installed on connecting ring 9, connecting ring 9 is installed on bed 8 through support, here The support is a closed static pressure guide rail, and the outer sleeve of the adapter ring 9 is equipped with a pulley 3. The central bottom of the adapter plate 1 is installed on the bed 8 through the support. This support is a radial static pressure bearing. The closed static pressure guide rail support includes The upper support block 4, the lower support block 5, the upper part of the upper support block 4 is press-fitted with a pressure ring 6, the pressure ring 6 is connected with the bed 8, the lower support block 5 is connected with the pad 7, and the pad 7 is connected with the bed 8 There is a pressure oil chamber between the upper support block 4, the lower support block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com