Device for adjusting knife door of numerical control hydraulic double-clamp veneer lathe

A technology of adjusting device and rotary cutting machine, which is applied in the manufacture of thin wood chips, wood processing appliances, manufacturing tools, etc., can solve the problems of low work efficiency, low adjustment precision, troublesome operation, etc., and achieves high work efficiency and high adjustment precision. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

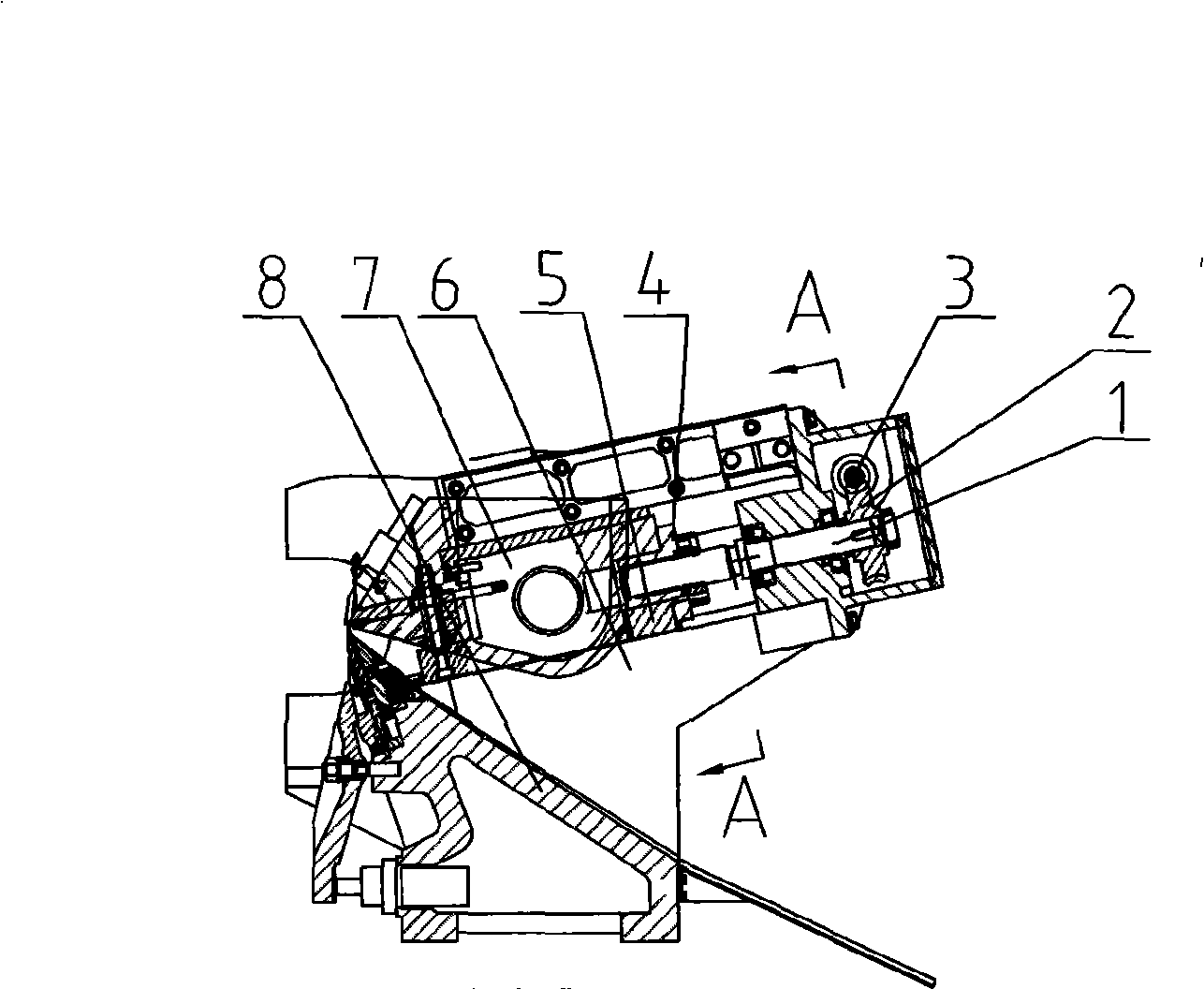

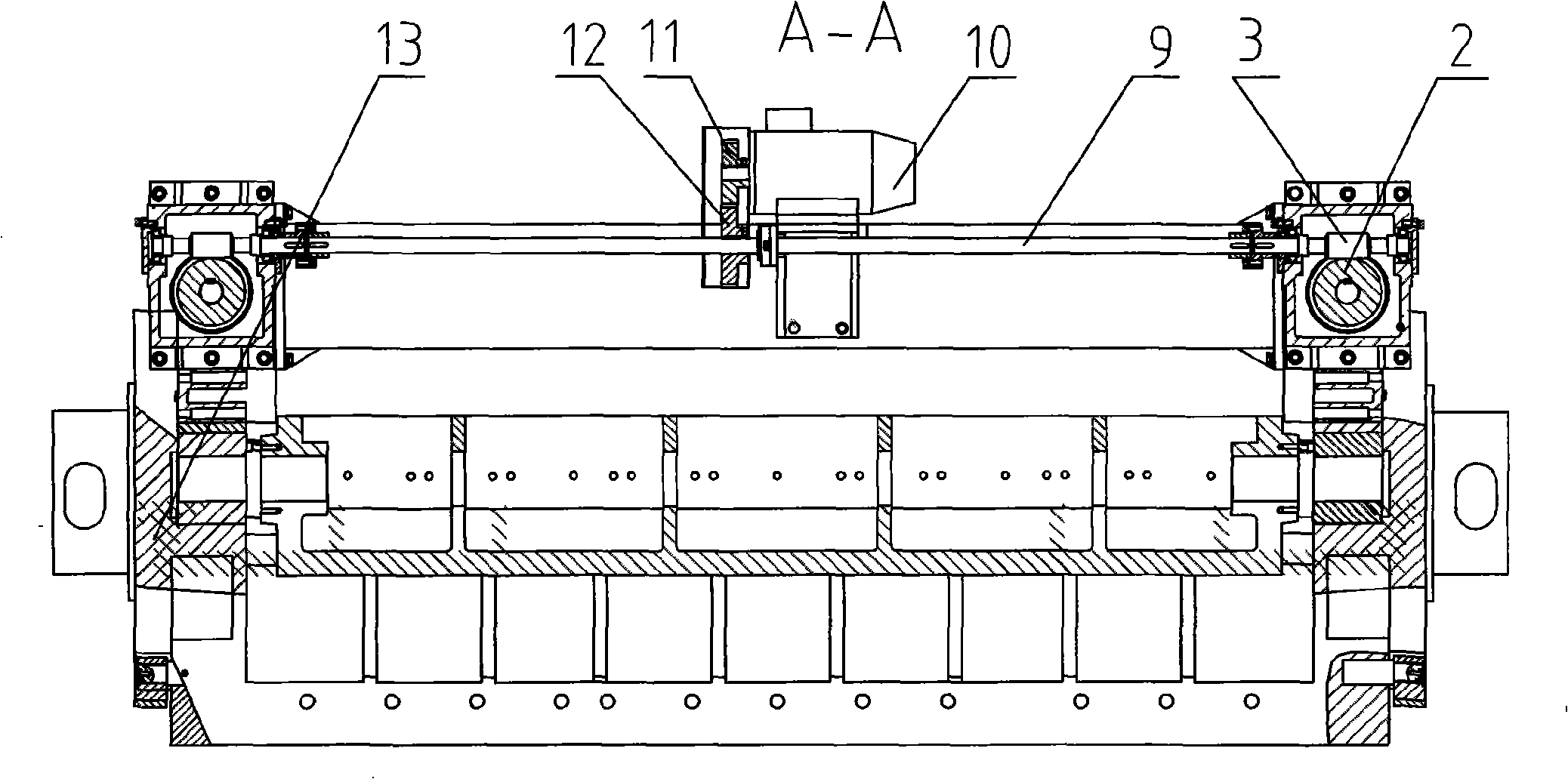

[0010] As shown in the figure, the knife door adjustment device of the CNC hydraulic double card shaft rotary cutter has a knife rest body 8 on the body 13, a guide rail 6 on the top of the knife rest body 8, a slide seat 5 on the guide rail 6, and a slide seat 5 on the guide rail 6. A pressure ruler frame 7 is provided on the top, and a servo motor 10 is provided on the body 13, and the servo motor 10 is connected with a leading screw 1, and the leading screw 1 is provided with a nut 4, and the nut 4 is connected with the sliding seat 5. As can be seen from the figure, the servo motor 10 is provided with a driving wheel 11, and one side of the servo motor 10 is provided with a transmission shaft 9, and the transmission shaft 9 is provided with a driven wheel 12, and the driving wheel 11 is meshed with the driven wheel 12, and the transmission shaft 9 one end is provided with worm screw 3, and worm screw 3 is provided with turbine 2, and turbine 2 is connected with lead screw 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com