Electronic thermostat

A thermostat and electronic technology, which is applied in the direction of machine/engine, coolant flow control, engine components, etc., can solve the problem that the intake air temperature cannot be considered comprehensively, so as to reduce CO and HC emissions, reduce smoke and dust emissions, reduce The effect of fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

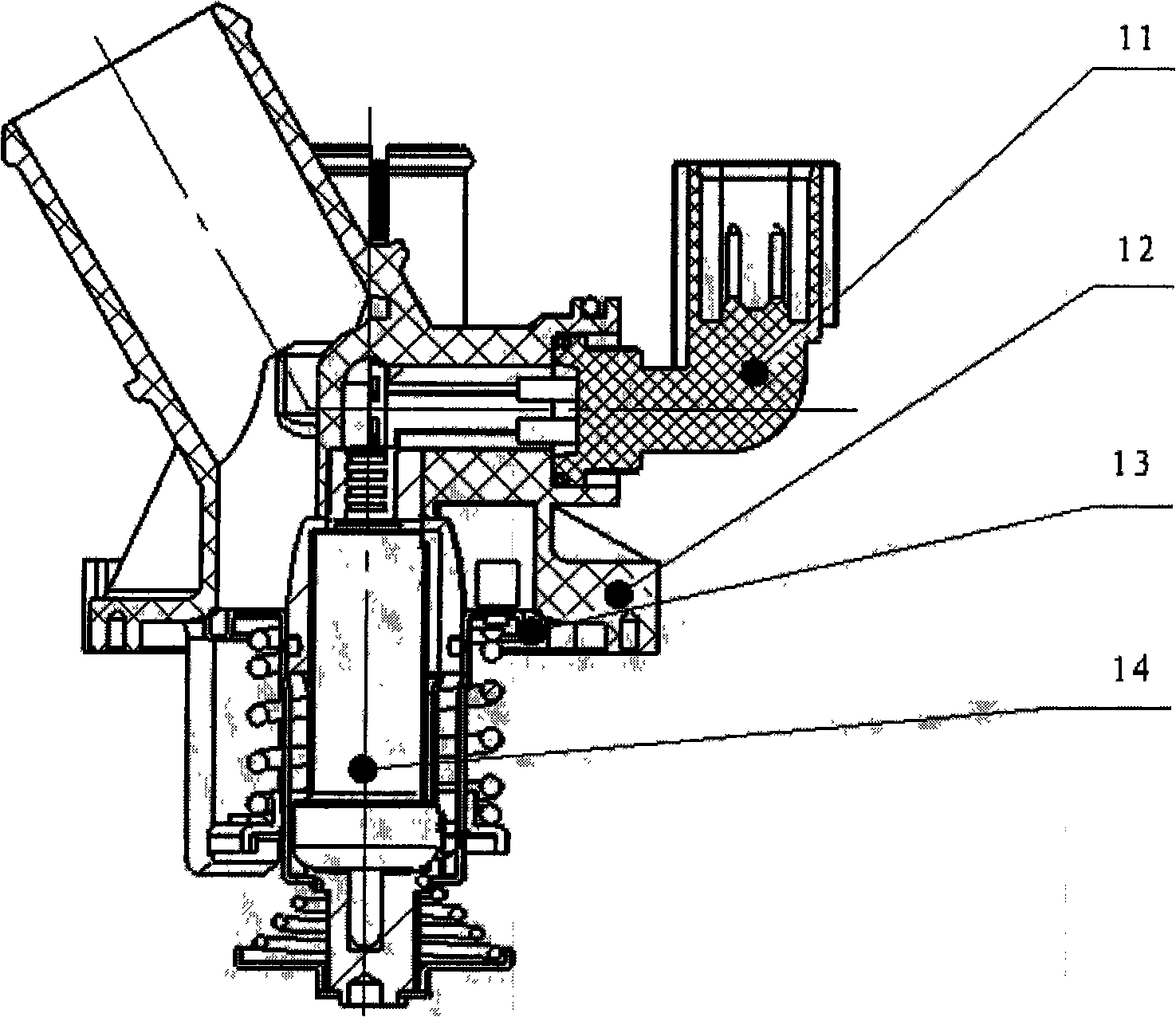

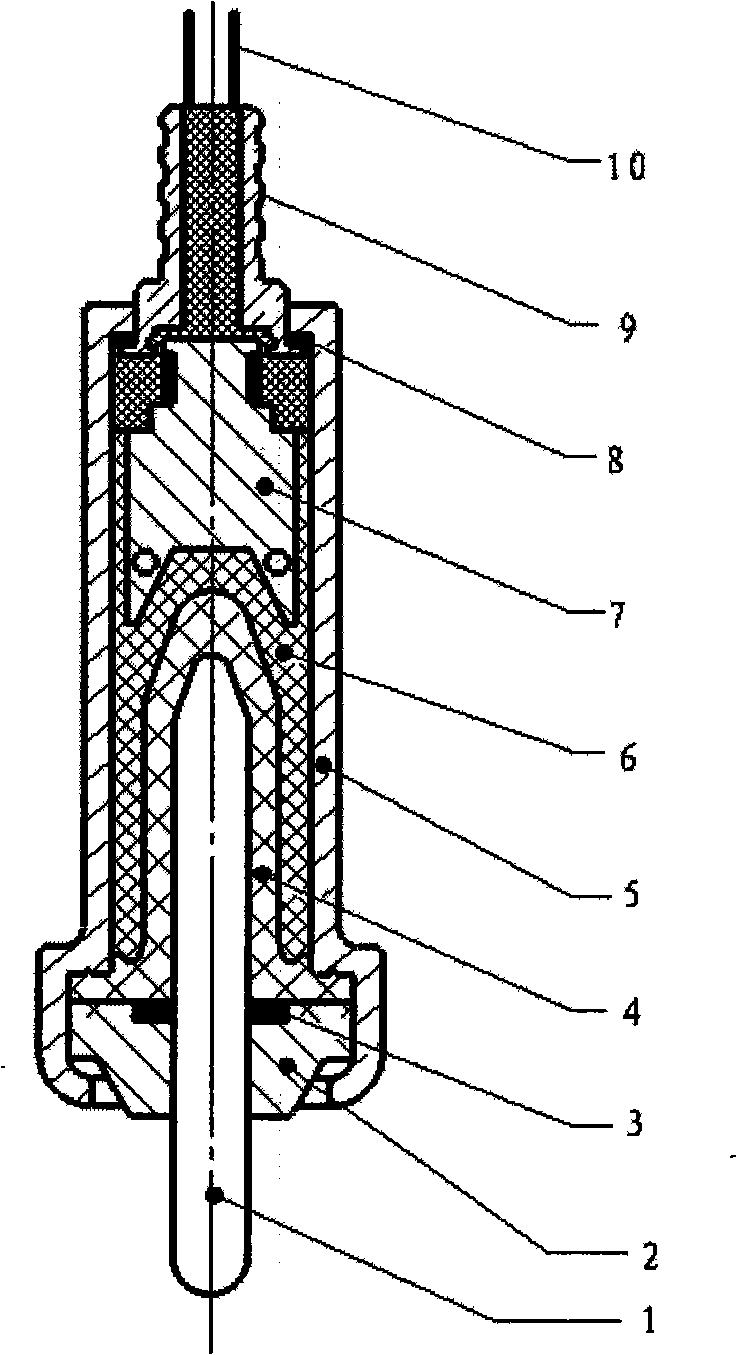

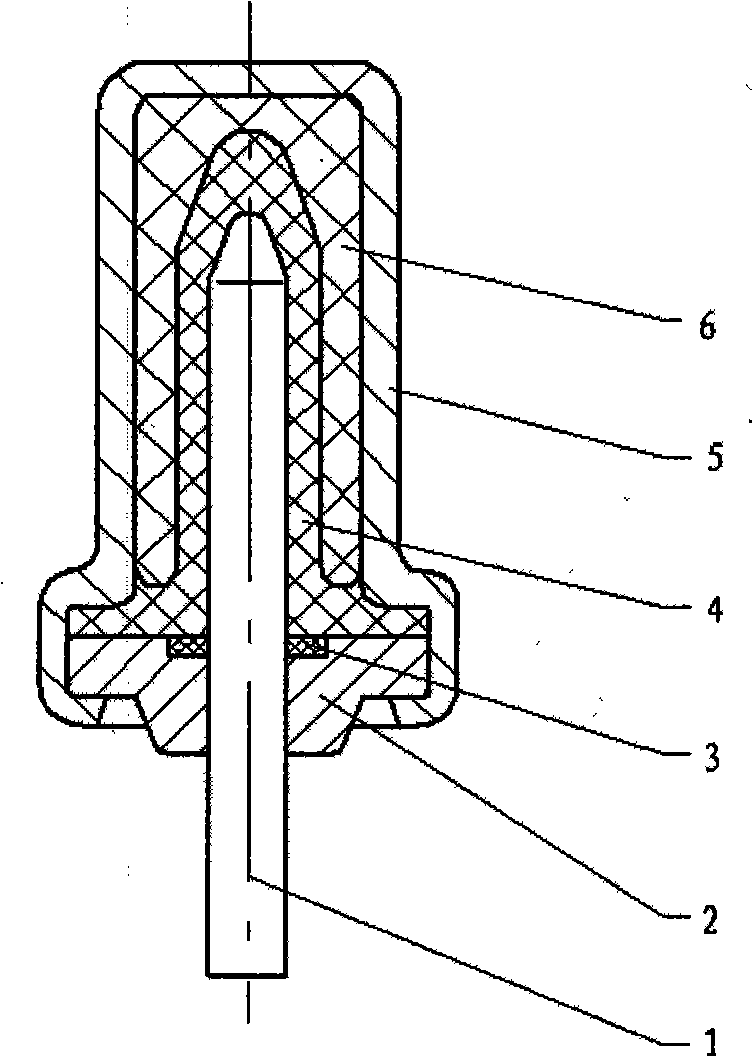

[0017] Such as figure 1 , 2 As shown, the electric heating element 7, the wire 10, and the tail handle 9 are injected together to form the electric heating element assembly. Then, the electric heating element assembly is pre-embedded in the body 5, and the electric heating element assembly and the body The junction of 5 is sealed with a graphite sealing gasket 8 to ensure the tightness of the product. Then the wax pill 6, the rubber hose 4, the sealing ring 3, the gland 2, and the push rod 1 are sequentially assembled into the body 5, and the parts are fixed together by the riveting process. The wire 10 is drawn out from the tail handle at the bottom of the induction body assembly 14, passes through the wire cavity that is integrated with the cavity, and is connected to the insert on the socket assembly 11 that is connected to the outside of the cavity assembly 12; the tail handle 9 and the wire cavity are sealed by a rubber sealing washer 8, and the socket assembly is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com