Oil-immersed type transformer for hatch winding iron core

A technology of oil-immersed transformers and coiled iron cores, which is applied in the field of transformer manufacturing, can solve the problems of low performance of laminated iron-core oil-immersed transformers, and achieve strong resistance to sudden short-circuits, reduced noise, and short magnetic circuits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] specific implementation plan

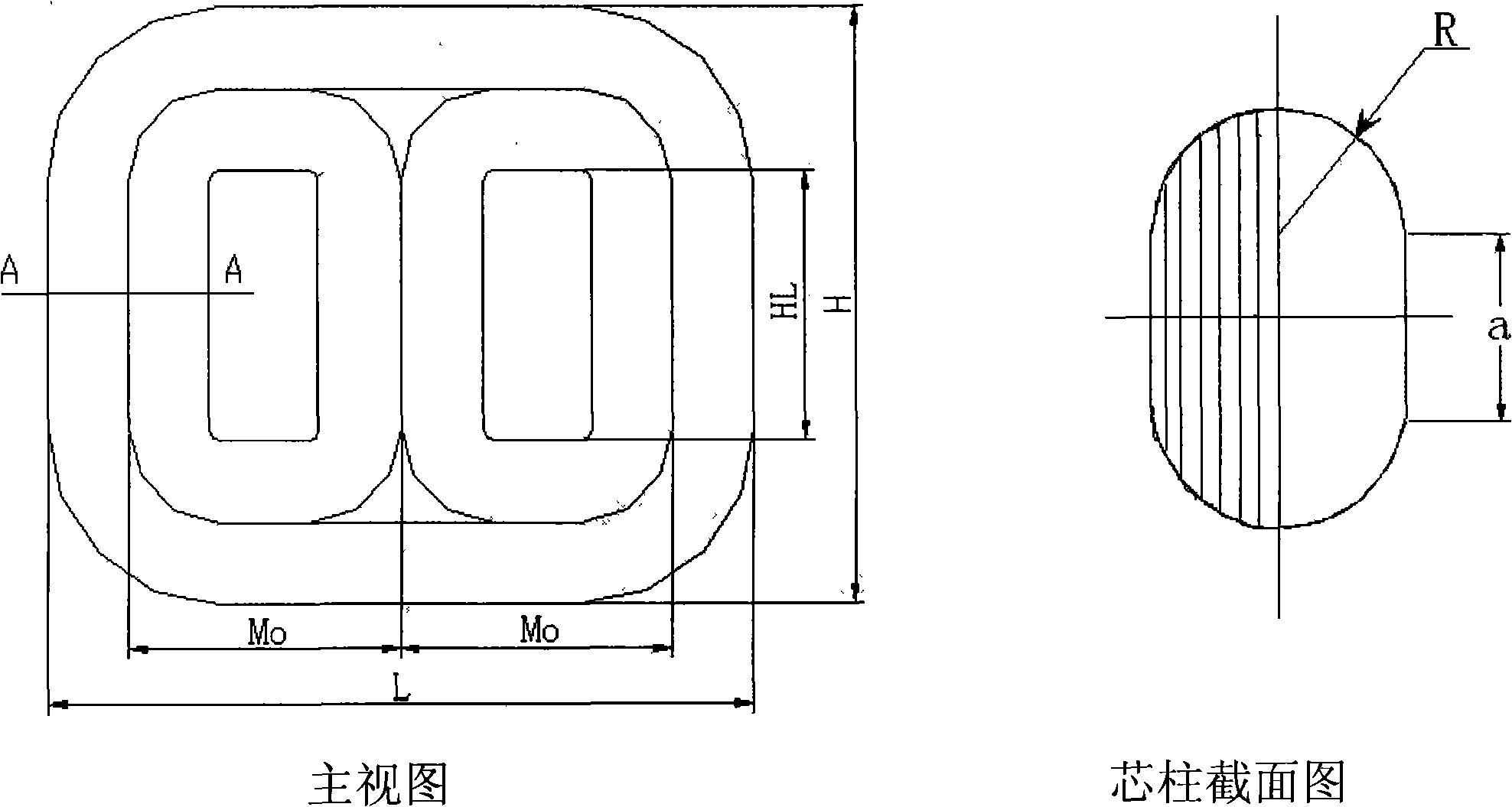

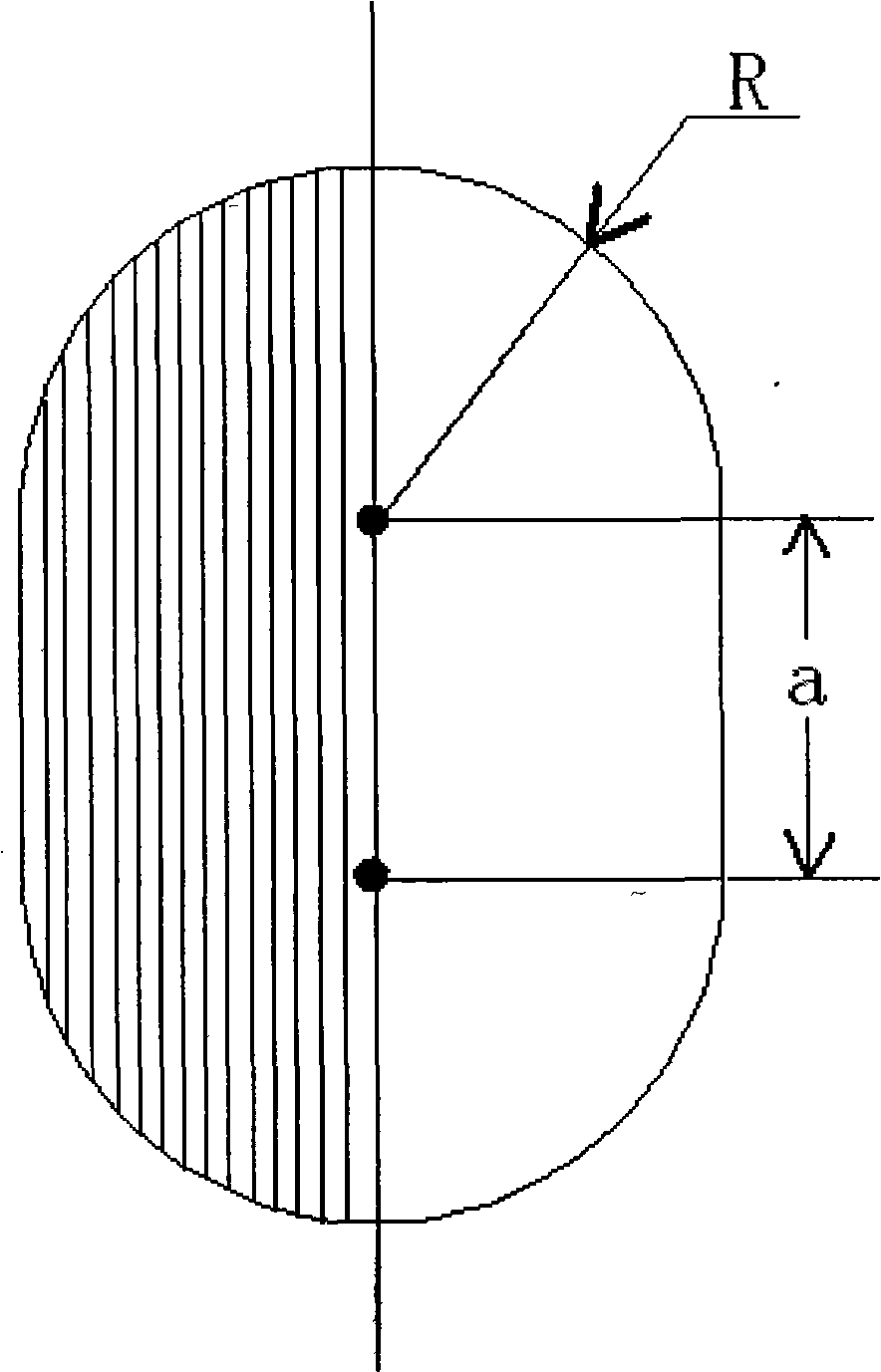

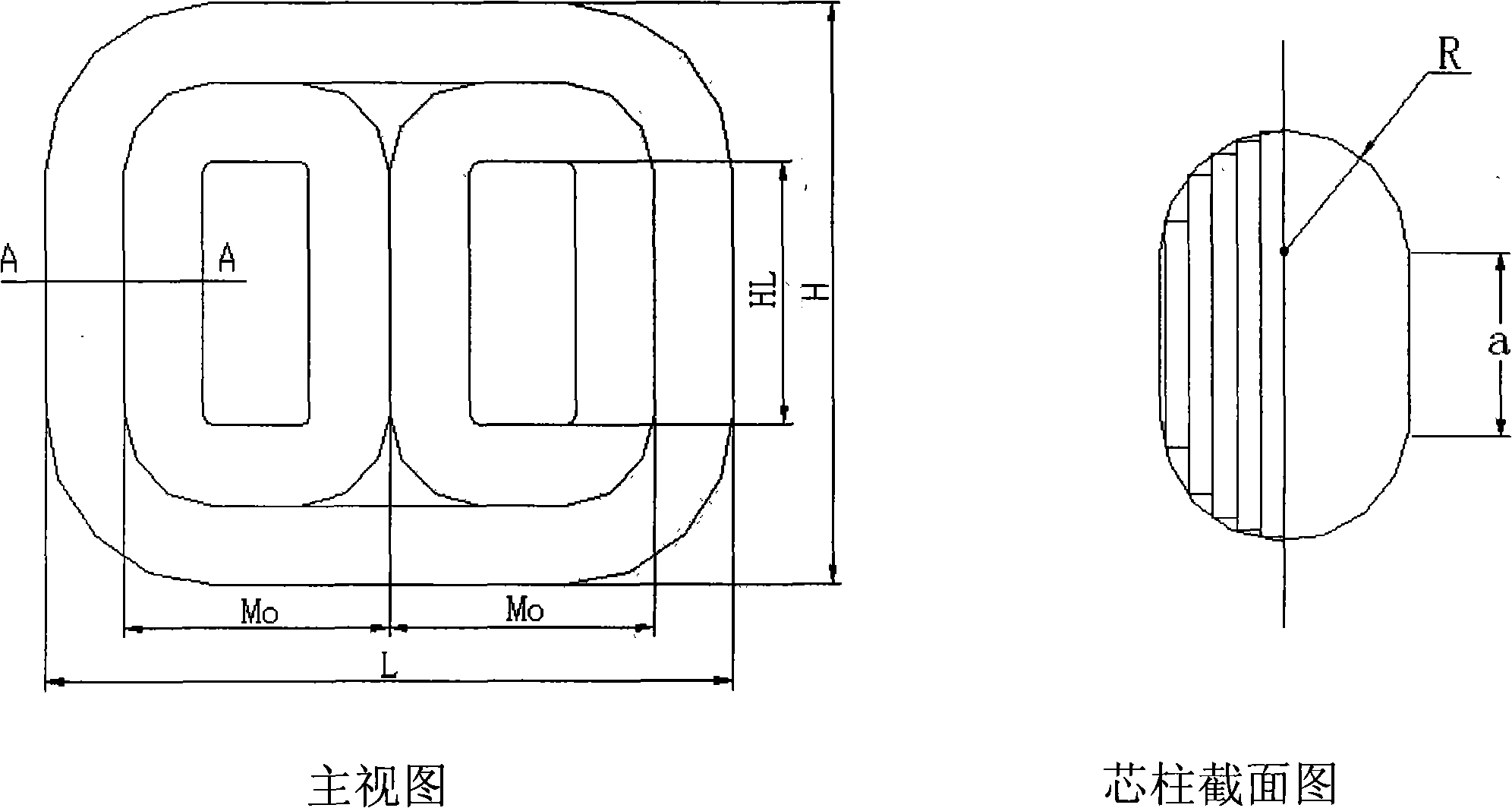

[0023] see Figure 5 , the transformer core is composed of two single-phase open coil cores (1) and (2) with a "mouth" shape and a concave semi-oblate cross section placed side by side to form a horizontal "day" shape rectangle. As for the frame body, the other cross-section is a single-phase open-rolled iron core rectangular frame body (3) with a convex semi-oblate circular shape that wraps (1) and (2) inside. see figure 2 , the cross-sections of the three core columns of the iron core are composed of two concave semi-oblate circles and one convex semi-oblate circle to form an oblate circle, and the cross-sections of the three core columns of the assembled iron core are all oblate circles . The three single-phase iron cores used to wind the entire iron core are all formed by continuous winding of silicon steel strips after cutting, instead of cutting the wound iron cores layer by layer. see image 3 , if the cross-sectional shape of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com