Packaging method and system of electric component

A technology of electrical components and installation methods, which is applied in the direction of electrical components, electrical components, electrical components, assembled printed circuits, etc., can solve problems such as low connection reliability, inability to fully ensure initial conduction resistance, insufficient heating connection reliability, etc. To achieve the effect of preventing voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

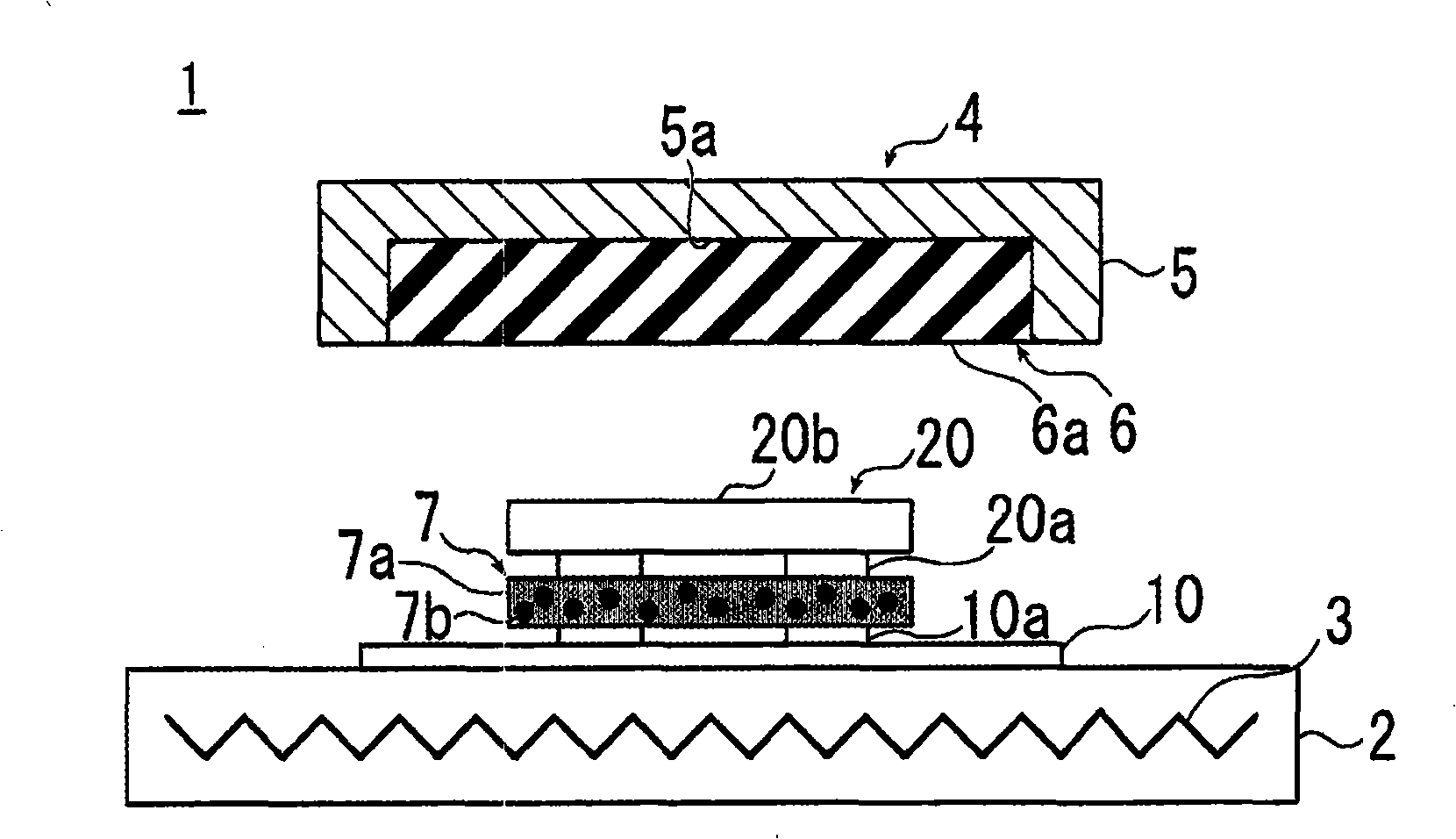

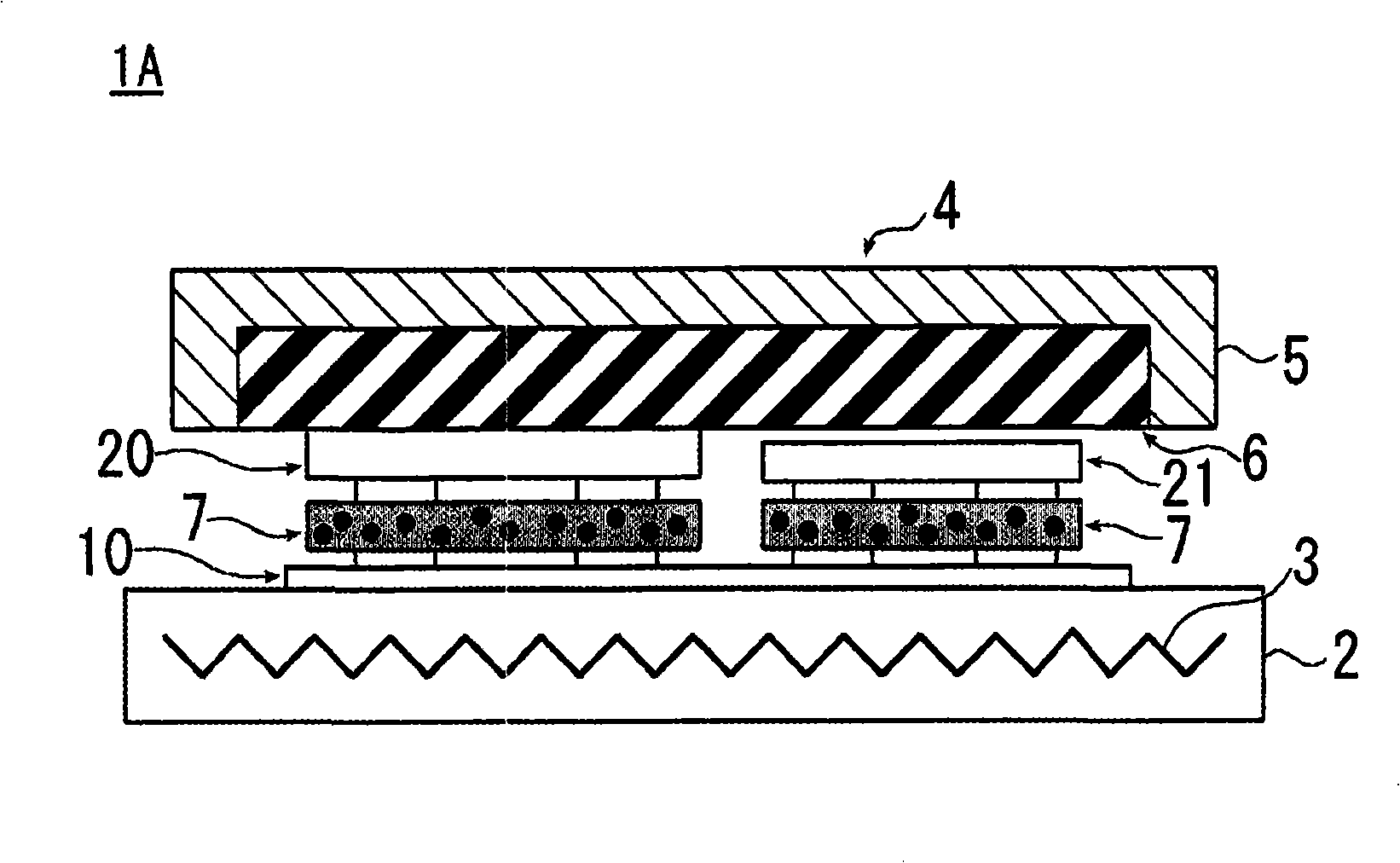

Embodiment 1

[0087] As the wiring substrate, a copper (Cu) pattern with a width of 75 μm and a pitch of 150 μm is formed on a glass fiber reinforced plastic substrate, and a rigid substrate plated with nickel and gold is used on it. As an IC chip, a size with bump electrodes with a pitch of 150 μm is prepared. 6×6mm, 0.4mm thick chip.

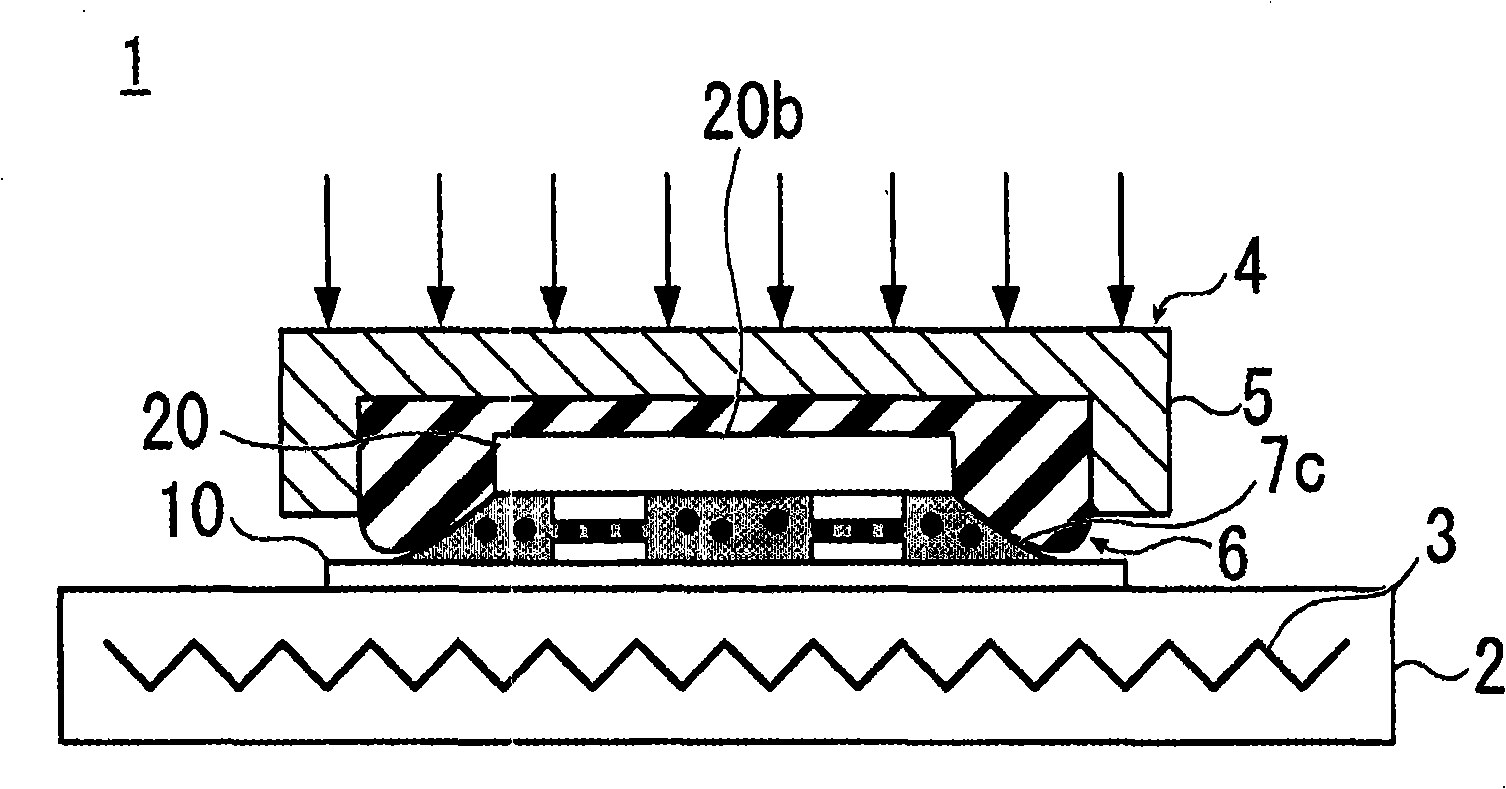

[0088] In addition, a thermocompression joint equipped with a crimping part made of silicone rubber with a size of 60×60mm, a thickness of 10mm, and a rubber hardness of 40 is used as an anisotropic conductive adhesive film with a melting viscosity of 1.0×10 5 A film in which conductive particles are dispersed in an adhesive resin of mPa·s to heat and compress the IC chip onto the wiring board.

[0089] In this case, control the temperature of the susceptor so that the temperature of the crimping part is 100℃, the temperature of the anisotropic conductive adhesive film is 200℃3, and the pressure is 100N / IC (278N / cm 2 ) Pressurize and heat within 15 seconds.

Embodiment 2

[0091] The thermocompression bonding was performed under the same conditions as in Example 1, except that a crimping portion made of silicone rubber with a rubber hardness of 80 was used.

Embodiment 3

[0097] Except when the melt viscosity is 1.0×10 2 Except for the anisotropic conductive adhesive film in which conductive particles are dispersed in the adhesive resin of mPa·s, thermocompression bonding was performed under the same conditions as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com