LED chip capable of improving light-discharging rate and preparation technique thereof

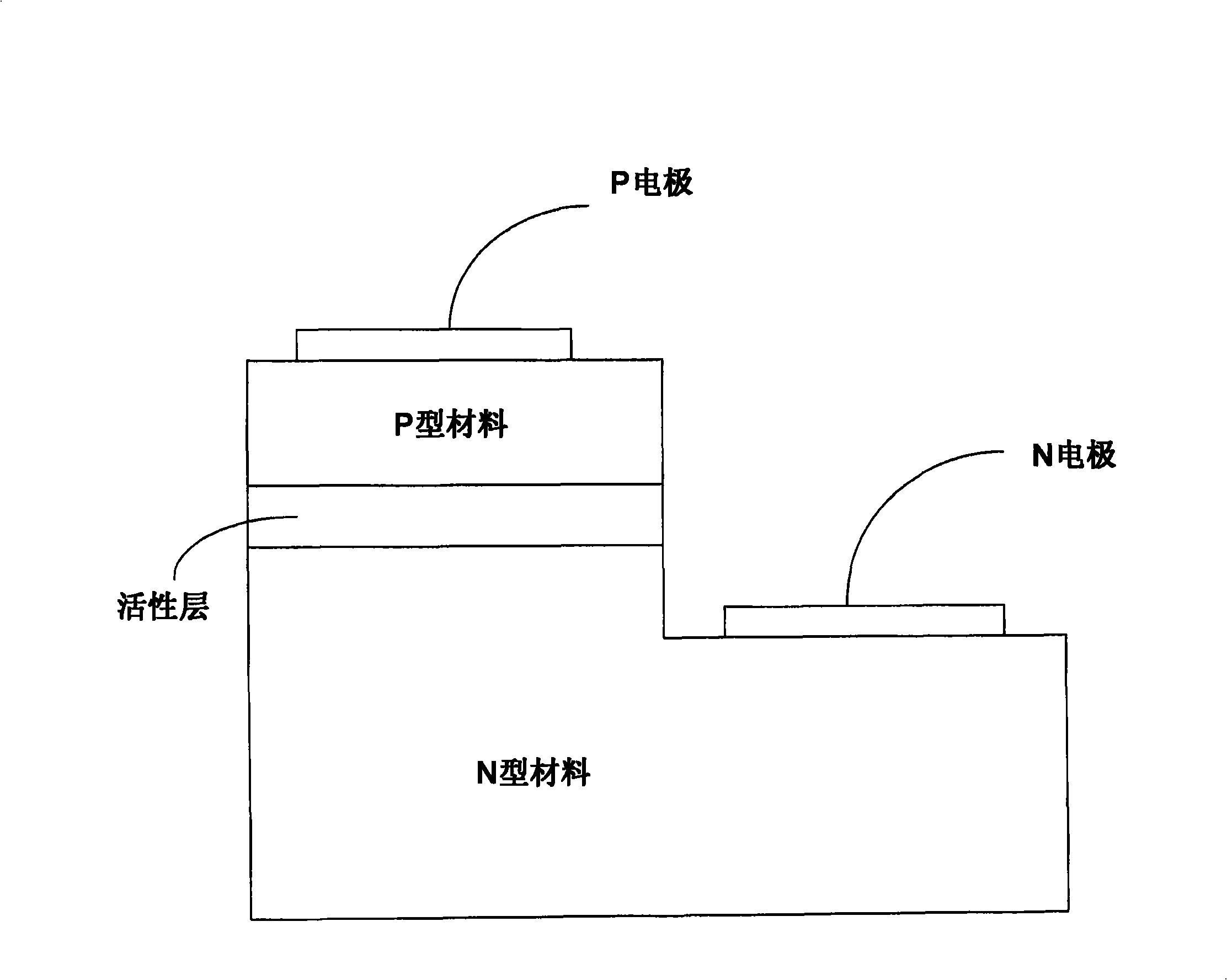

A technology of LED chips and light-emitting layers, which is applied to electrical components, circuits, semiconductor devices, etc., can solve problems such as uneven light-emitting performance of LED devices, and achieve the effect of improving the side wall area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

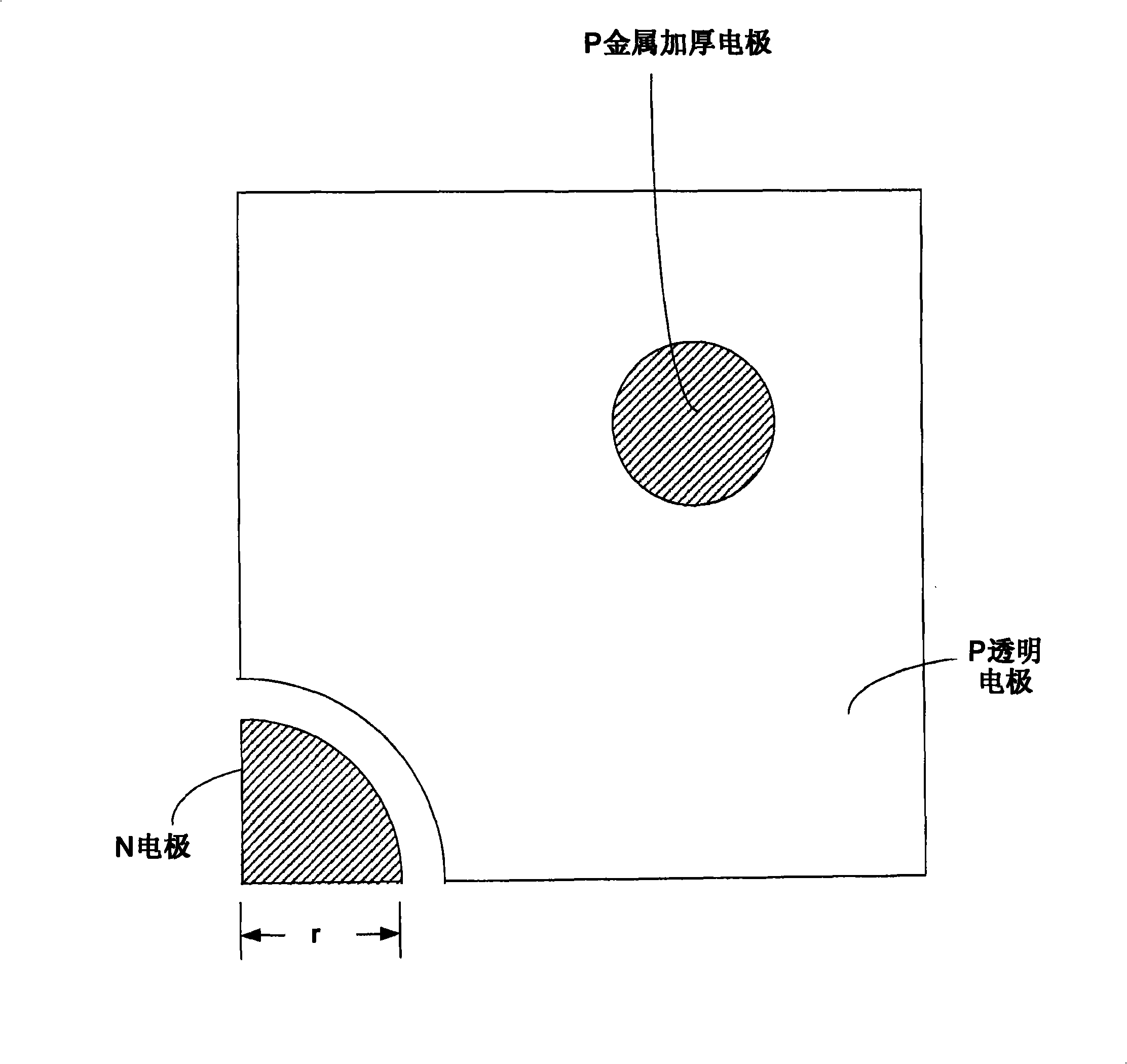

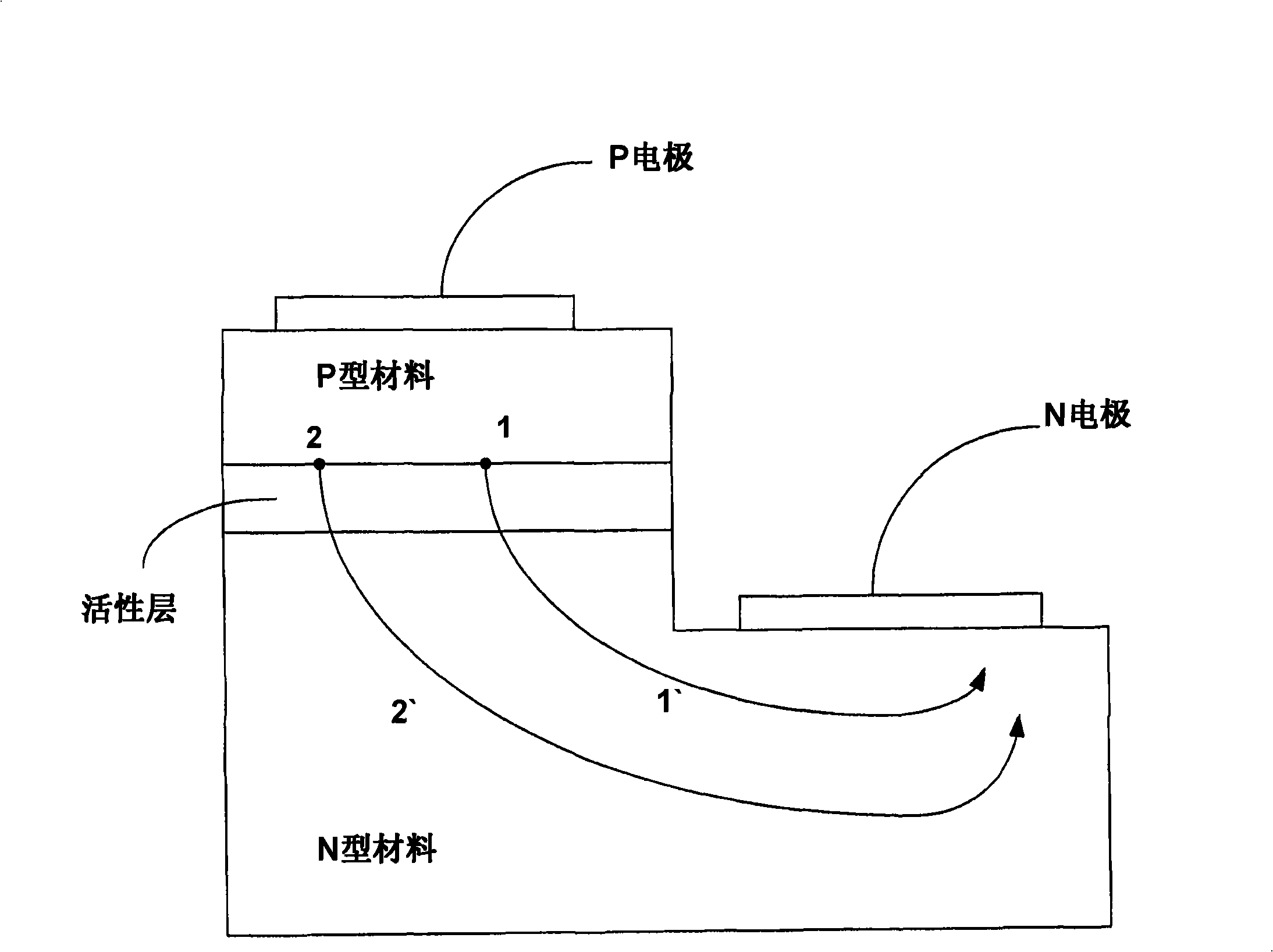

[0027] Figure 4 What is shown is a top view of an LED chip structure according to the present invention. Such as Figure 4 As shown, the LED chip includes a P electrode and an N electrode, wherein the N electrode is located (or approximately located) at the geometric center of the chip, and the P electrode includes a transparent electrode and a thickened electrode, wherein the transparent electrode is located around the N electrode. As mentioned earlier, when the LED is working, the current flowing into the P electrode tends to choose the conduction path with the least resistance to reach the N electrode. Therefore, it is better to enter the N-type material layer from the boundary of the "hollow" ring in the transparent electrode. , and the effect of entering the N-type material at a distance from the boundary of the central ring is secondary. Therefore, it can be considered that the luminous effect of LEDs in a certain place is negatively correlated with the "distance to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com