Concentrated fabric conditioner compositions

一种织物调理、组合物的技术,应用在洗涤剂组合物、洗涤组合物香料、洗涤剂配合剂等方向,能够解决不能用等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

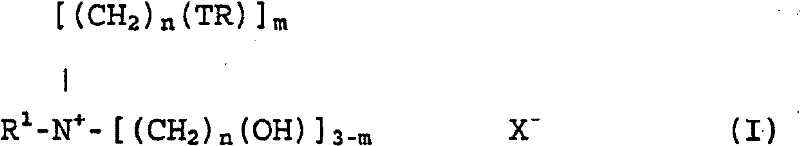

Method used

Image

Examples

Embodiment 1

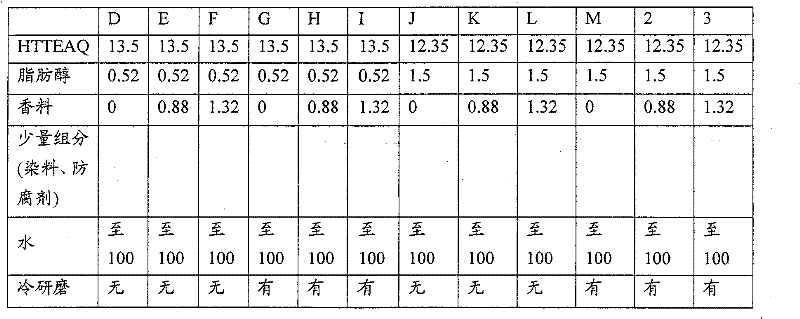

[0105] Prepare the samples reported in Table 1 below:

[0106] Table 1

[0107] A 1 B C Quaternary Ammonium Compound 1 1 13.46 - - - HTTEAQ - 12.35 - - Quaternary Ammonium Compound 3 3 - - 12.35 - Quaternary Ammonium Compound 4 4 - - - 14.00 fatty alcohol 5 1.5 1.5 1.5 1.5 spices 1.32 1.32 1.32 1.32 minor component water to 100 to 100 to 100 to 100

[0108] 1) 1,2-Bis[Hardened Tallowoyloxy]-3-Trimethylammoniopropane Chloride (78% active ingredient)

[0109] 2) Hardened tallow triethanolamine quaternary ammonium compound, based on the reaction of about 2 moles of hardened tallow fatty acid with 1 mole of triethanolamine, followed by quaternization of the reaction mixture with dimethyl sulfate (85% active ingredient). This quaternary ammonium substance contains approximately 20% by weight MEQ

[0110] 3) Bis(2-harde...

Embodiment 2 and 3

[0123] The samples reported in Table 4 below were prepared.

[0124] Table 4

[0125]

[0126] HTTEAQ and fatty alcohol were the same as used in previous samples.

[0127] The examples were cold ground as described in Example 1.

[0128] The room temperature stability of each embodiment is recorded in the table below (all viscosities are at 106 s with Haake RT20 viscometer -1 measured at shear rate).

[0129] table 5

[0130] time / sample D E F G H I J K L M 2 3 initial 542 221 205 326 135 132 225 149 127 110 61 70 32 days 590 210 224 382 104 132 360 157 121 89 74 69 67 days 528 185 183 367 107 117 234 150 116 113 62 65 92 days 548 180 176 371 105 113 238 142 111 108 63 64 206 days 445 148 141 319 97 100 208 132 100 97 61 6...

Embodiment 4

[0135] Prepare the following formulations:

[0136] 12.35% HTTEAQ

[0137] 1.5% fatty alcohol

[0138] 0.93% fragrance

[0139] A small amount of preservatives, dyes, defoamers

[0140] water to 100%

[0141] HTTEAQ and fatty alcohol are the same as in previous examples. This formulation was prepared as described in Example 1, followed by cold milling. Samples were taken after cold milling at 0, 1 BV (batch volume), 2 BV and 2.5 BV.

[0142] Viscosity changes with cold grinding (at 20 and 106s -1 down, expressed in cps)

[0143] 0BV 830 / 300

[0144] 1BV 330 / 135

[0145] 2BV 177 / 80

[0146] 2.5BV 116 / 54

[0147] The results show that product viscosity can be controlled by cold grinding. Furthermore, it was shown that there is no risk of shear-induced flocculation with longer milling, illustrating the excellent stability of the base formulation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com