Automatic spray conduit system and installation method thereof

A pipeline system and automatic spraying technology, which is applied in fire rescue and other fields, can solve the problems of large amount of high-altitude operations, low construction efficiency, and high construction difficulty, and achieve the effects of reducing high-altitude operations, improving construction efficiency, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

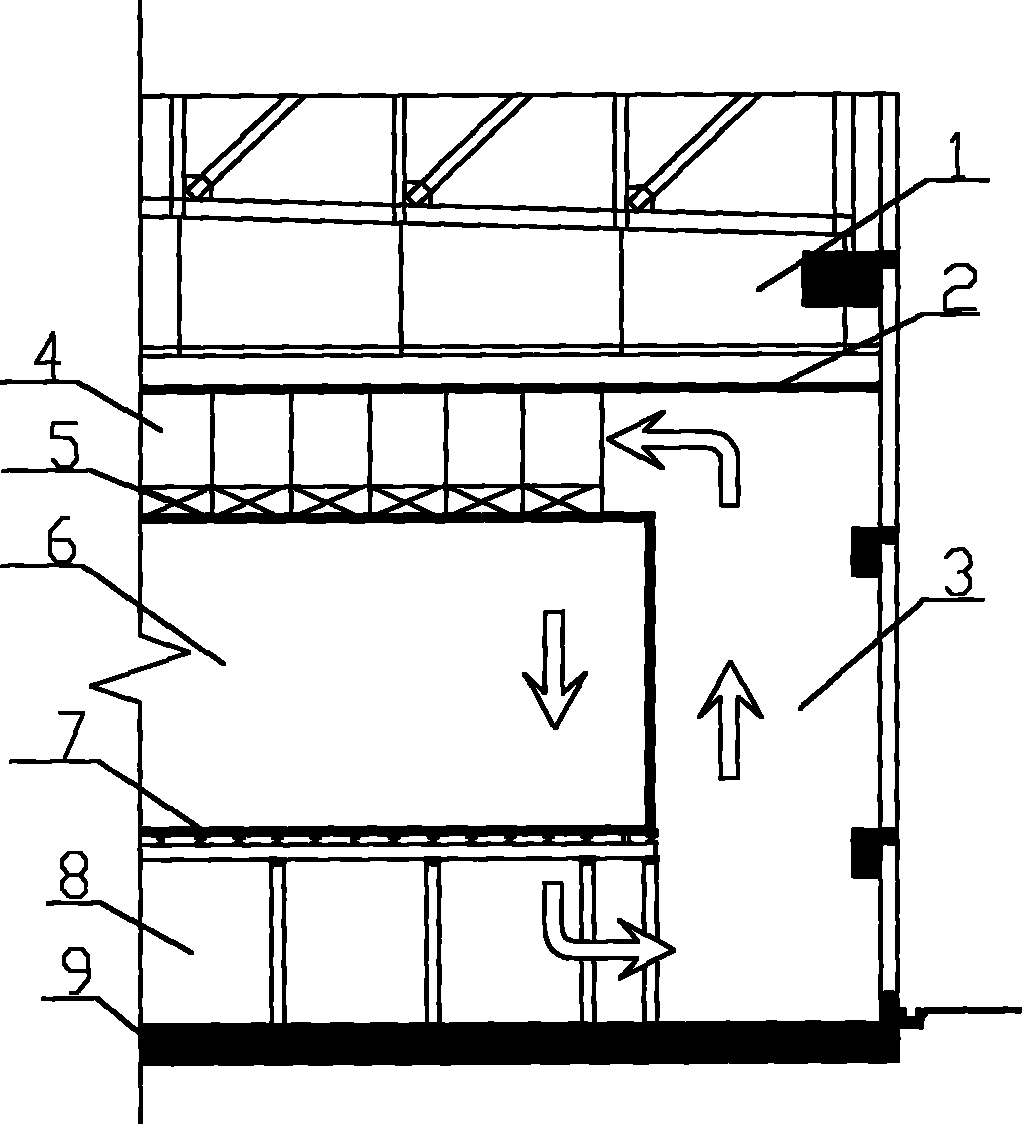

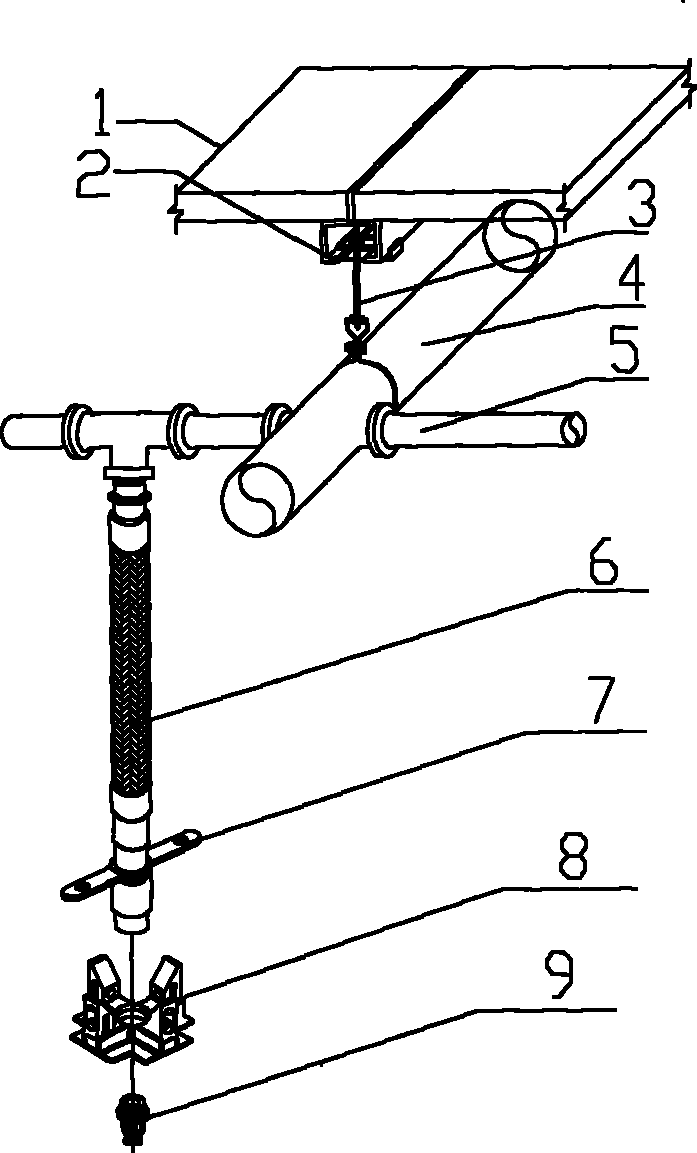

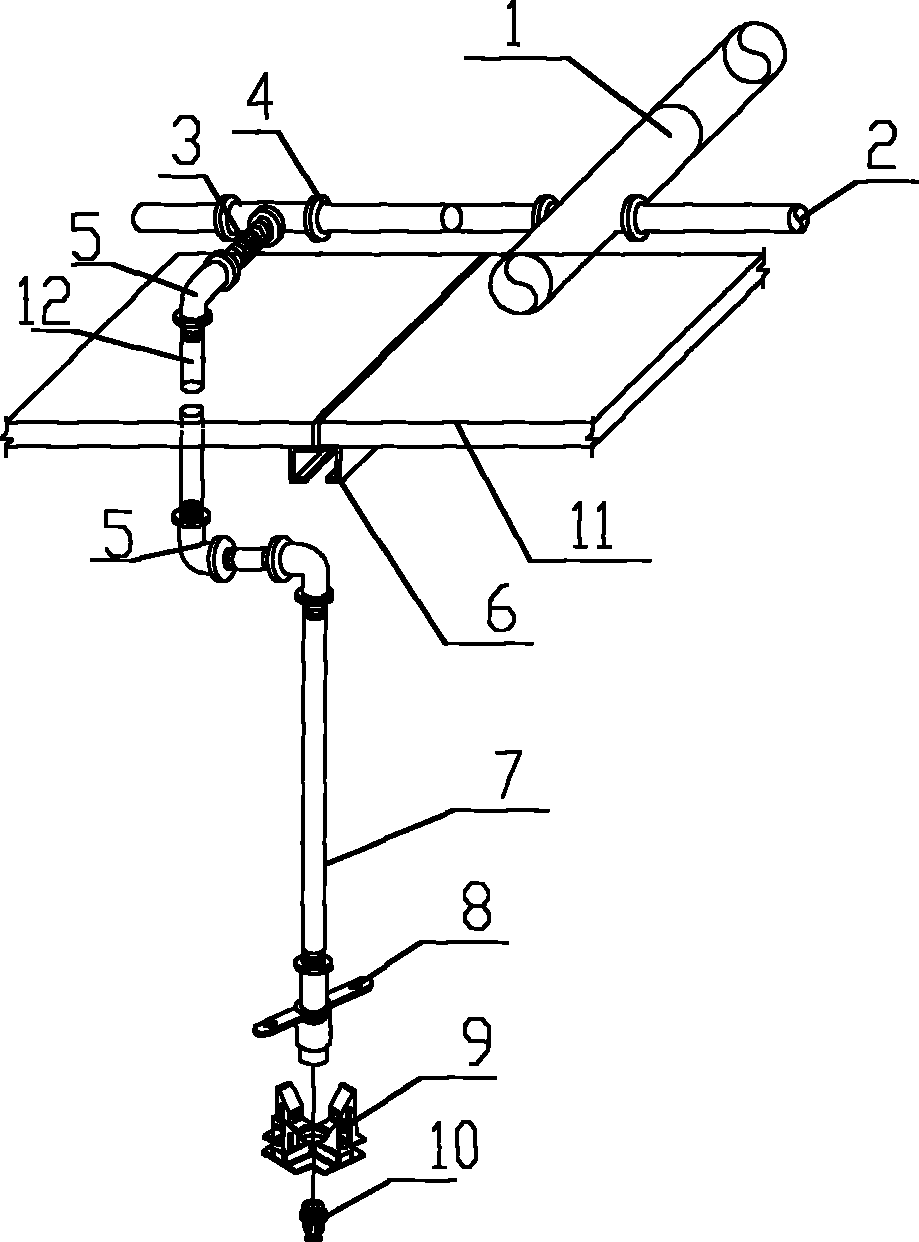

[0012] See image 3 , Figure 4 , the sprinkler pipeline system of the present invention includes a main pipeline 1, a main pipeline 2, a fire hose 3, a pipe fitting 8 fixed on a keel 9, a sprinkler head 10, and the main pipeline 1 and the main pipeline 2 are located in the static pressure tank 13 In the roof truss layer 14 above, the fire hose 3 is connected to the branch pipe 7 through the short pipe 12 and the elbow 5. The short pipe 12 passes through the top plate 11 of the static pressure box, and the other end of the branch pipe 7 is connected to the sprinkler head 10 fixed on the keel. Connected. One end of the prefabricated outer wire of the fire hose 3 is connected to the tee 4 on the dry pipeline 2, and the other end of the fire hose 3 is connected with the elbow 5 by the prefabricated inner wire. The fire hose 3 is made of SUS304 stainless steel, and the interior is stainless steel Corrugated pipe; in the installation and connection of pipe fittings, anaerobic glu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com