Technique for molding inclined connector saddle between main pipe and branch pipe as well as welding method

A technology of molding process and inclination angle, which is applied in the direction of pipes/pipe joints/fittings, pipes, branch pipelines, etc., can solve the problems of hidden accidents, poor welding strength, and difficulty in ensuring the flatness of the welding surface, etc., to achieve the expansion of welding area, Ensure the flatness and welding strength, and avoid the effect of main tube blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

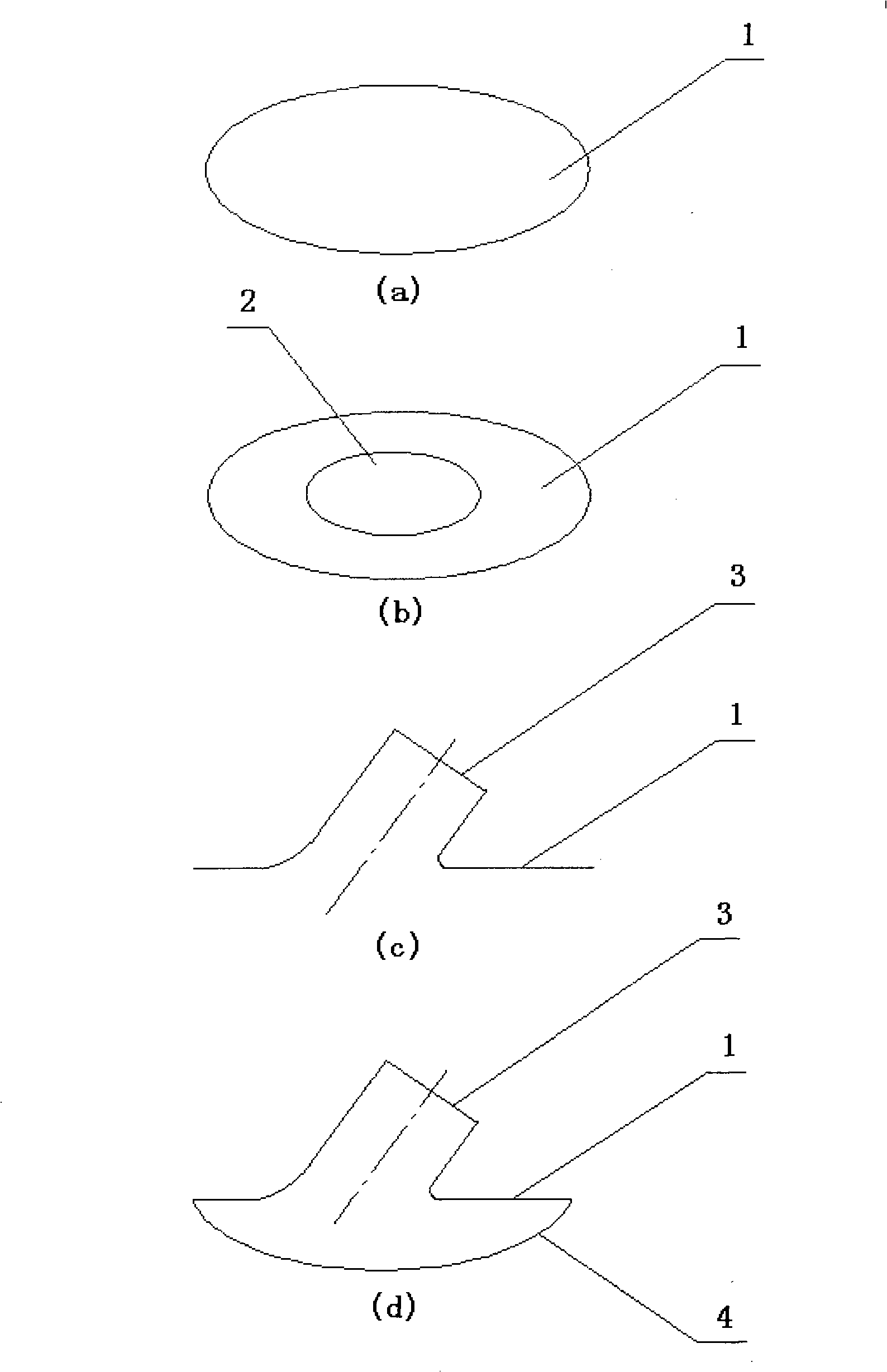

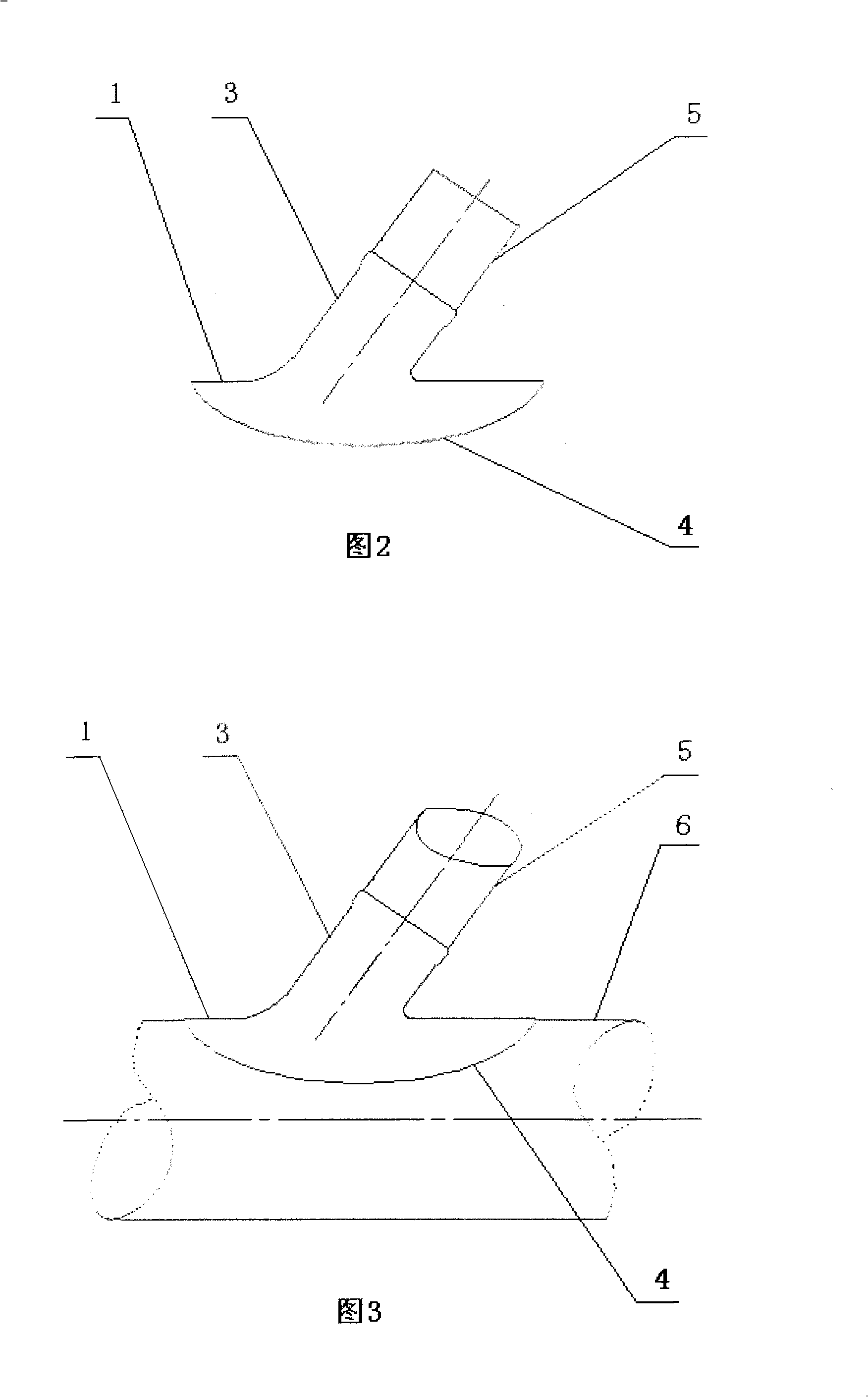

[0023] figure 1 The forming process of the saddle in the present invention is shown. refer to figure 1 (a), figure 1 (b), figure 1 (c), figure 1 (d) shown molding process, the molding method of saddle among the present invention comprises the following steps:

[0024] (1) According to the outer diameter of the main pipe and the branch pipe to be connected, use a punch to punch out a metal sheet 1 with a size and shape suitable for it;

[0025] (2) punch out the oval hole 2 on the metal sheet 1 with a punch press according to the inner diameter of the branch pipe;

[0026] (3) According to the inclination angle between the main pipe and the branch pipe, use a hydraulic press and a special mold to stretch the oval hole 2 on the metal sheet 1 to make it a boss 3 whose slope is suitable for the inclination angle between the main pipe and the branch pipe ;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com