Automatic sampling apparatus of ultrasonic wave detection and working method thereof

A sampling device and automatic detection technology, applied in the direction of sampling devices, etc., can solve the problems of losing the meaning of automaticity, reducing the randomness of samples, and affecting the quality of raw materials and fuels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

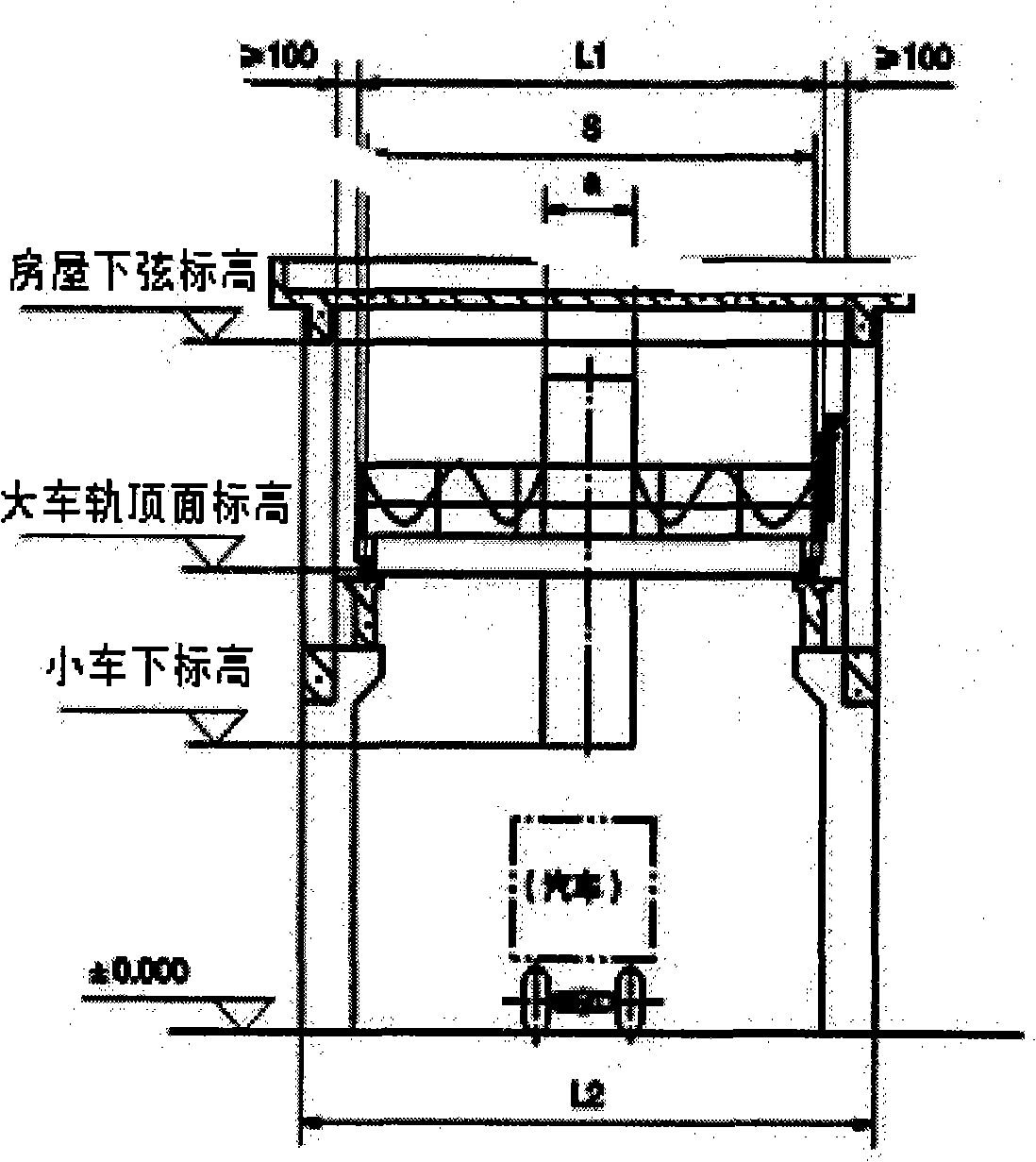

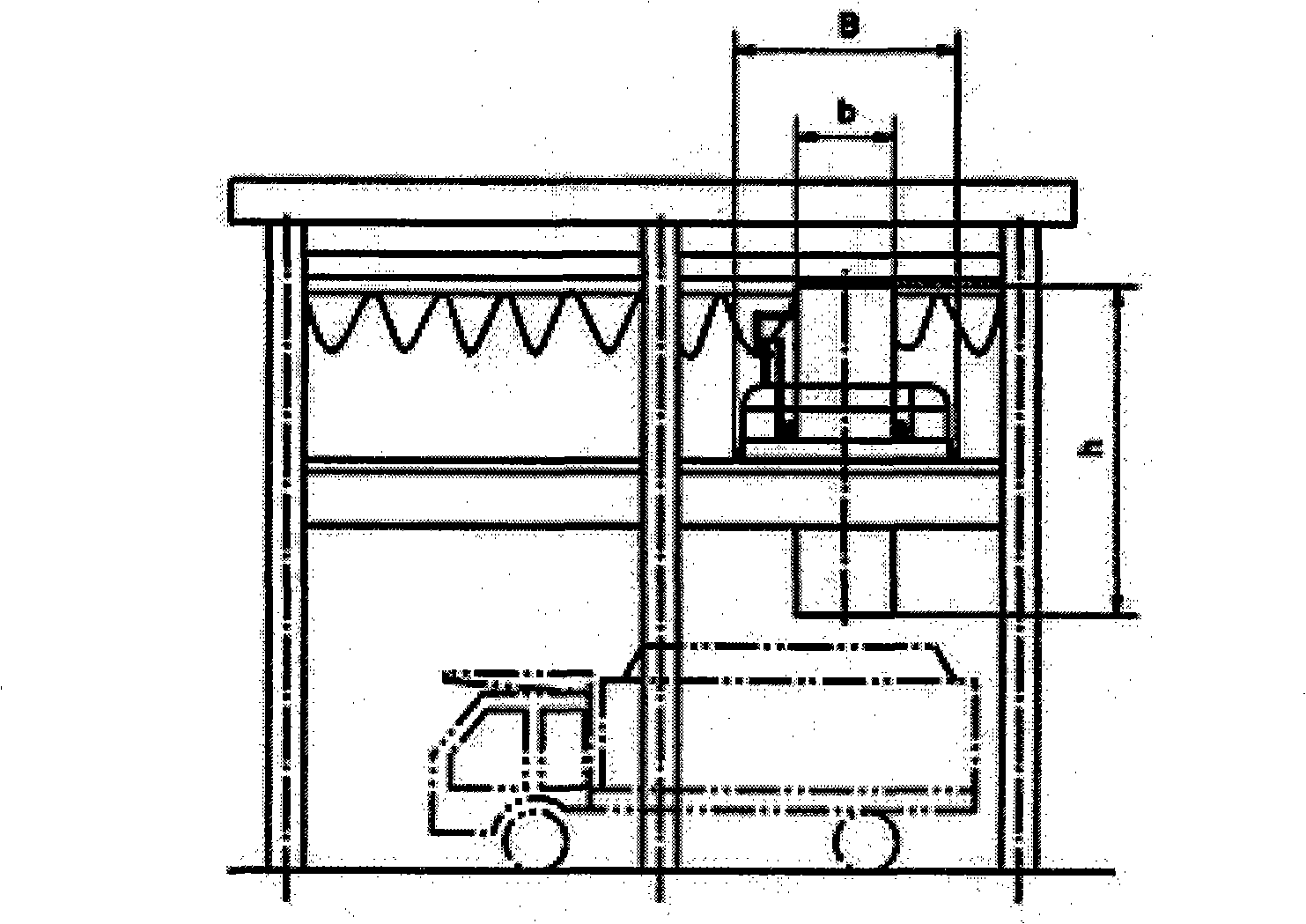

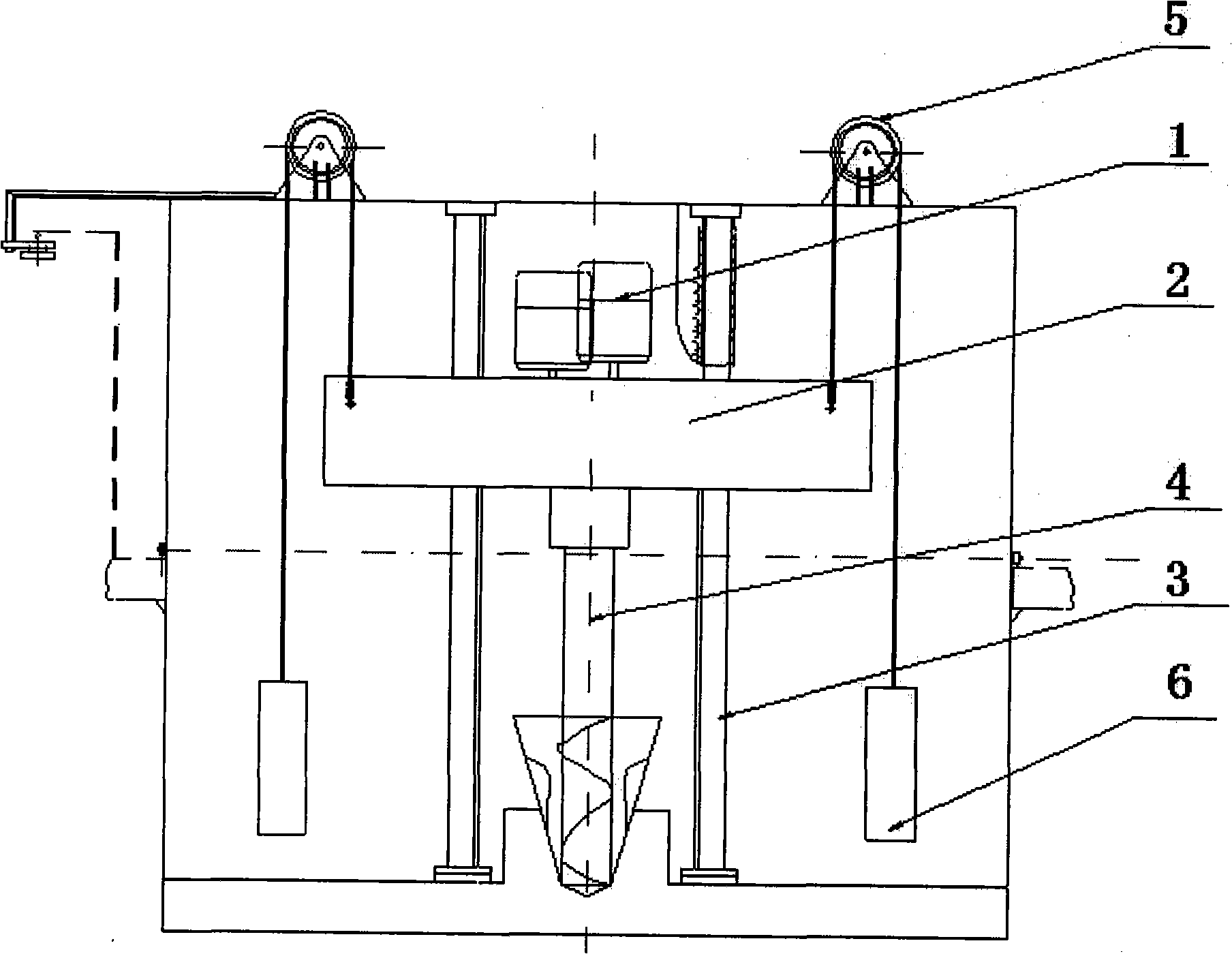

[0058] An automatic sampling device for ultrasonic detection, such as figure 1 , figure 2 and image 3 As shown, it includes sampling cart, sampling trolley, lifting mechanism, sampling device, auxiliary electrical equipment and operating room; the sampling trolley is connected to the sampling trolley, and both the sampling cart and the sampling trolley are equipped with proximity switches, which are connected to the computer. Connection; the lifting mechanism and the sampling device are installed in the sampling trolley, and the sampling trolley is equipped with an ultrasonic positioner. The sampling trolley moves along the Y-axis of the three-dimensional space under the drive of the motor, and the sampling trolley moves along the X-axis of the three-dimensional space under the drive of the motor. The motor is connected to the frequency converter; the auxiliary electrical equipment includes contactors, circuit breakers, photoelectric encoders, proximity switches, cameras a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com