Two-dimensional molybdenum ditelluride vertical heterojunction and preparation method and application thereof

A molybdenum ditelluride and heterojunction technology, which is applied in the field of two-dimensional materials, can solve the problems of unstable Mo-Te bond, low chemical reactivity, and easy transformation of two phases, so as to reduce the Schottky barrier, Evenly mixed and easy to steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

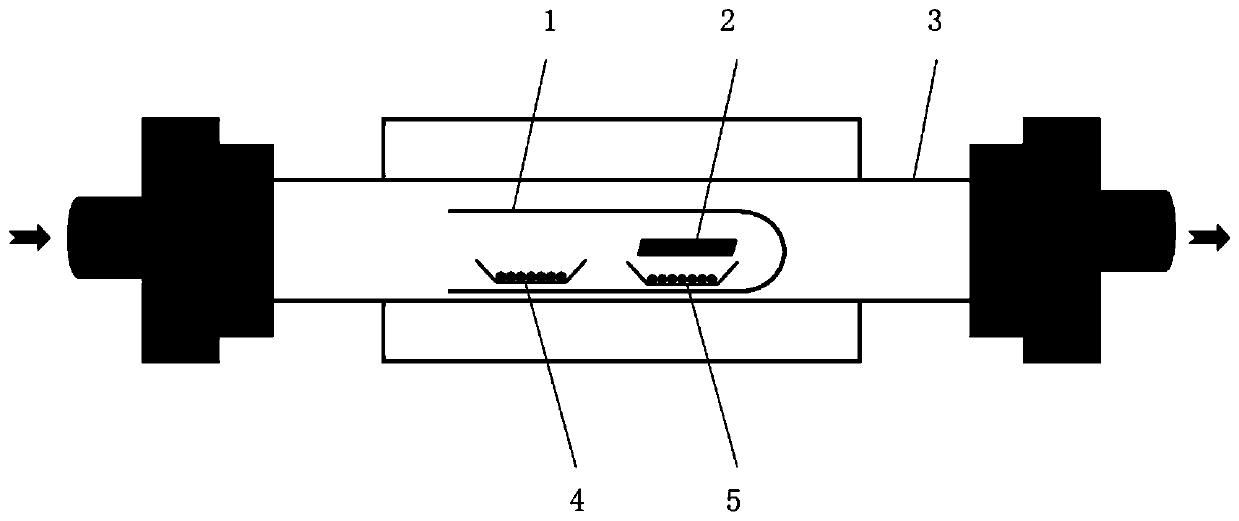

[0032] The embodiment of the present invention provides a method for preparing a two-dimensional molybdenum ditelluride vertical heterojunction, using such as figure 1The shown device comprises the steps of:

[0033] S1 Dried the mixed solution of ammonium tetramolybdate and sodium chloride and put it into the porcelain boat as the molybdenum source 5, and buckled a silicon wafer directly above the porcelain boat as the growth substrate 2, leaving about 5mm in between slit to ensure the ingress and egress of gas, tellurium powder is put into another porcelain boat as tellurium source 4; two porcelain boats are all put into the sleeve pipe 1 of an end opening (the preferred diameter of this sleeve pipe 1 is 2cm, and length is 17cm), and the tellurium source 4 is close to the open end of the casing 1, then the casing 1 is put into the horizontal tube furnace 3, and the molybdenum source 5 is positioned at the center of the horizontal tube furnace 3;

[0034] S2 Raise the temper...

Embodiment 1

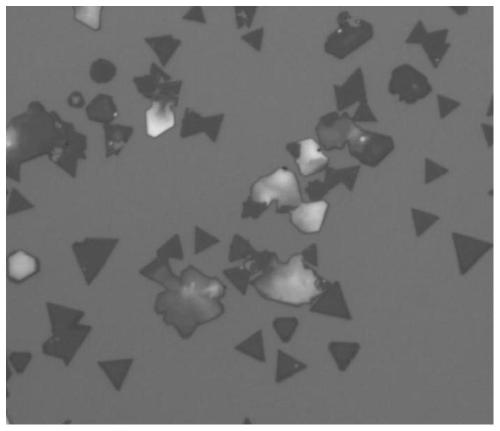

[0043] Place 1g of tellurium powder as the tellurium source in the upstream of the bushing, dissolve 30mg of ammonium tetramolybdate and 30mg of sodium chloride in 1mL of deionized water to prepare a mixed solution, and dry it at 120°C as the molybdenum source. A silicon wafer with a 300nm-thick oxide layer was soaked in a 1:10 hydrofluoric acid solution for 30 seconds, then used as a growth substrate, and placed upside down on the molybdenum source. Pre-evacuation was carried out prior to the reaction, and then argon gas with a flow rate of 400 sccm was introduced for 5 minutes to make the air pressure in the tube furnace reach one atmospheric pressure and remove residual oxygen. The heating rate was set at 40°C / min, and the reaction temperature was set at 650°C. During the reaction, the flows of argon and hydrogen were 80 sccm and 5 sccm respectively. After the reaction, the carrier gas was kept constant, and the product was cooled to room temperature with the furnace, and a...

Embodiment 2

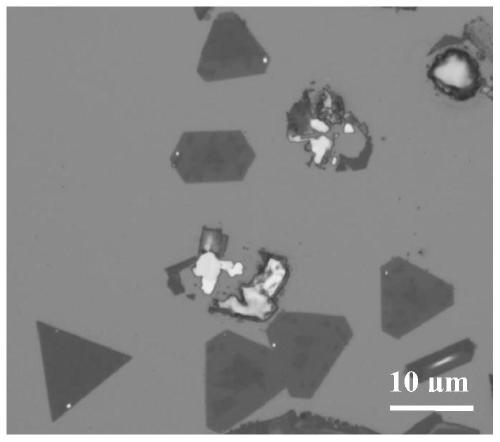

[0045] Place 1g of tellurium powder as the tellurium source in the upstream of the bushing, dissolve 30mg of ammonium tetramolybdate and 30mg of sodium chloride in 1mL of deionized water to prepare a mixed solution, and dry it at 120°C as the molybdenum source. A silicon wafer with a 300nm-thick oxide layer was soaked in a 1:10 hydrofluoric acid solution for 30 seconds, then used as a growth substrate, and placed upside down on the molybdenum source. Pre-evacuation was carried out prior to the reaction, and then argon gas with a flow rate of 400 sccm was introduced for 5 minutes to make the air pressure in the tube furnace reach one atmospheric pressure and remove residual oxygen. The heating rate was set at 40°C / min, and the reaction temperature was set at 700°C. During the reaction, the flows of argon and hydrogen were 80 sccm and 5 sccm respectively. After the reaction, the carrier gas was kept constant, and the product was cooled to room temperature with the furnace, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com