Laser marking label

A laser marking and marking technology, used in instruments, programming, layered products, etc., can solve the problems of insufficient durability, difficult white line patterns, poor resolution and resolution, and achieve good shading effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

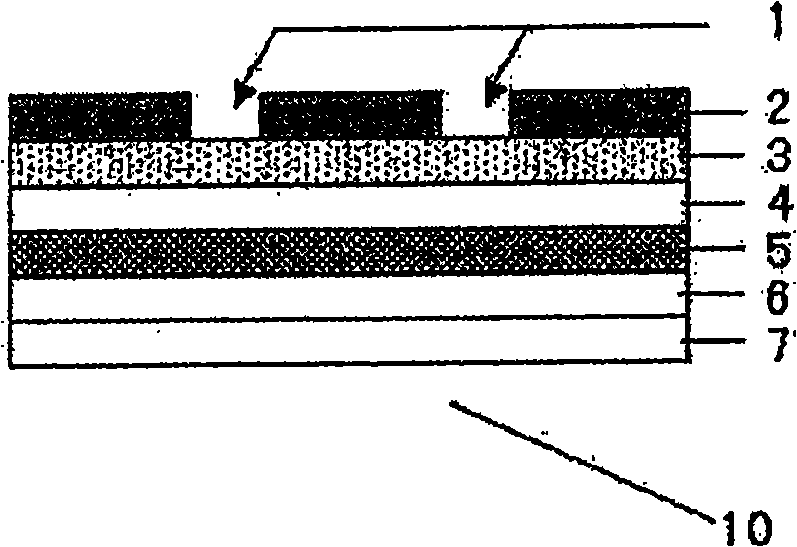

[0039] On both sides of the transparent PET film (Toray, lumirror S10, thickness 50μm) used as the support layer, the gravure printing (manufactured by Toshiba Machine Co., Ltd.) with black gravure ink (NB-300 manufactured by Dainichi Seika Co., Ltd.) was formed on one side to form 2μm. On the other side of the recording layer, use white gravure ink (NB-300 manufactured by Dainichi Seika Co., Ltd.) to form a base layer of 2μm in gravure printing, and use commercially available silver screen ink for screen printing (NEWLONG Precision Kogyo Co., Ltd.) After forming a 10μm light-shielding layer, an adhesive (acrylic type, thickness of 50μm) / separator (PET, thickness of 75μm) (manufactured by Nitto Denko, both sides / T LA- 50) As the adhesive layer and release liner, make laser marking marks. For this laser marking mark, use the KEYENCE laser marking machine MD-V9610 at 10J / cm 2 Under the laser irradiation conditions, a two-dimensional code with a cell size of 120μm is printed out. In ...

Embodiment 2

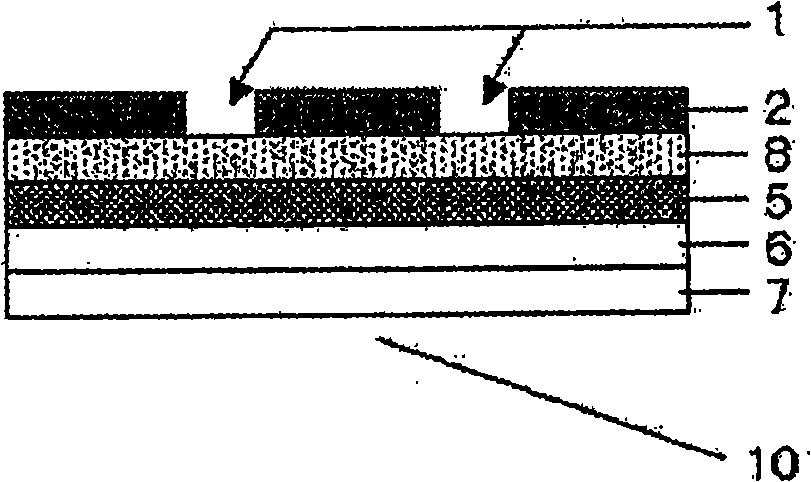

[0041] For both sides of the white PET film (Toray, lumirror E20, thickness 38μm) that becomes the support and base layer, gravure printing with black gravure ink (manufactured by Toyo Ink, Finestar) is used on one side to form a 2μm recording layer. The light-shielding layer (thickness: 50 nm) was formed by aluminum vapor deposition (using a roll-to-roll vacuum vapor deposition device manufactured by ULVAC Co., Ltd.) on one side, and it was carried out in the same manner as in Example 1 except that.

Embodiment 3

[0043] For both sides of the transparent PET film (Toray, lumirror S10, thickness 50μm) used as the support layer, a 2μm recording layer was formed on one side by gravure printing with white gravure ink (NB-300 manufactured by Dainichi Seika Co., Ltd.). On the other side, gravure printing with black gravure ink (NB-300 manufactured by Dainichi Seiki Co., Ltd.) is used to form a 2μm base layer, and aluminum vapor deposition is used to form a light-shielding layer (thickness 50nm) on the base layer side. Example 1 was implemented in the same way.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com