Combined cutting tool type airport pavement joint cleaning machine

A technology of combining cutter and seam cleaning machine, which is applied in the direction of roads, roads, road repair, etc., can solve the problems of difficulty in guaranteeing the quality of seam cleaning by manual operation, influence on navigation, and large workload, etc., and achieves high efficiency and flexibility in seam cleaning. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

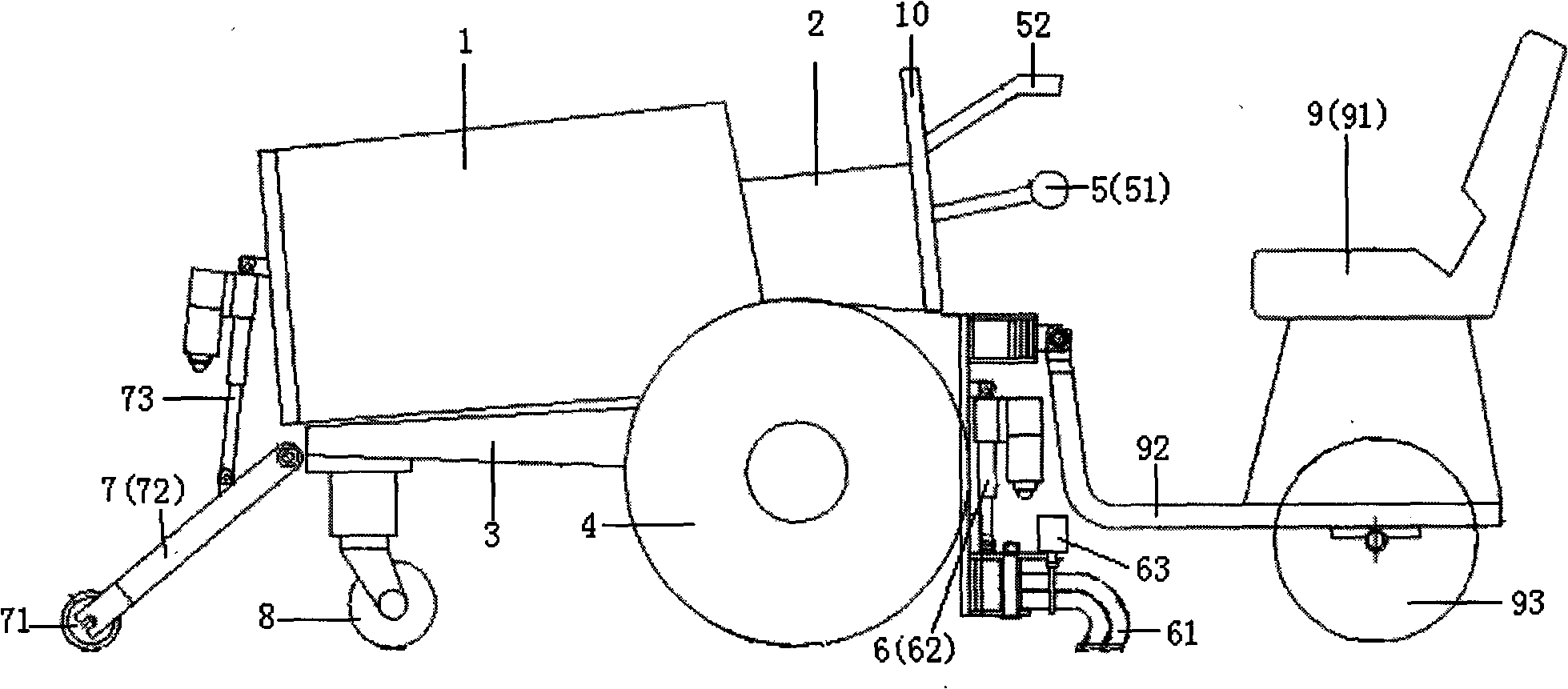

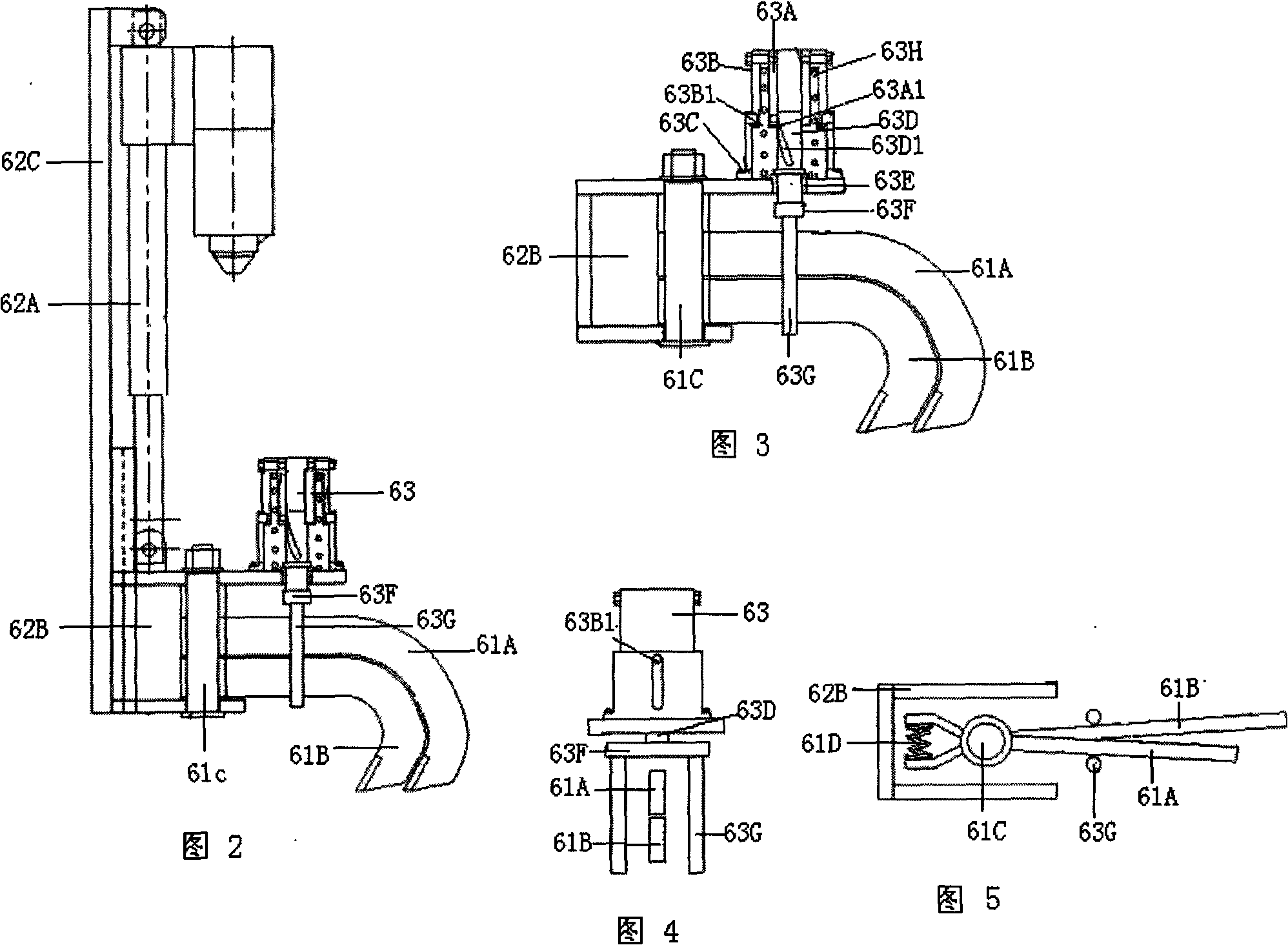

[0017] Such as figure 1 as shown,

[0018] Power plant of the present invention is identical with prior art, mainly comprises engine 1 (this engine or diesel engine, or is gasoline engine), gearbox 2, chassis 3, drive wheel 4, clutch and brake control mechanism 5. The difference is that it also includes an electric control operation seam cleaning device 6 and a guide device 7; a universal wheel 8 is also provided under the chassis; The engine and the gearbox of the present invention are arranged on the chassis, the clutch and brake operating mechanisms are connected with the gearbox, and the guiding device and the seam cleaning device are respectively arranged at the front and rear of the driving wheel. The electric control operation panel and the joystick of the clutch brake are arranged above the seam cleaning device. Described guiding device mainly is made up of guide wheel 71, guide pole 72, electric guide lifting push rod 73, and electric guide lift push rod control but...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com