Camera module

A camera module and chip technology, which is applied to printed circuits, installations, televisions, etc. where non-printed electrical components are connected, can solve the problems of reduced picture clarity, lack of electromagnetic protection measures for camera module 1, interference, and the like. Achieve the effect of being free from electromagnetic interference, improving clarity, and achieving electromagnetic shielding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

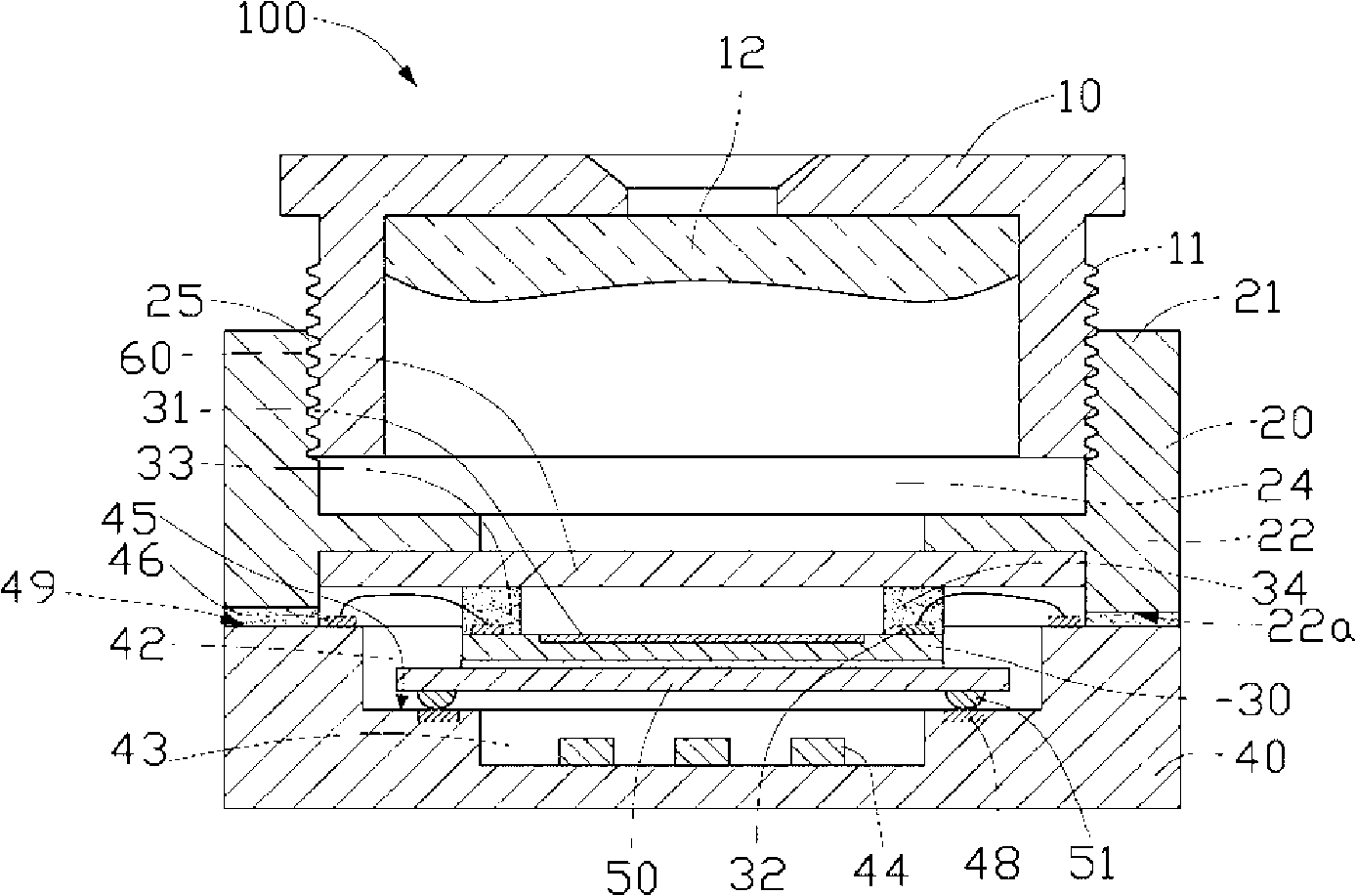

[0010] see figure 2 , is a cross-sectional view of the camera module 100 provided in the first embodiment of the present invention, which includes: a lens barrel 10 , a lens holder 20 , an image sensing chip 30 , and a substrate 40 . The mirror base 20 has a first end 21 and a second end 22 opposite to each other. The lens barrel 10 is sleeved on the first end 21 of the lens base 20 . The end surface 22 a of the second end 22 is bonded to the substrate 40 , and the image sensing chip 30 is fixed in the space enclosed by the mirror base 20 and the substrate 40 .

[0011] The outside of the lens barrel 10 has an external thread 11 and accommodates at least one lens 12 inside. The interior of the mirror base 20 is a penetrating chamber 24, and the side of the chamber 24 close to the first end 21 of the mirror base 20 is provided with an internal thread 25, which is compatible with the external thread of the lens barrel 10. 11 , so that the lens barrel 10 is sleeved on the len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com