Light-collecting device for projection apparatus

A projection device and light-collecting technology, which is applied in projection devices, optics, optical components, etc., can solve the problems of high manufacturing difficulty, difficult manufacturing, and large light loss of light-collecting devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

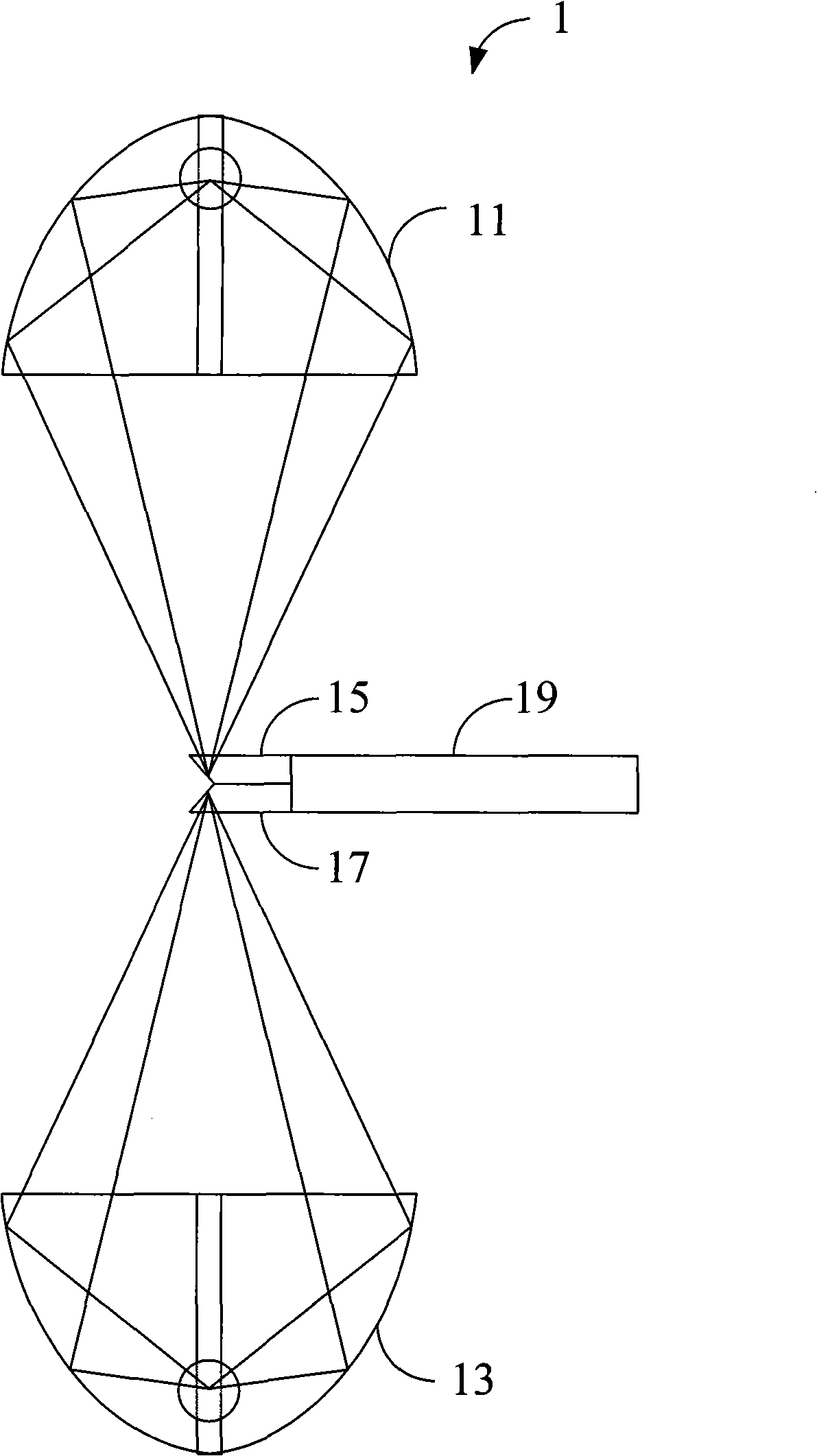

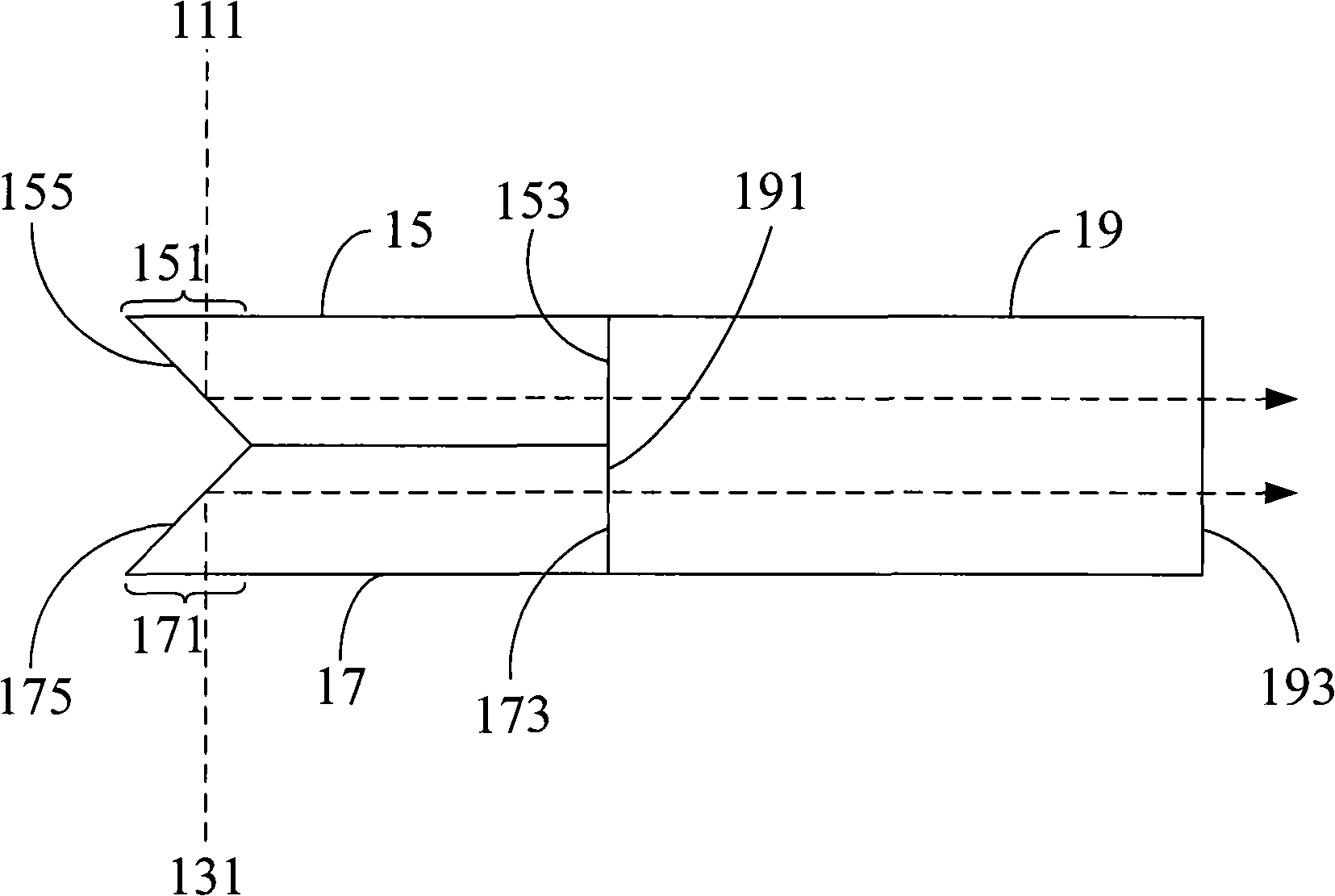

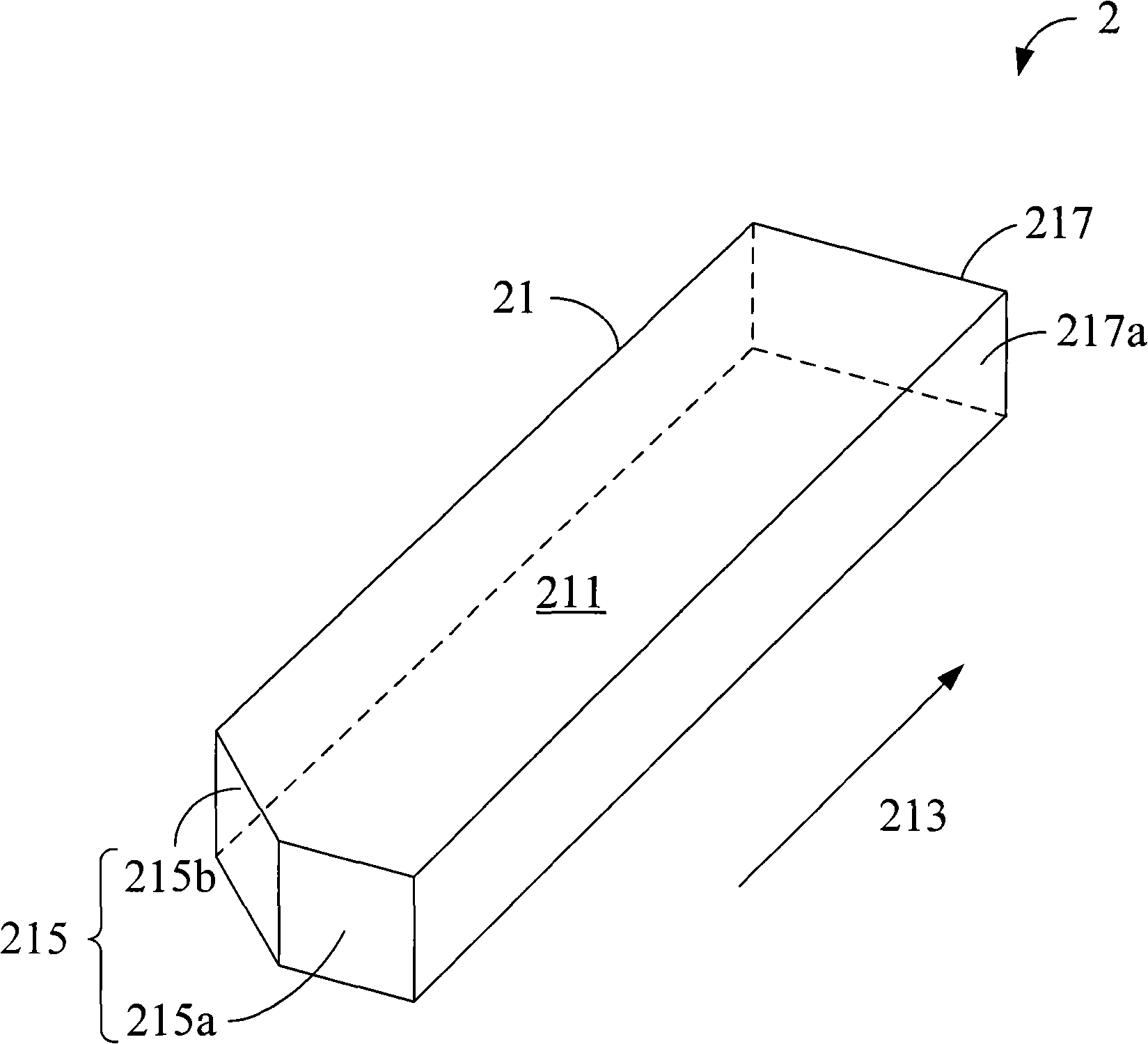

[0029] The present invention discloses a light collection device used in a projection device, in Figure 2A , 2B In the shown first embodiment, the projection device (not shown) includes a light collecting device 2, a first light source 20 and a second light source 22, wherein the perspective view of the light collecting device 2 is as Figure 2A As shown, the top view of the light collecting device 2 with the light source is as follows Figure 2B As shown, it should be noted that the drawings of the present invention illustrate the relationship between components, and are not intended to limit the size of each component. The light collecting device 2 includes a first light collecting rod 21 for collecting and homogenizing the light beams generated by the first light source 20 and the second light source 22 in the projection device. In addition, in this embodiment, both the first light source 20 and the second light source 22 are ultra high pressure mercury lamps (Ultra High...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com