Improved end cover for universal joint pin type universal coupler

A technology of universal joints and cross shafts, applied in the direction of couplings, elastic couplings, mechanical equipment, etc., which can solve the problems of difficult disassembly of screws, reduction of edge thickness of end caps, and high assembly requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

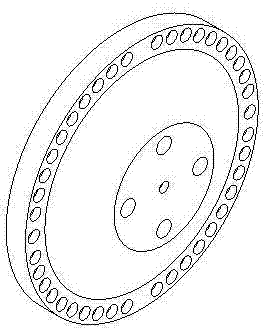

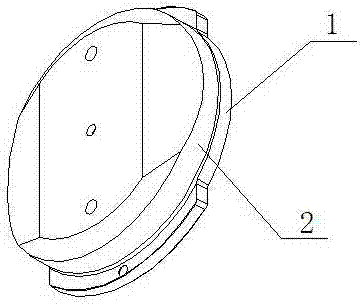

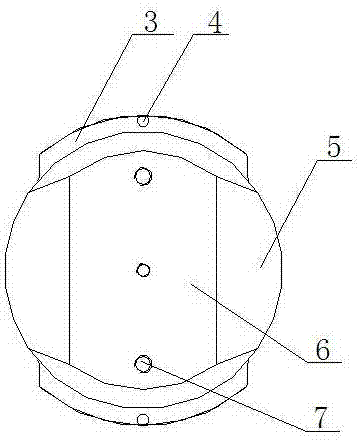

[0018] like figure 2 , 3 As shown, the cross-shaft universal joint uses an improved end cover, the end cover body 1 is disc-shaped, and the outer side of the end cover body is symmetrically provided with arc-shaped flanges 3, and each arc-shaped flange occupies The 1 / 4 circle of the end cap body, one side of the end cap body is provided with a flat cylinder 2, the diameter of the cylinder is the same as the diameter of the disc-shaped end cap body, and a slope 5 is respectively provided on the top surface 6 of the cylinder to both sides. The inclined plane is arranged symmetrically; the top surface of the cylinder is vertically provided with bolt holes 7 .

[0019] When the end cover body is connected with the flange yoke, the arc-shaped flange on the end cover body is embedded in the inner hole groove of the flange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com