Modular parallel great power DC power source switch apparatus

A technology of DC switch and power supply device, which is applied in the conversion device of output power, the conversion of DC power input to DC power output, electrical components, etc. problems, to achieve the effect of improving stability, reducing costs, and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

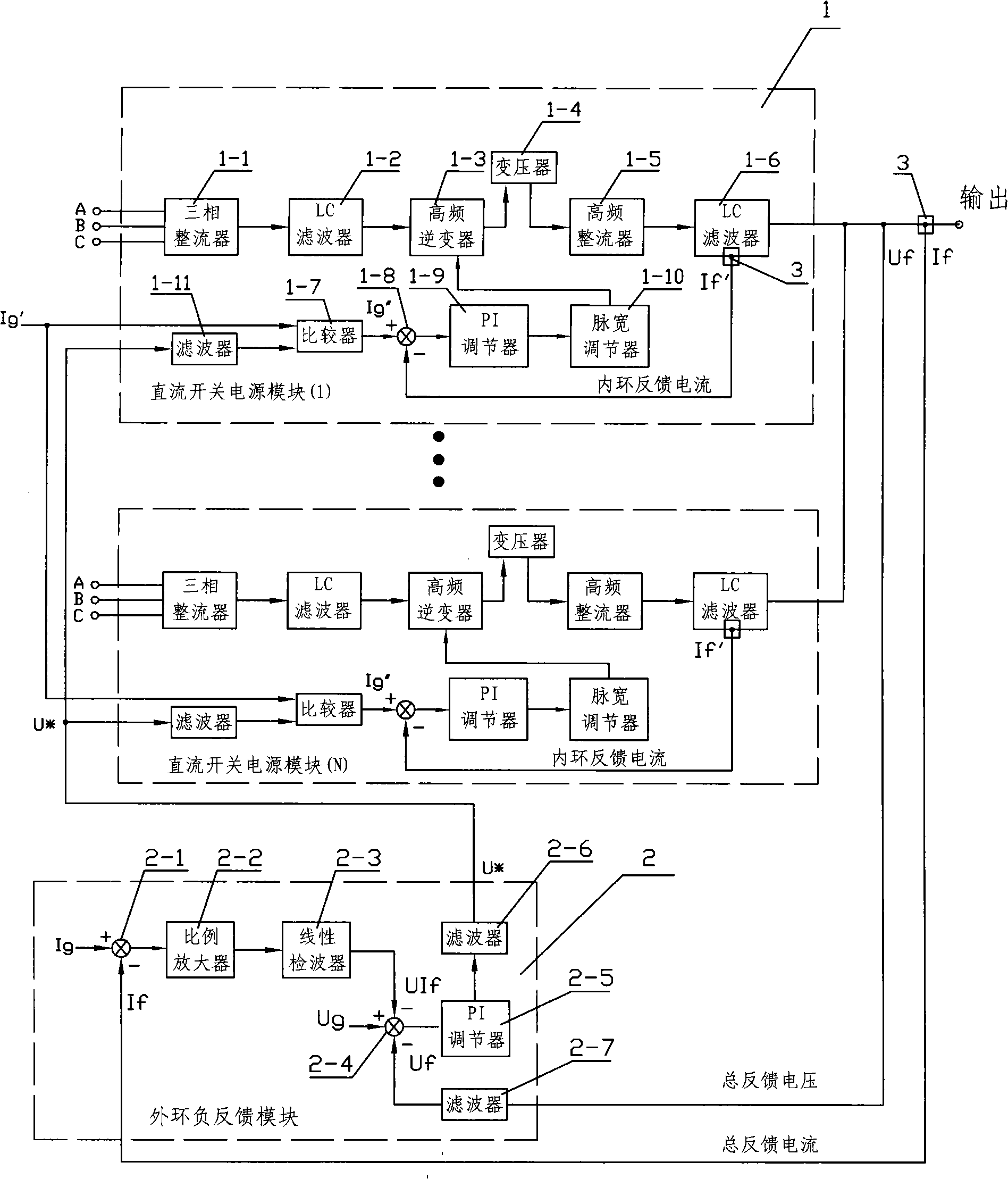

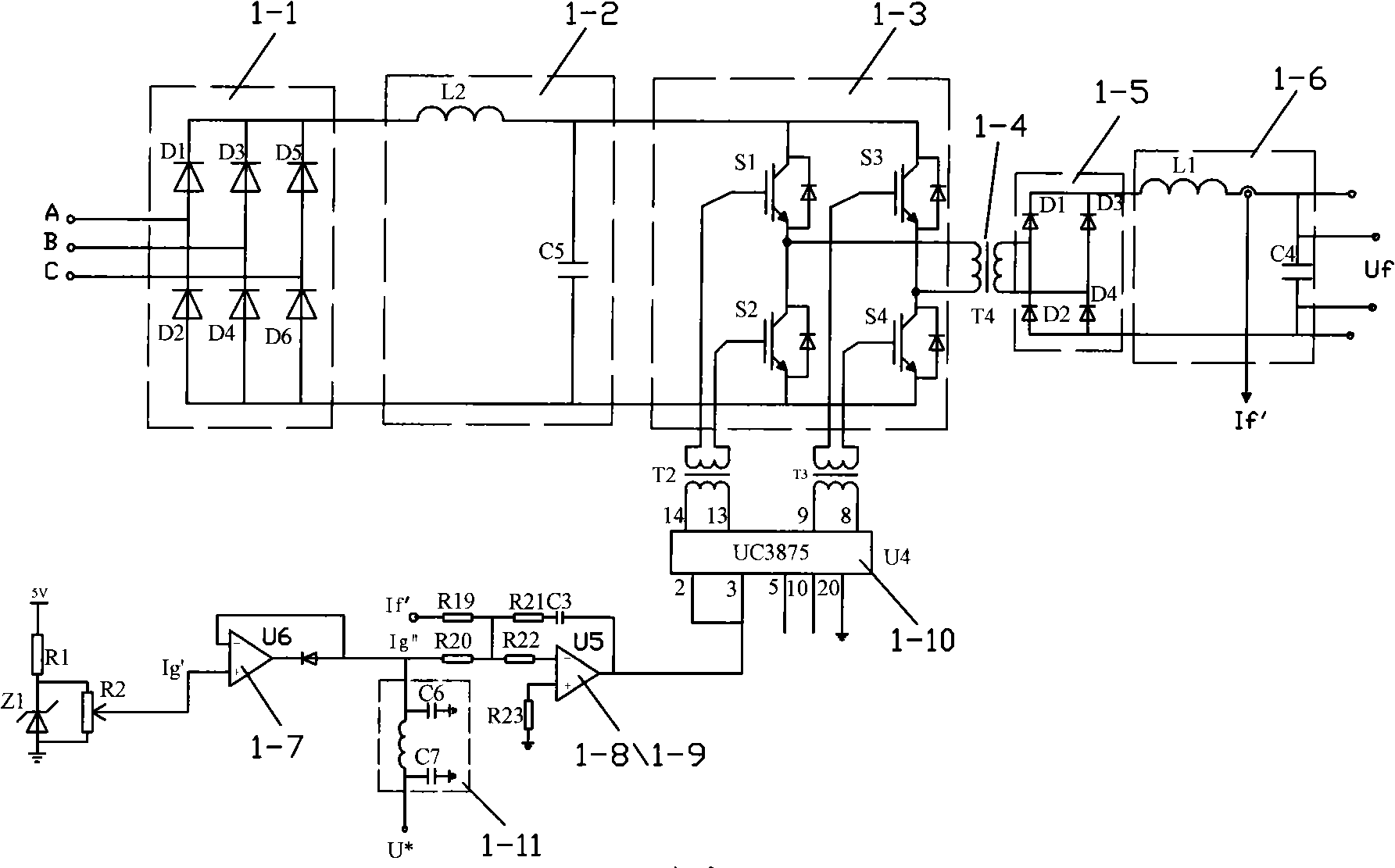

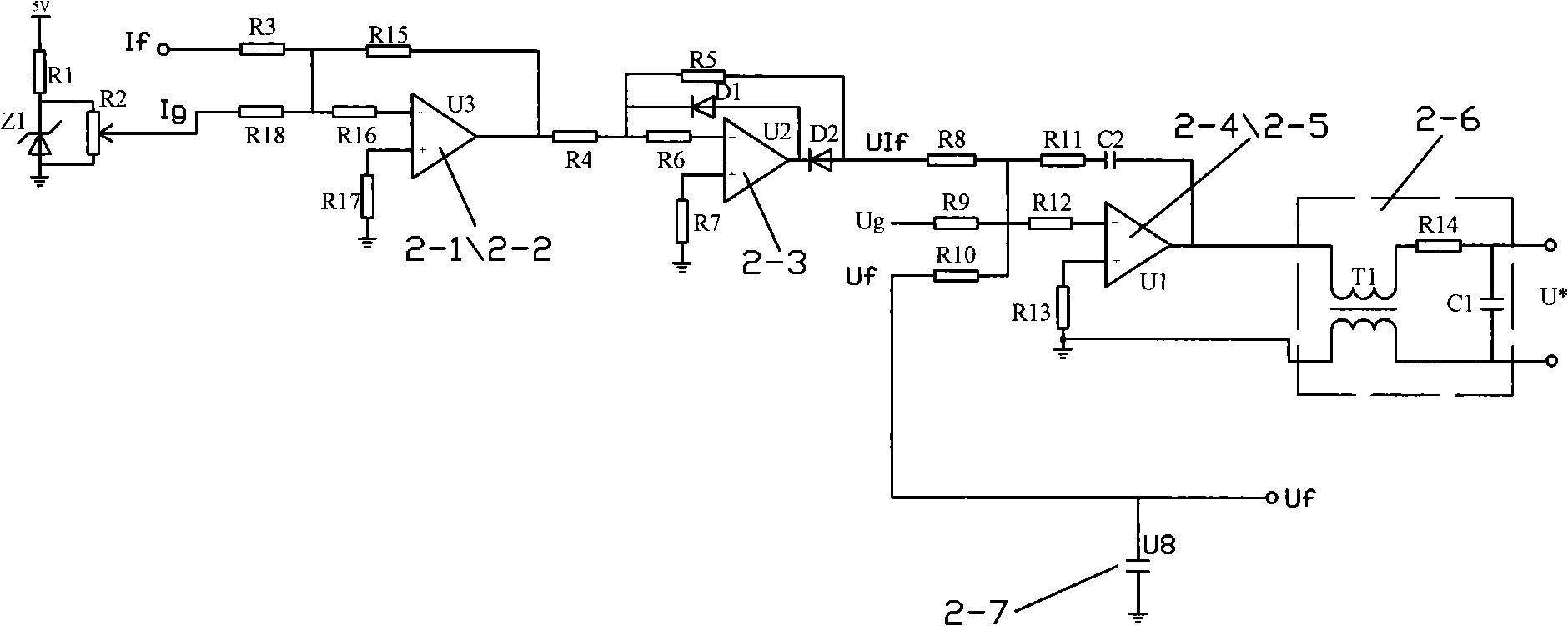

[0016] see figure 1 , 2 , the DC switching power supply module 1 has an AC-DC-AC-DC conversion main loop, which is mainly composed of a three-phase AC rectifier 1-1, an input LC filter 1-2, a high-frequency inverter 1-3, output transformer 1-4, high-frequency rectifier 1-5 and output LC filter 1-6 are connected to form, module 1 has a current negative feedback inner loop, which is composed of comparator 1-7, the first The three subtractors 1-8, the second voltage regulator 1-9 and the pulse width regulator 1-10 are connected to form. Among them, the comparator 1-7 is a comparison detector connected by the operational amplifier U6, which completes the output of the given current Ig' and the total feedback callback value U of this module. * The comparison of the lower one is selected as the actual given value Ig of this module at the same time; the third subtractor 1-8 and the second voltage regulator 1-9 are composed of operational amplifier U5 and resistance and capacitance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com