Spray nozzles

一种喷嘴、流体的技术,应用在喷射装置、喷射装置、液体喷射装置等方向,能够解决机械接合损坏等问题,达到小化催化剂腐蚀、减小催化剂腐蚀、大化流动面积的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

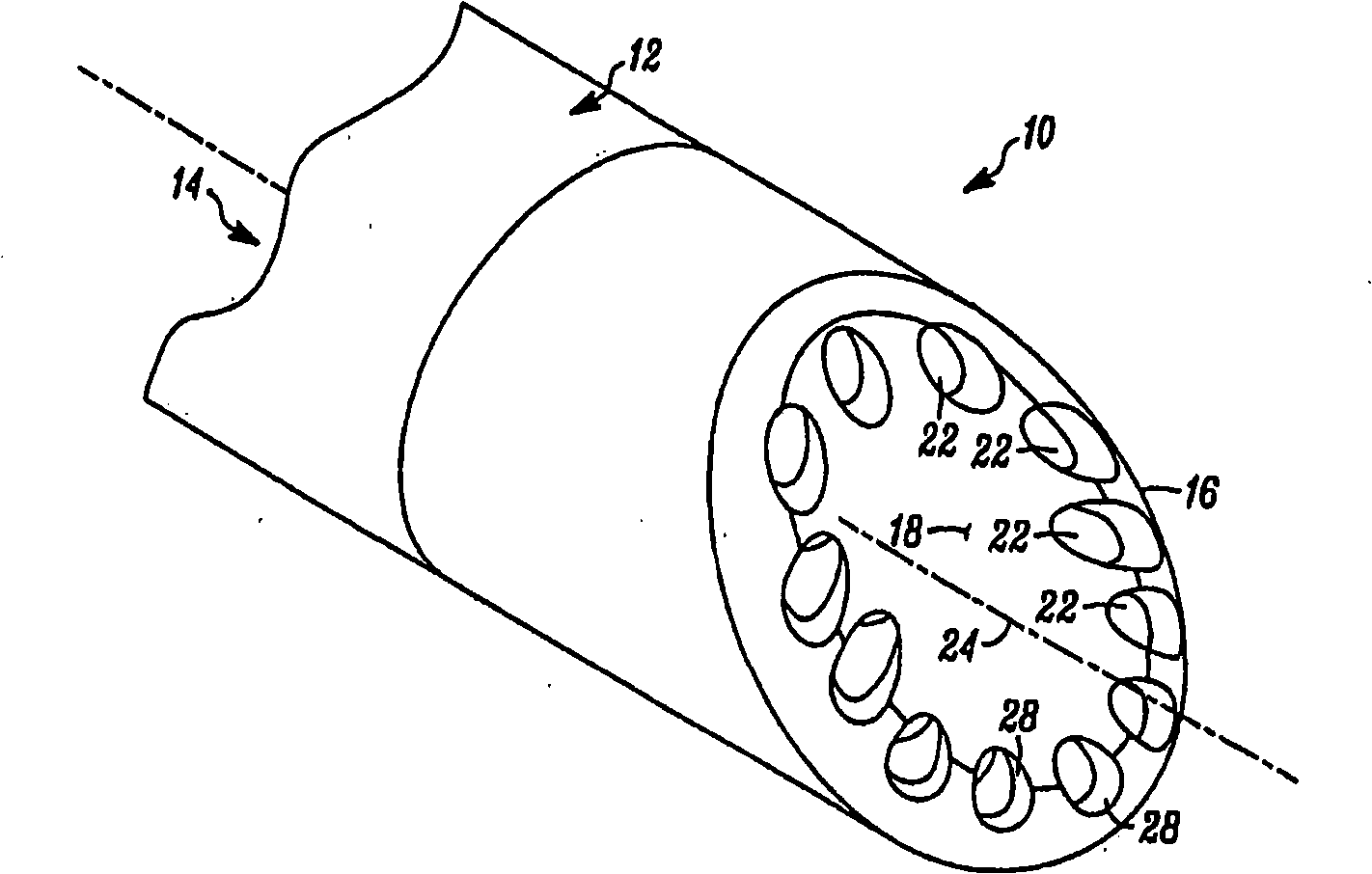

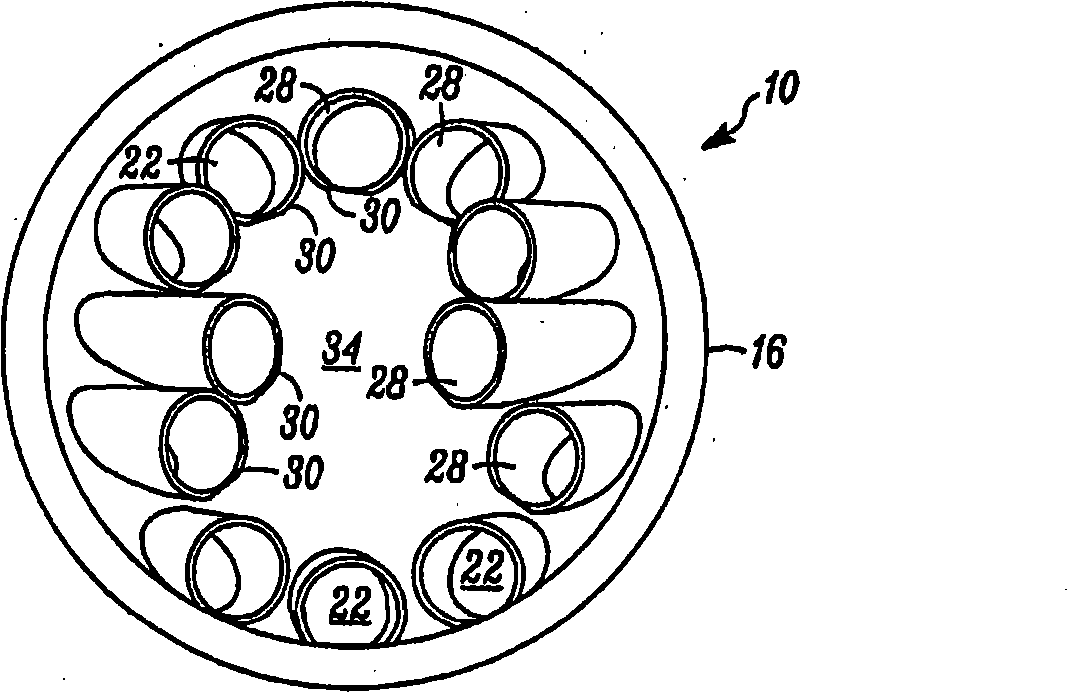

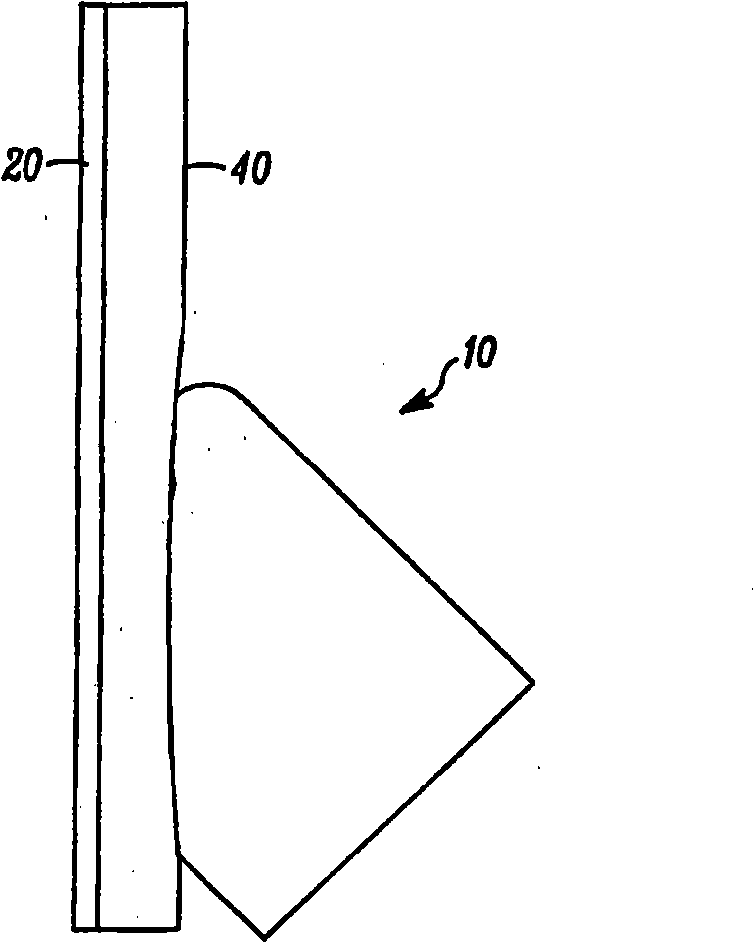

[0044] exist Figure 1-8 The nozzle of the first embodiment of the present invention is generally indicated by reference numeral 10 . The nozzle 10 is used to discharge the first and second fluids as atomized jets into a container 20 defining an inner contour. In one embodiment of the invention, the first fluid is oil, the second fluid is gas or steam, and the vessel is a catalytic cracking vessel. However, as one of ordinary skill in the relevant art will recognize based on the teachings herein, the nozzles of the present invention may be equally used with any of a variety of different types of fluids, as well as many different types of fluids now known or hereafter known. Any application of type .

[0045] The nozzle 10 includes an inlet portion 12 defining at least one inlet conduit 14 for receiving at least one fluid, in one embodiment first and second fluids. The outlet portion 16 of the nozzle defines an outer surface 18 conforming substantially to the interior contou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com