Hemming working method and working apparatus

A processing method and technology for processing equipment, which are applied in the field of hemming processing and hemming processing equipment, can solve the problems of expensive hemming equipment, difficult part hemming processing with a large radius of curvature, and expensive hemming forming equipment, etc. Edge processing, accurate and fast positioning, and the effect of preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

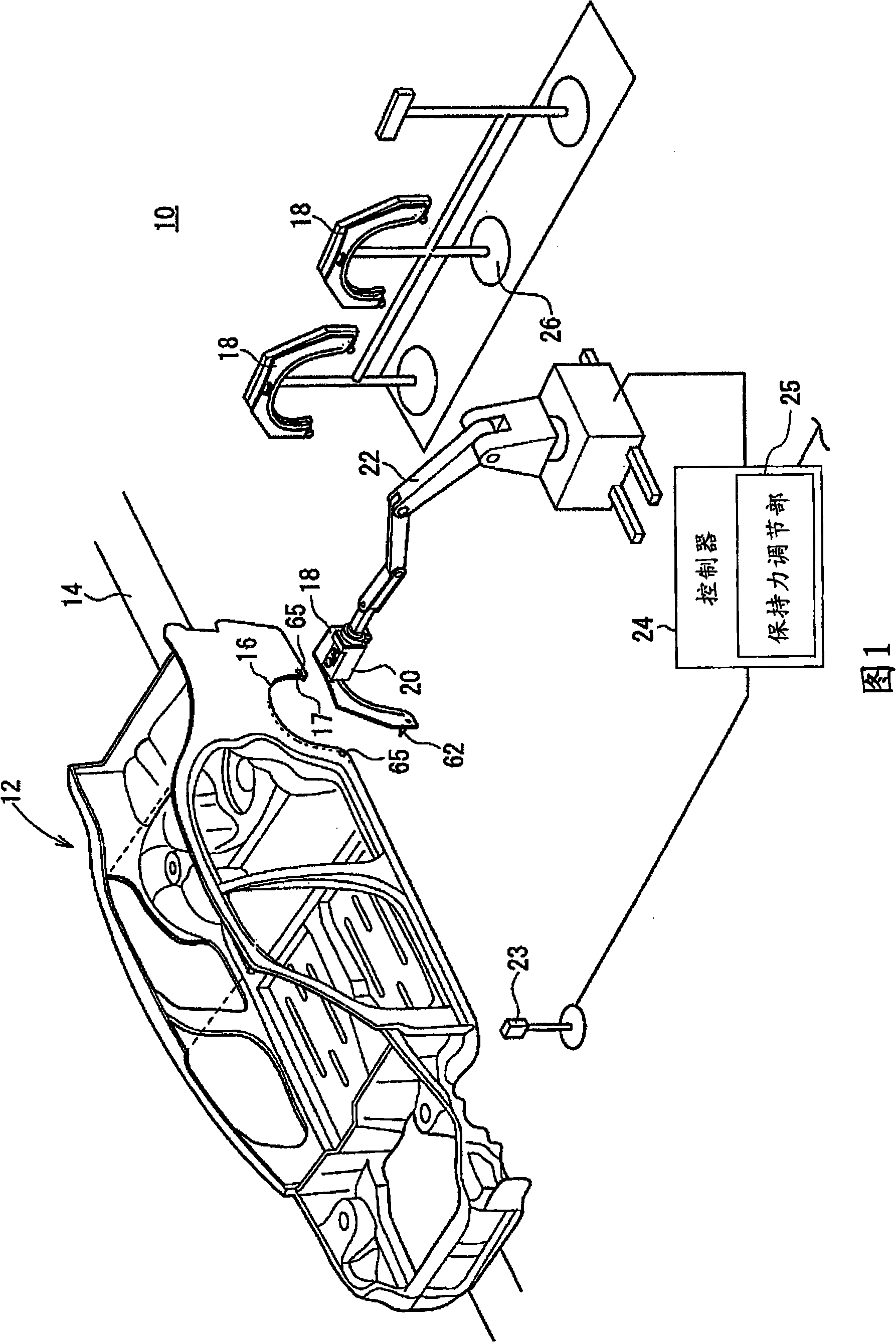

[0219] Hereinafter, a hemming processing method and a hemming processing apparatus according to exemplary embodiments of the present invention will be described with reference to the accompanying drawings.

[0220]

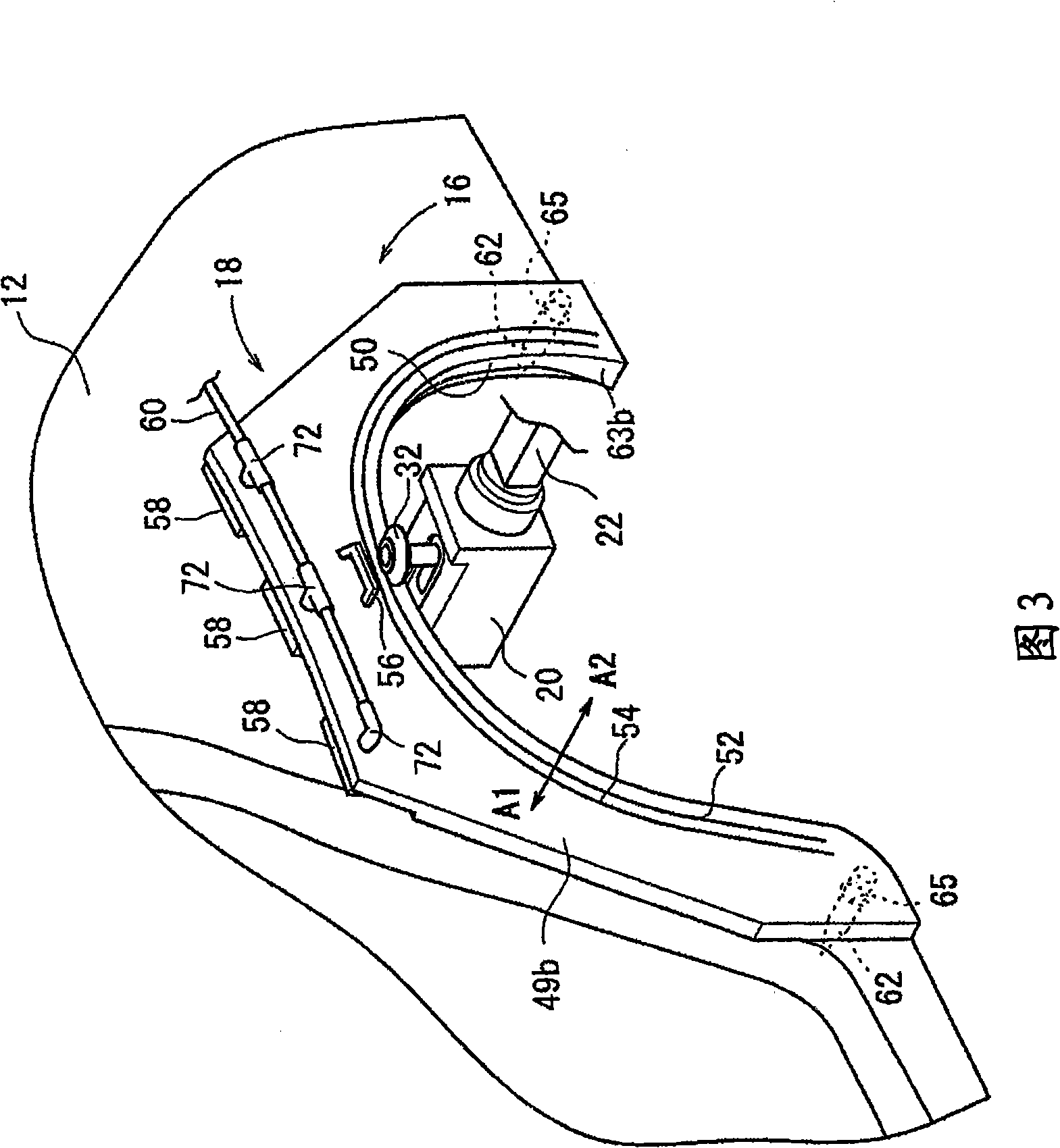

[0221] As shown in FIG. 1 , the hemming processing apparatus 10 according to the present embodiment is provided at an intermediate step of a production line 14 for assembling and processing a vehicle (workpiece) 12 in a so-called body-in-white state. The flange 17 of the wheel arch is an equipment for roll hemming. The wheel arch portion 16 is configured in a substantially circular arc shape of 180°. In a state before being processed by the hemming apparatus 10 , the flange 17 is configured in a shape bent inwardly by 90° from the end portion 16 a (see FIG. 6 ) of the wheel arch portion 16 .

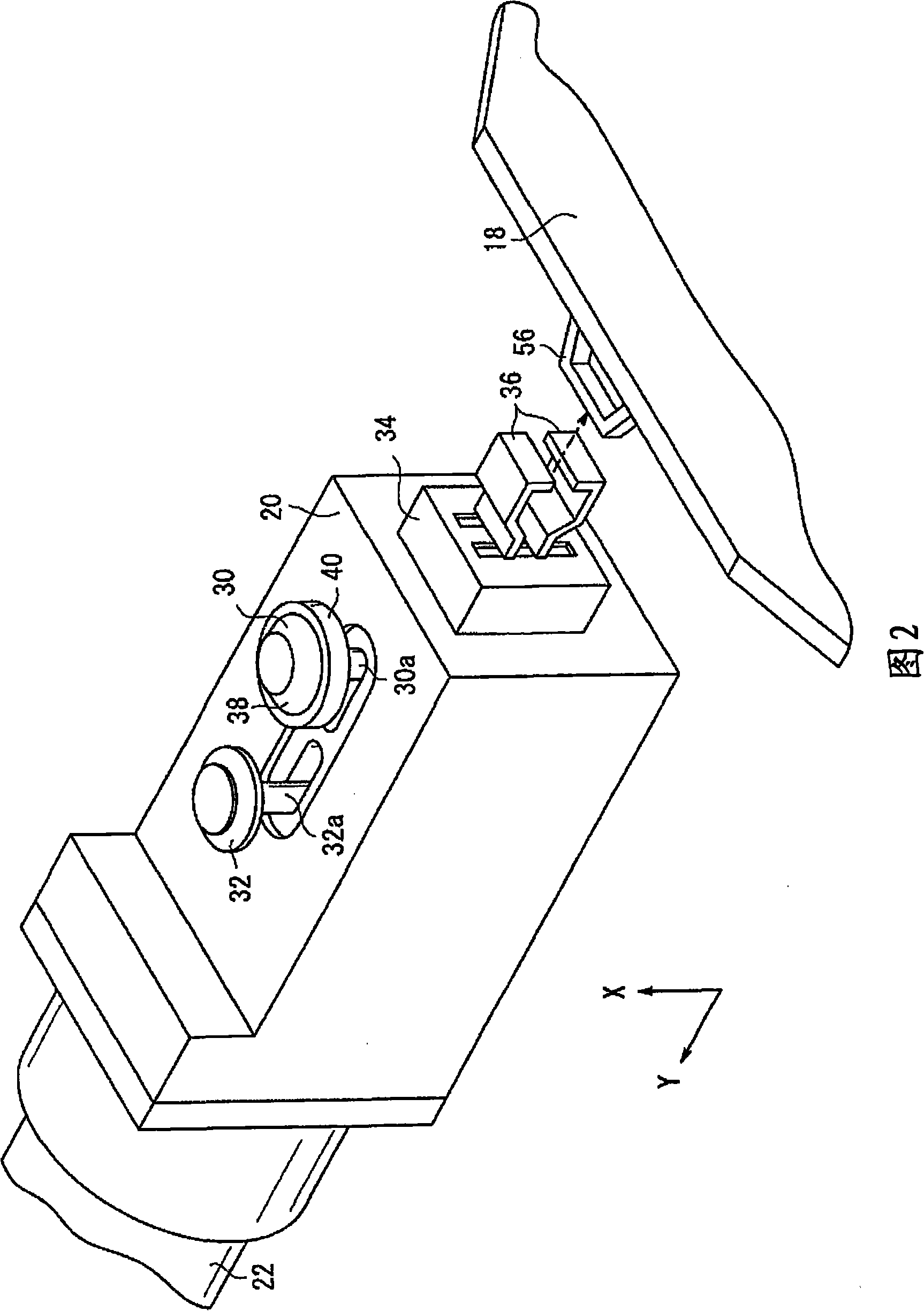

[0222] The hemming processing apparatus 10 includes a moving die 18, which is in contact with the wheel arch 16 of the vehicle 12 (which constitutes a workpiece), a robot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com