Multi-nutrient composite yeast powder

A compound yeast, multi-nutrient technology, applied in food preparation, application, food science and other directions, can solve problems such as large side effects and poor effect, and achieve high content, improve malnutrition, and be beneficial to human nutritional balance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

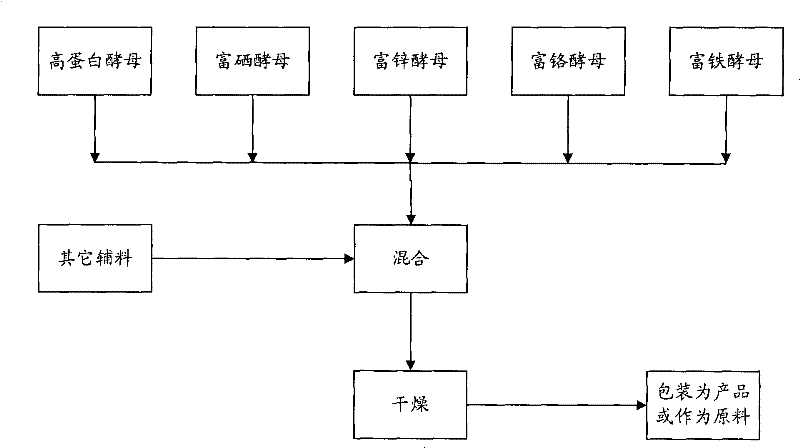

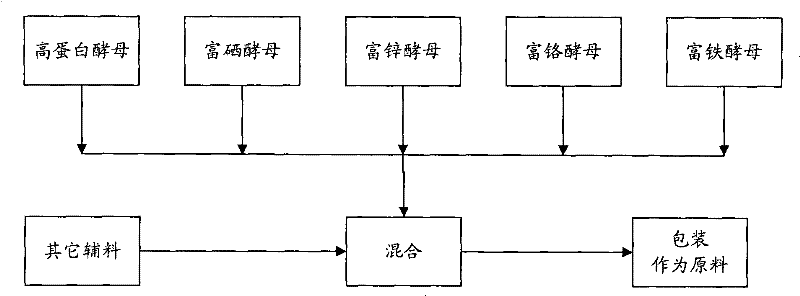

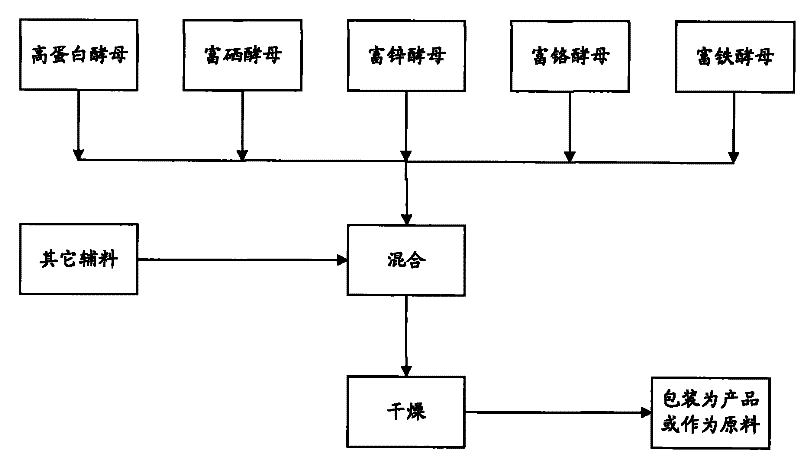

Method used

Image

Examples

preparation example Construction

[0037] In one embodiment of the present invention, a kind of preparation method of high protein yeast is provided, comprises the steps:

[0038] (1) High-protein yeast seed culture: inoculate the high-protein yeast strain culture solution into 0.5-15L sugar-containing (wort or molasses or a mixture of wort and molasses) with an amount of 25-30%, ammonia water or urea The content is 16%, the ammonium dihydrogen phosphate content is 10%, and the pH value is 4.6-5.0 in a seed fermenter, and cultivated at 28-30 DEG C for 24-48 hours. Among them, sugar source, nitrogen source and phosphorus source are added in feeding mode.

[0039] (2) Preparation of high-protein yeast: Inoculate the seed culture solution to 1-300 tons of sugar-containing (starch hydrolyzed sugar or molasses or a mixture of starch hydrolyzed sugar and molasses) amount of 25-30%, ammonia or urea content of 16% , the content of ammonium dihydrogen phosphate is 10%, and the pH value is 4.8~6.5 in the fermenter tank,...

Embodiment 1

[0057] Embodiment 1: the preparation of high protein yeast

[0058] (1) High-protein yeast seed culture: inoculate the high-protein yeast strain culture solution into 5L sugar-containing (wort or molasses or a mixture of wort and molasses) amount of 25%, ammonia or urea content of 16% , the content of ammonium dihydrogen phosphate is 10%, and the pH value is 4.8 in a seed fermenter, and cultivated at 30° C. for 48 hours. Among them, sugar source, nitrogen source and phosphorus source are added in feeding mode.

[0059] (2) Preparation of high-protein yeast: inoculate the seed culture solution to 1 ton of sugar-containing (starch hydrolysis sugar or molasses or starch hydrolysis sugar and molasses mixture) amount of 25%, ammonia or urea content of 16%, dihydrogen phosphate In a fermenter with an ammonium content of 10% and a pH value of 4.8, the nutrient source used is fed-batch, the concentration of ammonia or urea in the fermentation liquid is controlled, and cultured at 3...

Embodiment 2

[0060] Embodiment 2: Preparation of chromium-rich yeast

[0061] (1) Chromium-enriched yeast seed culture: inoculate the chromium-enriched yeast culture solution into a 10L container containing 20% sugar (wort or molasses or a mixture of wort and molasses), chromium (chromium trichloride) The concentration is 100 μg / ml, supplemented with appropriate nitrogen source and phosphorus source, and cultured at 32° C. for 36 hours in a seed fermenter with a pH value of 5.5.

[0062] (2) Preparation of chromium-rich yeast: inoculate the seed culture solution to 1 ton of sugar-containing (starch hydrolyzed sugar or molasses or starch hydrolyzed sugar and molasses mixture) amount of 20%, chromium (chromium trichloride) concentration is 100 μ g / ml, supplemented with appropriate nitrogen and phosphorus sources, in a fermenter with a pH value of 5.5, the nutrient source used was fed-batch, and chromium was added in batches. After cultivating for 24 hours at 32°C, centrifuge and remove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com