Multi-path circulation peanut shell remover

A peeling machine and peanut technology, which is applied in the fields of shelling, pod removal, food science, etc., can solve the problems of high damage rate of peanuts, high impurity content of peanuts, small shells that are not clean, and achieve the effect of shelling Good, improve the peeling degree, reduce the effect of impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

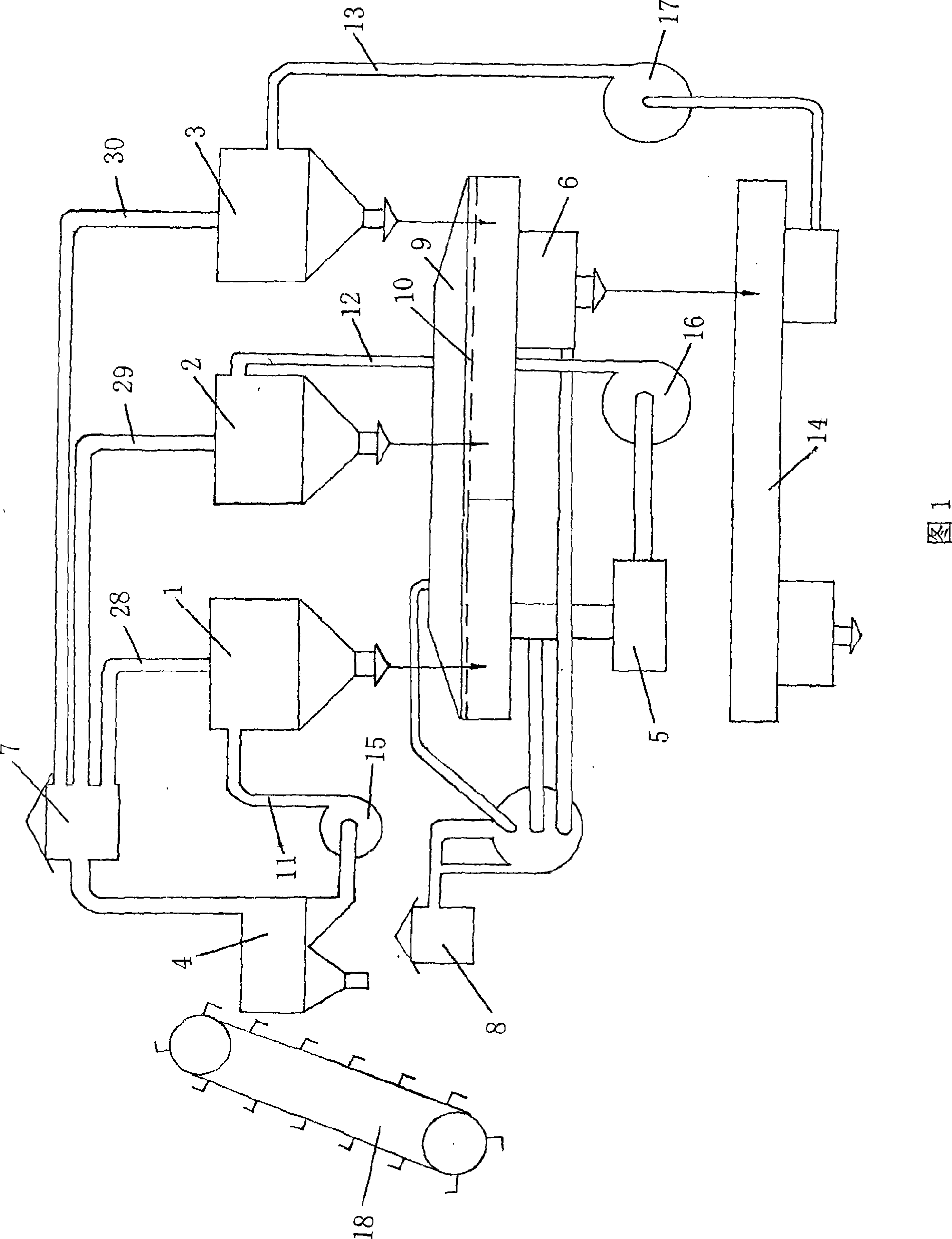

[0021] Referring to Fig. 1, a large fruit peeler 1, a medium fruit peeler 2 and a small fruit peeler 3 are arranged in three levels; below each peeler, a sorting vibrating screen 9 is set, and the sorting vibrating screen 9 The materials on the upper layer of the screen separated by the screen 10 are dropped in the secondary hopper 5, and the materials on the lower layer of the screen are dropped in the tertiary hopper 6;

[0022] As shown in Figure 1, the three-stage shellers are arranged in series, including setting the raw material hopper as the first-stage hopper 4, and the vibrating specific gravity device 14 as the discharge hopper; the first-stage hopper 4 is used as the input hopper of the large fruit sheller 1, and the second-stage hopper is used as the input hopper of the large fruit sheller 1. The hopper 5 is the input hopper of the middle fruit peeler 2 , the three-stage hopper 6 is the input hopper of the small fruit peeler 3 , and the vibrating specific gravity me...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap