Flotation column pulp quadric mineralising method

A flotation column and pulp technology, used in flotation, solid separation, etc., can solve the problems of uneven bubble size, reduced pulp throughput, easy scaling and clogging of corrugated plates, and achieves large flotation rate constants and mineral recovery. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following pages will further illustrate the present invention in conjunction with the accompanying drawings and specific embodiments.

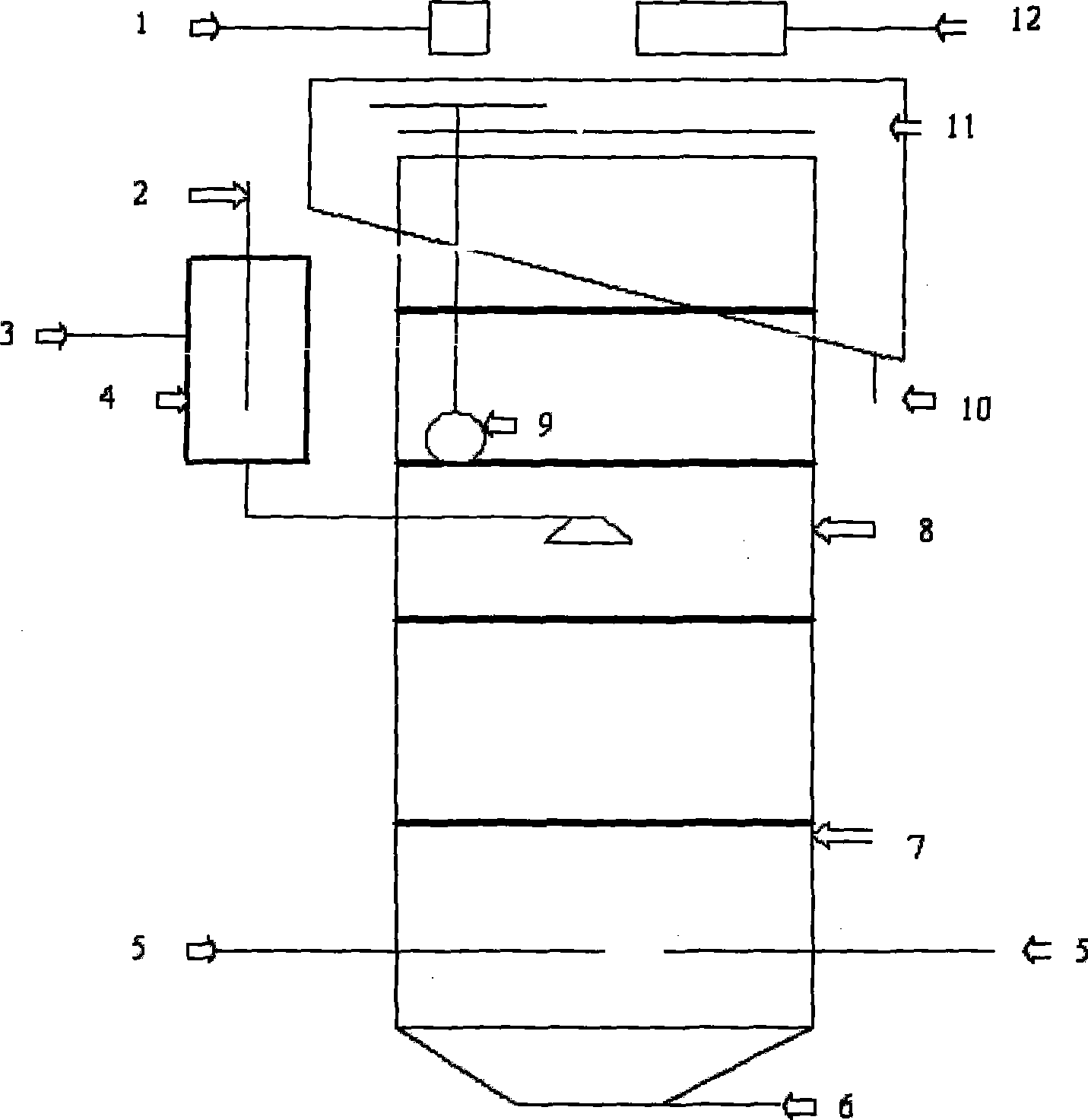

[0015] see figure 1 , The flotation column body is round or square, consisting of 3-8 sections, each section is 500-2000mm long, and the sections are connected by flanges; figure 1 The middle ultrasonic liquid level gauge 1 and the floating ball 9 are linked to measure the thickness of the foam layer; figure 1 Among them, the external pulp pre-mineralization device 4 uses the microporous bubble generator 2 to pre-mineralize the pulp, and each flotation column has at least two groups. The external microporous bubble generator 2 is used to generate microbubbles to effectively mineralize the target minerals under the condition of strong turbulent flow; a jet bubbler 5 is installed at the lower part of the flotation column to make the unfloated target minerals flow back again Mineralization and flotation have improved the recovery rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com