A modified carboxymethyl cellulose-based mineral flotation inhibitor, its preparation method and its use method

A technology of carboxymethyl cellulose and sodium carboxymethyl cellulose, which is applied in the field of modified carboxymethyl cellulose-based mineral flotation inhibitors, can solve the problems of difficult uniform dispersion, poor inhibition effect, complex composition, etc. Achieve significant economic and social benefits, increase mineral recovery rate, and improve silicon removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

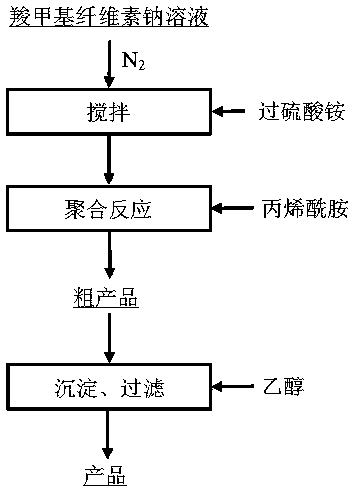

[0018] A modified carboxymethylcellulose-based mineral flotation inhibitor, the preparation process of which includes two steps of crude and refined: sodium carboxymethylcellulose, ammonium persulfate, and acrylamide in a mass ratio of 1:0.01:1 ; Dissolve 1 g sodium carboxymethylcellulose in 100 mL deionized water to make a 1% (w / v) solution, and then in N 2 Add 0.01 g of ammonium persulfate under protection, stir and mix for 30 min, then add 1 g of acrylamide, stir and react at 50 °C for 2 h to obtain the crude product of modified carboxymethylcellulose-based mineral flotation inhibitor; The crude product was added to 200 mL of ethanol, precipitated, filtered, washed, and vacuum-dried at 50 °C for 12 hours to obtain a refined modified carboxymethylcellulose-based mineral flotation inhibitor.

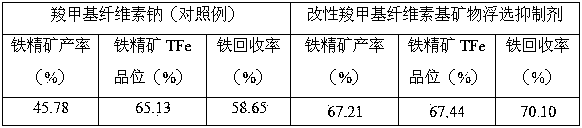

[0019] When the modified carboxymethylcellulose-based mineral flotation inhibitor is used for reverse flotation hematite desiliconization (iron content TFe=64.66wt%), the modified carbo...

Embodiment 2

[0023] A modified carboxymethylcellulose-based mineral flotation inhibitor, the preparation process of which includes two steps of crude and refined: sodium carboxymethylcellulose, ammonium persulfate, and acrylamide in a mass ratio of 1:0.01:2 ; Dissolve 1 g sodium carboxymethylcellulose in 100 mL deionized water to make a 1% (w / v) solution, and then in N 2 Add 0.01 g of ammonium persulfate under protection, stir and mix for 30 min, then add 2 g of acrylamide, stir and react at 60 °C for 3 h to obtain the crude product of modified carboxymethyl cellulose-based mineral flotation inhibitor; add the crude product to 200 mL Ethanol, precipitation, filtration, washing, and vacuum drying at 50 °C for 12 h to obtain a refined modified carboxymethyl cellulose-based mineral flotation inhibitor.

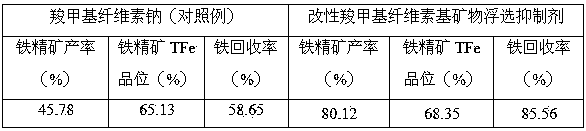

[0024] When the modified carboxymethylcellulose-based mineral flotation inhibitor is used for reverse flotation hematite desiliconization (iron content TFe=64.66wt%), the modified carboxymeth...

Embodiment 3

[0028] A modified carboxymethylcellulose-based mineral flotation inhibitor, the preparation process of which includes two steps of crude and refined: sodium carboxymethylcellulose, ammonium persulfate, and acrylamide in a mass ratio of 1:0.01:4 ; Dissolve 1 g sodium carboxymethylcellulose in 100 mL deionized water to make a 1% (w / v) solution, and then in N 2 Add 0.01 g of ammonium persulfate under protection, stir and mix for 60 min, then add 4 g of acrylamide, stir and react at 60 °C for 3 h to obtain the crude product of modified carboxymethyl cellulose-based mineral flotation inhibitor; add the crude product to 300 mL Ethanol, precipitation, filtration, washing, and vacuum drying at 50 °C for 24 h to obtain a refined modified carboxymethyl cellulose-based mineral flotation inhibitor.

[0029] When the modified carboxymethylcellulose-based mineral flotation inhibitor is used for reverse flotation hematite desiliconization (iron content TFe=64.66wt%), the modified carboxymeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com