Polishing apparatus, substrate manufacturing method, and electronic apparatus manufacturing method

A technology for polishing devices and substrates, which is applied in the direction of grinding/polishing safety devices, surface polishing machine tools, manufacturing tools, etc., and can solve the problems of not considering the prevention and removal of dust, and the inability to provide high-quality polishing processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

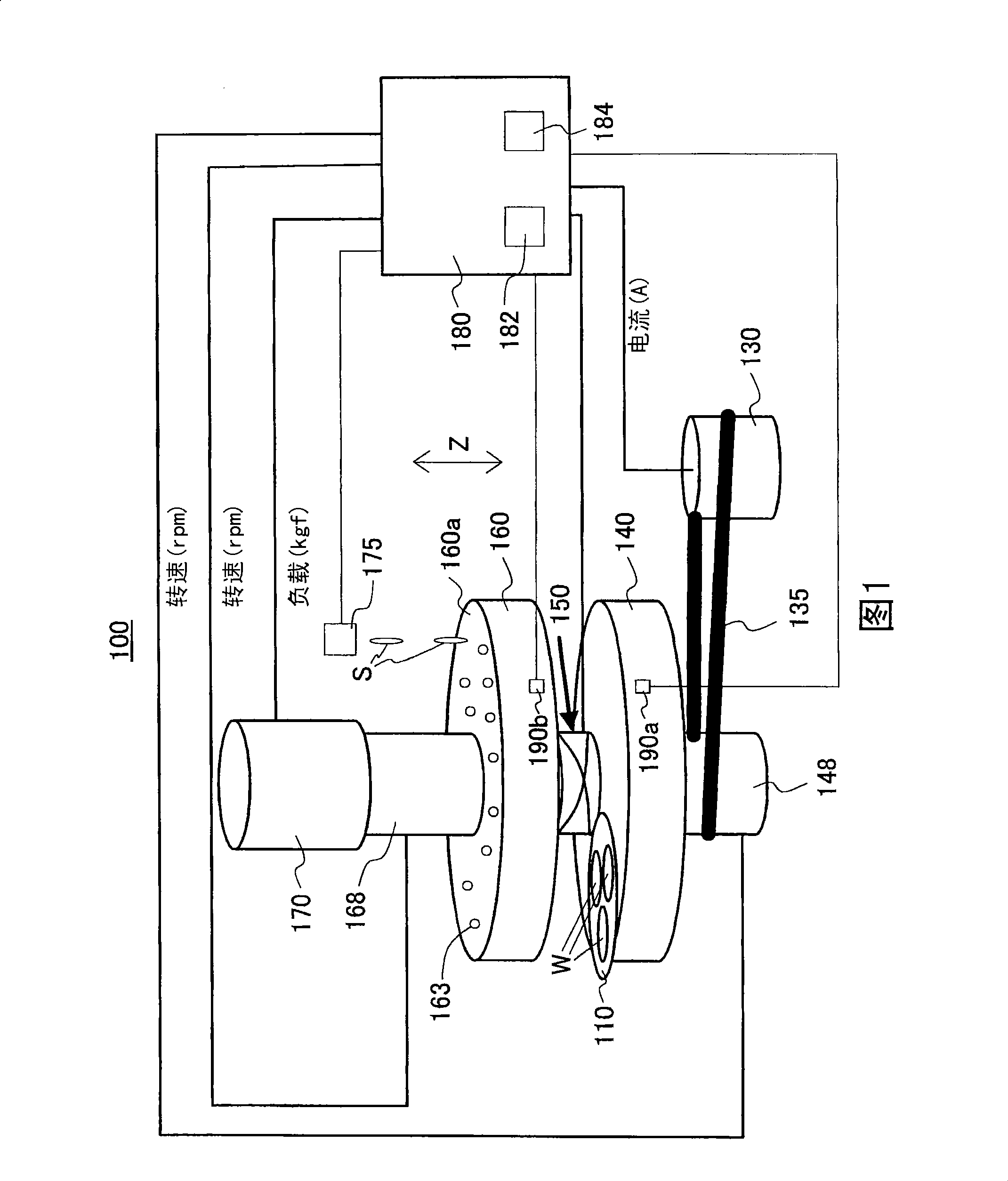

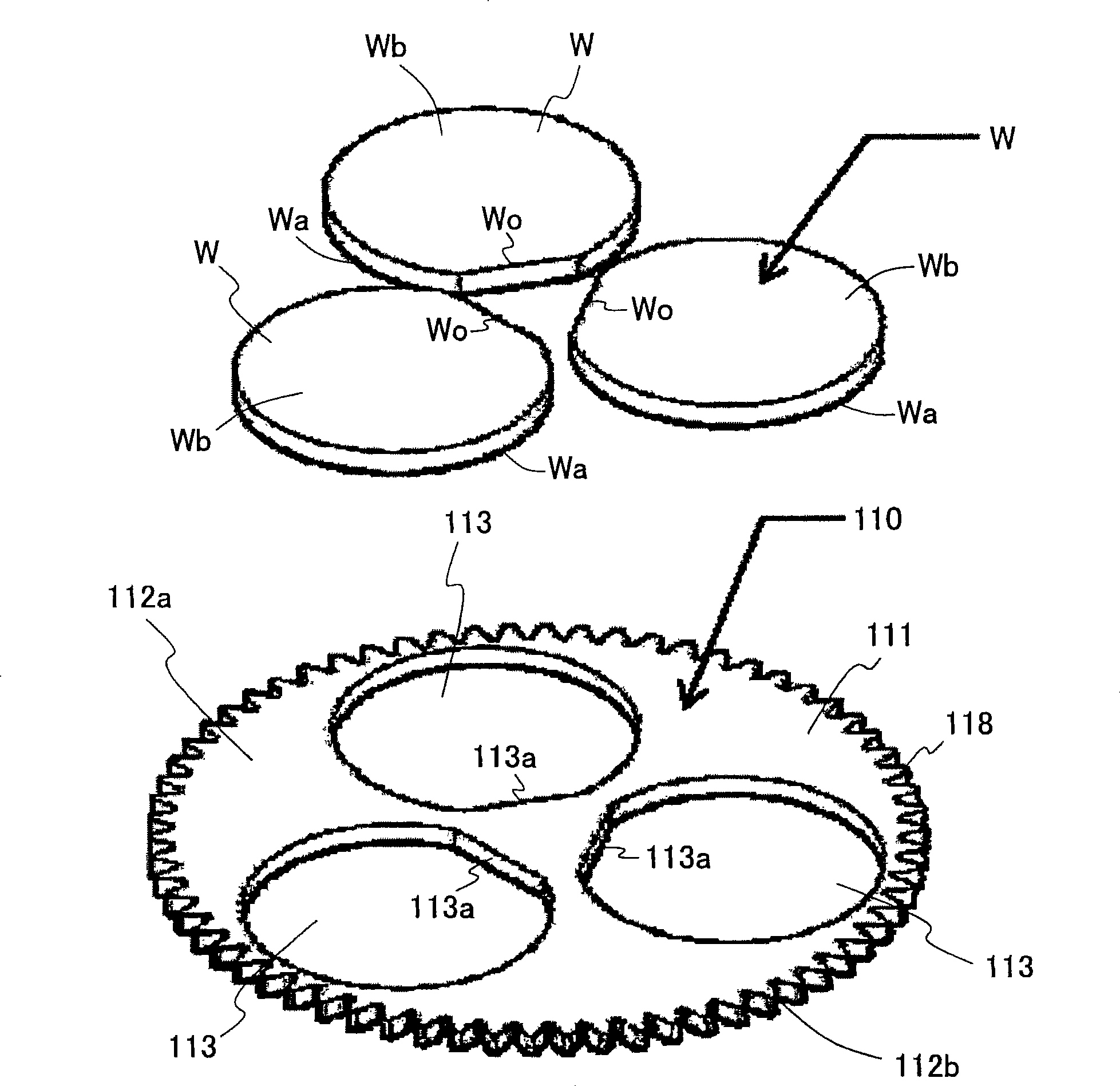

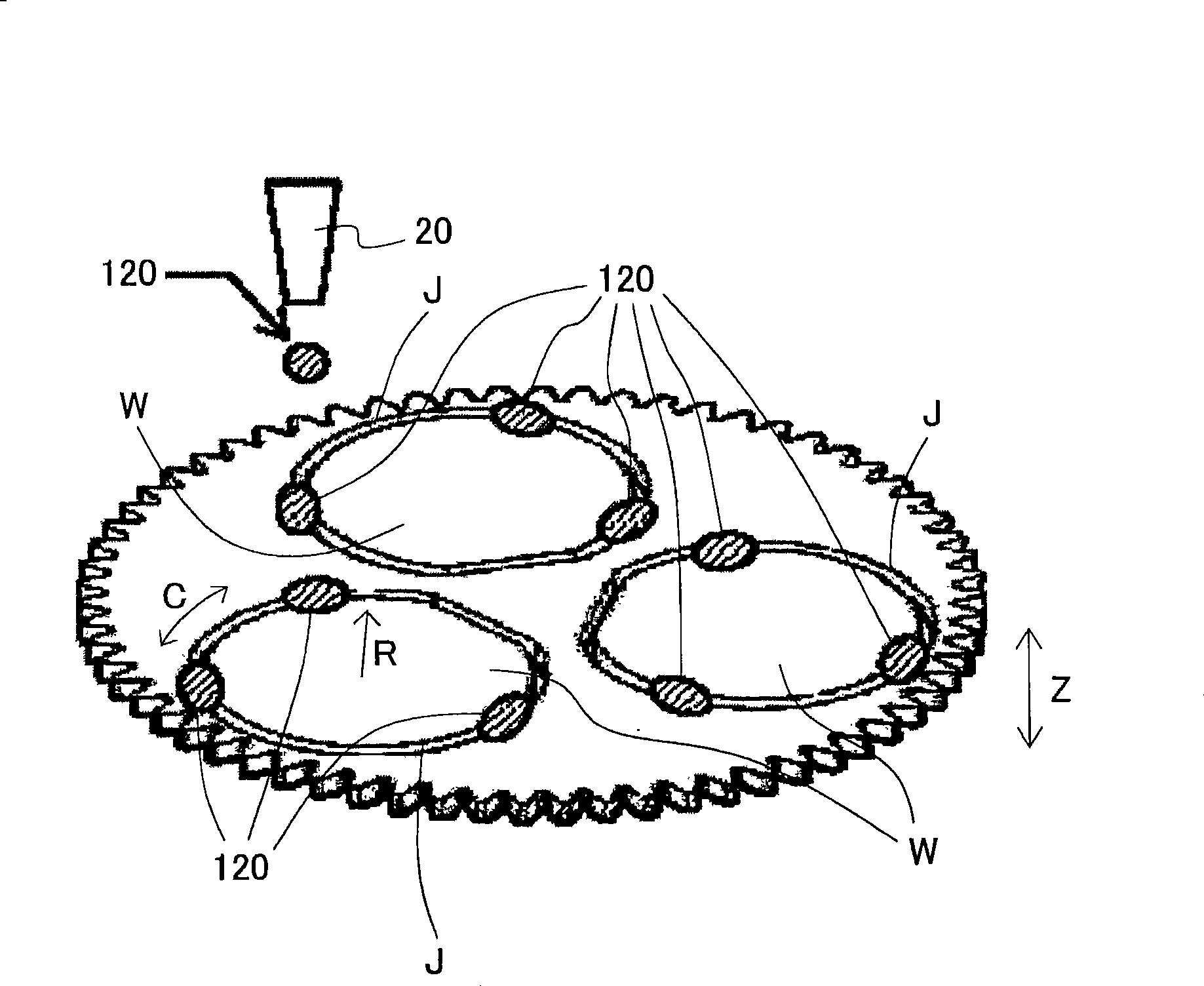

[0052] Referring now to the drawings, a polishing apparatus 100 according to an embodiment of the present invention will be described. FIG. 1 is a schematic perspective view of a polishing apparatus 100 according to the present invention. The polishing apparatus 100 is configured to simultaneously polish both surfaces of the workpiece W by chemical mechanical polishing, however, the polishing apparatus of the present invention is applicable to any polishing apparatus other than a CMP apparatus such as a polishing apparatus for finishing.

[0053] The workpiece W of this embodiment is a substrate, which is a target to be polished. Substrates include glass substrates, silicon substrates, ceramic substrates (including laminate substrates), and any other substrate made of single crystal material. Typical shapes of these substrates are disks (in the case of wafers, disks with an orientation flat) or rectangular plates. Usually, the diameter or length of the substrate is about ten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com