Acoustical insulation floor for construction and laying method thereof

A technology for construction and construction sand, which is applied to building components, sound insulation, floors, etc. It can solve the problems of complex process, expensive cost, and harsh construction conditions, and achieve simple construction process, low cost, and improved sound insulation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

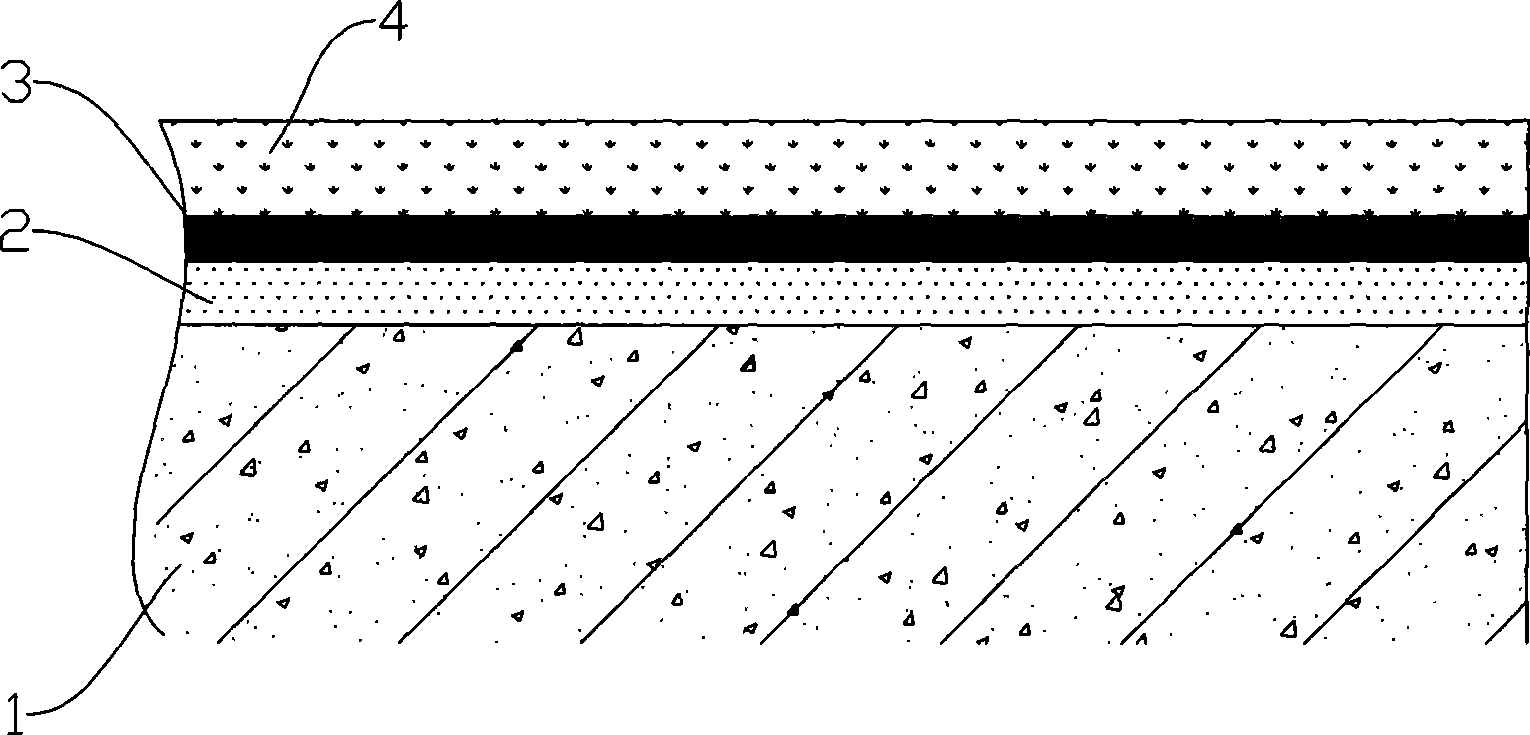

[0026] as attached figure 1 As shown in , the sound insulation floor slab of the present invention comprises an ordinary cement mortar leveling layer on the upper floor and a damping mortar plastering layer on the lower floor; the damping mortar plastering layer is laid by sound damping mortar, and the sound damping mortar The ingredients are: sand for construction, rubber granules and fine powder for construction. The sand for construction can be medium sand or fine sand for construction. In this embodiment, the spun yarn is selected, and the fineness of the selected rubber particles is required to be close to that of the spun yarn. The fine powder for construction can be fly ash or talcum powder. Fly ash is selected in this embodiment.

[0027] 60 kilograms of building sand, 20 kilograms of rubber granules and 20 kilograms of building fine powder are prepared for materials. Then carry out paving construction according to the following process steps:

[0028] A: Base tre...

Embodiment 2

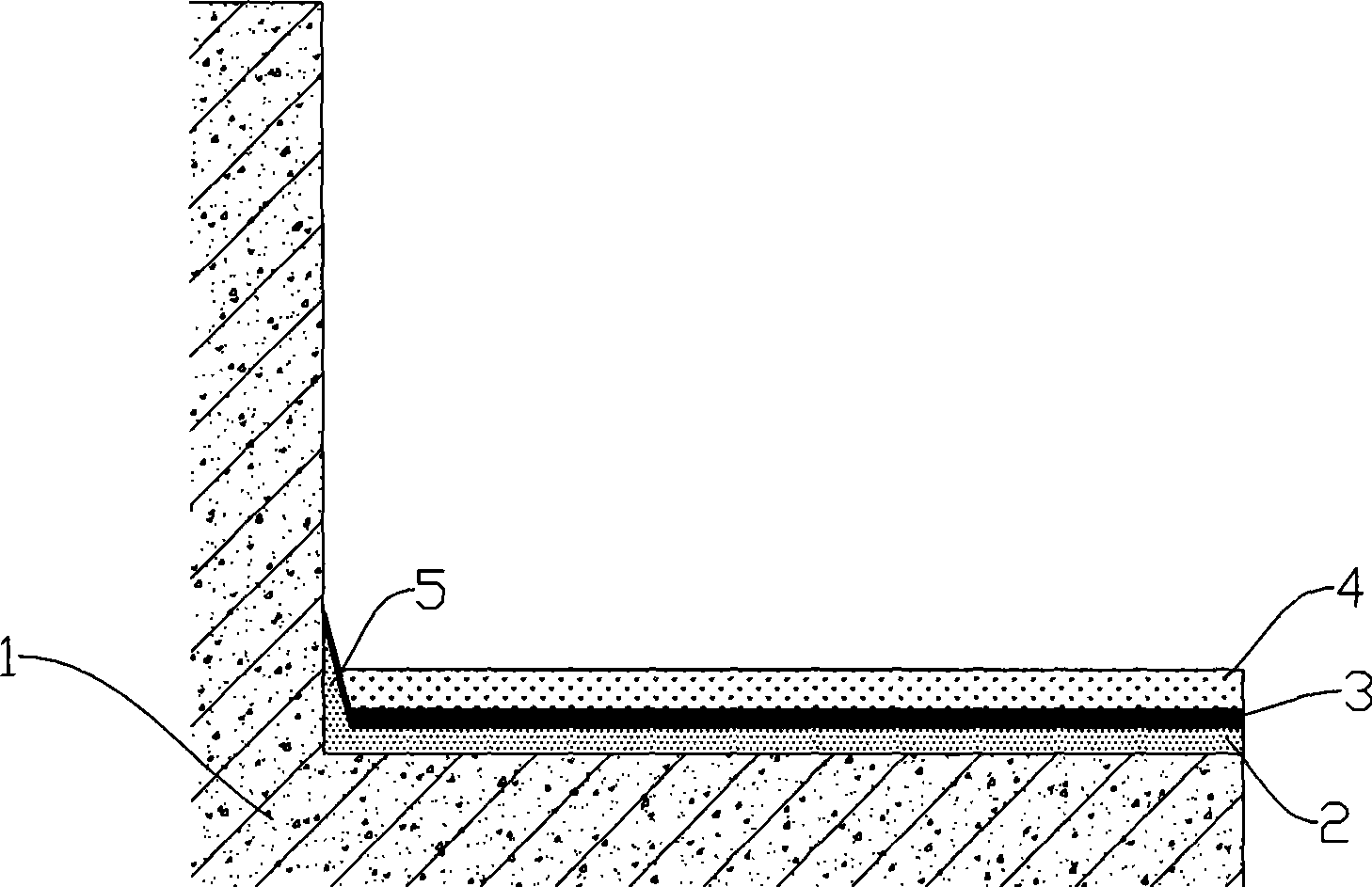

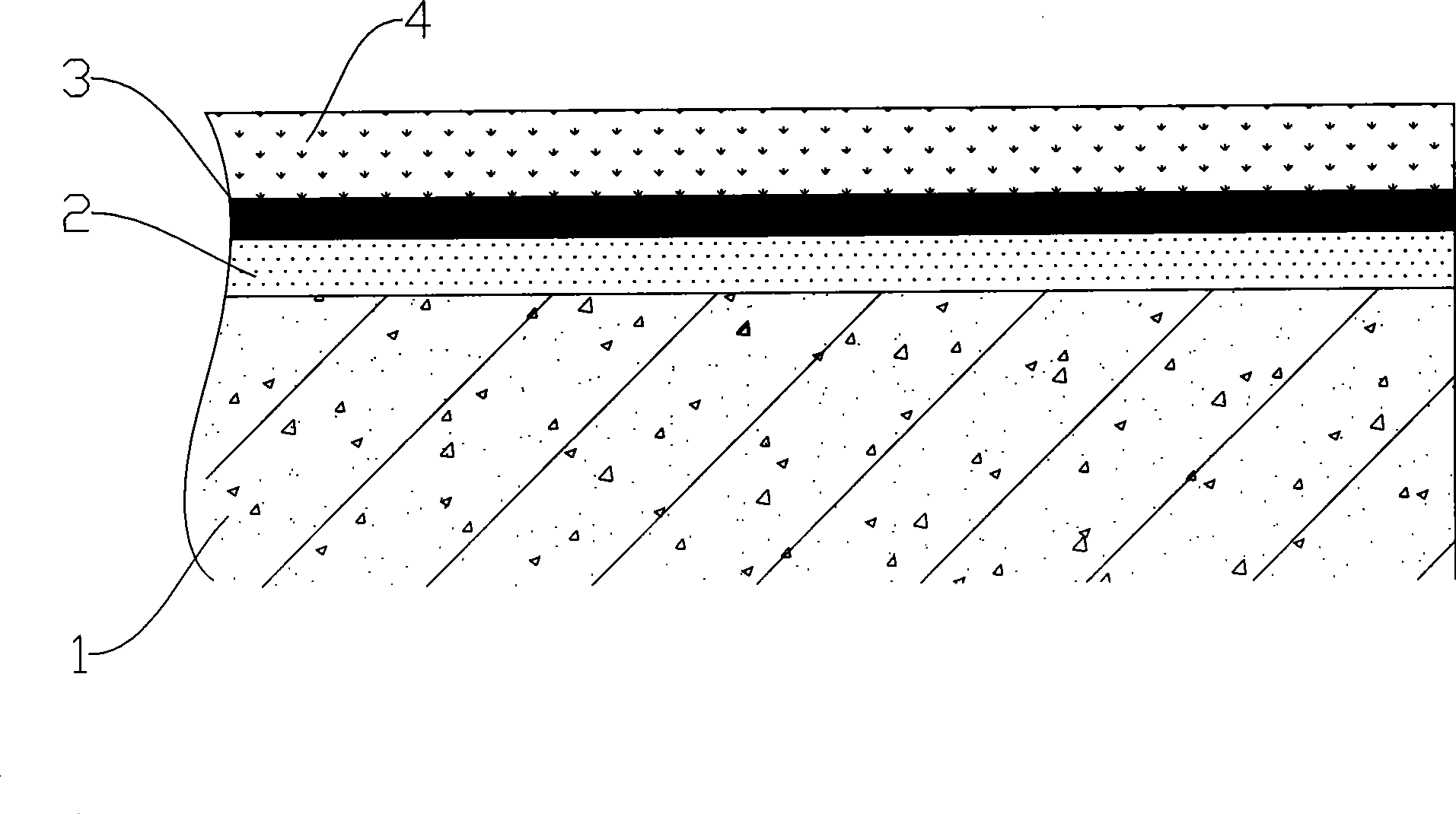

[0033] like figure 2 as shown in:

[0034] In this embodiment, first prepare the damping mortar, mix construction sand, rubber particles and construction fine powder according to the weight ratio of 80 kg of construction sand, 10 kg of rubber particles and 10 kg of construction fine powder, and then mix them evenly Add an appropriate amount of water to the damping mortar, stir evenly, and lay it on the treated floor base 1 by the method of ordinary mortar leveling layer to form a damping mortar plastering layer 2, and the thickness of the damping mortar plastering layer can be controlled to 10mm . In order to prevent sound bridges, the damping mortar plaster layer at the corner 5 should be returned to the wall for about 50mm, and its thickness should be gradually reduced from 10mm to 0mm. In order to further reduce the cost, dry cement powder is mixed with construction spun yarn at a ratio of 2:1, and then sieved on the thickness of the damping mortar plaster layer with a 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com