Anode roasting furnace for aluminum

A technology for anode roasting furnaces and furnace chambers, applied in the field of roasting furnaces, which can solve problems such as poor operating conditions of the furnace, poor process performance of the furnace, and damage to the fuel box of the furnace, so as to reduce the oxidation of anode products, improve working conditions, and prolong the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

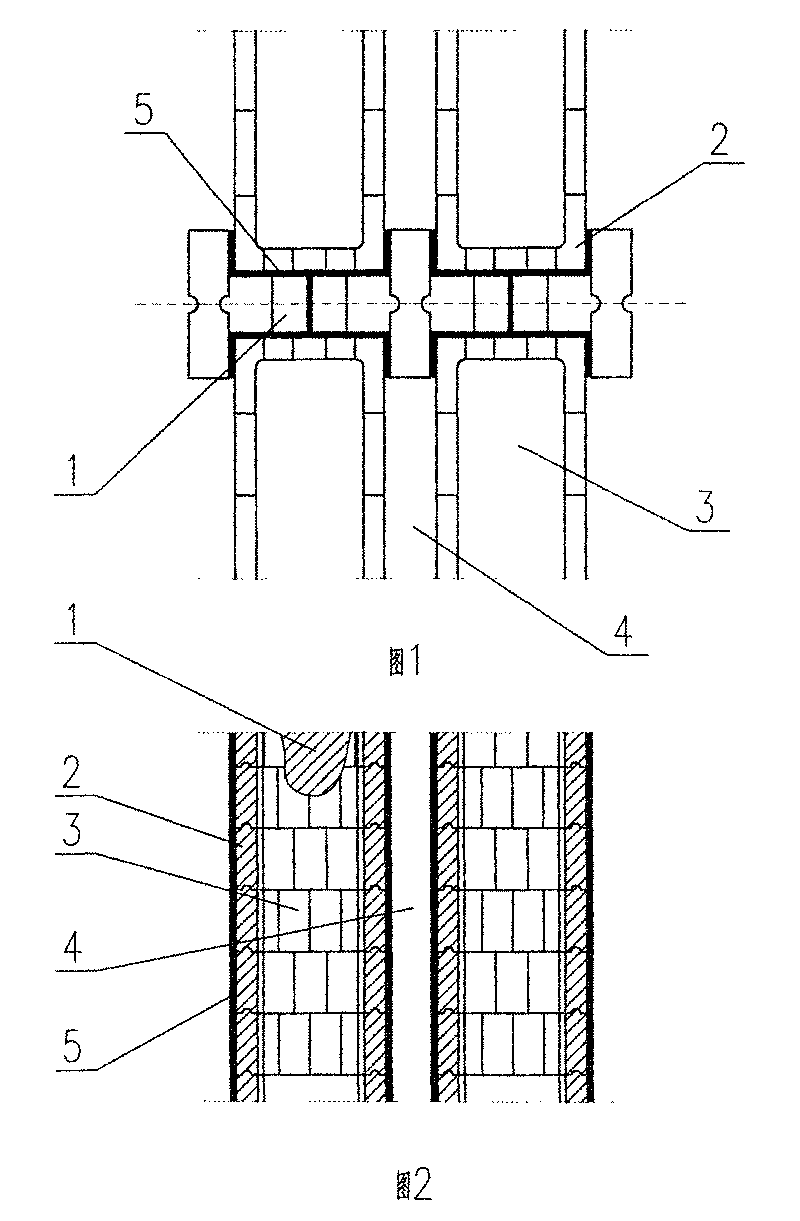

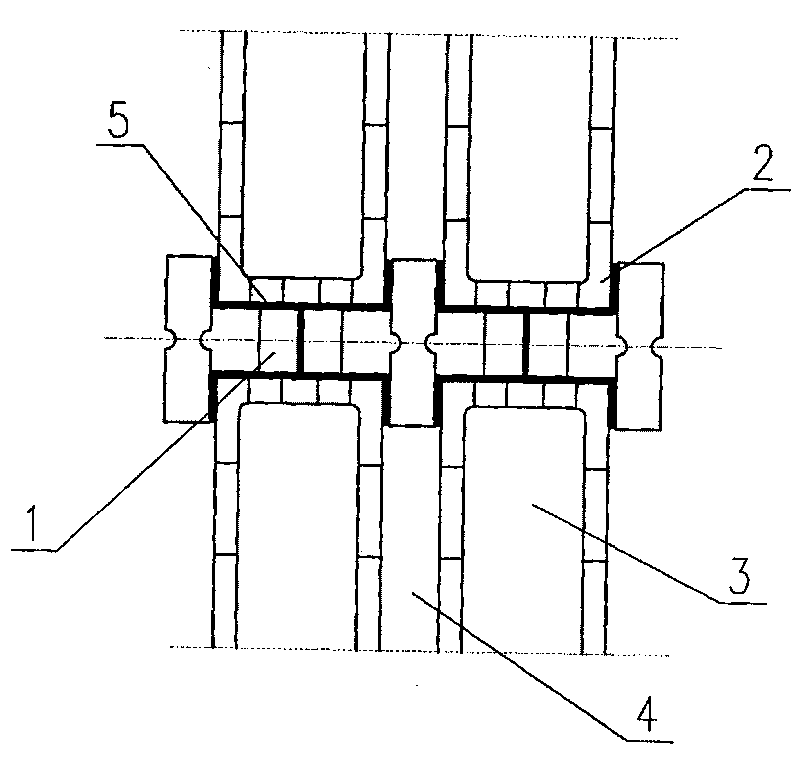

[0025] Such as figure 1 and figure 2 A kind of anode baking furnace for aluminum of the present invention shown in the present invention, it comprises transverse wall 1, flue 4 and material box 3, and material box 3 is built by laying bricks or stones 2 masonry cuboids by special-shaped bricks, and the thickness of the brick seam that special-shaped bricks 2 masonry is set can be 0 ~ 20mm, the brick joints are empty joints or filled with fillers, and the fillers can be refractory mud or high-temperature cement; the fire channel 4 is between the left and right adjacent material boxes 3, and a transverse wall 1 is provided between adjacent furnace chambers , The material box is embedded in the transverse wall. There is a gap on the horizontal wall 1, and the mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com