Rock quartz micro mechanical gyroscope based on shear stress detection and method for making same

A technology of micro-mechanical gyroscope and shear stress, which is applied to piezoelectric effect/electrostrictive or magnetostrictive motors, gyro effect for speed measurement, gyroscope/steering sensing equipment, etc., which can solve the limitation of micro-mechanical gyroscope sensitivity, Gyro zero bias has a great influence, complex electrode manufacturing process and other issues, to achieve the effects of eliminating unbalanced effects, improving anti-interference, and improving resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

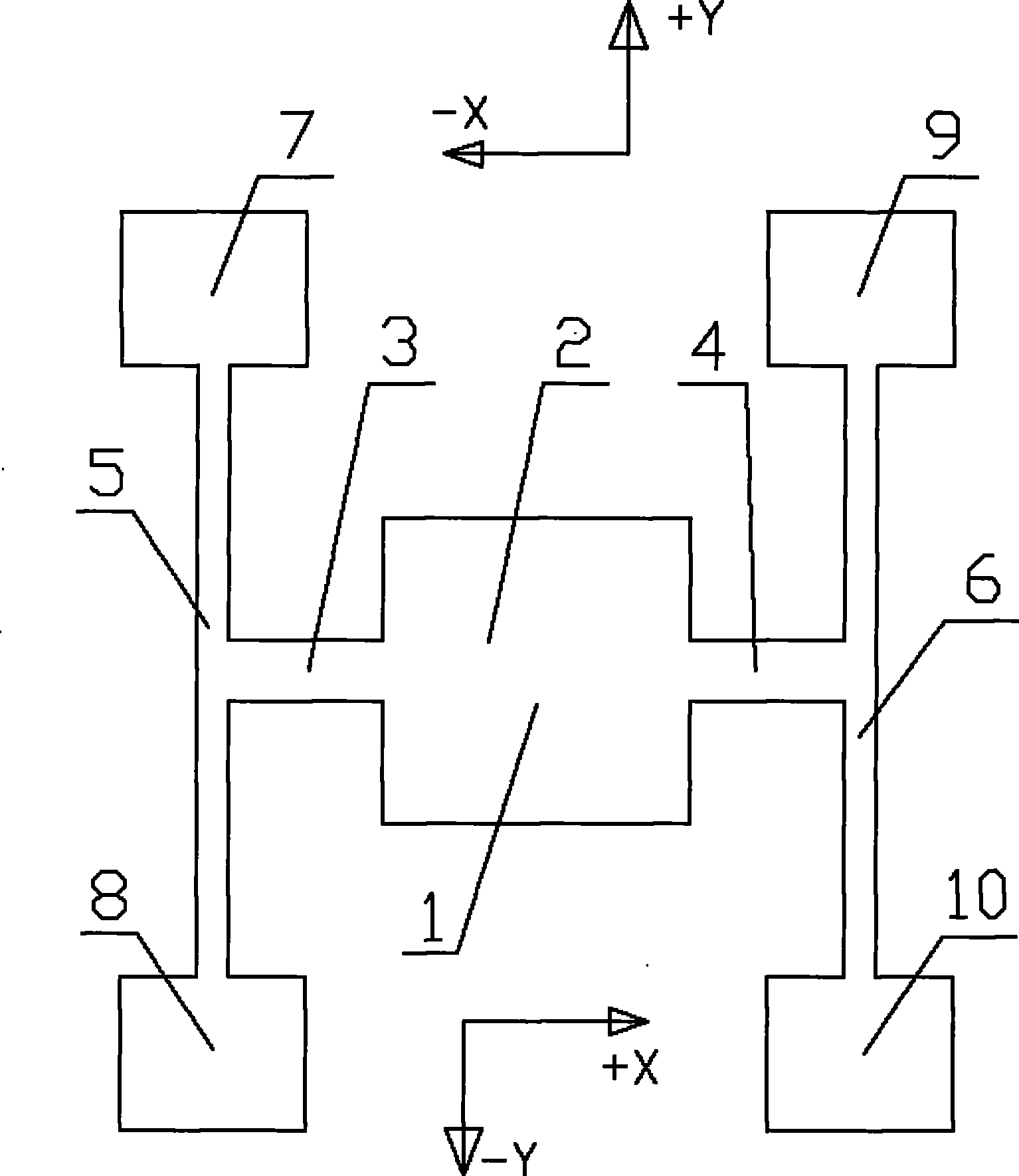

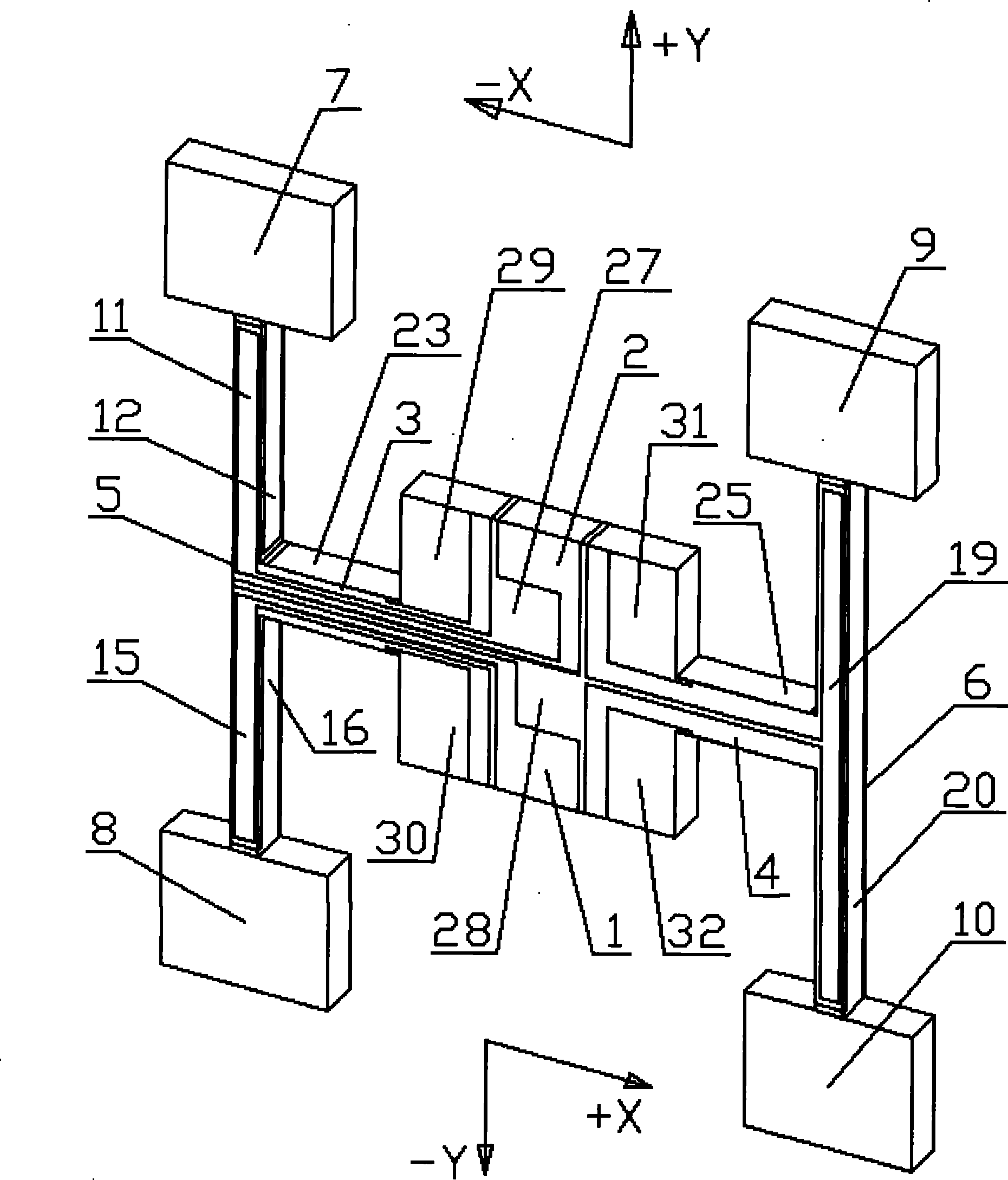

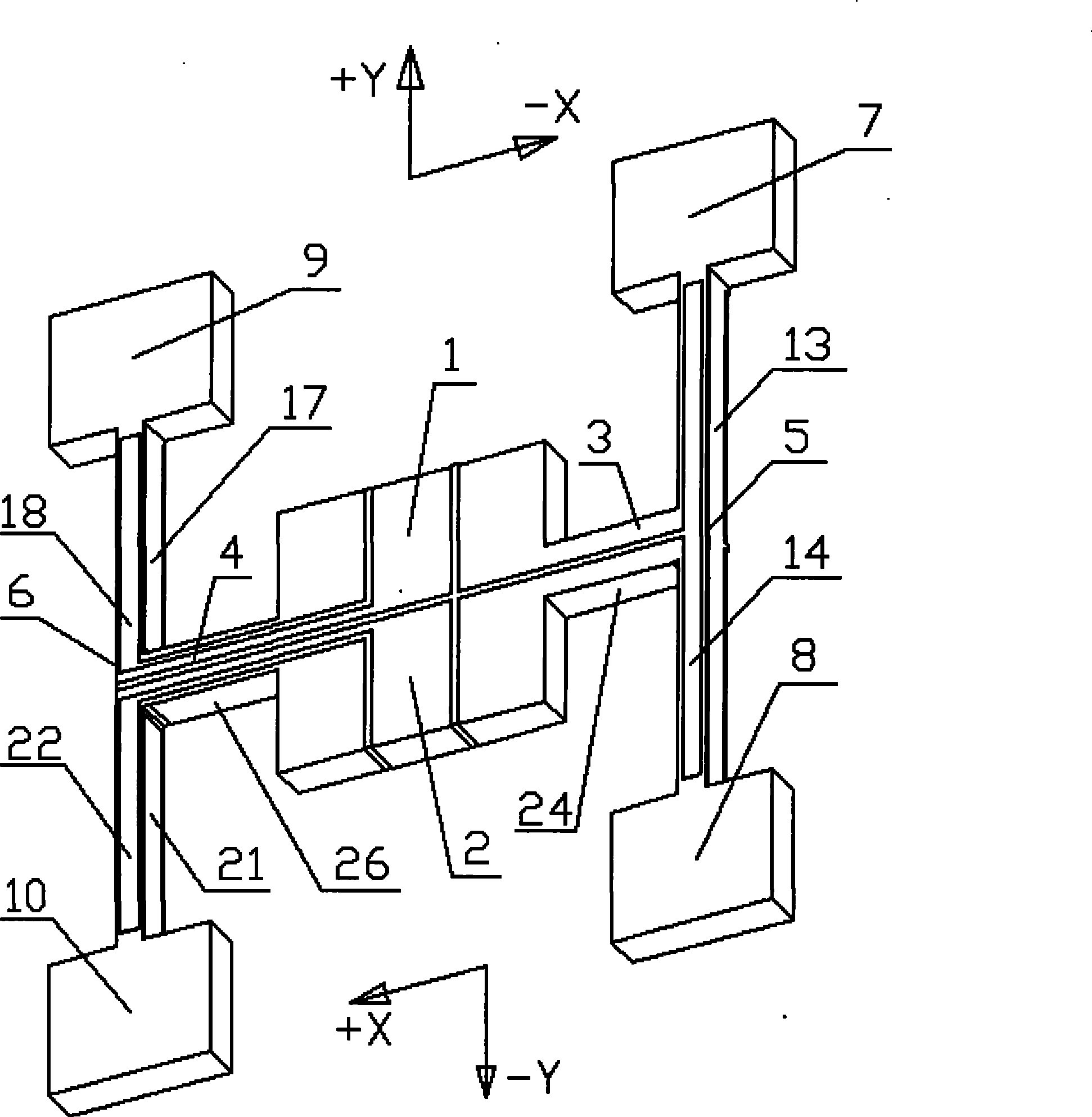

[0042] Such as figure 1 , figure 2 and image 3 Shown, a kind of quartz micromechanical gyroscope based on shear stress detection of the present invention, it comprises support mass block 2, the first cantilever beam 3, the second cantilever beam 4, the first driving beam 5, the second driving beam 6, four A movable mass and a driving electrode and a detecting electrode, the first cantilever beam 3 and the second cantilever beam 4 are symmetrically arranged at both ends of the supporting mass 2, and the supporting mass 2 passes through the first cantilever beam 3 and the first driving beam 5 connected, the supporting mass 2 is connected with the second driving beam 6 through the second cantilever beam 4, and the arrangement direction of the first driving beam 5 and the second driving beam 6 is the same as that of the first cantilev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com