Fatigue-tesing machine for ball socket bearing of helicopter main rotor

A fatigue testing machine and main rotor ball technology, applied in the direction of mechanical bearing testing, etc., can solve the problems of too conservative data, waste, and large access to industrial and mining, and achieve the effect of compact structure, convenient operation and maintenance, and beautiful appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

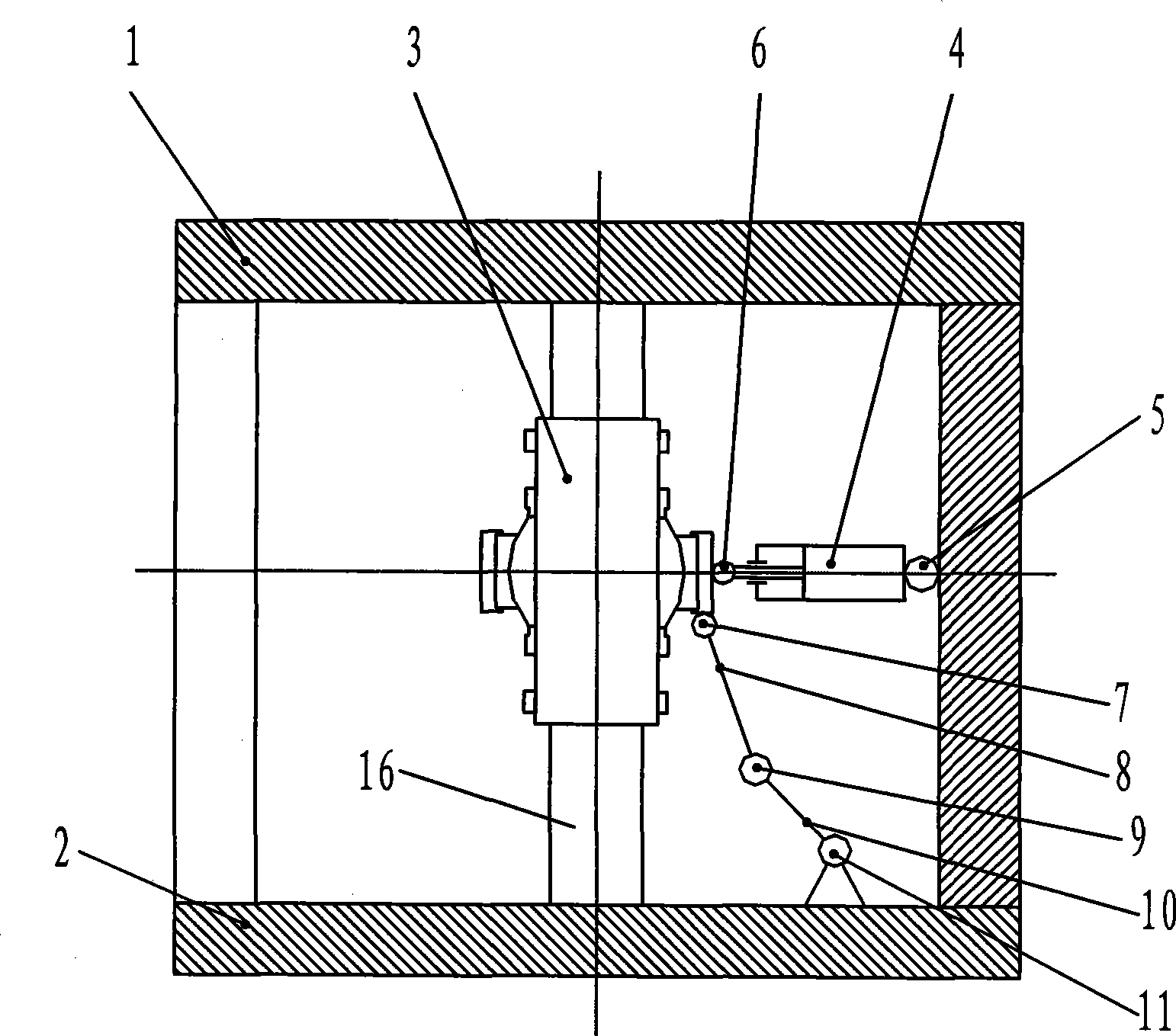

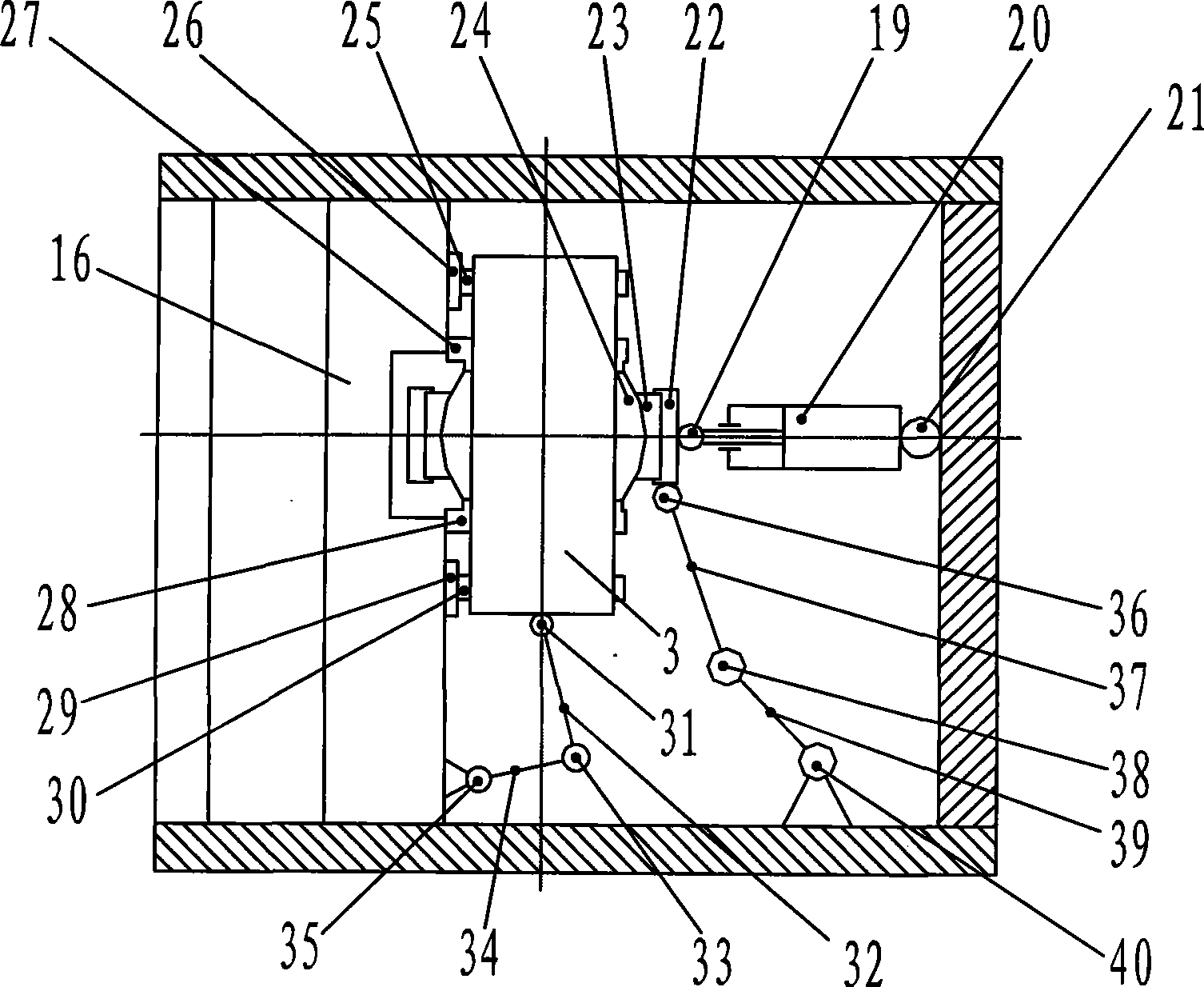

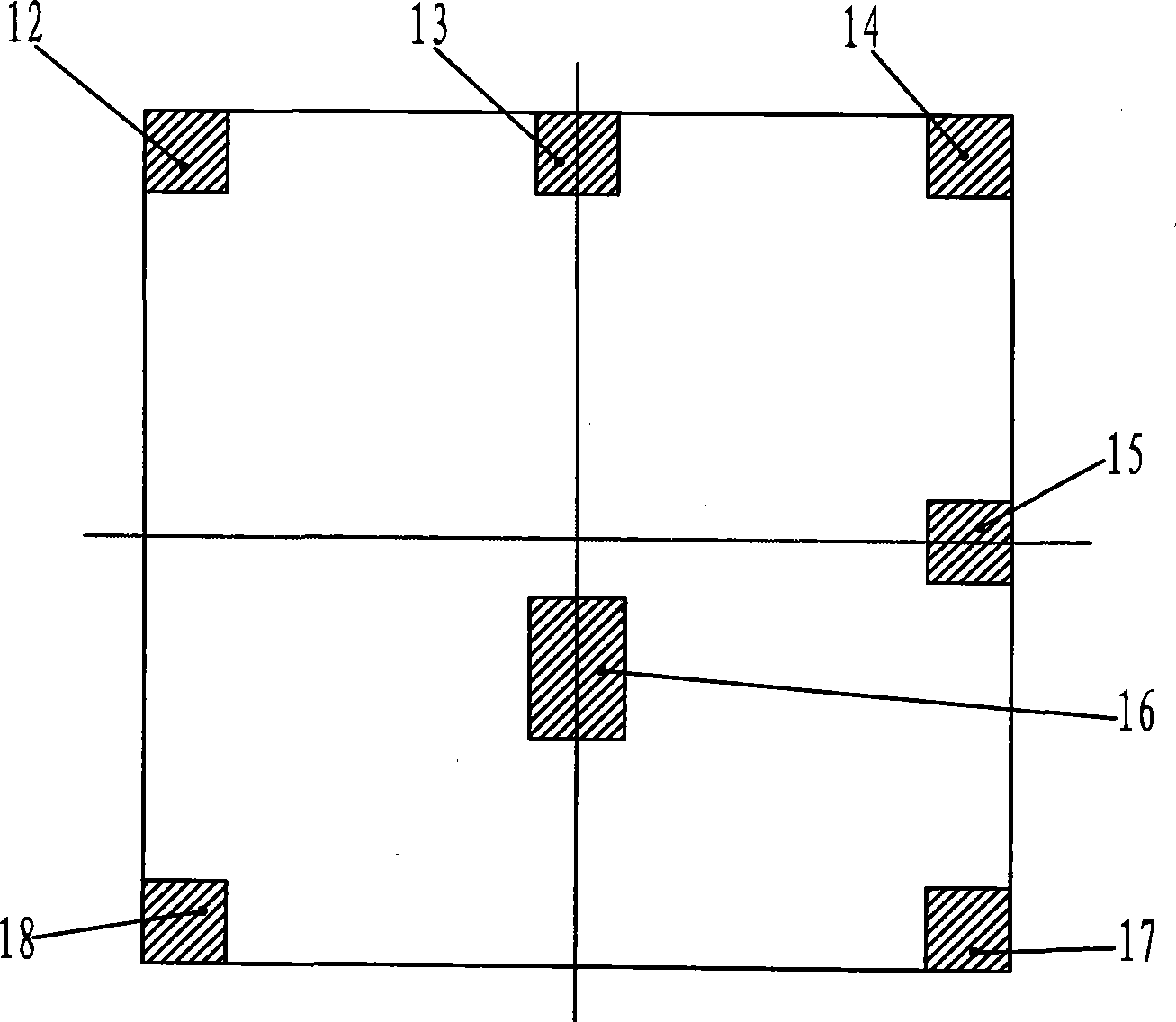

[0014] figure 1 , Figure II , Figure three As an embodiment disclosed by the present invention, the upper platform 1, the lower platform 2, the first side column 12, the second side column 13, the third side column 14, the fourth side column 15, the fifth side column 17, the sixth side column The column 18 and the central column 16 are fixedly connected together to form a frame. The first rolling guide rail 26 and the second rolling guide rail 29 are fixedly connected on the central column 16, the first bearing sleeve 25 is fixedly connected on the first rolling guide rail 26, the second bearing sleeve 30 is fixedly connected on the second rolling guide rail 29, and the second bearing sleeve 30 is fixedly connected on the second rolling guide rail 29. A support sleeve 25 and a second support sleeve 30 jointly support the rotor main shaft 3, the inner hole of the main rotor automatic tilter spherical hinge bearing inner ring 24 matches the outer cylindrical surface of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com