Adjustable ring vector light beam producing system

A ring-shaped, adjustable technology, applied in the field of optics, can solve the problems of low efficiency, high requirements for incident light beams, and inability to realize the conversion process of incoherent incident light beams.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with drawings and embodiments.

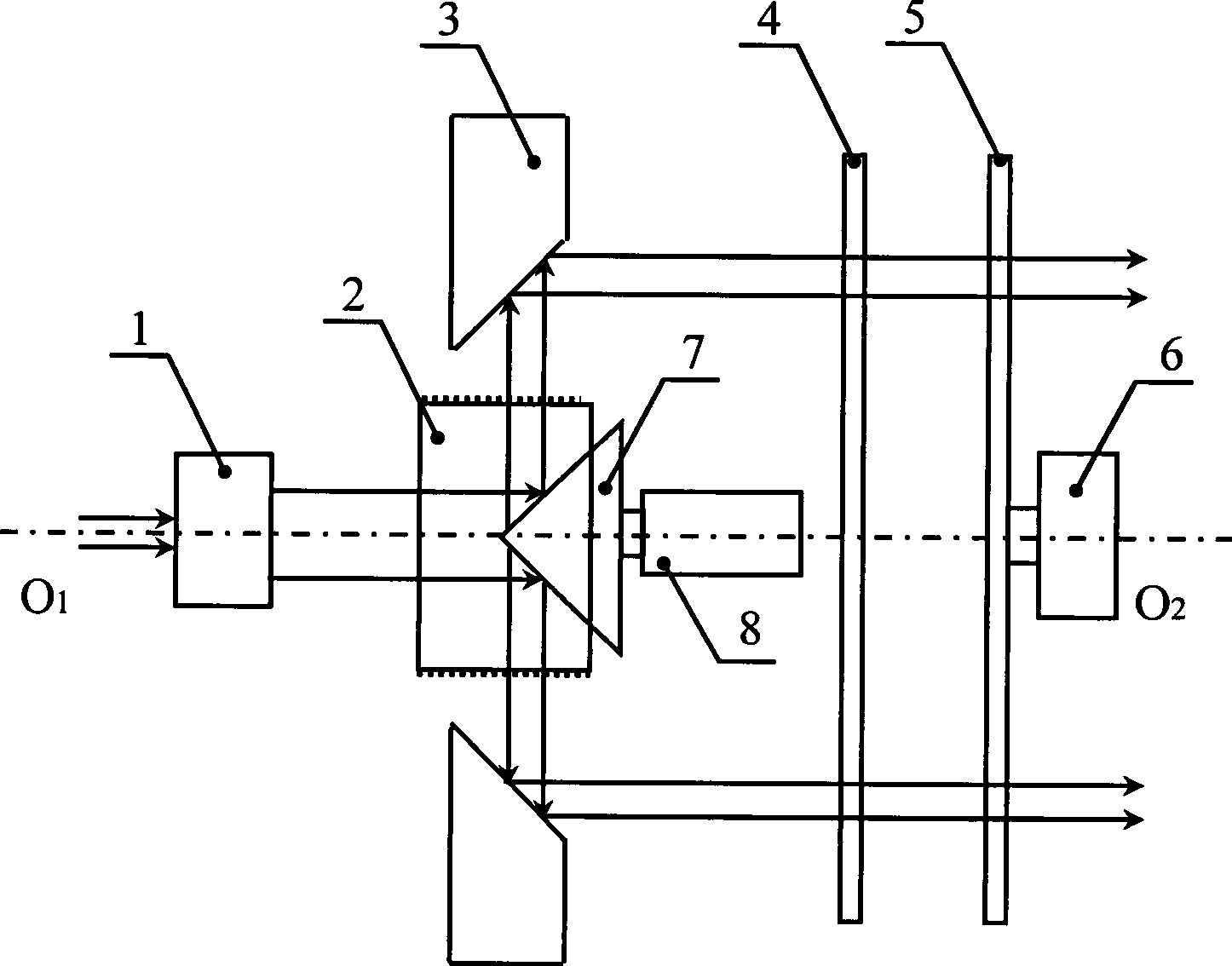

[0022] Adjustable ring-shaped vector beam generation system, with the same symmetrical optical axis O in the direction of incident beam propagation 1 o 2 Beam expander shaper 1, external reflective conical mirror 7, cylindrical curved polarizer 2, internal reflective conical mirror 3, incident half-wave plate 4 and outgoing half-wave Composed of sheet 5; the incident beam is expanded and shaped by the beam expander and shaper 1, and then the radially propagated beam is formed after being reflected by the external reflection conical mirror 7, and the cylindrical curved surface of the cylindrical curved surface polarizer 2 and the radially propagated beam Vertical; the reflective cone of the external reflective conical mirror 7 is parallel to the reflective cone of the internal reflective conical reflector 3, and the reflective cone of the external reflective conical ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com