DC motor for electric automobile

A technology of DC motors and electric vehicles, applied in the field of electric motors, can solve the problems of large consumption of raw materials, large amount of enameled wire, troublesome use, etc., and achieve the effect of less consumption of raw materials, less consumption, and lower production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

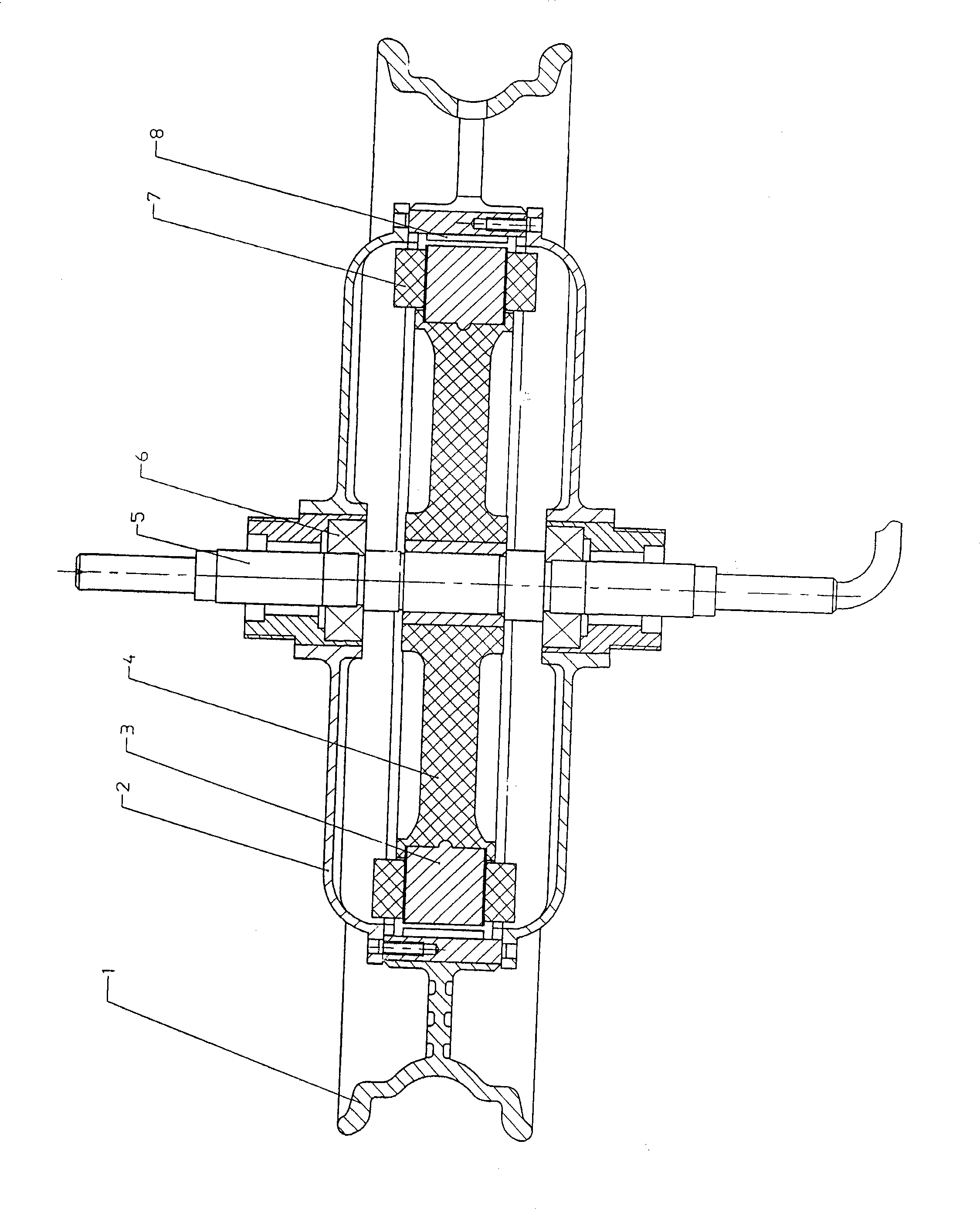

[0010] As shown in the drawings, the DC motor of the electric vehicle of the present invention includes an axle 5, a disc-shaped bracket 4 is fixed in the middle of the wheel-axle 5, and the outer side of the disc-shaped bracket 4 is provided with a wheel rim 1 with a space therebetween. A silicon steel sheet assembly 3 and a coil 7 are installed on the outer circumference of the disc-shaped bracket 4 , and a permanent magnet 8 is fixed on the inner circumference of the wheel rim 1 . Covers 2 are provided on both sides of the wheel rim 1 , and a center hole is machined on the two covers. The axle 5 and the center hole are movably matched through a bearing 6 . Three Hall magnetic induction elements are installed on the silicon steel sheet combination 3 .

[0011] When working, a special controller is used to obtain the N.S pole direction of a group of permanent magnets 8 on the wheel rim through three Hall magnetic induction elements installed on the silicon steel sheet combina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com