Food debris processor

A food residue and processor technology, applied in organic fertilizers, climate change adaptation, etc., can solve problems such as limited use conditions, unhygienic, troublesome cleaning, etc., and achieve the effects of prolonging service life, proper disposal, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

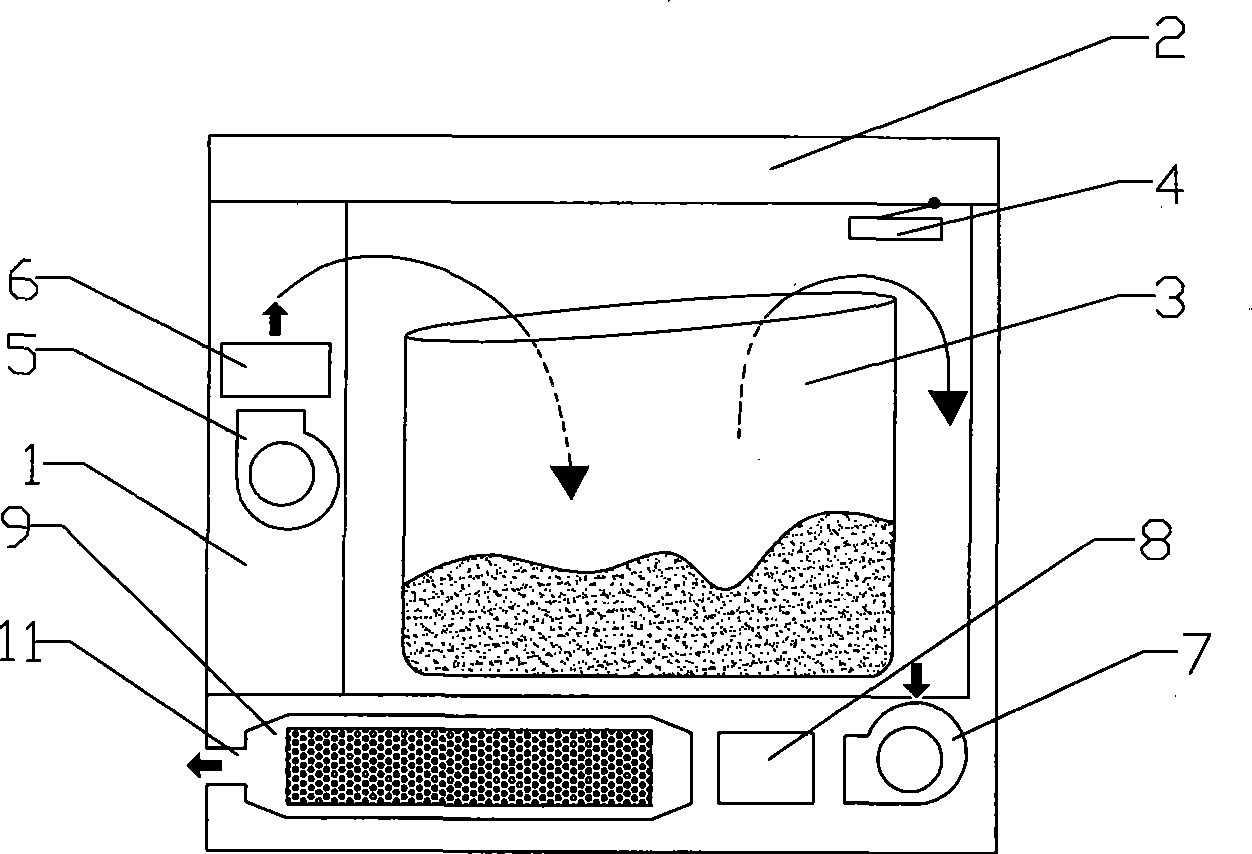

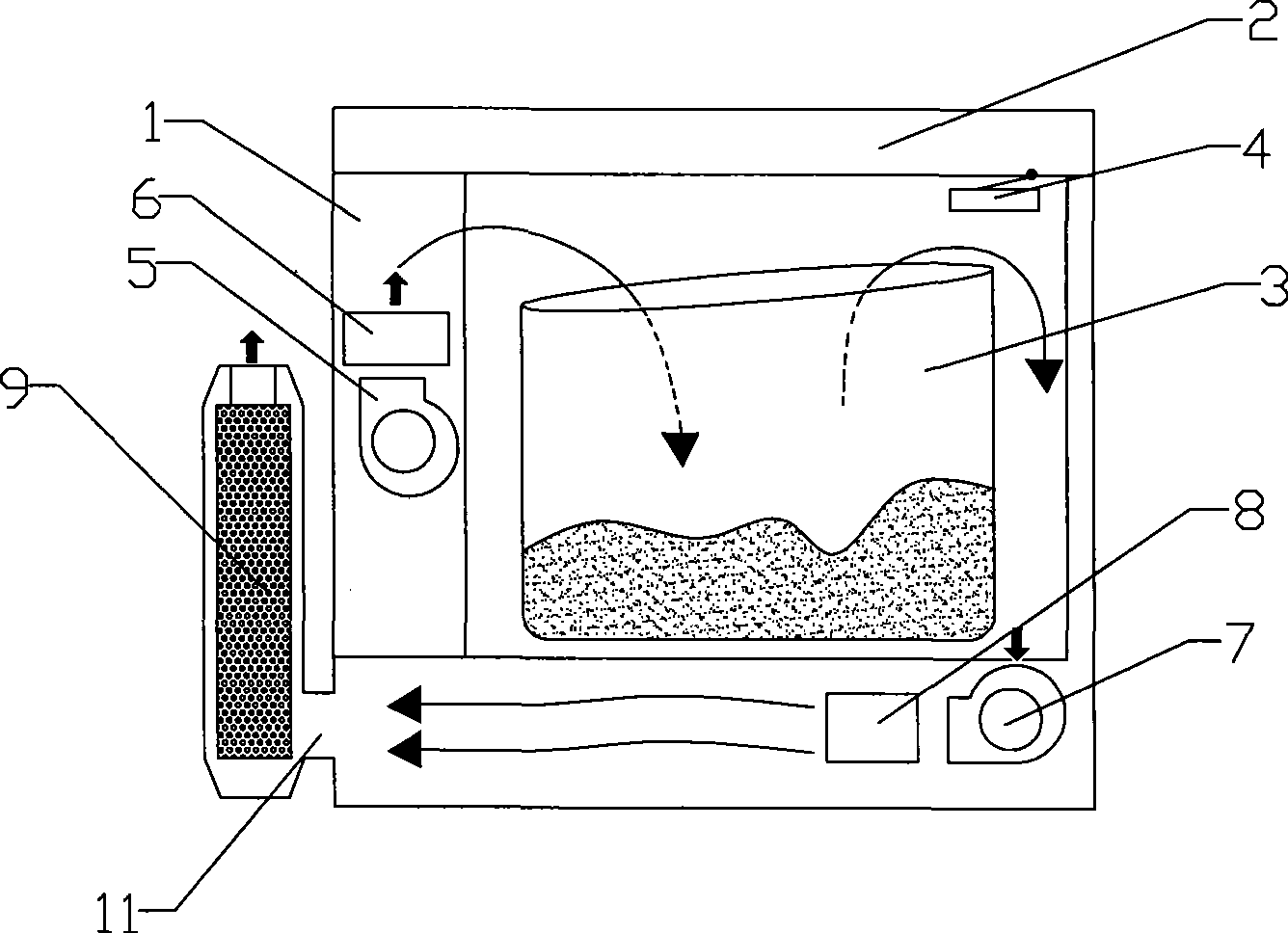

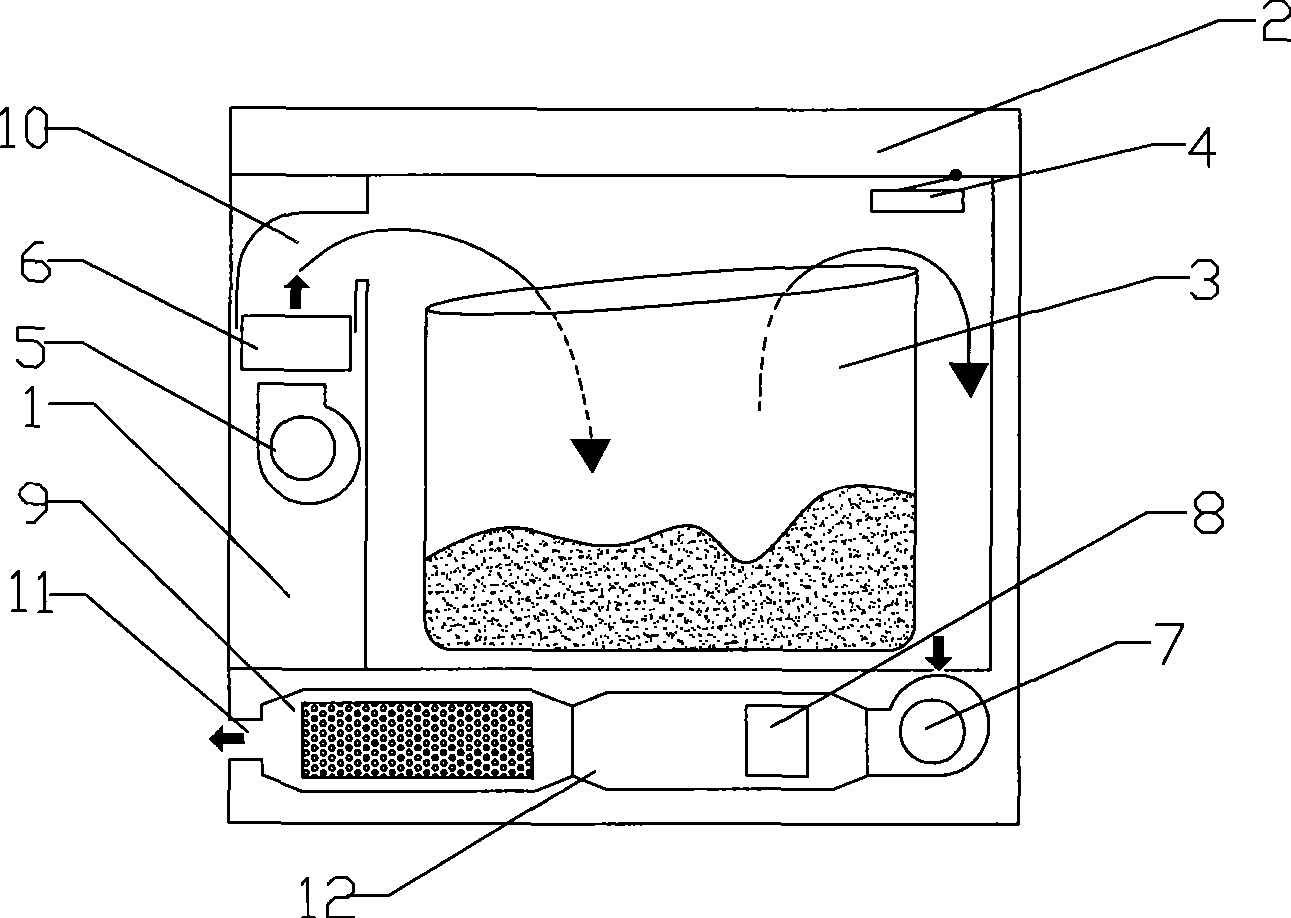

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] According to attached figure 1 As shown, the food residue disposer of the present invention includes a housing 1, a cover body 2, an accommodating cavity 3 and a control circuit module, wherein the cover body 2 is mounted on the upper end of the housing 1 and connected with the housing 1, and the accommodating cavity 3 and the control circuit module are installed in the housing 1. The food residue disposer of the present invention also includes induction device 4, blower device 5, heating device 6, exhaust device 7, ozone generator 8 and filtering device 9 connected in sequence, induction device 4, blower device 5, heating device 6. The ventilation device 7 and the ozone generator 8 are respectively electrically connected to the control circuit module. Wherein the induction device 4 is an electromagnetic induction switch, the induction device 4 is arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com