Printing automatic paste mixer

An automatic adjustment and printing technology, applied in mixers, textile processing machine accessories, dissolving and other directions, can solve problems such as inconsistency between samples and production, prescription management cannot achieve computerized information management, human factors, etc., and achieve advanced and reliable control technology. , the effect of improving accuracy and production efficiency, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

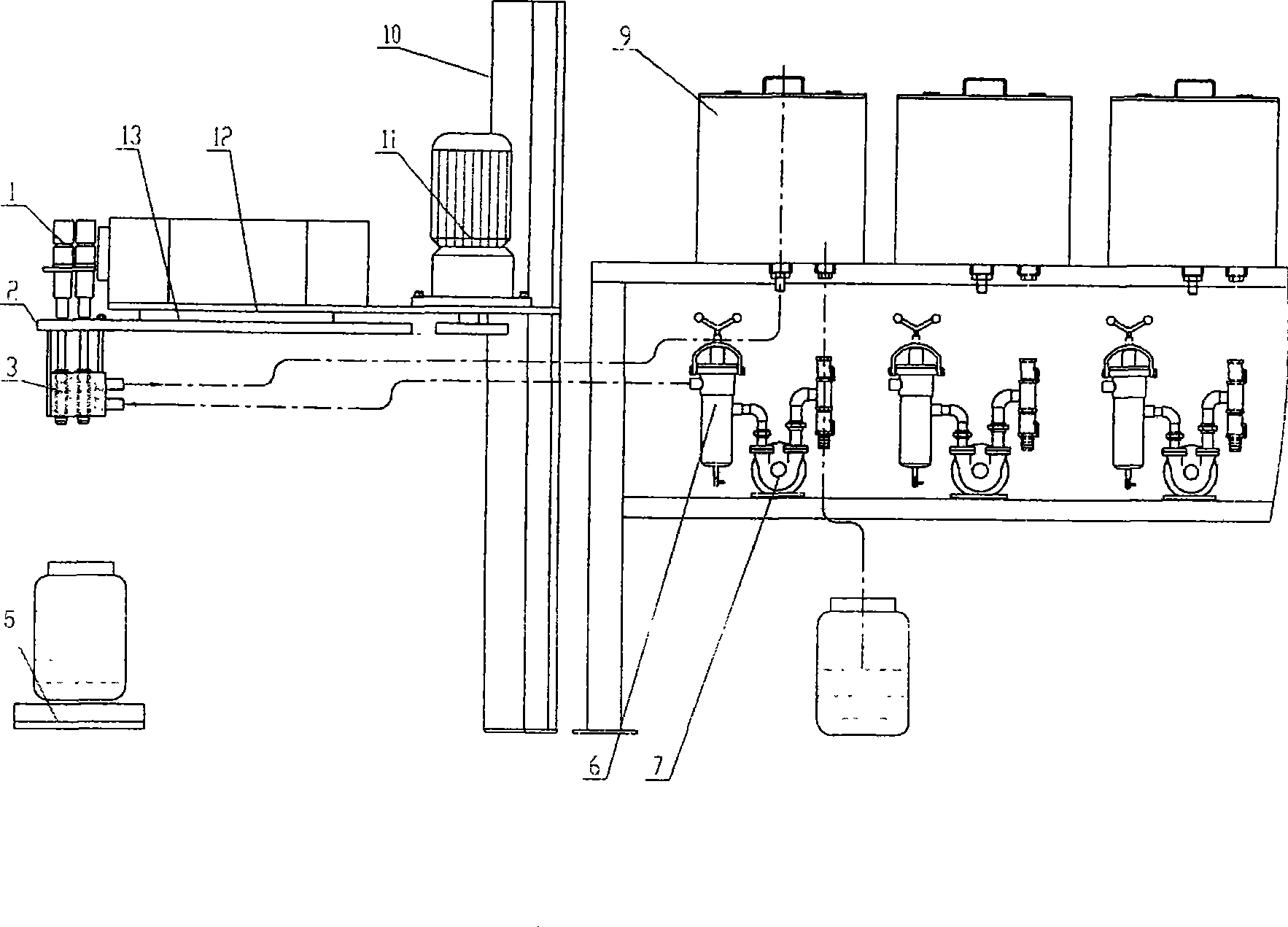

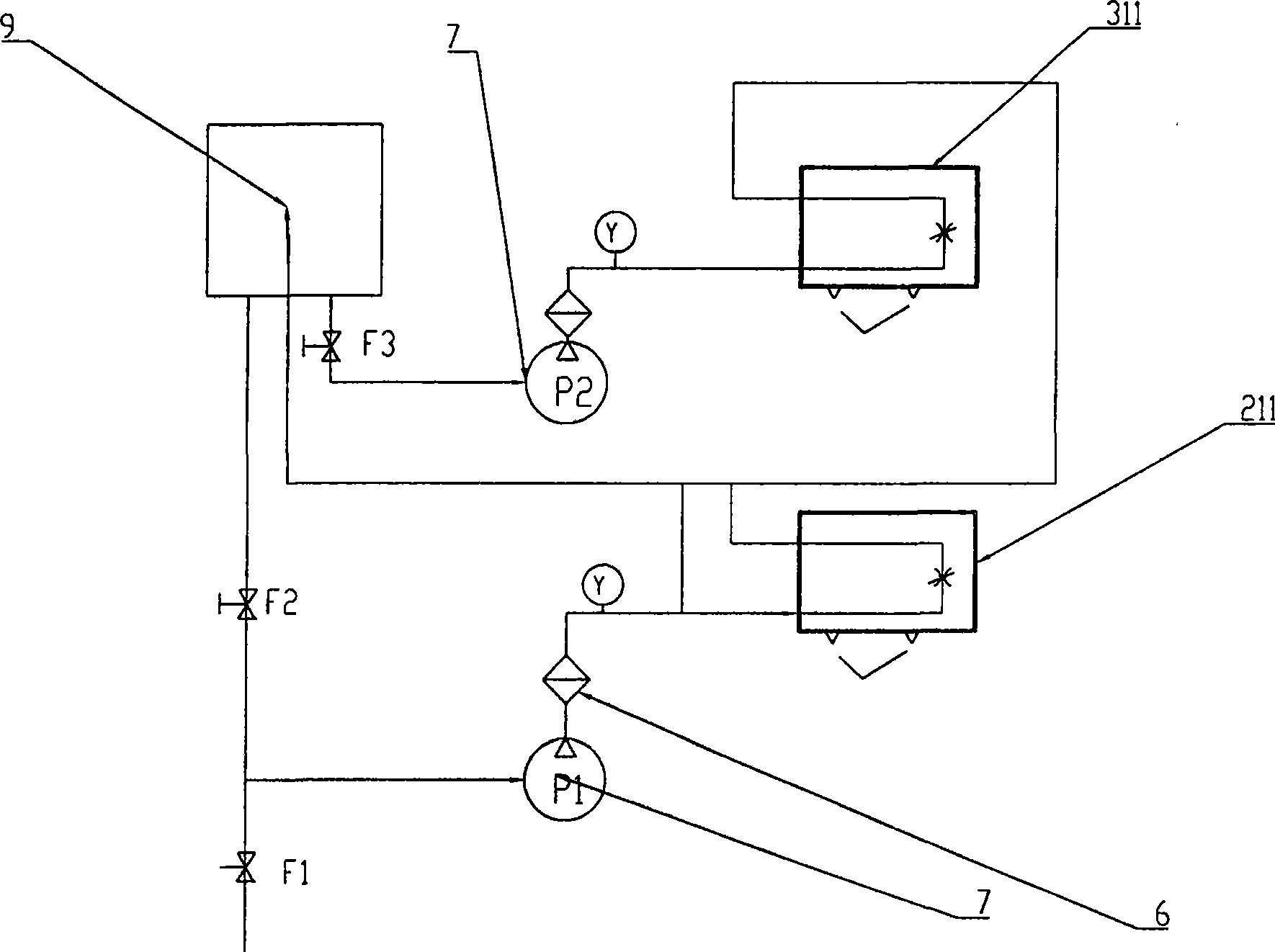

[0015] Referring to the accompanying drawings, a printing automatic pulping machine includes a frame 10, a mother liquor storage tank 9, a filter 6, a pump 7, a distribution head 3, a weighing device 5 and a control circuit, and the mother liquor tank 9 and the pump 7 are installed on the machine. On the frame 10, three groups of distribution heads 3 are installed on the turntable 2, and the distribution head 3 is connected with the driving device; the distribution head 3 is connected with the outlet pipeline of the mother liquid storage tank 9, and the pipeline is connected with the pump 7 and the filter 6; the turntable 2 is connected with the Frame 10 links to each other through bearing 12, and turntable 2 links to each other with driving dress spring simultaneously.

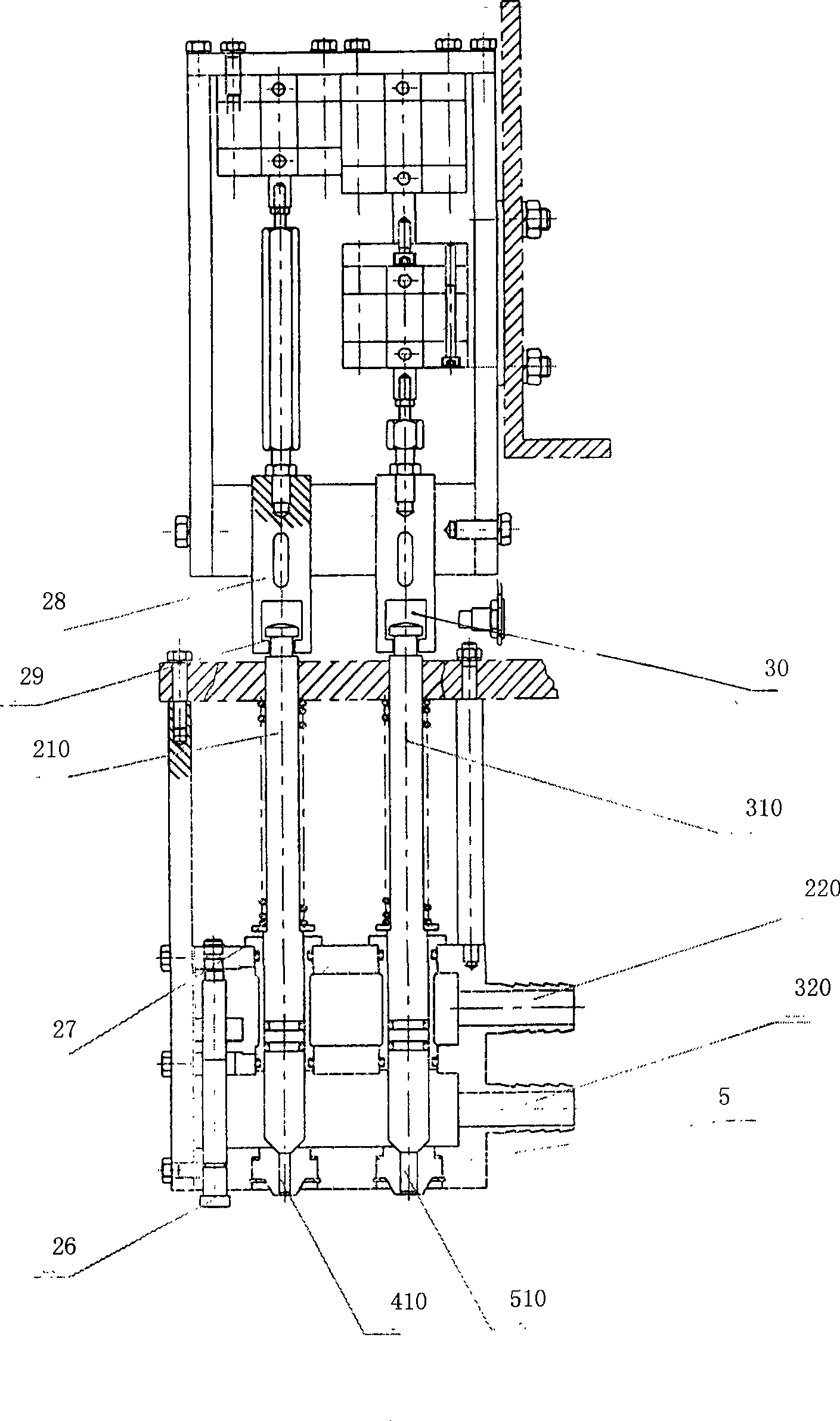

[0016] The distribution head 3 includes a valve body 5, two valve stems 210, 310, nozzles 410, 510 and inlet and outlet ports 220, 320, a spring is installed between the valve stem and the valve body, and one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com