Method and control system for laying a road paving

A technology for regulating systems and covering layers, which is applied in the field of regulating systems and can solve problems such as blockage of leveling cylinders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

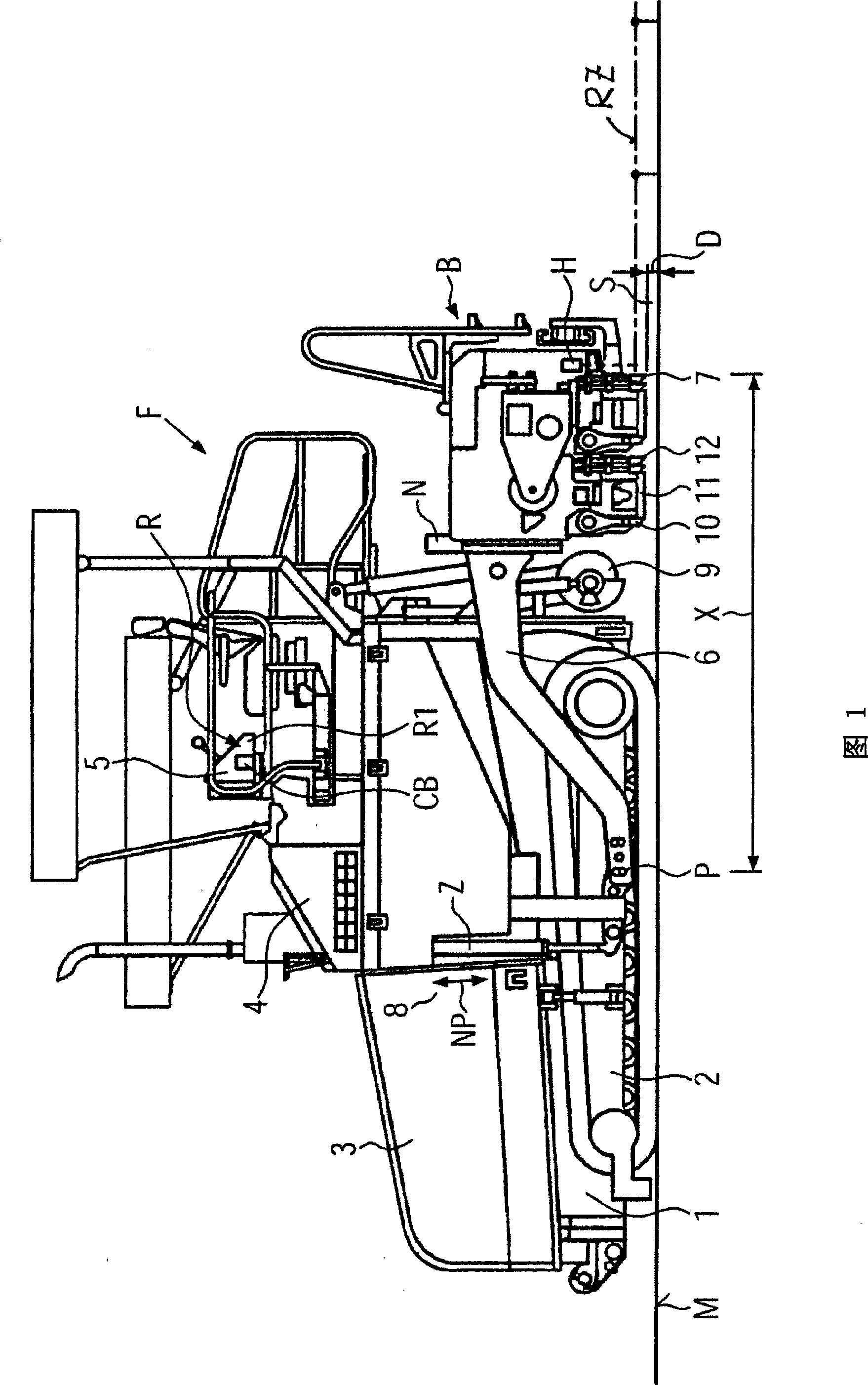

[0015] A road paver F shown in FIG. 1 has a chassis 1 on an undercarriage and a road paving hopper 3 at the front end of the chassis 1 . A main drive source 4 such as a diesel engine is installed in the chassis 1 behind the paving hopper 3 . An operator's platform with a console housing computerized controls 5 is located behind the main drive source 4 . The regulation system R is integrated or connected to the control device 5 . The regulating system R or the control device 5 is equipped with a self-acquiring lay ratio controller R1 which then enlarges or reduces, ie increases or decreases, the value of the earlier input taken into account by the regulating system R. The laying ratio factor, eg when the thickness correction measurement initiated by adjusting the leveling cylinder Z does not yield the desired result at all, or eg after a predetermined duration. In addition, the calculation part CB is provided in the adjustment system R. As shown in FIG. As with conventional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com