Powder smoke shielding and isolating device

A technology for isolating devices and dust, applied in the direction of oil fume removal, household heating, lighting and heating equipment, etc., can solve the problems of kitchen environment re-pollution, incomplete combustion, insufficient oxygen supply, etc., to eliminate air pollution and reduce carbon monoxide Produces, effects clean and thorough results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

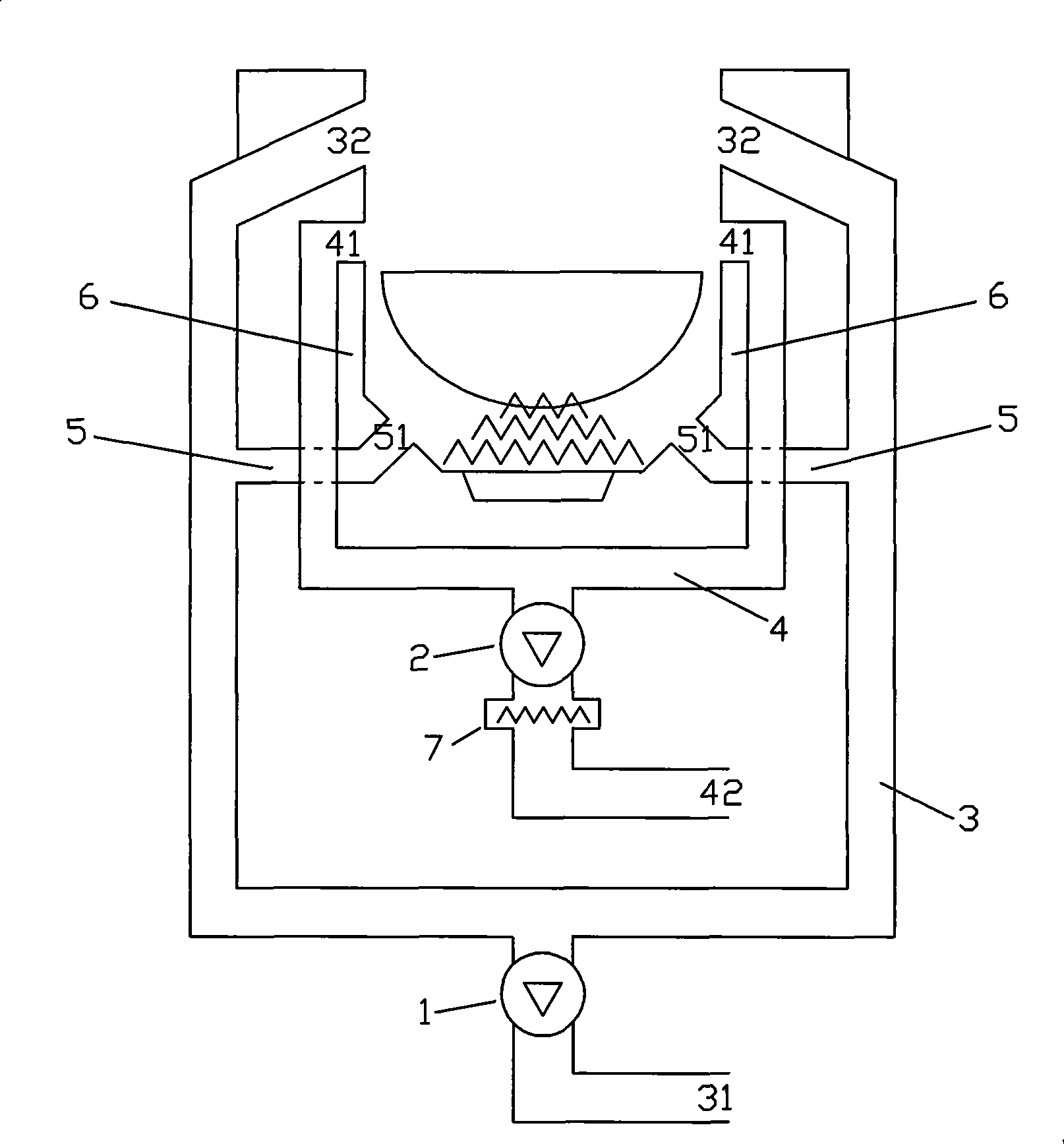

[0015] The connection mode of the present invention is: see figure 1 , the suction motor 1 is installed on the air inlet 31 of the outer air duct, the air outlet 32 of the outer air duct is located above the burner ring 6, the exhaust motor 2 is installed on the air outlet 42 of the inner air duct, and the inner air The air inlet 41 of the duct pipe is located above the burner ring 6, the outer air duct pipe 3 and the burner ring 6 are connected through the oxygen supply pipe 5, and the oil collector 7 is installed at the outlet of the exhaust motor 2 and the inner air duct pipe. Between the tuyere 42.

[0016] The embodiment of the present invention is: the powder smoke generated during cooking will freely spread upwards or to the surroundings. The faster the diffusion, the worse the suction and discharge effect. The dust shielding and isolation device can effectively curb the spread of powder and dust.

[0017] see figure 1 , the main feature of this device is to contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com