Ice house high-efficiency electric-heating defrosting device and use method

A high-efficiency, cold storage technology, applied in the field of defrosting by electric heating in cold storage, refrigeration equipment in cold storage, and refrigeration equipment, can solve problems such as insufficient use of energy, increase power consumption of refrigeration units, and affect the quality of storage in cold storage. Defrost thermal efficiency, full use of energy, and the effect of maintaining close contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

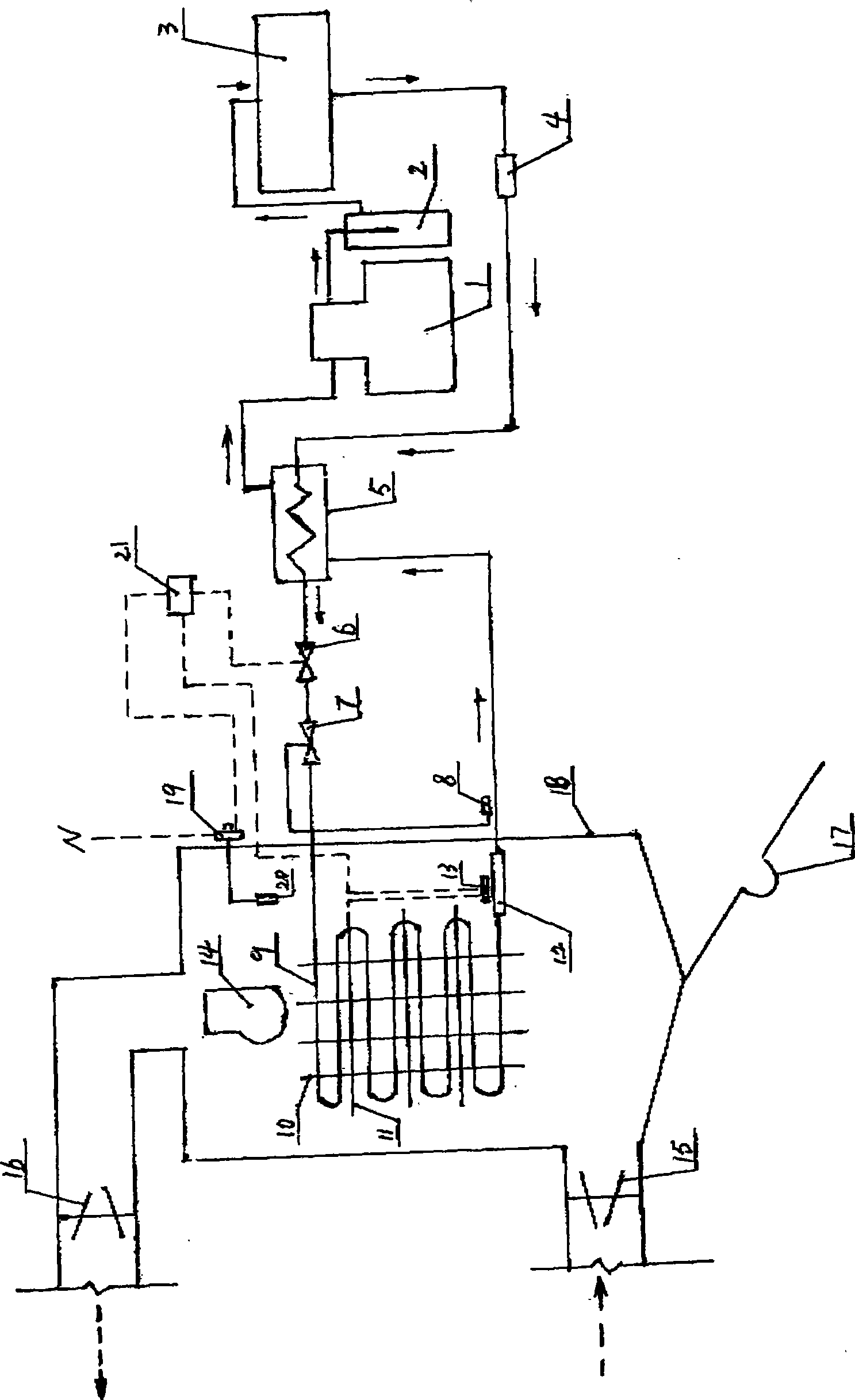

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings. As shown in the accompanying drawings:

[0047] A method of using a high-efficiency electric heating defrosting device for a cold storage, according to the following steps:

[0048] ①. Apply the high-efficiency electric defrosting device for cold storage described in Embodiment 1;

[0049] ②. Set the trip temperature of the defrosting thermostat 13 to 8°C and the reset temperature to 3°C;

[0050] ③. Set the delay time between the cooling period and the defrosting period of the controller 21 of the defrosting time. In the delay time between the set cooling period and the defrosting period, close the electromagnetic valve 6 for liquid supply, The fan 14 of the evaporator is not working, the compressor 1 and the condenser 3 are both working, and the low-temperature refrigerant retained in the evaporator is introduced into the condenser 3 through the compressor 1 to conde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com